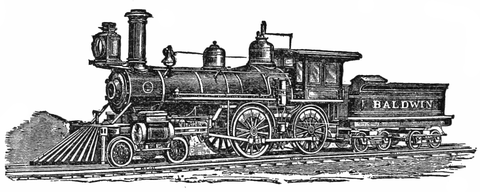

Title: Locomotive Engine Running and Management

Author: Angus Sinclair

Release date: July 11, 2020 [eBook #62609]

Most recently updated: October 18, 2024

Language: English

Credits: Produced by deaurider, Charlie Howard, and the Online

Distributed Proofreading Team at https://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

Transcriber’s Note

Cover created by Transcriber and placed in the Public Domain.

Some large diagrams (such as Fig. 12) may be reduced in size to fit your screen. In most browsers, you can see a larger, more detailed version of such an image by enlarging the window or right-clicking the image and selecting "open image" or "view image" (wording varies by browser). If the Browser then shows a magnifying glass, clicking again will show the image full-size.

On some eReaders, stretching and/or double-tapping an image will magnify it and show more detail, including better readability of small print.

A Treatise on Locomotive Engines,

SHOWING THEIR PERFORMANCE IN RUNNING DIFFERENT

KINDS OF TRAINS WITH ECONOMY AND DISPATCH;

ALSO DIRECTIONS REGARDING THE CARE,

MANAGEMENT, AND REPAIRS OF

LOCOMOTIVES AND ALL

THEIR CONNECTIONS.

BY

ANGUS SINCLAIR,

MEMBER OF THE BROTHERHOOD OF LOCOMOTIVE ENGINEERS, MEMBER OF THE

AMERICAN SOCIETY OF MECHANICAL ENGINEERS, ASSOCIATE MEMBER

OF THE AMERICAN RAILWAY MASTER MECHANICS’ ASSOCIATION,

ASSOCIATE MEMBER OF THE UNITED

STATES NAVAL INSTITUTE, ETC.

TENTH EDITION.

NEW YORK:

JOHN WILEY AND SONS.

1888.

Copyright, 1884,

By JOHN WILEY & SONS.

ELECTROTYPED AND PRINTED

BY RAND, AVERY, AND COMPANY,

BOSTON, MASS.

While following the occupation of a locomotive engineer, I often observed peculiarities about the working of my engine, while running, that I did not entirely understand. As I was perfectly aware, even before making my first trip on a locomotive engine, that there is no effect without a cause, I never felt satisfied to accept any thing as incomprehensible without investigation, and fell into the habit of noting down facts about the working of the engine, with the view of studying out, at leisure, any thing which was not quite clear. When, some years ago, I abandoned engine-running to take charge of the round-house at the mechanical headquarters of the Burlington, Cedar Rapids, and Northern Railway, in Iowa, the practice of keeping notes was continued. The work connected with the ordinary repairing of running-engines, the emergency repairing executed to get engines ready hurriedly to meet the traffic demands on a road then chronically short of power, and diagnosing the numerousiv diseases that locomotives are heir to, provided ample material for voluminous notes. Those notes formed the raw material from which this book was constructed.

The original intention was, to publish a book on Locomotive Engine Running alone, and the first portion of the work was prepared with that idea in view; but, before the articles were finished, I joined the editorial staff of the American Machinist. The correspondence in the office of that paper convinced me that an urgent demand existed, among engineers, machinists, and others, for plainly given information relating to numerous operations connected with the repairing and maintenance of locomotives. To meet this demand, the chapters on “Valve-Motion” and all the succeeding part of the book were written. Most of that matter was originally written for the pages of the American Machinist, but was afterwards re-arranged for the book.

In preparing a book for the use of engineers, firemen, machinists, and others interested in locomotive matters, it has been my aim to treat all subjects discussed in such a way that any reader would easily understand every sentence written. No attempt is made to convey instruction in any thing beyond elementary problems in mechanical engineering, and all problems brought forward are treated in the simplest manner possible.

The practice of applying to books for informationv concerning their work, is rapidly spreading among the engineers and mechanics of this school-spangled country; and this book is published in the hope that its pages may furnish a share of the needed assistance. Those men, who, Socrates-like, search for knowledge from the recorded experience of others, are the men, who, in the near future, will take leading places in our march of national progress. To such men, who are earnestly toiling up the steep grade of Self-help, this book is respectfully dedicated.

Angus Sinclair.

New York City,

Jan. 1, 1885.

I desire to thank the railroad world and the technical press for the kind reception they have extended to my book. The necessity for publishing the third edition within three months after the first one was issued, indicates that the book was wanted.

In the present edition I have corrected a few errors, and made some necessary alterations, that will add to the value of the book.

Angus Sinclair,

New York, April 6, 1885.

| CHAPTER I. | |

| PAGE | |

| Engineers and their Duties | 1 |

| Attributes that make a Good Engineer.—How Engineering Knowledge and Skill are Acquired.—Public Interest in Locomotive Engineers.—Ignorance versus Knowledge.—Illiterate Engineers not wanted in America.—Growing Importance of Engineers’ Duties.—Individuality of American Engineers.—Necessity for Class Improvement.—The Skill of Engineers influences Operating Expenses.—Methods of Self-improvement.—Observing Shop Operations.—Where Ignorance was Ruin.—Prejudice against studying Books.—The Kind of Knowledge gained from Books. | |

| CHAPTER II. | |

| How Locomotive Engineers are made | 11 |

| Reliable Men needed to run Locomotives.—Early Methods of making Locomotive Engineers.—Practice of raising Engineers from Machinists and Technical-school Graduates not found satisfactory.—Experience demonstrated that Firemen made the Best Engineers.—Difficulties of running Locomotives at Night, and during Bad Weather.—Kind of Men to be chosen as Firemen.—Modern Methods of selecting Firemen.—First Trips.—Popular Misconception of a Fireman’s Duties.—Learning Firemen’s Duties.—A Good Fireman makes a Good Engineer.—Learning an Engineer’s Duties.—Conditions of Engine Running that vanquish the Inexperienced Man.—Learning tox keep the Locomotive in Running-order.—Methods of Promotion on our Leading Roads.—Nature of Examination to be passed.—Master Mechanics on the Best Method of Educating Young Men for Engineers. | |

| CHAPTER III. | |

| Inspection of the Locomotive | 30 |

| Locomotive Inspectors.—Good Engineers Inspect their own Engines.—What comes of neglecting Systematic Inspection of Locomotives.—Confidence on the Road derived from Inspection.—Inspection on the Pit.—Outside Inspection.—Oil-cups.—Inspection of Running-gear.—Attentions to the Boiler.—Miscellaneous Attentions.—Reward of Thorough Inspection. | |

| CHAPTER IV. | |

| Getting ready for the Road | 39 |

| Raising Steam.—Precautions against Scorching Boilers.—Starting the Fire.—Fireman’s First Duties.—Saving the Grates.—Supplies.—Engineer’s First Duties.—Reaching his Engine in Good Season.—Oiling the Machinery.—Quantity of Oil that Different Bearings need.—Leaving the Engine-house. | |

| CHAPTER V. | |

| Running a Fast Freight Train | 48 |

| Running Freight Trains.—The Engine.—The Train.—The Division.—Pulling out.—Hooking back the Links.—Working the Steam Expansively.—Advantage of Cutting-off Short.—Boiler Pressure Best for Economical Working.—Running with Low Steam.—The Throttle-lever.—Management of the Fire.—Conditions that demand Good Firing.—Highest Type of Fireman.—Scientific Methods of Good Firemen.—The Medium Fireman.—The Hopelessly Bad Fireman.—Who is to Blame for Bad Firing? | |

| xi | |

| CHAPTER VI. | |

| Getting up the Hill | 61 |

| Special Skill and Attention required to get a Train up a Steep Grade.—Getting Ready for the Grade.—Working up the Hill.—Wheel-slipping.—How to use Sand.—Slippery Engines.—Feeding the Boiler.—Choice of Pump and Injector.—Fall of Boiler-temperature not indicated by the Steam-gauge.—Some Effects of Injudicious Boiler-feeding.—Careful Feeding and Firing preserve Boilers.—Operating the Dampers.—Loss of Heat through Excess of Air.—Loss of Heat from Bad Dampers. | |

| CHAPTER VII. | |

| Finishing the Trip | 74 |

| Running over Ordinary Track.—Stopping-places.—Knowledge of Train-rights.—Precautions to be observed in approaching and passing Stations.—The Best Rules must be Supplemented by Good Judgment.—Operating Single Tracks Safely.—Causes of Anxiety to Engineers.—Acquaintance with the Road.—Final Duties of the Trip. | |

| CHAPTER VIII. | |

| Running a Fast Passenger Train | 82 |

| Average Speed.—Speed between Jersey City and Philadelphia.—Requisites of a High-speed Locomotive.—Making up the Fire.—Getting ready for the Trip.—The Train to be pulled.—The Start.—Getting the Train over the Road.—How the Engineer did his Work.—Qualifications that make a Successful Engineer.—How the Firing was done. | |

