Title: Profits from scrap

Author: Chicago American Bureau of Engineering

Release date: August 8, 2016 [eBook #52754]

Most recently updated: October 23, 2024

Language: English

Credits: Produced by Richard Tonsing and the Online Distributed

Proofreading Team at http://www.pgdp.net (This file was

produced from images generously made available by The

Internet Archive)

Transcriber's Note:

The cover image was created by the transcriber and is placed in the public domain.

The phenomenal growth of this Institution is due to the fact that it has, from the start, anticipated the needs for authoritative information and adequate shop equipment to take care of the ELECTRICAL side of the automotive and allied industries.

It has four active divisions:

Before reading the following pages, Mr. Batteryman, just stop a few minutes and take a good look around your shop. You know your business, certainly or you would not have a shop, but are you operating in a way to make the greatest profit?

When you stop to think it over, are not some of your methods rather crude? Haven't you often thought, when you were doing some disagreeable job, that there ought to be a better and quicker way? Haven't you often wished that you knew how to turn that rapid accumulation of “junk” parts into real money?

The American Bureau of Engineering is not trying to tell you how to run your business, but we are trying to help you realize a greater profit by showing you some “better” methods.

Lead moulding is but one of many ways that spare time and material, usually junked, can be turned into profit.

Every piece of equipment we mention has been carefully developed in our own shop, every method recommended is one which we have found, by actual experience to be best for the purpose described.

A strict observance of the instructions will save you all the experimenting we have done and save you many disappointments. If for any reason our instructions do not produce the results you think they should, remember it is a pleasure for our Engineers to help you solve your personal difficulties.

President.

In his every day work, the storage battery service man must deal chiefly with three materials, wood, rubber and lead.

The wooden parts, such as boxes and separators are pretty well standardized, can be purchased at reasonable prices and are used solely for replacements. It would not pay the battery man to equip his shop to manufacture any of these items.

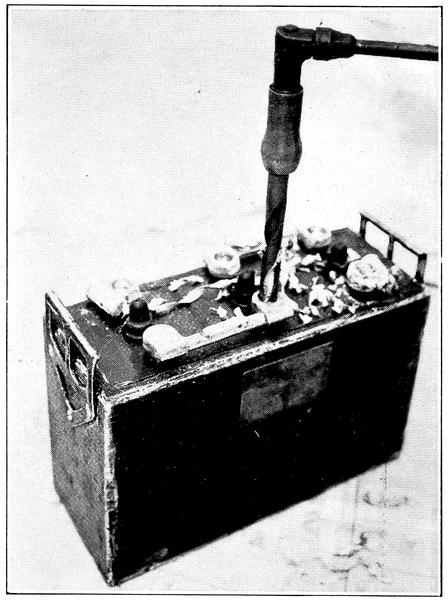

Figure 1

The same is true of the rubber parts, the jars and top covers. A dozen different sizes in stock will take care of nearly all the various makes and models of batteries which come in for repair.

With the lead parts, however, the conditions are entirely different. All the active and wearing parts are made of lead, or its compounds, and practically every battery that needs repair, needs some of them replaced. Then again there is a much greater variety in the design of these parts and the up-to-date shop, in order to give real service, must carry a large assorted stock of end connectors, connector straps, plate straps and posts.

4In speaking of lead parts, however, the plates are to be considered on the same basis as the rubber parts or wooden boxes, because it would not pay the ordinary battery shop to try and cast grids, mix paste and manufacture plates. It is much more satisfactory to purchase plates made by a responsible manufacturer who has the facilities and capital to properly develop his formulae and processes.

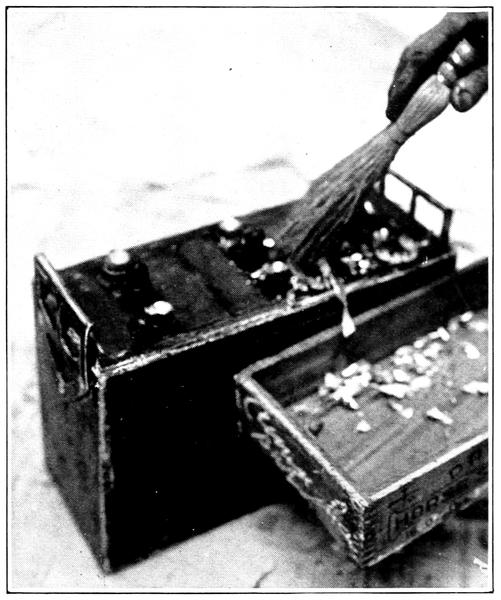

Every battery that has to be opened must have the top connectors drilled off as in Fig. 1, which naturally makes a lot of lead chips. These drillings have to be cleaned off before proceeding with the repair and can, with no loss of time, all be collected, as in Fig. 2, and saved. Then the old sulphated end connectors and parts from “junked” batteries accumulate very fast.

Figure 2

This then is the situation—The battery service station is constantly in need of new lead parts. Should they be obtained from a manufacturer at a price that includes material, labor and the manufacturer's profit—OR—should equipment be purchased that will permit of moulding these same parts from the accumulated scrap lead at a cost of nothing but the time employed in pouring, with no cost for material and no “Profits” added?

No matter how cheap you think you are buying your lead parts, just compare the market price per pound on lead with the weight of a few of your “cheapest” ones.

It is now common practice to melt some of this accumulation of scrap lead and pour it into sticks or bars for use in lead burning on 5repair work. A great amount, especially old groups, is generally sold at a low price in order to get it out of the way. The one important fact, and one generally overlooked, is, that the battery man who melts lead and moulds it into sticks for lead burning, certainly is able to melt the same metal and mould it into the lead parts he requires, provided, of course, that he has the proper moulds.

Many a wide awake man has whittled a wooden mould for some part that he wanted in a hurry and couldn't wait for the manufacturer to deliver. Naturally this condition, really an effort to render service to the customer, created a demand for moulds of a permanent character.

In an effort to supply this demand, the moulds that have been produced were all made for some individual part, were light in weight and easily became overheated, making them hard to handle and often burning the workman's hands.

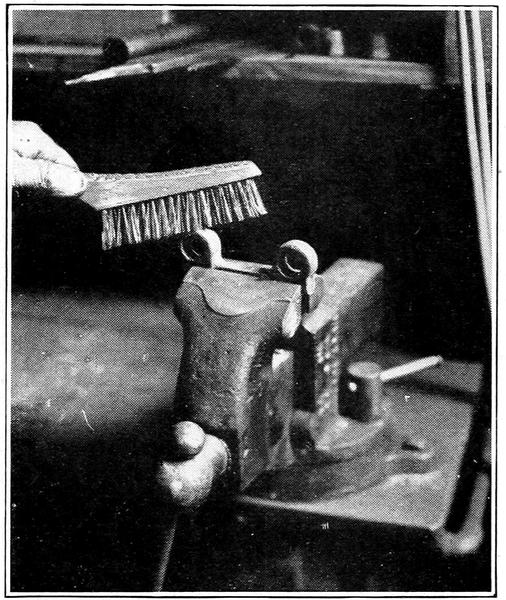

Figure 3

From a business standpoint, it would certainly be mighty profitable for a battery shop to be able at a moment's notice, to convert junk lead into new salable parts. In addition to the large profit from the sale of these new parts, another good feature, is that, instead of tieing up a lot of capital in stock, the new parts can be made as needed, without a cent of investment.