| CHAPTER IX. | |

| Hard-steaming Engines | 92 |

| Importance of Locomotives Steaming Freely.—Essentials for Good-steaming Engines.—Causes Detrimental to makingxii Steam.—Petticoat-pipe.—The Smoke-stack.—Obstructions to Draught.—Choking the Netting with Oil.—Silicious Deposit on Flue-sheet.—The Extended Smoke-box.—Steam-pipes leaking.—Defects of Grates.—Lime, Scale, and Mud.—Preventing Accumulation of Mud in Boilers.—Temporary Cures for Leaky Flues.—Good Management Makes Engines Steam.—Intermittent Boiler-feeding.—Too Much Piston Clearance.—Badly Proportioned Smoke-stacks.—The Exhaust Nozzles. | |

| CHAPTER X. | |

| Shortness of Water.—Pump Disorders | 109 |

| Trouble develops Natural Energy.—Shortness of Water a Serious Predicament.—How to deal with Shortness of Water.—Watching the Water-gauges.—What to do when the Tender is found empty between Stations.—A Trying Position.—Watching the Strainers.—Care of Pumps.—How the Condition of Pumps can be tested.—Lift of Pump-valves.—Keep Pipes tight, and Packing in Order.—Sand in the Pump-chambers.—Delivery Orifice choked with Lime Sediment.—Minor Pump Troubles. | |

| CHAPTER XI. | |

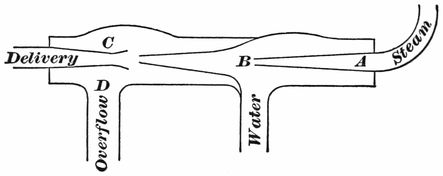

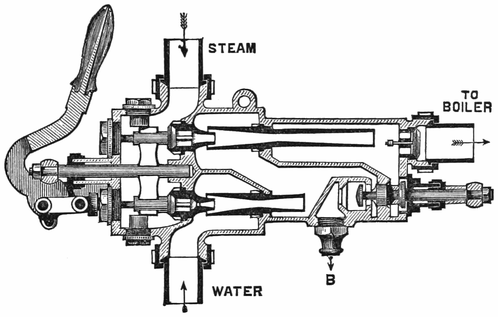

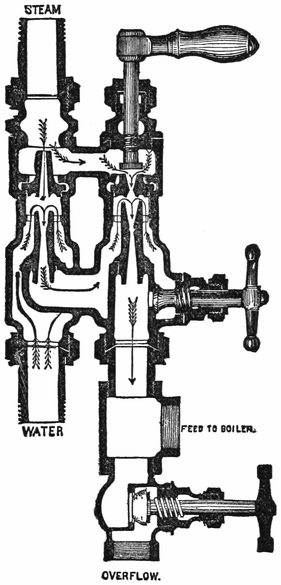

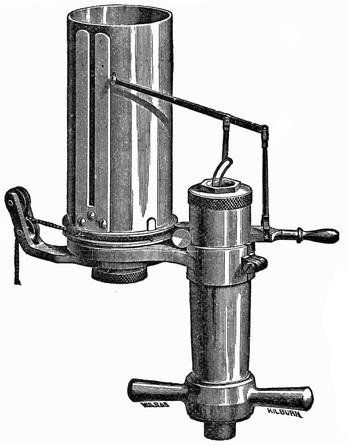

| Injectors | 119 |

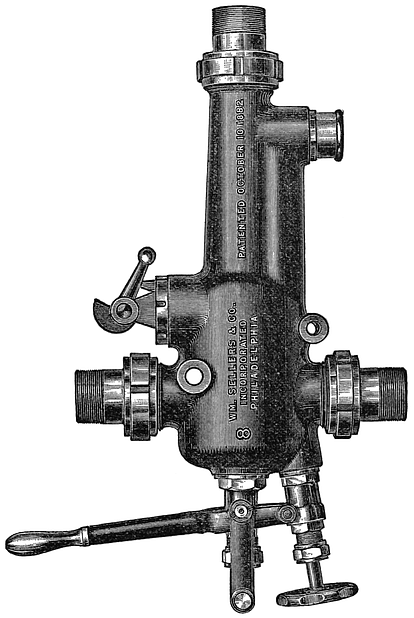

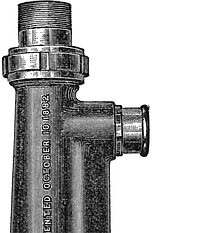

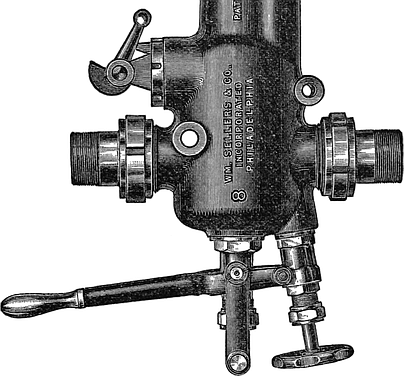

| Invention of the Injector.—Trying to find out how the Injector worked.—The Principle of the Injector’s Action.—Different Forms of Injector.—A Heater-pipe acting as an Injector.—Skill and Reflection Needed in Repairing Injectors.—Care of Injectors.—The Most Common Causes of Derangement.—How to Keep an Injector in Good Order.—Curious Cases of Trouble with an Injector.—Common Defects.—Care of Injectors in Winter.—Sellers Injector.—The Nathan Manufacturing Company’s Monitor Injector.—The Korting Injector.—The Hancock Inspirator. | |

| xiii | |

| CHAPTER XII. | |

| Boilers and Fire-boxes | 136 |

| Care of Locomotive Boilers.—Factor of Safety.—Boiler Explosions.—Preservation of Boilers.—Causing Injury to Boilers.—Dangers of Mud and Scale.—Blowing off Boilers.—Over-pressure.—Relieving Over-pressure.—Bursted Flues. | |

| CHAPTER XIII. | |

| Accidents to the Valve-motion | 143 |

| Running Worn-out Engines.—Care and Energy defy Defeat.—Watching the Exhaust.—The Attentive Ear detects Deterioration of Valves.—Locating the Four Exhaust Sounds.—Identifying Defects by Sound of the Steam.—Accidents Prevented by attending to the Note of Warning from the Exhaust.—Neglecting a Warning.—How an Eccentric-strap Punched a Hole in a Fire-box.—Interest in the Valve-motion among Engineers.—Trouble with the Valve-motion.—A Wrong Conclusion.—Locating Defects of the Valve-motion.—Position of Eccentrics.—Method of Setting Slipped Eccentrics.—Slipped Eccentric-rods.—Detecting the Cause of a Lame Exhaust.—What to do when Eccentrics, Straps, or Rods Break.—Different Ways of securing the Cross-head.—Broken Tumbling-shaft.—Broken Valve-stem, or Valve-yoke.—When a Rocker-shaft or Lower Rocker-arm Breaks.—Miscellaneous Accidents to Valve-motion.—Broken Steam-chest Cover.—Steam-pipe Bursted.—Testing the Valves. | |

| CHAPTER XIV. | |

| Accidents to Cylinders and Steam Connections | 162 |

| Importance of the Piston in the Train of Mechanism.—Causes that lead to Broken Cylinder-heads.—Broken Cylinder-heads often Preventable.—When a Main Rod breaks.—Crank-pin broken.—Throttle disconnected.—Oiling the Valves when the Throttle is Disconnected.—What causes a Disconnected Throttle.—Bursting a Dry Pipe.—Other Throttle Accidents.—Pounding of the Working-parts.—Some Causes of Pounding.—Locating a Mysterious Pound. | |

| xiv | |

| CHAPTER XV. | |

| Off the Track.—Accidents to Running-gear | 172 |

| Getting Ditched.—Dealing with Sudden Emergencies.—Stopping a Freight Train in Case of Danger.—Saving the Heating Surfaces.—Getting the Engine on the Track.—Understanding the Running-gear.—Broken Driving-spring.—Equalizer Broken.—Accidents to Trucks.—Broken Frame.—Broken Driving Axles, Wheels, and Tires. | |

| CHAPTER XVI. | |

| Connecting-rods, Side Rods, and Wedges | 182 |

| Care of Locomotive Rods.—Functions of Connecting-rods.—Effects of Bad Fitting.—Striking Points and Clearance.—Watching Rods on the Road.—Side Rods.—Adjustment of Side Rods.—Keying Side Rods.—Difficulty in locating Defects.—Pounding in Driving-boxes and Wedges.—Importance of having Wedges properly Fitted.—Influence of Half-round Brasses.—Position of Boxes while setting up Wedges.—Necessity for keeping Boxes and Wedges Clean.—Temperature of the Box to be considered.—Small Disorders that cause Rough Riding. | |

| CHAPTER XVII. | |

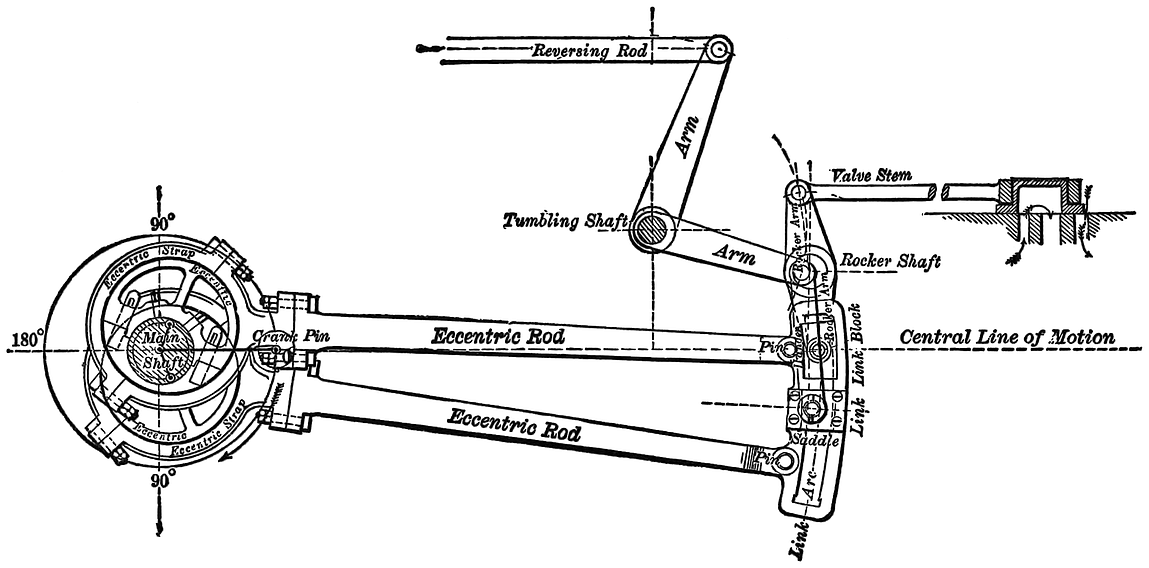

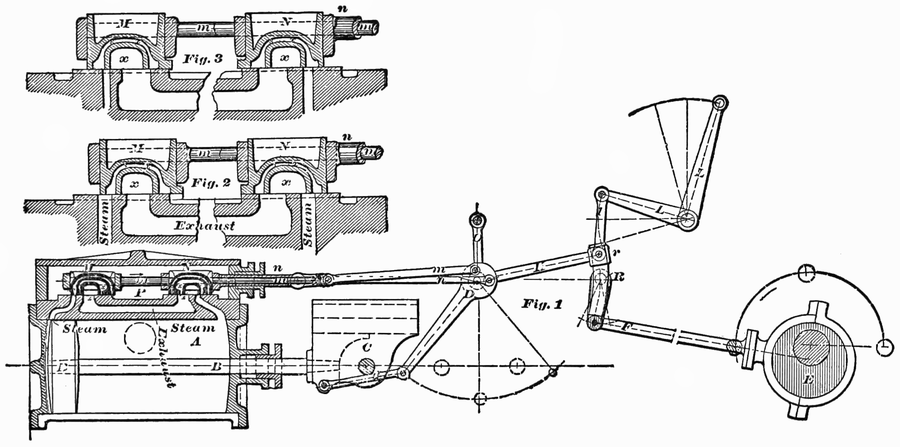

| The Valve-motion | 199 |

| The Locomotive Slide-valve.—Invention and Application of the Slide-valve.—Description of the Slide-valve.—Primitive Slide-valve.—Outside Lap.—Some Effects of Lap.—Inside Lap.—The Extent of Lap usually adopted.—First Application of Lap.—The Allen Valve.—Advantages of the Allen Valve.—Case where the Allen Valve proved its Value.—Inside Clearance.—Lead.—Operation of the Steam in the Cylinders.—Back Pressure in the Cylinders.—Effect of too Much Inside Lap.—Running into a Hill.—Compression.—Definition of an Eccentric.—Early Application of the Eccentric.—Relative Motion of Piston and Crank, Slide-valve, and Eccentrics.—Attempts to Abolish the Crank.—Valve Movement.—Effect of Lap on thexv Eccentric’s Position.—Angular Advance of Eccentrics.—Angularity of Connecting-rod.—Effect on the Valve-motion of Connecting-rod Angularity.—Aids to the Study of Valve-motion.—Events of the Piston Stroke.—What Happens Inside the Cylinders when an Engine is Reversed.—Events of the Stroke in Reversed Motion.—Purpose of Relief-valve on Dry Pipe.—Using Reverse-motion as a Brake. | |

| CHAPTER XVIII. | |

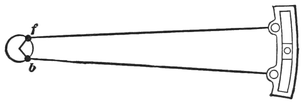

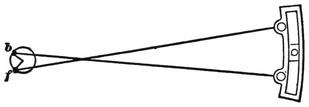

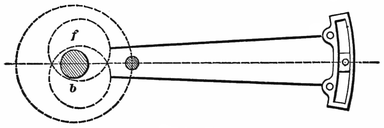

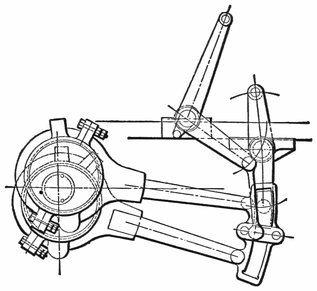

| The Shifting-link | 229 |

| Early Reversing Motions.—Invention of the Link.—Construction of the Shifting Link.—Action of the Link.—Valve-motion of a Fast Passenger Locomotive.—Effect of changing Valve-travel.—Weak Points of the Link-motion.—Why Decreasing the Valve-travel Increases the Period of Expansion.—Influence of Eccentric Throw on the Valve.—Harmony of Working-parts.—Adjustment of Link.—Slip of the Link.—Radius of Link.—Increase of Lead. | |

| CHAPTER XIX. | |

| Setting the Valves | 246 |

| The Men who learn Valve-setting.—Best way to learn Valve-setting.—Preliminary Operations.—Connecting Eccentric-rods to Link.—Marking the Valve-stem.—Length of the Valve-rod.—Accuracy Essential in Locating the Dead Center Points.—Finding the Dead Centers.—Turning Wheels and Moving Eccentrics.—Setting by the Lead Opening.—Ascertaining the Point of Cut-off.—Adjustment of Cut-off. | |