From a service standpoint, it is a cheaper and faster process to cast a new top connector than to spend a lot of valuable time, whittling an old one so that it can be used again.

How much time have you or your men wasted cleaning up an old terminal as in Fig. 3, so that you could burn it on again?

6All new connectors and terminals put on a rebuilt or reinsulated job make the customer feel that he is getting a real repair. He sees a new finished job.

From an electrical standpoint, the new parts mean better work, because better burning can be done, certainly a new connection will allow the battery to deliver more current than an old partly sulphated one could ever do.

The question that naturally comes up is, can the ordinary battery man make good lead castings? We will answer “Yes,” very emphatically. There is nothing mysterious about the work and all the talk of alloys, compounds and formulae does not mean a great deal.

Pure lead is not hard or rigid enough to make good battery parts, therefore, it is necessary to add some other metal that will provide the strength, not be affected by the acid and not increase the resistance electrically. Antimony has all the necessary qualities, and is, therefore, commonly used by mixing it with the pure lead.

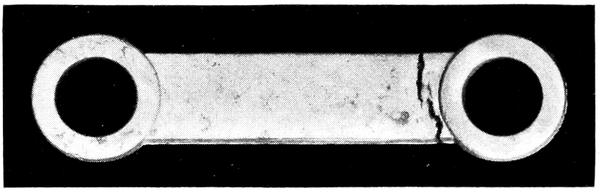

Figure 4

The various manufacturers recommend from 2 to 12 percent antimony, as the proper combination, but in buying new pig lead for castings, a 4 percent antimony compound is very satisfactory.

In using old battery lead, however, due to chemical action the proportion of antimony is apt to be too high to produce perfect castings. This usually shows up by cracks or shrinkage, as in Figure 4. To overcome this trouble, pure lead is added, until a perfect casting is made. Pure lead can be purchased (in the form of bars, lead pipe, or sheet lead) from a manufacturer such as the National Lead Company—your accessory jobber, the local plumber, or the junk dealer. When buying from a junk dealer, however, care must be taken that there is no solder or tin present.

In order to pour the lead some means of melting and a proper container must be provided.

7As pure lead melts at about 620°F., and antimony at 785°F., an ordinary gas flame will furnish sufficient heat. For the small shop, without an artificial gas supply, a plumber's furnace which can be secured from Hardware Jobber or Plumber Jobber will work satisfactorily. See page 19 for gas melting pots.

An ordinary cast iron solder pot will be found the most suitable container. It should be about 8 inches in diameter.

It is advisable to obtain as large a pot as above, because for steady pouring a sufficient supply of melted metal should always be available. Then too, the constant addition of scrap or pig lead in a small pot will often change the proportion of antimony so that the castings crack and have to be melted over again.

Wash the pot thoroughly with gasoline or kerosene to remove all traces of oil. Then after it has been carefully dried, put it over the flame and heat it gradually. Do this before putting in any lead.

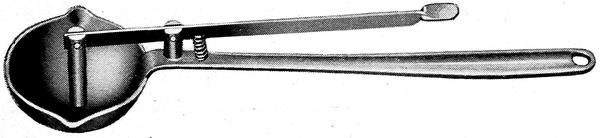

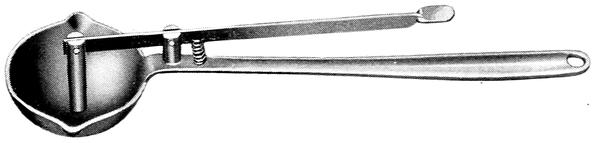

The only other equipment necessary to handle the melted lead is a ladle. For this purpose a malleable iron melting ladle five inches in diameter should be purchased. It can be used for stirring, skimming and pouring, and the type with a spout, illustrated in Fig. 5 will be found most suitable. The ladle should be cleaned and treated exactly like the melting pot.

Figure 5

The scrap or pig lead can now be put in the pot and melted. It is a time saving plan to pick out carefully all the pieces of wood, rubber and sealing compound from the scrap lead before it is put in the pot. Old plates are not worth while melting, but a lot of good lead can be salvaged by sawing the strap and post off old groups. Above all things make sure that no wet parts or moisture of any kind ever gets into the lead pot.

As the lead melts most of the dross or dirt will come to the top and float. When all the pieces are melted stir the lead with the ladle and then skim off all the dirt.

To help the cleaning process a piece of paraffin can be dropped into the pot. After it has burned, the dross is more easily skimmed off.

Another method of cleaning is to add to every ten pounds of metal, one teaspoonful of equal parts of powdered rosin, borax and flour of 8sulphur. Stir this compound in a little and when the lead is at the proper temperature there will be a flare, flash or a little burning. A sort of tinfoil popcorn effect will be noticed floating on top of the metal. Continue stirring until this melts down and then skim off the soft particles.

An easy way to test the temperature of the melted lead is to insert the end of a pine stick for a moment. When the wood blackens or burns, the lead is hot enough to pour.

Whenever the lead is in melted form and exposed to the air, as in the iron pot, there will be a slight oxidation take place which appears as a yellowish-red scum. Do not confuse this with the dross and dirt which is to be skimmed off, but if the scum gets thick, then skim it off before pouring any of the metal.

One of the greatest difficulties in making lead castings has been to get the metal to completely fill the mould. There are several reasons for this, but they can easily be overcome.

If the mould, which is generally made of iron, is very cold, it will chill the melted lead and cause it to become solid before it has reached all parts.

The surface of a cast iron mould is very porous, and the melted lead, partially entering the pores of the iron, is held back long enough to chill and set.

To remedy these faults, it is sometimes advisable to heat the mould in order to get perfectly shaped castings.

To close the pores of the iron moulds they are sometimes “smoked” with a flame like that of “Prest-O-Lite” gas or else dusted with graphite.

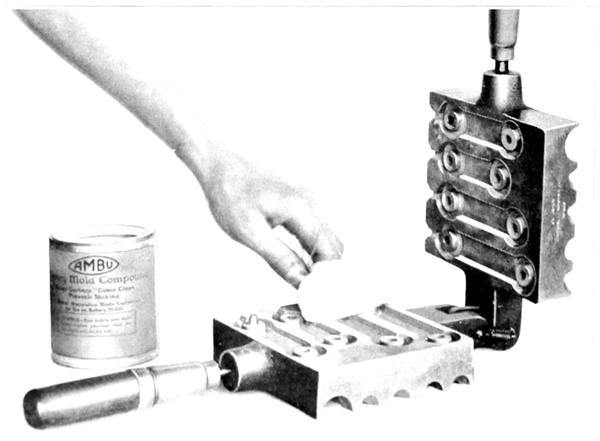

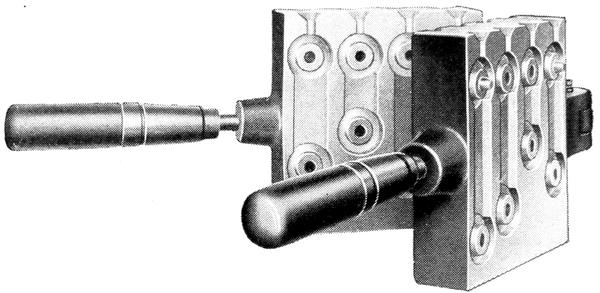

Figure 6

The AMBU mould compound has been developed to eliminate the 9necessity for heating or smoking the mould—it remedies all the pouring troubles and in addition, has chemical ingredients that aid in preventing the mould from rusting. AMBU mould compound is placed in a little sack, contained in each can, and the surface of the mould dusted with the sack, as shown in Figure 6.