| CHAPTER XX. | |

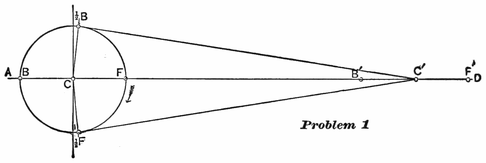

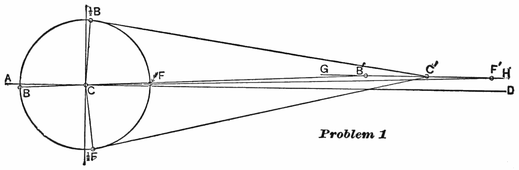

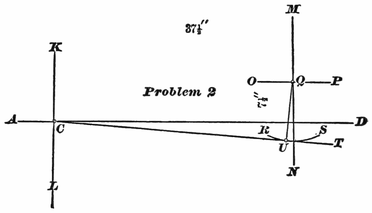

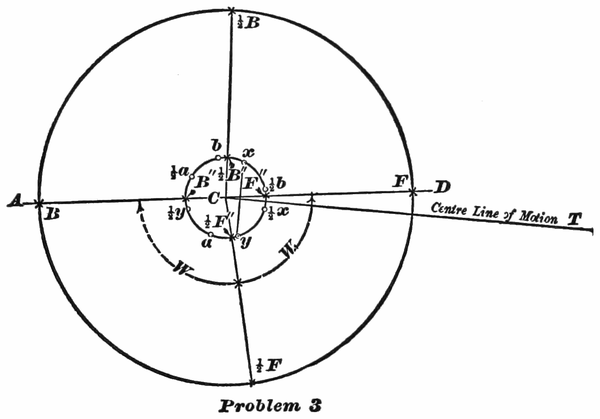

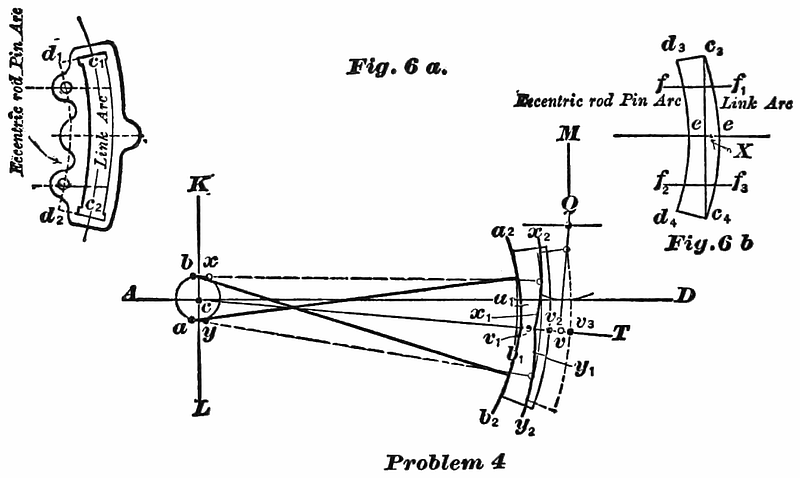

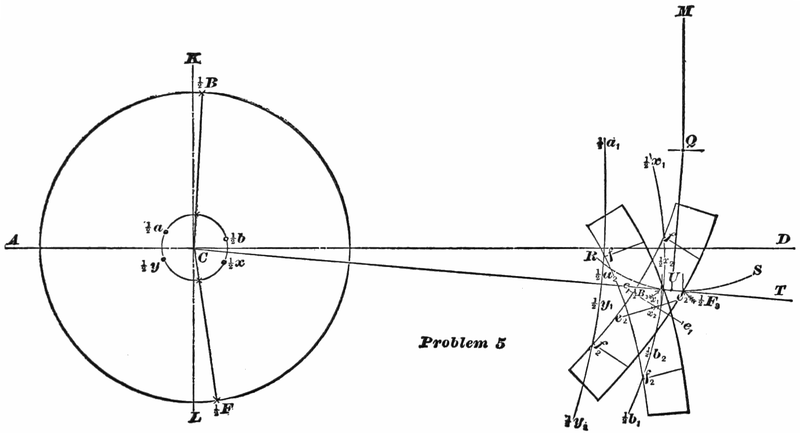

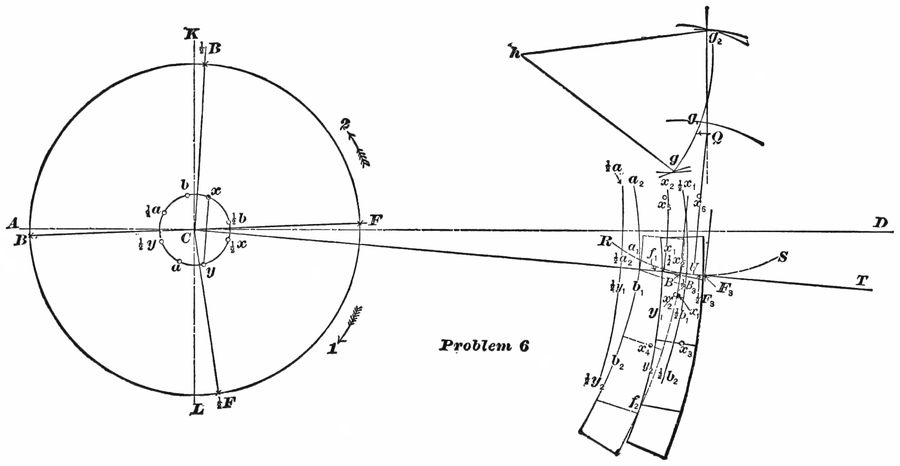

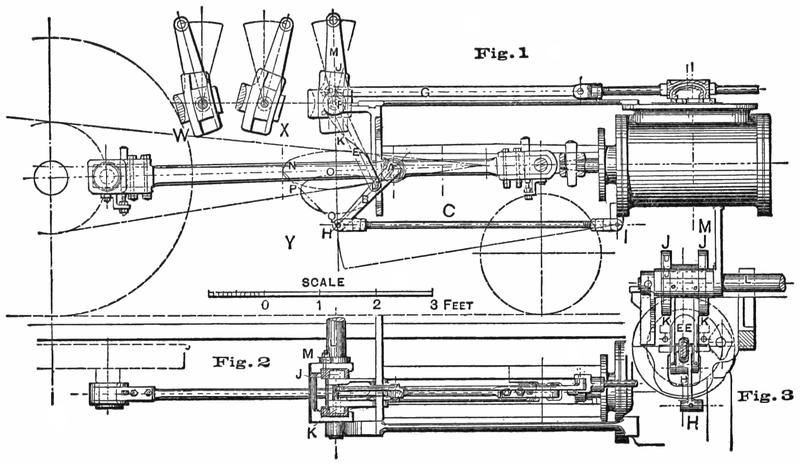

| Laying out Link-motion | 257 |

| Preliminary Explanations.—Definition of Terms used.—Conditions.—Problems Involved in Laying Out Link-motion.—To find the Position of Crank when the Piston is at Full and Halfxvi Stroke.—To find the Center Line of Motion and the Amount of Offset in the Lower Rocker-arm.—To find the Relative Positions of Crank-pin and Eccentrics when the Piston is at Full and Half Stroke.—To determine the Correct Length of the Eccentric-rods.—To find the Position of the Center of Saddle-pin.—To Find the Position of the Center of Lifting-shaft and the Length of its Arms.—Dimensions of Locomotives. | |

| CHAPTER XXI. | |

| The Stevens Valve-gear | 287 |

| Description of Motion.—Arrangement of the Motion.—Valve Movement.—Valve-stems and Stuffing-boxes.—How Movement of Valve is Governed.—How Exhaust Lead is Controlled. | |

| CHAPTER XXII. | |

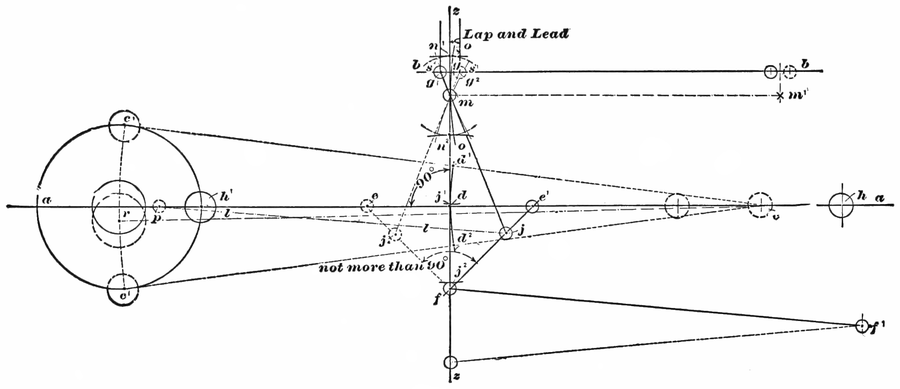

| The Joy Valve-gear | 292 |

| Description of Motion.—How to Apply this Gear to American Locomotives.—Construction Directions.—How Lap and Lead are Regulated.—Advantages claimed for the Motion.—Action of the Motion.—Rules for laying down the Center Lines of the Motion. | |

| CHAPTER XXIII. | |

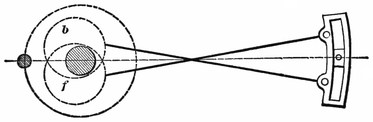

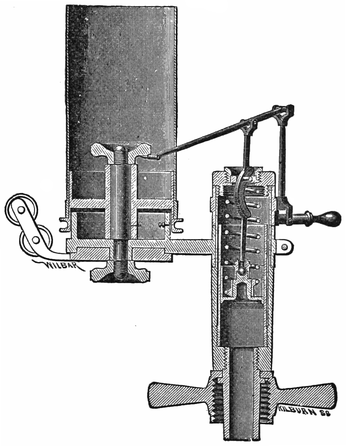

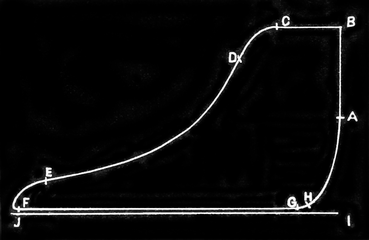

| The Steam Engine Indicator | 303 |

| Purpose of the Indicator.—Description of Instrument.—Operation of the Indicator.—Lines of the Diagram.—Data Necessary for Analyzing the Diagram.—Advantages of Indicating Locomotives. | |