The compound completely fills the pores of the iron, produces perfect castings with a cold mould and prevents the finished part from sticking. It does not wear off as quickly as the “smoke,” and dusting from time to time, while castings are being made will produce a high polish on the mould surface which will result in even better castings.

The mould in Figure 6 is the new AMBU Washburn combination link mould, which casts 15 parts, being reversible much like the ordinary “waffle iron.” The side being “dusted” casts four top connectors of different lengths.

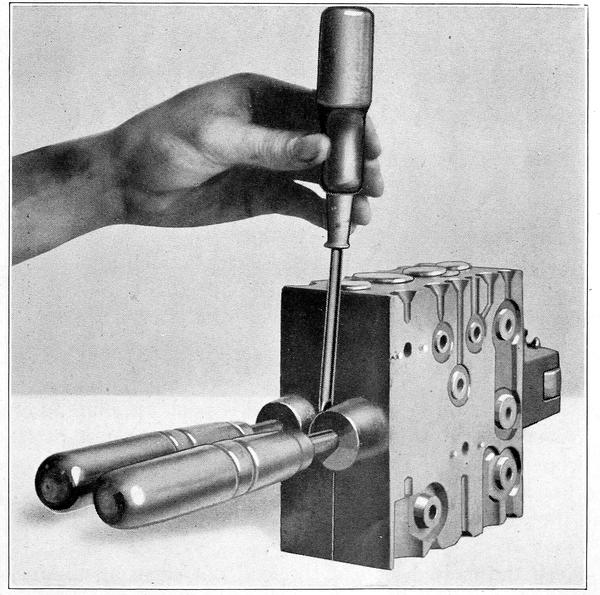

Placing the mould as in Figure 7, the lead is poured in the four openings until the metal projects slightly above the top.

To pour properly first skim the dross as previously explained, then with the ladle, push the film of oxide away and dip into the clean pure lead. Pour steadily until the mould is filled and the metal projects slightly above the top. As it cools there will be quite a little contraction which takes up most of the excess lead.

Figure 7

10Never, under any conditions, stop pouring with a mould partially filled. Always be sure there is enough melted lead in the ladle to completely fill the mould, before starting to pour.

The mould can now be easily opened by pulling on the handles especially if it has been properly dusted with the Ambu Mould Compound.

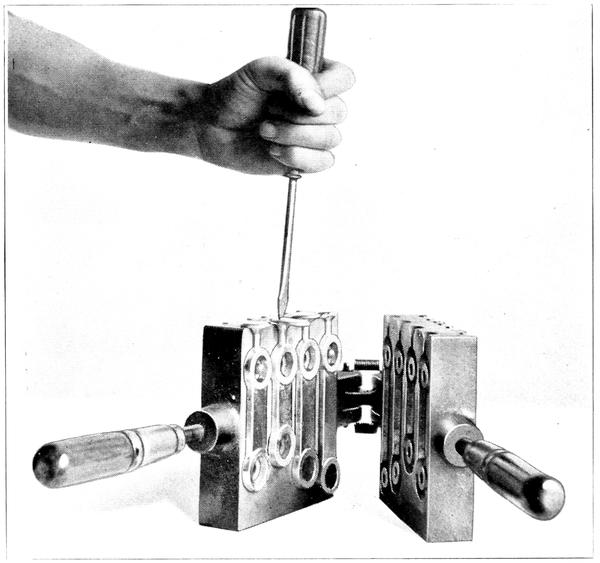

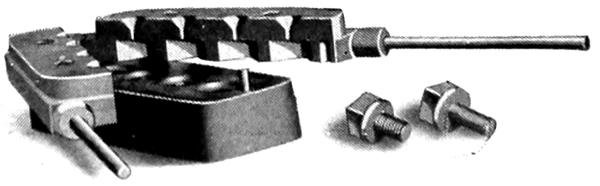

After the mould is opened, Figure 8, the castings are easily removed, without damage to either the mould or the casting proper. The workman does not, at any time, handle the hot parts of the mould or the hot castings.

Figure 8

The mould weighs 25 pounds, and is large enough to absorb sufficient heat to allow continuous pouring without becoming overheated. It is solid enough to be used without the need of a vise.

In all lead moulding, there are several important points to remember:

1. Never put anything in the lead pot that is not perfectly dry. A few drops of water in a pot of melted lead will cause an explosion and the hot lead will be thrown all over the shop burning and perhaps blinding the workman.

2. Have all moulds clean and dry.

3. Keep the melted lead in the lead pot clean at all times.

4. Always completely fill each mould at one pouring.

115. Dust moulds well with Ambu mould compound before pouring.

6. When castings “shrink” and crack, add pure lead to that in the pot until the trouble is remedied.

7. Be sure melted lead is of proper temperature, by pine stick test, before starting to pour.

8. Remove castings as soon as they set, to prevent the mould from becoming too hot.

9. A perfect casting, that breaks when taken out of the mould, has probably not been allowed sufficient time to “set” or cool properly.

10. Never use a hammer on the surface of the mould. If a casting should stick, pry it out.

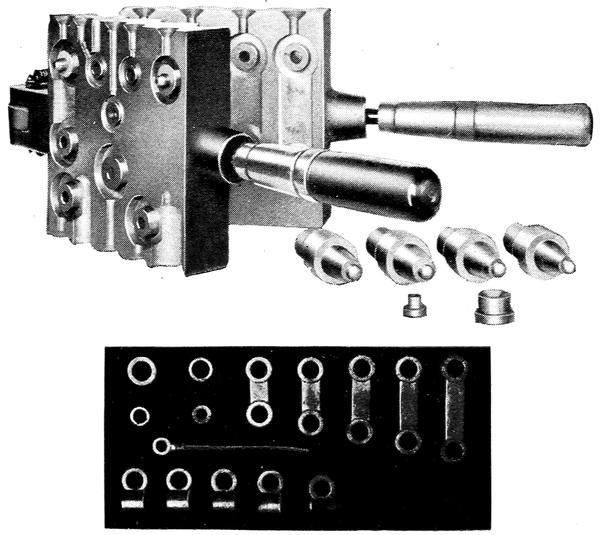

Using both sides, this mould casts five of the most used connectors for all batteries, using Standard Jars, 7-9-11-13-15 Plate four end connectors (two Dodge Tapers and two Standard Tapers, Negative and Positive), one end connector, ⅜-inch wire leed used on 12-volt Maxwell and other cars using wire leed. One small wire leed to connect with end post on storage battery requiring direct connection. Post support rings, which fit the two sizes standard rubber covers; also fit perfectly all posts cast with our post mould. Two handy washers that sometimes are badly needed when installing a new or rent battery.

Figure 8A[1]

Extra taper plugs can be furnished, also extra bushings for different size cable. Standard equipment as furnished includes four taper plugs, one large and one small cable bushing.

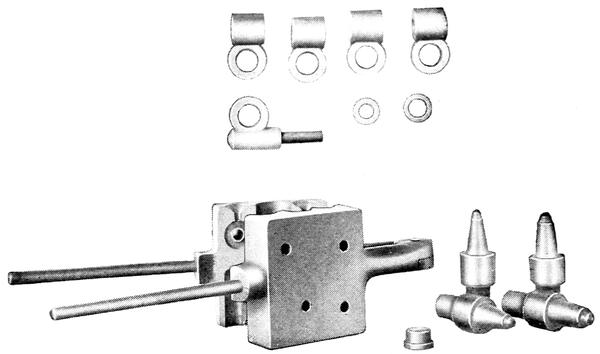

The top connectors most frequently replaced are the taper end connections 12and end connections with wire cable leads. For battery men desiring these parts, but not the large combination link mould, the AMBU-Washburn terminal mould, Figure 9, has been designed. It has the same general good features of the larger mould, and casts four end connectors, one wire cable leed and two washers.

Figure 9[1]

Perhaps the most expensive item of a stock in a battery station, is the supply of positive and negative groups. While two or three sizes of plates will fit practically every battery, each size battery requires a different size of group.

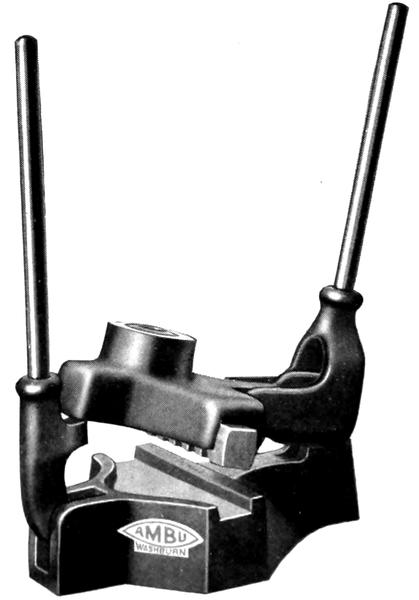

Figure 10[1]

The AMBU-Washburn Post Strap Mould has been developed in order that a comparatively small stock of plates can be instantly available for making any size of group. You will notice in Figure 10, that 13the same features, as those of the link mould of Figure 8 are used, namely; a large substantial base, no need of handling hot parts and the easy removal of castings. All parts of the moulds are carefully machined to produce perfect castings and the patented movable tooth rack will make odd or even numbers of teeth on the post strap. The teeth are correctly spaced for all standard batteries, or by reversing the tooth rack, blank posts can be cast.

Two bushings, bored and reamed for standard size posts, are furnished, but special bushings are available making it possible to cast any type of post strap.

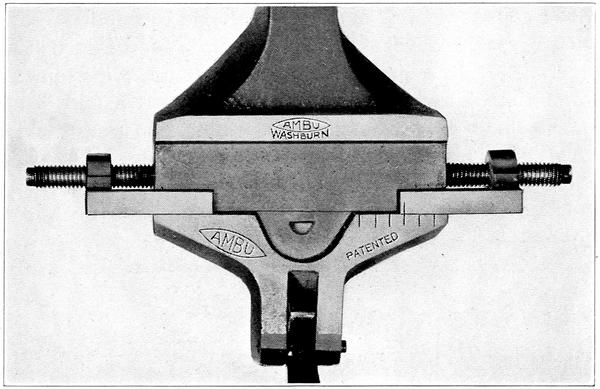

For the large shop or manufacturer, the AMBU-Washburn Post Strap Mould, is made with the special indexing feature of Figure 11. This is easily adjustable and will cast straps of both odd and even numbers of teeth for 7 to 19 plate groups. Otherwise its construction and appearance is the same as Figure 10.

Both of these moulds are made for real use and will turn out three perfect castings per minute. This unusual speed can be maintained because the castings are easily removed. In Figure 10, the upper part of the mould is resting on a part of the handle made for that purpose and a slight blow on a hardwood stick, on the top of the post, will drop the casting instantly.

Figure 11[1]

The AMBU-Washburn Cell Connector Mould is a combination mould which will cast practically all of the cell connectors used on standard storage batteries, 7-11-13 and 15 plate, such as the Exide, Willard, U. 14S. L., Vesta, Philadelphia and other nationally known batteries. Its design is similar to our Link Combination Mould.

Made of fine gray iron, carefully machined. Castings are easily removed, and it is heavy enough so that it will not overheat where speed is required.

Figure 12

After re-insulating or repairing, the job looks more complete and satisfactory to your customer if the battery is furnished with a new set of connectors. Use your scrap lead and make new connectors for each job. It pays.

The lead capped screws of the taper type terminal are another of the frequently replaced parts. Although the round knurled head type is no longer installed, a great many men still use pliers on the square head terminal screws with the result that the soft square lead head is damaged to such an extent that a tight connection cannot be made.

The AMBU-Washburn Screw Mould, Figure 13, will cast standard square edged heads on four screws in one operation, two 5⁄16-inch and two ⅜-inch. It has screw adjustments in the base, making it adaptable to any length screw.

Figure 13[1]

As the finished screws are removable from the top, the position of the mould is not changed while in use and castings can be made at the rate of 12 screws a minute.

In order to properly burn in and assemble the new lead parts, it is necessary that they be fused and new lead added, and this requires that a supply of lead sticks be available. These are usually made by melting the smaller particles of scrap and junk lead which is cast in convenient size.

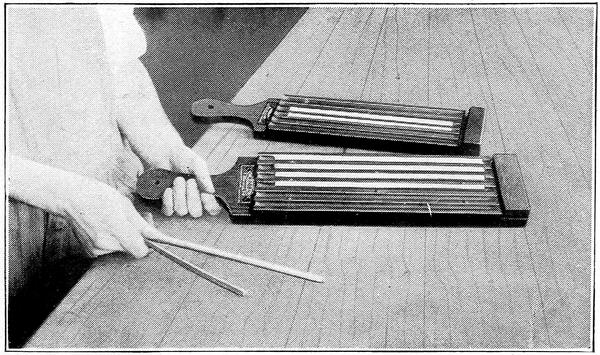

The Ambu Mould, Figure 14, is especially designed for this purpose. It is made of heavy sheet iron, die stamped into grooves and mounted on a wooden base with a strong wooden handle at one end. A heavy pad of asbestos is placed under the iron to protect the wood.

Figure 14[1]

This construction allows the lead to completely fill the grooves before cooling, but prevents the mould from becoming exceedingly hot with constant pouring. A pair of these moulds will keep one workman busy, as he pours one, the other is cooling. This eliminates all waiting and waste of time.

The sticks made are 15 inches long, 5⁄16 inch thick, ⅜ inch wide at the top and ¼ inch at the bottom. In pouring in an open mould of this type, pour the lead in each groove at one end, so that the dross will all gather in one spot. Never move the ladle along the groove when pouring, as this will scatter the dross and make the entire stick dirty.