| CHAPTER XXIV. | |

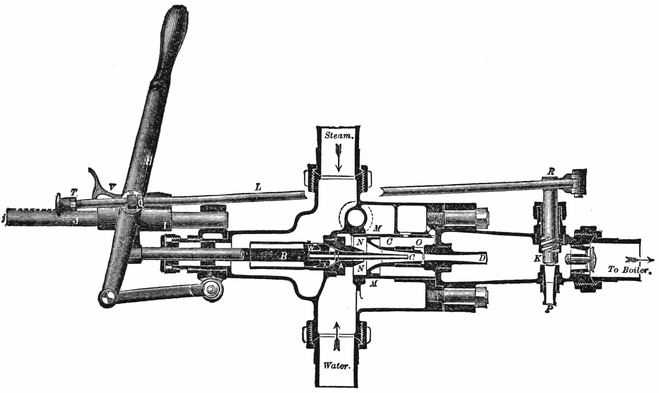

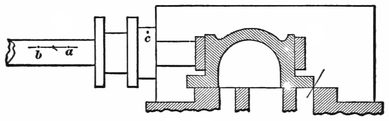

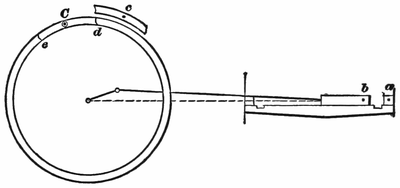

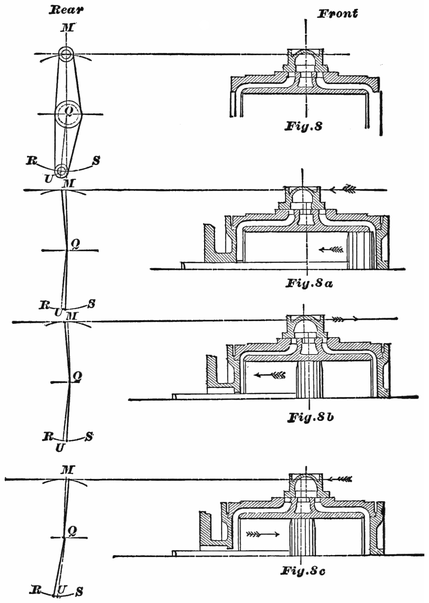

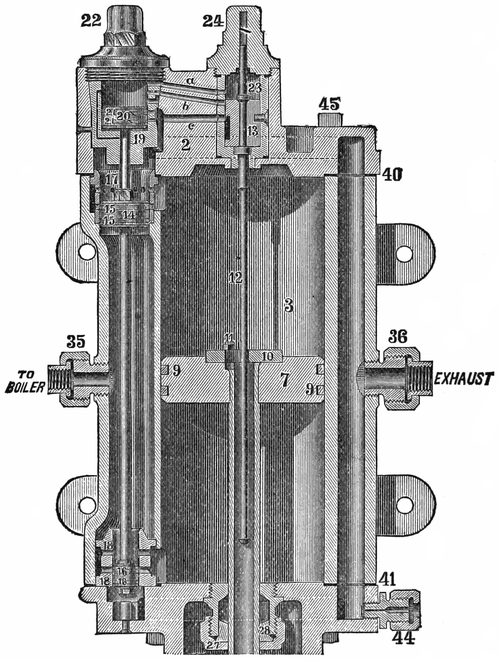

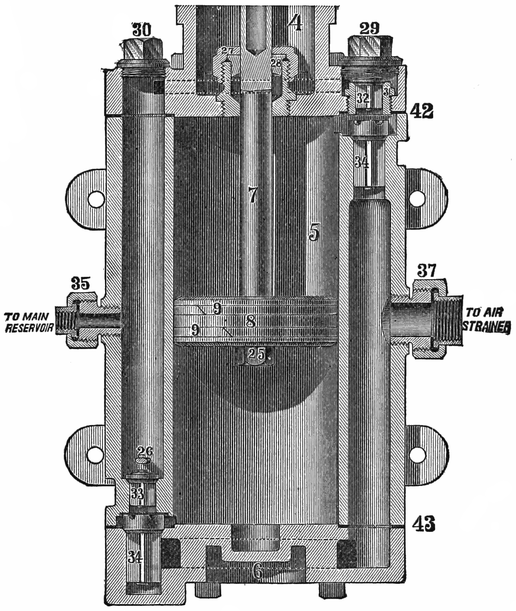

| The Westinghouse Air-brake | 309 |

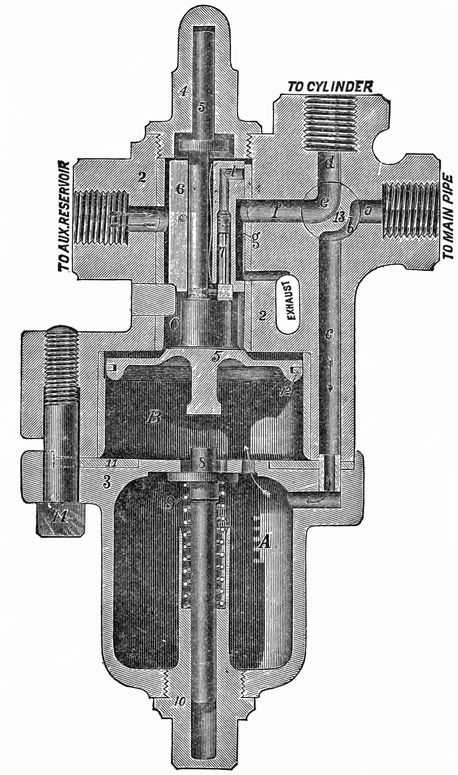

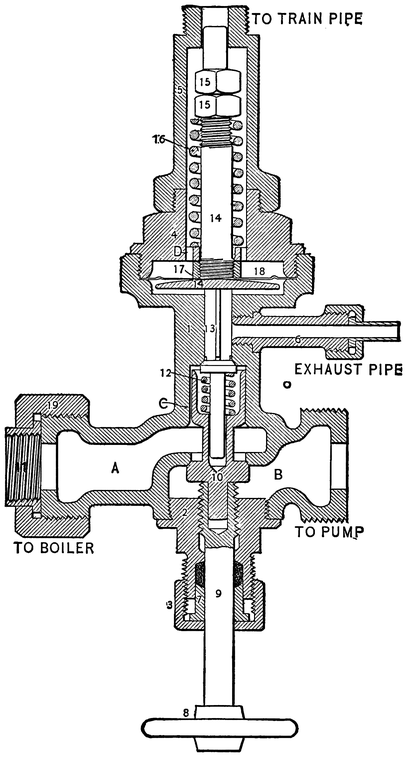

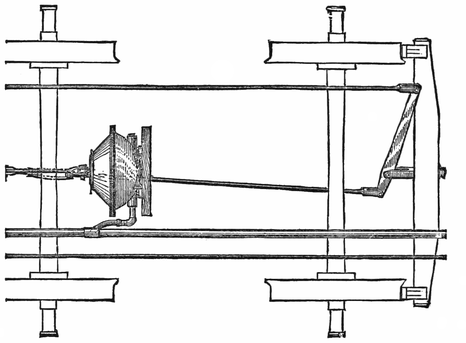

| Invention of the Westinghouse Atmospheric Brake.—Distinct Classes of Inventions.—Benefits conferred on Train Men byxvii Good Brakes.—First Trials of the Westinghouse Atmospheric Brake.—First Roads that Adopted the Westinghouse Brake.—Outlines of the Atmospheric Brake.—How Eastern Railroads kept aloof from the Westinghouse Brake.—Lesson of the Revere Railroad Accident.—Weak Points of the Atmospheric Brake.—The Westinghouse Automatic Air-brake.—Life-saving Value of the Automatic Brake.—First Railroads that adopted the Westinghouse Automatic Air-brake.—Essential Parts of the Westinghouse Automatic Air-brake.—The Air-pump.—How the Air-pump Works.—How the Air-end Operates.—Air-pump Disorders.—Puny Difficulties Vanquish the Ignorant Engineer.—Causes that make Brakes Inoperative often Easily Remedied.—Care of the Air-pump.—Pump Packing.—How Steam Passages get Choked.—Sagacity needed in Repairing Air-pumps.—Gradual Degeneration of the Air-pump.—Causes that make a Pump Pound.—The Triple Valve.—Action of the Triple Valve.—To prevent creeping on of Brakes.—How to Apply and Release the Brake. | |

| CHAPTER XXV. | |

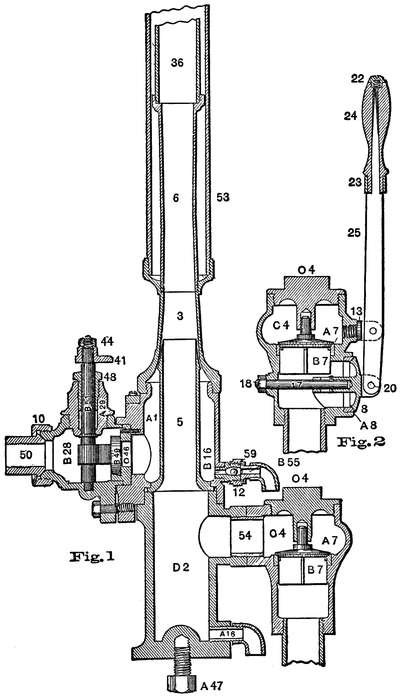

| The Eames Vacuum Brake | 341 |

| Efficiency of the Brake on the Elevated Railroads.—Operation of the Brake.—The Diaphragm.—The Ejector.—Care of the Brake. | |

| CHAPTER XXVI. | |

| Power of Locomotives and Train Resistances | 346 |

| Calculating Power of Locomotives.—Proportion of Adhesion to Traction.—Estimating Tractive Power.—Horse-power of Locomotives.—Formulas of Train Resistances.—Experiments of Train Resistances on the Erie Railway.—Conditions that Increase Train Resistances.—Resistance of Curves.—Work done by a Locomotive pulling a Train.—Record of Fast Express Train made by Professor P. H. Dudley’s Dynagraph Car.—Calculations of Weight of Trains that Locomotives can Pull. | |

| xviii | |

| CHAPTER XXVII. | |

| Water for Locomotive Boilers | 359 |

| How Water gets mixed with Lime.—Expense entailed by using Bad Water.—Efforts of Master Mechanics to secure Good Water.—Loss of Faith in Purifying Methods.—Scale-making Agencies.—To Ascertain the Quality of Water.—Appliances needed in Testing Water.—Preparing for the Experiments.—Lime held in Solution by Free Carbonic Acid.—Test for Lime Salts.—Test for Sulphate of Lime.—Test for Carbonate of Magnesia.—Test for Salts of Iron.—Test for Chlorine.—Learning the Manipulation of Tests.—Making Qualitative Tests.—The Soap-test for Hardness.—Modification of the Clark Soap-test.—Applying the Soap-test.—Difficulties of purifying Water for Locomotives.—Mud.—Carbonate of Lime. | |

| CHAPTER XXVIII. | |

| Examination for Locomotive Engineers | 376 |

| Principal Duties of an Engineer.—Carrying Water in Boiler.—Procedure when Short of Water.—Boiler-foaming.—Disconnecting the Engine.—Slipping an Eccentric.—Breaking a Valve-yoke.—Cylinder-packing Blowing.—Broken Rocker-arm.—Broken Link-hanger.—Broken Side Rods.—Throttle Disconnected.—Broken Tires. |

The locomotive engine which reaches nearest perfection, is one which performs the greatest amount of work at the least cost for fuel, lubricants, wear and tear of machinery, and of the track traversed: the nearest approach to perfection in an engineer, is the man who can work the engine so as to develop its best capabilities at the least cost. Poets are said to be born, not made. The same may be said of engineers. One man may have charge of an engine for only a few months, and yet exhibit thorough knowledge of his business, displaying sagacity resembling instinct concerning the treatment necessary to secure the best performance from his engine: another man, who appears equally intelligent in matters not pertaining to the locomotive, never develops a thorough understanding of the machine.