When poured at one end only, a short length of the stick may be broken off, thus removing all the dross.

Dusting the mould occasionally with Ambu mould compound will produce better castings and permit greater speed in the work.

The building of groups, even after the plates and post straps are secured is a job that requires quite a lot of skill. Before the plates 16can be burned to the strap, they must be absolutely parallel, must be the correct distance apart, and the top surface of the strap must be at right angles to the surface of the plates.

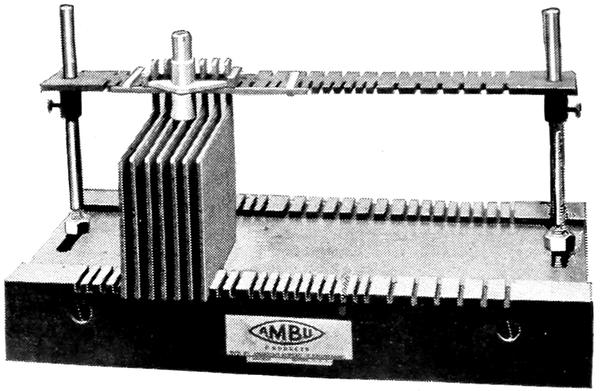

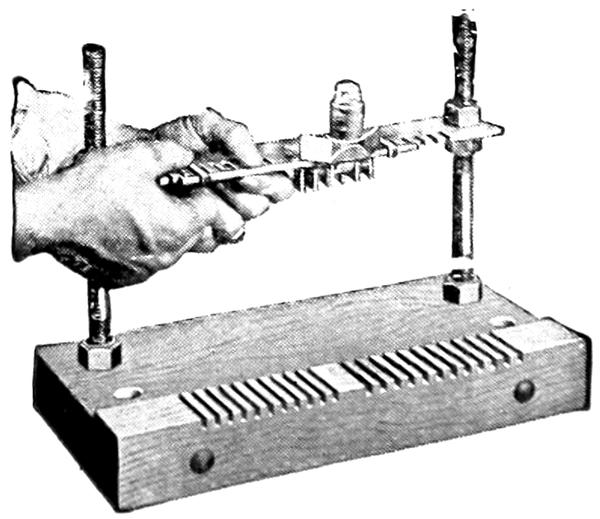

The Ambu Plate Burning Rack, Figure 15, has been designed to easily secure the proper conditions. It consists of a wooden base with six different sets of slots properly spaced which cares for 98% of the batteries on the market. The guide bar or “comb” on top is slotted to match up with the base. (See figure 15.)

Figure 15[1]

The positions of the base and comb are so arranged that the plates are securely held on opposite corners, at exactly the right distance apart and are absolutely straight and parallel.

The wooden base prevents the plate proper from coming in contact with any metal and thus eliminates any possibility of later trouble due to impurities in the cell.

Figure 16[1]

In order to accommodate the different sizes and spacings, the comb can be adjusted vertically and the slots are arranged in groups of different spacings. These adjustments are flexible enough to allow the setting up of practically all the various groups used in the different makes and type of batteries.

Special fittings are provided so that after the plates and post are properly set a form can be built on the comb which not only locks the 17plates in the comb but prevents the hot lead from running off while burning and makes the finished strap of exactly the proper dimensions to properly fit into the jar.

For use in the smaller shop the small Ambu Plate Burning Rack, Figure 16, is recommended. It has all the features of the larger rack but the spacings of the combs limit it to the 7⁄64" and ⅛" spacings such as are found in all the popular batteries.

After the top connectors have been drilled off and the group is to be reassembled in the repaired battery, in order to make a good quick weld to the top strap, the post must be built up to its original height.

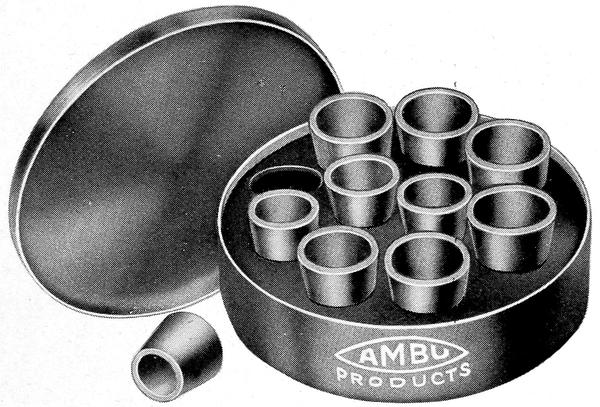

Figure 17. See bottom of page

The Ambu Post Builders, Figure 17, have been built to speed up the post building process. They are made of high grade steel and are of the proper size to rebuild all the standard battery posts.

Simply place the proper Ambu Post Builder on the stub post, and burn in molten lead to the proper height. The construction is such that the post builder is easily removed, leaving a new and perfectly sized post for burning to the cell connector.

The set of ten, illustrated in Figure 17, covers all standard makes of batteries.

Following are prices of equipment illustrated in preceding pages

which may be purchased from the Battery Appliance Division, American Bureau of Engineering,

Inc., 2632 Prairie Avenue, Chicago, or from your Jobber.

| Adjustable Screw Mould (Fig. 13) | $12.50 |

| Battery Post Builders. Set of Ten (Fig. 17) | 2.00 |

| Ladle for Pouring Lead and Sealing Compound (Fig. 17) | 2.75 |

| Lead Stick Moulds (Fig. 14). (Pair, $2.75), each | 1.50 |

| Link Combination Mould (Fig. 8A) complete | 35.00 |

| Mould Compound for making castings “come clean” (Fig. 6) | .50 |

| Plate Burning Rack, Large Type “B” (Fig. 15) | 8.75 |

| Plate Burning Rack, Small Type “A” (Fig. 16) | 5.95 |

| Post Strap Mould (Fig. 10) complete | 18.00 |

| Production Post Strap Mould (Fig. 11) complete | 35.00 |

| Terminal Mould (Fig. 9) complete | 9.85 |

HELPS for the Service Station

HELPS for the Service Station

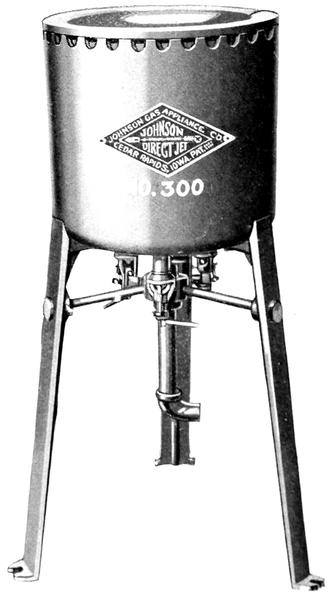

No. 300

No. 8

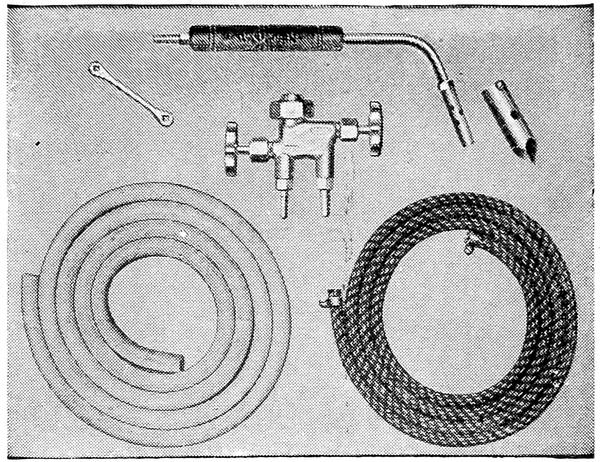

In line with our desire to serve the Battery Service Stations of the country, we have arranged to offer the Johnson Direct-jet Gas-fired Melting Pots. These furnaces use either natural or manufactured gas. They embody a special patented Gas-regulator which permits of a quick change in the size of the gas orifice, by the turn of a wrench.

This Regulator throws a sharp, clean jet of gas straight up the center of the mixing tube, giving the nearest approach to 100% combustion that can be imagined.

No Blowers or Forced Draft are necessary. City gas pressure is enough.

No. 300 Pot. Melts 150 lbs. lead at a charge, using only 40 cubic feet of city gas per hour. Has 3 Direct-jet Burners. No forced draft necessary. Height, 28 inches; weight, 100 lbs. Price f. o. b. Cedar Rapids, Iowa, $25.00. Stock No. MJP1.

No. 8 Combined Torch and Pot. Melts 25 lbs. of lead at a charge. Height, 14 inches; weight, 9½ lb. Single adjustable burner, with pilot. Can be used as an efficient hand torch. Consumes 20 to 25 cubic feet of gas per hour. Price complete with 6 inch Pot, as shown, f. o. b. Cedar Rapids, Iowa, $9.00. Stock No. MJP2.

PRODUCTS that MAKE MONEY and SAVE

TIME FOR BATTERY REPAIR SHOPS

PRODUCTS that MAKE MONEY and SAVE

TIME FOR BATTERY REPAIR SHOPS

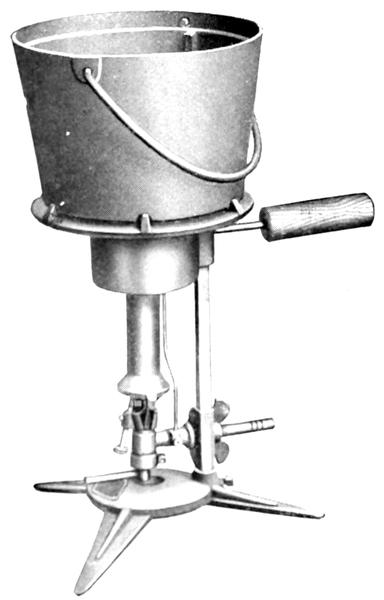

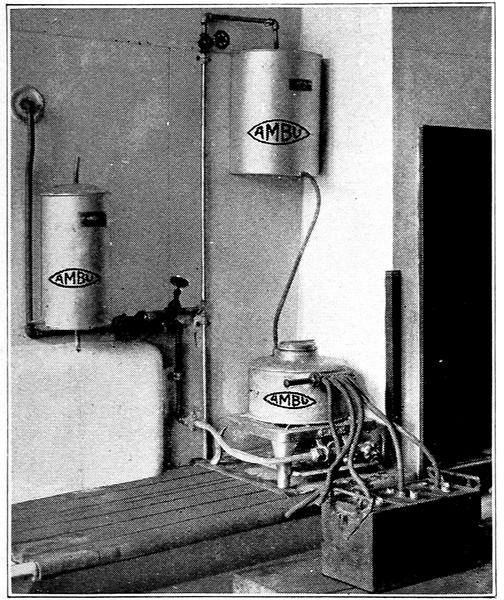

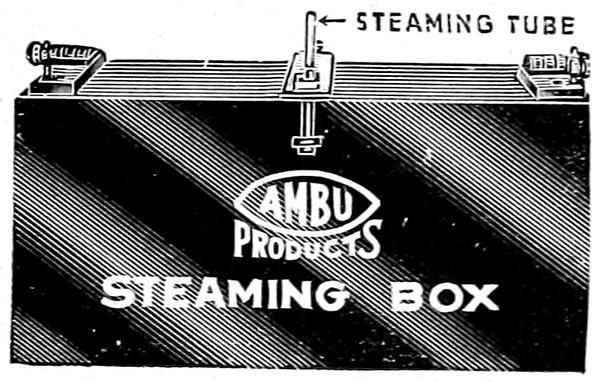

Battery Steamers

Battery Steamers

Softens sealing compound on batteries. Within less than five minutes prepares them so that elements can be easily removed.

Automatic valve regulates water supply. Steam is quickly produced. Saves time and fuel cost.

For use with gas, gasoline, kerosene or electric stoves. Has six outlets and adjustable valve for opening the required number of outlets.

For Battery Men desiring to steam one or more batteries at one time, depending upon their size, we offer the Type “A” Steamer with Steaming Box.

AMBU CONDENSER FOR DISTILLING WATER, accompanies either type Steamer, if desired. When Steamer is not being used for steaming batteries, and when used in conjunction with this Condenser, will produce about one gallon of distilled water per hour at very small cost.

| Type “B” Ambu Steamer complete with Condenser | |

| Type “B” Ambu Steamer without Condenser | Prices |

| Type “A” Ambu Steamer complete with Condenser | on |

| Type “A” Ambu Steamer without Condenser | request |

| Ambu Condenser for Distilling Water |

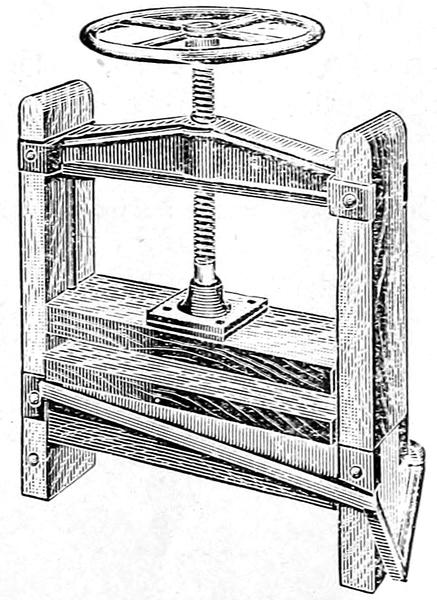

Battery Plate Press

Battery Plate Press

Three Groups of Plates Pressed at One Time

With the Ambu Plate Press there is no possibility of iron, the greatest enemy of a battery, touching the plates.

In discharged negative plates, the active material is bulged out and must be pressed back flush with the grids before the plates can be used again.

The Ambu Battery Plate Press is made of heavy hardwood timber with two horizontal wooden jaws between which the battery plates are pressed. A set of lead covered troughs carries away the acid. The upper jaw of the press is attached to a screw shaft for raising or lowering it. A complete set of transite boards for placing between the plates, and a substantial wall support are included in the purchase price. Press complete, including set of press separator boards sufficient to press three groups, and substantial wall support. Price on request.

Ambu Press Separator Boards in sets as above also may be purchased separately. Price on request.