A man who possesses the natural gifts necessary for the making of a good engineer, will advance more rapidly in acquiring mastery of the business than does one2 whom Nature intended for a ditcher. But there is no royal road to the knowledge requisite for making a first-class engineer. The capability of handling an engine can be acquired by a few months’ practice. Opening the throttle, and moving the reverse lever, require but scanty skill; there is no great accomplishment in being able to pack a gland, or tighten up a loose nut; but the magazine of practical knowledge, which enables an engineer to meet every emergency with calmness and promptitude, is obtained only by years of experience on the footboard, and by assiduous observation while there.

Ever since the incipiency of the railroad system, a close interest has been manifested by the general public in the character and capabilities of locomotive engineers. This is natural, for no other class of men hold the safe-keeping of so much life and property in their hands.

Two leading pioneers of railway progress in Europe took diametrically opposite views of the intellectual qualities best calculated to make a good engineer. George Stephenson preferred intelligent men, well educated and read up in mechanical and physical science; Brunel recommended illiterate men for taking charge of engines, on the novel hypothesis, that, having nothing else in their heads, there would be abundant room for the acquirement of knowledge respecting their work. In every test of skill, the intelligent men proved victors.

No demand for illiterate or ignorant engineers has ever arisen in America. Many men who have spent an important portion of their lives on the footboard, have risen to grace the highest ranks of the mechanical and social world. The pioneer engines, which demonstrated the successful working of locomotive power, were run by some of the most accomplished mechanical engineers in the country. As an engine adapted to the work it has to perform, the American locomotive is recognized to have always kept ahead of its compeers in other parts of the world. No inconsiderable part of this superiority is due to the fact, that nearly all the master mechanics who control the designing of our locomotives have had experience in running them, and thereby understand exactly the qualities most needed for the work to be done.

The safe and punctual operation of our railroads has always depended to a great extent upon the discriminating care of the engineer. The present tendency of railroad operating is to increase his responsibility. Every advance in brake improvement increases the duties of the enginemen, and upon them will soon devolve the entire management and control of trains while in motion.

Writing on the fitness of various railroad employés for their duties, that eminent authority, Ex-Railroad-Commissioner Charles F. Adams, jun., says, “In discussing4 and comparing the appliances used in the practical operating of railroads in different countries, there is one element, however, which can never be left out of the account. The intelligence, quickness of perception, and capacity for taking care of themselves,—that combination of qualities, which, taken together, constitute individuality, and adaptability to circumstances,—vary greatly among the railroad employés of different countries. The American locomotive engineer, as he is called, is especially gifted in this way. He can be relied on to take care of himself and his train under circumstances which in other countries would be thought to insure disaster.”

While American locomotive engineers can confidently invite comparison between their own mechanical and intellectual attainments and those of their compeers in any nation under the sun, there still remains ample room for improvement. If they are not advancing, they are retrograding. The engineer who looks back to companions of a generation ago, and says that we know as much as they did, but no more, implies the assertion that his class is going backward. On very few roads, and in but rare instances, can this grave charge be made, that the engineers are falling behind in the intellectual race. On the contrary, there are signs all around us of substantial work in the cause of intellectual and moral advancement.

No class of railroad-men affects the expenses of operating so directly as engineers do. The daily wages5 paid to an engineer is a trifling sum compared to the amount he can save or waste by good or bad management of his engine. Fuel wasted, lubricants thrown away, supplies destroyed, and machinery abused, leading to extravagant running repairs, make up a long bill by the end of each month, where enginemen are incompetent. Every man with any spark of manliness in his breast will strive to become master of his work; and, stirred by this ambition, he will avoid wasting the material of his employer just as zealously as if the stores were his own property; and only such men deserve a position on the footboard.

The day has passed away when an engineer was regarded as perfectly competent so long as he could take his train over the road on time. Nowadays a man must get the train along on schedule time to be tolerated at all, and he is not considered a first-class engineer unless he possesses the knowledge which enables him to take the greatest amount of work out of the engine with the least possible expense. To accomplish such results, a thorough acquaintance with all details of the engine is essential, so that the entire machine may be operated as a harmonious unit, without jar or pound: the various methods of economizing heat must be intimately understood, and the laws which govern combustion should be well known so far as they apply to the management of the fire.

To obtain this knowledge, which gives power, and directly increases a man’s intrinsic value, young engineers and aspiring firemen must devote a portion6 of their leisure time to the form of self-improvement relating to the locomotive. Socrates, a sagacious old Greek philosopher, believed that the easiest way to obtain knowledge was by persistently asking questions. Young engineers can turn this system to good account. Never feel ashamed to ask for information where it is needed, and do not imagine that a man has reached the limit of mechanical knowledge when he knows how to open and shut the throttle-valve. The more a man progresses in studying out the philosophy of the locomotive and its economical operation, the more he gets convinced of his own limited knowledge. A young engineer who seeks for knowledge by questioning his elders must not feel discouraged at a rebuff. Men who refuse to answer civilly questions asked by juniors searching for information, are generally in the dark themselves, and attempt by rudeness to conceal their own ignorance.

The system in vogue in most of our States, especially in the West, of taking on men for firemen who have received no previous mechanical training, leaves a wide field open for engineering instruction. Such men can not spend too much time watching the operations going on in repair-shops; every detail of round-house work should be closely observed; the various parts of the great machine they are learning to manage should be studied in detail. No operation of repairs is too trifling to receive strict attention. Where the machinists are examining piston-packing, facing valves, reducing rod-brasses, or lining down wedges, the ambitious7 novice will, by close watching of the work, obtain knowledge of the most useful kind. Looking on will not teach him how to do the work, but interesting himself in the procedure is a long step in the direction of learning. Repairing of pumps and injectors is interesting work, full of instructive points which may prove invaluable on the road. The rough work performed by the men who change truck-wheels, put new brasses in oil-boxes, and replace broken springs, is worthy of close attention; for it is just such work that enginemen are most likely to be called upon to perform on the road in cases of accident. To obtain a thorough insight into the working of the locomotive, no detail of its construction is too trifling for attention. The unison of the aggregate machine depends upon the harmonious adjustment of the various parts; and, unless a man understands the connection of the details, he is never likely to become skillful in detecting derangements.

I knew a case where the neglect to learn how minor work about the engine was done, proved fatal to the prospects of a young engineer. A new engine-truck box had been adopted shortly before he went running; and, although he had often seen the cellar taken down by the round-house men when they were packing the trucks, he never paid close attention to how it was done. As the new plan was a radical change from the old practice, taking down the new cellar was a little puzzling at first to a man who did not know how to do it. One day this young engineer took out an engine with the new kind of truck, and a journal got running8 hot. He crept under the truck among snow and slush, to take the cellar down for packing; but he struggled half an hour over it, and could not get the thing down. Then the conductor came along, to see what was the matter; and, being posted on such work, he perceived that the young engineer did not know how to take the cellar out of the box. The conductor helped the engineer to do a job he should have needed no assistance with. The story was presently carried to headquarters with additions, and was the means of returning the young engineer to the left-hand side.

There is a silly prejudice in some quarters against engineers applying to books for information respecting their engines. Engineers are numerous who boast noisily that all their knowledge is derived from actual experience, and they despise theorists who study books, drawings, or models in acquiring particulars concerning the construction or operation of the locomotive parts. Such men have nothing to boast of. They never learn much, because ignorant egotism keeps them blind. They keep the ranks of the mere stopper and starter well filled.

The books on mechanical practice which these ultra practical men despise, contain in condensed form the experience and discoveries that have been gleaned from the hardest workers and thinkers of past ages. The product of long years of toilful experiment, where intense thought has furrowed expansive brows, and9 weary watching has whitened raven locks, is often recorded on a few pages. A mechanical fact which an experimenter has spent years in discovering and elucidating, can be learned and tested by a student in as many hours. The man who despises book-knowledge relating to any calling or profession, rejects the wisdom begotten of former recorded labor.