Compound and Lead Ladle

Compound and Lead Ladle

A ladle that will permit of pouring sealing compound into the small openings between top covers or jars without spilling or slopping over top of battery. With the special center drain controlled by taper pin with touch of your thumb you are able to control the flow of sealing compound from the stream as fine as a pin to a stream as thick as your thumb.

Designed also for pouring lead, and has many advantages over ordinary ladle.

Made of forged malleable iron, extra deep, with two lips in addition to center spout, four inches in diameter. Price on request.

PRODUCTS that MAKE MONEY and SAVE

TIME FOR BATTERY REPAIR SHOPS

PRODUCTS that MAKE MONEY and SAVE

TIME FOR BATTERY REPAIR SHOPS

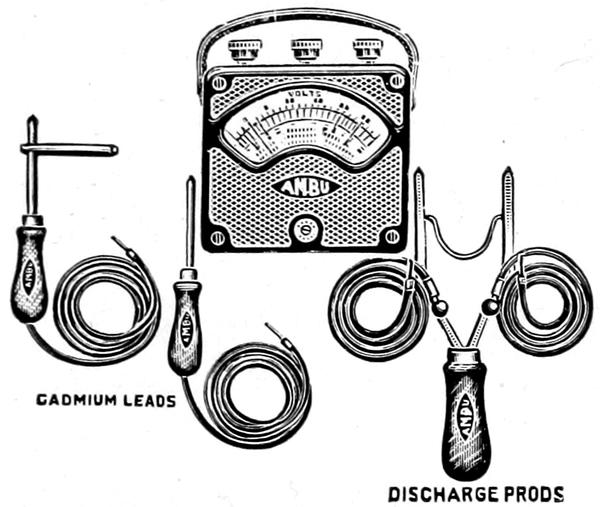

Battery Test Set

Battery Test Set

Consisting of a high grade accurate voltmeter with two scales, permitting readings as high as 25 volts; Cadmium Leads, and Pair discharge prods and leads. With this complete set all tests necessary to determine the inside condition of a battery can be made, except those obtained through hydrometer readings. Sold as a complete set or as individual units. Price on request.

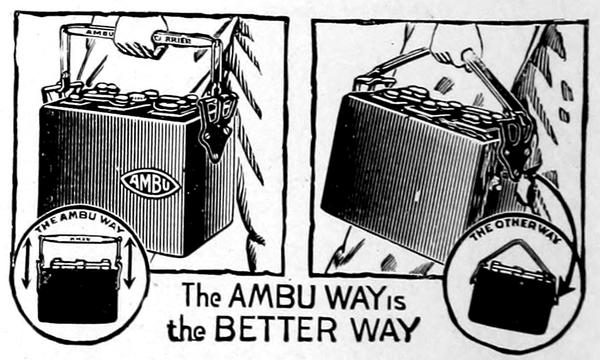

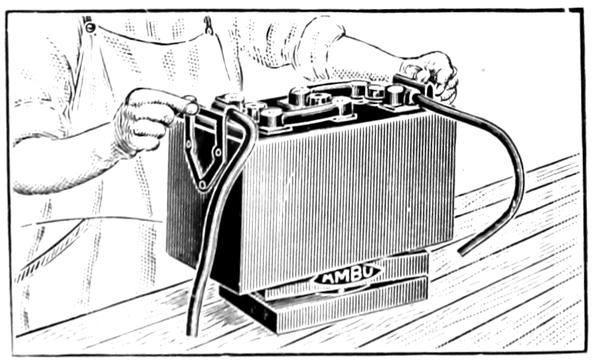

Battery Carrier

Battery Carrier

The AMBU Battery Carrier, designed to make the carrying of batteries easy, as well as the removing and placing of batteries in cars. An unusually handy tool around a shop. Made of a hardwood handle with a swinging steel arm at each end, to which is attached a strong steel lock for engaging the handles of a battery box. Sold singly or in pairs.

Battery Turntable

Battery Turntable

Designed to make the handling of a battery on the work bench easy. Permits getting at all sides of the battery with least amount of effort.

Made of two stout pieces of hard wood pivoted to each other and mounted on ball bearings. It is also handy for working on heavy generators and starting motors.

HELPS for the Service Station

HELPS for the Service Station

Torch

Torch

This torch produces a soft pointed flame. Especially adapted for all torch uses in repairing of storage batteries. Can be nosed into post builder; stirring molten lead with nose of torch without popping out. Not affected by wind. Burns clean, requiring heat up to 5300 degrees Fahrenheit.

The torch operates on Prest-o-lite Gas and Compressed Air. Tank attachment on Mixing Valve is easily adapted to A, B or E size Prest-o-lite tank. Air derived from any air line furnishing 20 lbs. pressure or over. Small air tank with foot pump can be used. Needle point flame instantly adjustable through a range of 4000 degrees without changing tip. The most economical, efficient and time saving torch on the market doing the same class of work.

These attachments are great time savers in the repairing of radiators, giving the operator a combination open flame and soldering iron in repairing tubular and honeycomb radiators.

Sold only for use with the Ambu Washburn Torch.

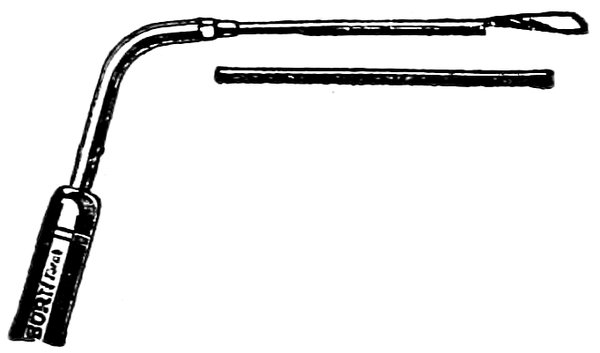

Electric Solder Iron

Electric Solder Iron

Works wherever there is a storage battery, on the car, in the shop or garage.

Furnished complete with wires, clamps, supply of carbon tips, wire solder and solder paste. Ready to use.

Handy for quick soldering jobs.

Is not necessary to wait fifteen minutes, nor even one minute to get it hot—IT HEATS UP INSTANTLY. Cannot burn out—no parts to break. No current wasted when not in use. Price on request.

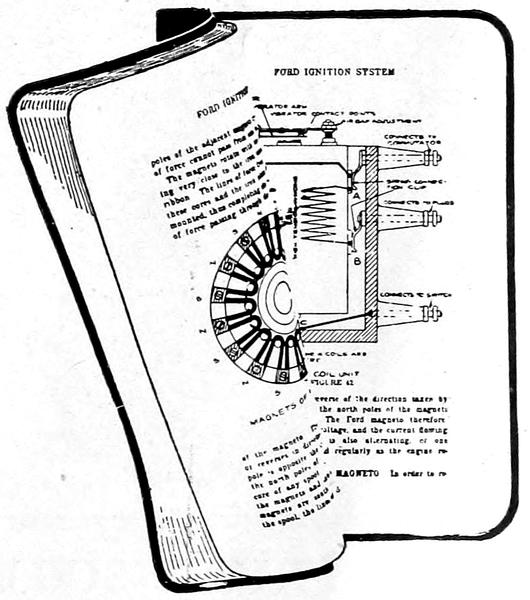

Covers F-A or Liberty Electrical System now standard equipment now put on the Ford car at the factory.

Each unit is described in detail and illustrated by internal and external wiring diagrams.

Complete instruction is also given on the location and correction of starting, lighting, and ignition troubles.

Tells how to adjust the generator. Explained so clearly and simply that even the inexperienced can make necessary repairs or adjustments. No mechanic or owner who attempts repairs on this system can afford to be without this authoritative book.

Printed on high grade enameled paper with flexible binding—150 pages—49 illustrations.

Money back if not satisfied and book is returned within five days.

| Price delivered | $2.00 |

HELPS for the Service Station

HELPS for the Service Station

Containing both internal and external wiring diagrams, test and performance data.

Illustrates each type of starting motor, generator, cut-out or regulator by large diagrams. Shows field coils, brushes and connections exactly as they should be. Internal diagram of generator, also shows wiring of cut-out or regulator, ammeter and battery on same page, thus giving clear diagram of entire charging circuit.

Prepared so that you can instantly find information you desire. Car Equipment Tables give name of car, model, year, make of equipment, type of generator, its regulation, type of starting motor, and instantly gives you description, test data, setting of generator, the drive, test data and description of starting motor. A separate list is also given of each make and type of generator and starting motor so that if you do not know the car model but have the number or type of generator or starting motor, the information is easily found.

Contains also a Battery Table, furnishing make, type, voltage, ampere hour capacity, dimensions and order number of battery used on each particular car.

Each book is printed on strong kraft paper, in a beautiful flexible binding, containing over 600 pages.

| Ambu 1920-21 Service Manual} | |

| Ambu 1918-19 Service Manual} | $5.75 Each |

| Ambu 1916-17 Service Manual} |

It gives complete information on what a storage battery is, how to take care of it, the tools required, the right shop equipment, proper charging methods, best repair methods, etc.

There are 400 pages written in easy-to-understand language, profusely illustrated with diagrams and photographic reproductions that bring out the text matter clearly. The theory, manufacture and maintenance are explained in detail, also complete instructions given on the efficient management and operation of a battery repair shop.

This book is recognized as the most complete and authoritative treatise on the automobile storage battery that has ever been published.

Guaranteed satisfactory or money refunded, if book is returned within five days after receipt.

| Price, delivered | $5.00 |

|---|

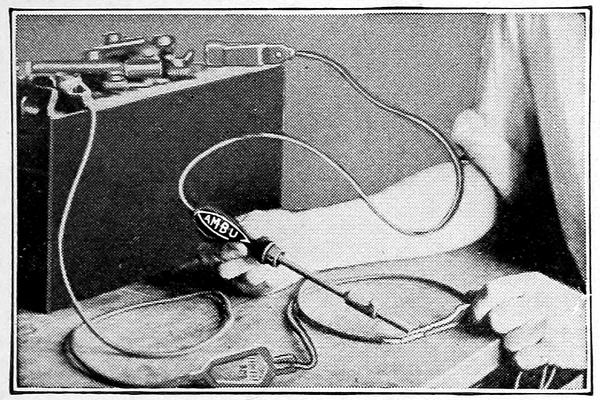

Makes starting, lighting, ignition and battery repair work definite, accurate, more profitable. Eliminates all guesswork, groping in the dark, trusting to luck methods. Provides the necessary and essential testing equipment for auto electric repair in one compact, portable efficient system.

Thousands of garages, repair shops, battery and electric service stations are adding hundreds of dollars and new customers through the use of the AMBU system. Millions of car owners know of the worlds and worlds of trouble the electric equipment of a car is giving. They are seeking the shop well equipped and that KNOWS HOW. With the AMBU System and a knowledge of electricity your ability to handle electrical repair work is never in doubt. AMBU enables you to locate trouble in ONE SIXTH the time usually required and far more efficiently.

With between 600 and 700 different types of starting, lighting, ignition and battery equipment used in over 1,300 makes and models of cars, no man can even expect to know their details—regulation—rates of charge, discharge, motor and generator, test data, etc. The AMBU System supplies these bewildering details, quickly, easily and accurately. No matter what is wrong—The AMBU System shoots the trouble and never fails.

To secure a franchise for an Official Ambu Service Station is to have greater prestige and earn more and bigger profits. Automobile owners from Coast to Coast know that the Official Ambu Service Station sign on a garage, repair shop, battery or electrical Service Station stands for the highest degree of efficiency in electrical repair work. To maintain this reputation AMBU Franchises are given with care. If you are not now qualified—we have a plan that will give you the necessary knowledge.

Most auto troubles are found in the electric equipment; and require hours of searching; from the commutator to the battery and back again. Equip yourself to eliminate this useless searching and make the big profits. The cost of AMBU is a trifling detail compared to its tremendous earning power. You can pay as you earn on our deferred payment plan if you choose.

The free test day plan brings new customers to you at once. The monthly test card assures you a steady number of permanent customers and a fixed income. Motorists pay you in advance for monthly testing service and give you all repair work. You circularize the car owners in your community with letters, mailings, literature and selling ideas supplied free by us. We help you build your business bigger, better and more profitable.

Not a single minute to lose. Write now for further facts. Act Quick.

HELPS for the Service Station

HELPS for the Service Station

Simplest, most efficient and easiest to read battery tester ever yet offered to the battery owner. Unlike any hydrometer or tester on the market. Instead of the glass float used on ordinary hydrometers, which are hard to read and understand, it has three balls, colored red, white and green which tell the whole story.

Astonishingly simple to test a battery with it, because the following jingle regarding the three balls, and the positions they assume in the electrolyte or liquid tells the story—

A battery can be tested with it with as much accuracy as any hydrometer on the market. The specific gravity of each ball is accurate to the fourth decimal point. It can be “read” in semi-darkness.

Is only 6½ inches long and designed so that it can be carried in the tool box where it is Always Handy—A mighty big value for only 75c.

Furnished to the Dealer in an attractive counter display box, one dozen to each package. When placed on the counter it sells itself.

Write for dealers' prices and details on this fast selling article.

You have been reading how to increase the profits of your shop through the use of materials previously wasted. There is another way of stopping leaks and increasing earnings. That is by making the best possible use of every man's time.

In this connection we would like to tell you briefly about the activities of the Educational Division of the American Bureau of Engineering, Inc.

This institution foresaw the need of providing instruction on fundamental electricity, ignition, starting and lighting and storage batteries, so that garage owners, foremen, general repair men and mechanics could handle electrical repair jobs at a profit.

Here in Chicago we are offering an eight weeks' course of forty-four hours per week, devoted to intensive instruction in theory and practical shop work. This training enables the student to become an expert in this highly specialized field, fitting him to supervise the work of other mechanics or to operate a shop of his own as an expert in Automotive Electrical Repairs.

For those unable to leave their employment and come to Chicago, we have developed a series of Home Study problems and solutions which have proved interesting and practical. Lesson schedules can be arranged to suit the individual student. Close personal cooperation aids the Home Study student in making satisfactory progress.

The two methods of instruction are identical with the exception that the Resident Student gets actual practice in addition to theory.

Through our other activities we are able to keep in close touch with the situation and be certain that the instruction offered is strictly up-to-date and practical.

AMBU PRODUCTS