A careful perusal of Forney’s Catechism of the Locomotive will teach the young engineer valuable lessons about his engine which can be daily substantiated by practice. In nearly every instance, reading such a work acts as a stimulant to the perceptive faculties of an engineer. An explanation of a point helps to throw new light on something that was hazy, but now appears perfectly clear. An assertion made that a man does not agree with provokes thought, and thought leads to investigation. A writer may continually present matters at variance with the views of a reader, and yet be the means of imparting valuable knowledge. When an engineer wishes to gain a thorough knowledge of the valve-motion,—and most of us pride ourselves on what we know about this subject,—he may go in for a systematic study of Auchincloss on Link and Valve Motions. Here he will obtain information that can never be reached by mere practice with the actual motion; yet access to, and observation of, the working-motion, will engrave the principles upon his memory so that they can never be forgotten. Porter on the Indicator is a good source from whence accurate knowledge respecting the expansive working of steam can be obtained. Many other springs of knowledge flow clear and free. What is needed is the inclination to receive10 and the determination to obtain. When a man is searching honestly for information upon mechanical subjects, he will quickly find means of gratifying his desire.

Locomotive engine running is one of the most modern of trades, consequently its acquirement has not been controlled by the exact methods associated with ancient guild apprenticeships. Nevertheless, graduates to this business do not take charge of the iron horse without the full meed of experience and skill requisite for performing their duties successfully. The man who runs a locomotive engine on our crowded railroads has so much valuable property, directly and indirectly, under his care, so much of life and limb depending upon his skill and ability, that railroad companies are not likely to intrust the position to those with a suspicion of incompetency resting upon them.

The prevailing methods of raising locomotive engineers have been evolved from experience with the kind of men best adapted to fill the position. In the early days of the railroad world, when such men as George Stephenson, Horatio Allen, John B. Jervis, Ross Winans, and other pioneer engineers, demonstrated the successful operation of the locomotive, they usually turned12 over the care of their engines to the men who had assisted in constructing the machines, or in putting them together. This was the best that could be done at the time; and the men selected generally proved competent for the trust reposed in them; but it gave rise to a belief that no man could run a locomotive successfully unless he were a machinist. The possession of mechanical skill necessary for making repairs was considered the best recommendation for an engineer. Under this system, all that a machinist was required to do,—so that he could graduate as a full-fledged engineer,—was to practice moving engines round in the yard for a few days, when he was reported ready for the road. Akin to this sentiment was that which recommended youths of natural mechanical ability for the position of locomotive engineer without subjecting them to any previous special training. Graduates from mechanical institutes were deemed capable of running an engine as soon as they were perfectly certain about how to start and stop the machine. The late Alexander L. Holley used to relate an anecdote of this kind of an engineer. During a severe winter storm, the train Holley was traveling on got firmly stalled in a snow-bank. In its struggles with the frozen elements, the engine got short of water; and Holley found the engineer trying to fill the boiler by shoveling snow down the smoke-stack!

But it came to pass that more light in the matter of engine-running dawned upon the minds of railroad managers. They discovered that expertness in effecting13 repairs on locomotives was not so essential in an engineer as was the less pretentious ability of working the engine so that the train would be pulled over the road safely and on time: they perceived but scanty merit in inherited mechanical genius which did not inspire a youth with sagacity enough to see that certain destruction would befall the heating-surface when he attempted to run without water in the boiler. Experience demonstrated, that, to manage an engine on the road so that its best work should be developed at the least cost, certain traits of skill and training were necessary, which were altogether different from the culture that made a man smart at constructing or repairing machinery. It was found that one man might be a good machinist, and yet make no kind of a decent runner; a second man would be equally expert in both capacities; while a third man, who never could do a respectable job with tools, developed into an excellent engineer. One of the best millwrights I ever knew, a man who achieved considerable celebrity for skill in his craft, became a fireman with the ambition of becoming a locomotive runner. He fired acceptably for two years, then was promoted, but quickly found that he could not run an engine, and acknowledged that to be the case by returning to the left side. He was too nervous, and lacked confidence in himself. Overweening egotism is not an attractive feature in a man’s character; but, every thing else being equal, it is the self-confident man that makes the successful engineer.

The experiment of raising locomotive engineers from machinists and mechanical empirics was the uncertain groping in the dark for the right man to fill the right place. When the search for pretentious men proved unsatisfactory, the right men were found at hand, accumulating the necessary experience on the fireman’s side of the engine. Then it became a recognized fact, that, to take hold and run an engine to advantage, a man must learn the business by working as fireman. There have been frequent cases of men becoming successful locomotive engineers without any previous training as firemen, but they were the exceptions that proved the rule.

In the matter of speed alone, there is much to learn before a man can safely run a locomotive. During daylight a novice will generally be half out in estimating speed; and his judgment is merely wild guess-work, regulated more by the condition of the track than by the velocity his train is reaching. On a smooth piece of track, he thinks he is making twenty-five miles an hour, when forty miles is about the correct speed: then he strikes a rough portion of the road-bed, and concludes he is tearing along at thirty miles an hour, when he is scarcely reaching twenty miles; since the first lurchy spot made him shut off twenty per cent of the steam. At night the case is much worse, especially when the weather proves unfavorable. On a wild, stormy night, the accumulated experience of years on15 the footboard, which trains a man to judge of speed by sound of the revolving-wheels, and to locate his position between stations from a tree, a shrub, a protruding bank, or any other trifling object that would pass unnoticed by a less cultivated eye, is all needed to aid an engineer in working along with unvaried speed without jolt or tumult. On such a night, a man strange to the business can not work a locomotive, and exercise proper control over its movements. He may place the reverse lever-latch in a certain notch, and keep the steam on; he can regulate the pump after a fashion, and watch that the water shall not get too low in the boiler; he can shut off in good season while approaching stations, and blunder into each depot by repeatedly applying steam; but he exerts no control over the train, knows nothing of what the engine is doing, and is constantly liable to break the train in two. A diagram of his speed would fluctuate as irregularly as the profile lines of a bluffy country. This is where a machinist’s skill does not apply to locomotive-running until it is supplemented by an intimate knowledge of speed, of facility at handling a train, and keeping the couplings intact, and of insight into the best methods of economizing steam.

These are essentials which every man should possess before he is put in charge of a locomotive on the road. The great fund of practical knowledge which stamps the first-class engineer, is amassed by general labor during years of vigilant observation on the footboard, amidst many changes of fair and foul weather.

As passing through the occupation of fireman was the only way men could obtain practical knowledge of engine-running before taking charge, railroad officials16 all over the world gradually fell into the way of regarding that as the proper channel for men to traverse before reaching the right-hand side of the locomotive.

As the pay for firemen rules moderately good, even when compared with other skilled labor; and as the higher position of engineer looms like a beacon not far ahead,—there is always a liberal choice of good men to begin work as firemen. Most railroad companies recognize the importance of exercising judgment and discretion in selecting the men who are to run as their future engineers. Sobriety, industry, and intelligence are essential attributes in a fireman who is going to prove a success in his calling. Lack in any one of these qualities will quickly prove fatal to a fireman’s prospects of advancement. Sobriety is of the first importance, because a man who is not strictly temperate should not be tolerated for a moment about a locomotive, since he is a source of danger to himself and others; industry is needed to lighten the burden of a fireman’s duties, for oftentimes they are arduous beyond the conception of strangers; and wanting in the third quality, intelligence, a man can never be a good fireman in the wide sense of the word, since one deficient in mental tact never rises higher than a human machine. An intelligent fireman may be ignorant of the scientific nomenclature relating to combustion, but he will be perfectly familiar with all the practical phenomena connected with the economical generation of steam. Such a man does not imagine that he has reached the limit of locomotive knowledge when he understands how17 to keep an engine hot, and can shine up the jacket. Every trip reveals something new about his art, every day opens his vision to strange facts about the wonderful machine he is learning to manage. And so, week by week, he goes on his way, attending cheerfully to his duties, and accumulating the knowledge that will eventually make him a first-class locomotive engineer.

On the various roads throughout the North American continent, there is great diversity of practice in the selection of men for the position of fireman.

On numerous roads, especially in the Western States, men are taken from all occupations; no preliminary training being deemed necessary before putting a man on an engine as fireman. A list of applicants is kept by the master mechanic, and likely men recommended for firemen. When a man is wanted, the first one who can be found conveniently is sent out; and the engineer must break him in as best he can. On other roads, again, the men intended for firemen are taken to work about the round-house, and are employed in helping with the cleaning, repairing, and preparing of locomotives for the road. This plan is greatly in vogue in Europe, and on certain of the older roads of America; and it has many features to recommend it over the practice of placing men entirely devoid of railroad experience upon engines. It is better for the men themselves, since working about engines familiarizes each to some extent with the work he is expected to do as an engineer’s helper, for that is really a fireman’s position; it is better for the company, since the18 officers get the opportunity of observing a man’s habits before he receives training that entails some expense; it is better for the engineer, since his assistant is not entirely strange to the work he is expected to do.

A youth entirely unacquainted with all the operations which a fireman is called upon to perform, finds the first trip a terribly arduous ordeal, even with some previous experience of railroad work. When his first trip introduces him to the locomotive and to railroad life at the same time, the day is certain to be a record of personal tribulation. To ride for ten or twelve hours on an engine for the first time, standing on one’s feet, and subject to the shaking motion, is intensely tiresome, even if a man has no work to do. But when he has to ride during that period, and in addition has to shovel six or eight tons of coal, most of which has to be handled twice, the job proves no sinecure. Then, the posture of his body while doing work is new; he is expected and required to pitch coal upon certain exact spots, through a small door, while the engine is swinging about so that he can scarcely keep his feet; his hands get blistered with the shovel, and his eyes grow dazzled from the resplendent light of the fire. Then come the additional side duties of taking water, shaking the grates, cleaning the ash-pan, or even the fire, where bad coal is used, filling oil-cans, and trimming lamps, to say nothing of polishing and keeping things clean and tidy. By the time all these duties are attended to, the young fireman does not find a great deal of leisure to admire the passing scenery.

A great many idle young fellows, ignorant of railroad affairs, imagine that a fireman’s principal work consists in ringing the bell, and showing himself off conspicuously in coming into stations. They look upon the business as being of the heroic kind, and strive to get taken on as firemen. If a youth of this kind happens to succeed, and starts out on a run of one hundred and fifty miles with every car a heavy engine will pull stuck on behind, his visions of having reached something easy are quickly dispelled.

Like nearly every other occupation, that of fireman has its drawbacks to counterbalance its advantages; and the drawbacks weigh heaviest during the first ten days. The man who enters the business under the delusion that he can lead a life of semi-idleness must change his views, or he will prove a failure. The man who becomes a fireman with a spirit ready and willing to overcome all difficulties, with a cheerful determination to do his duty with all his might, is certain of success; and to such a man the work becomes easy after a few weeks’ practice.

Practice, combined with intelligent observation, gradually makes a man familiar with the best styles of firing, as adapted to all varieties of engines; and he gets to understand intimately all the qualities of coal to be met with, good, bad, and indifferent. As his experience widens, his fire management is regulated to accord with the kind of coal on hand, the steaming properties of the engine, the weight of the train, the20 character of the road and of the weather. Firing, with all the details connected with it, is the central figure of his work, the object of pre-eminent concern; but a good man does not allow this to prevent him from attending regularly and exactly to his remaining routine duties.

There is a familiar adage among railroad men, that a good fireman is certain to make a good engineer; and it rarely fails to come out true. To hear some firemen of three months’ standing talk, a stranger might conclude that they knew more about engine running than the oldest engineer in the district. These are not the good firemen. Good firemen learn their own business with the humility born of earnestness, and they do not undertake to instruct others in matters beyond their own knowledge. It is the man who goes into the heart of a subject, who understands how much there is to learn, and is therefore modest in parading his own acquirements, that succeeds.

When a fireman has mastered his duties sufficiently to keep them going smoothly, he begins to find time for watching the operations of the engineer. He notes how the boiler is fed; and, upon his knowledge of the engineer’s practice in this respect, much of his firing is regulated. The different methods of using the steam by engineers, so that trains can be taken over the road with the least expenditure of coal, are engraven upon the memory of the observant fireman. Many of the21 acquirements which commend a good fireman for promotion are learned by imperceptible degrees,—the knowledge of speed, for instance, which enables a man to tell how fast a train is running on all kinds of track, and under all conditions of weather. There would be no use in one strange to train service going out for a few runs to learn speed. He might learn nearly all other requisites of engine running before he was able to judge within ten miles of how fast the train was going under adverse circumstances. The same may be said of the sound which indicates how an engine is working. It requires an experienced ear to detect the false note which indicates that something is wrong. Amidst the mingled sounds produced by an engine and train hammering over a steel track, the novice hears nothing but a medley of confused noises, strange and meaningless as are the harmonies of an opera to an untutored savage. But the trained ear of an engineer can distinguish a strange sound amidst all the tumult of thundering exhaust, screaming steam, and clashing steel, as readily as an accomplished musician can detect a false note in a many-voiced chorus. Upon this ability to detect growing defects which pave the way to disaster, depends much of an engineer’s chances of success in his calling. This kind of skill is not obtained by a few weeks’ industry: it is the gradual accumulation of months and years of patient labor.

I once knew a machine-shop foreman, a man of extensive experience in building and repairing engines,22 who took a locomotive out on trial trip. A side-rod pin began to run hot; and, although he was leaning out of the cab-window, he did not observe any thing wrong till a drop of babbitt struck him in the eye. An experienced engineer watching the rods would have detected the condition of affairs before babbitt was thrown.

A difficult thing for an inexperienced man to control in running a locomotive at night, when the conditions of adhesion are bad, is the slipping of the drivers. Slipping is a simple matter enough to those who feel it in the vibrations of the engine; but the novice has not this sensitiveness to slipping vibration developed, and he must depend upon his eyesight or his hearing to detect it. On a dark, stormy night, the eye is useless as a means of judging as to the regularity of the revolving wheels: the howling wind or rain, rattling on the cab, drowns the sound of the exhaust. Under circumstances of this kind, an engine might jerk the pins out before the empirical engineer discovered the wheels were slipping.

As his acquaintance with the handling and ordinary working of the locomotive extends, the aspiring fireman learns all about the packing of glands, and how they should be kept so as to run to the best advantage: he displays an active interest in every thing relating to lubrication, from the packing of a box-cellar to the regulating of a rod-cup. When the engineer is round keying up rods, or doing other necessary work about his engine, the ambitious fireman should give a helping hand, and thereby become familiar with the operations23 that are likely to be of service when he is required to draw upon his own resources for doing the same work.

Of late years the art of locomotive construction has been so highly developed, the amount of strain and shocks to which each working part is subjected has been so well calculated and provided against, that breakages are really very rare on roads where the motive-power is kept in first-class condition. Consequently, firemen gain comparatively small insight, on the road, into the best and quickest methods of disconnecting engines, or of fixing up mishaps promptly, so that a train may not be delayed longer than is absolutely necessary. A fireman must get this information beyond the daily routine of his experience. He must search for the knowledge among those competent to give it. Persistent inquiry among the men posted on these matters; observation amidst machine-shop and round-house operations; and careful study of locomotive construction, so that a clear insight into the physiology of the machine may be obtained,—will prepare one to meet accidents, armed with the knowledge which vanquishes all difficulties. Reflecting on probable or possible mishaps, and calculating what is best to be done under all contingencies that can be conceived, prepare a man to act promptly when a breakdown occurs.

In the method of promotion of firemen, considerable diversity of practice is followed by the different railroads. On certain roads, with well-established business, and little fluctuation of traffic, firemen begin work on switch engines, and are promoted by seniority, or by24 selection through the various grades of freight trains, thence to passenger service, from whence they emerge as incipient engineers. A more common practice, and one almost invariably followed in the West, is for firemen to begin as extra men, in place of firemen who are sick or lying off. From firing extra, they get advanced, if found competent and deserving, to regular engines. Then, step by step, they go ahead to the best paying runs, till their turn for being “set up” comes round. Passenger engines are not fired by any but experienced men, but the oldest firemen do not always claim passenger-runs. For learning the business of engine-running, freight service is considered most valuable; and many ambitious firemen prefer the hard work of a freight engine on this account.

When a fireman has obtained the experience that recommends him for promotion, on nearly all well-regulated roads he is subjected to some form of examination before being put in charge of an engine. In some cases this examination is quite thorough. The tendency to require firemen to pass such an ordeal is extending, and its beneficial effect upon the men is unquestioned. The usual form of examination is, for officers connected with the locomotive department to question the candidate for promotion on matters relating to the management of the locomotive, and how he would proceed in the event of certain mishaps befalling the engine. Parties belonging to the traffic department propound questions relating to road-rules, train-rights, understanding of time-card, and so on.

The Master Mechanics’ Association appointed a committee to investigate the “best manner of educating young men for locomotive engineers,” and the following report was made:—

“Considering this subject to be of vital importance to the Association, and to the public in general, and that proper care and attention have not been given to it in the past, the committee have spared no pains to get all the information they possibly could on this subject, knowing and feeling that men selected to fill the responsible position of locomotive engineers must possess faculties, that, as a general thing, do not belong to all the human race; and, as locomotive engineers have to be selected from the ranks of firemen, they feel that due care and caution should be exercised in selecting young men for firemen. Now, to arrive at a proper conclusion,—one that would be satisfactory to the Association and to the railways of the country,—your committee sent circulars to all the master mechanics in the United States, Canada, and Mexico. We sent out five hundred and thirty-two circulars, to which we received seventy-six replies; being an average of one answer to every seven sent. Many of these replies contain very valuable information, and were from many of the leading roads of this country, Canada, and Mexico. Your committee beg leave to return thanks for the answers to their circular.

“The opinions given us by the different master mechanics who replied, were as follows: Five recommended that none but machinists should be locomotive26 engineers; nineteen thought that nothing more was needed than to have a young man fire from three to four years with good, competent engineers, to make him a good runner; fifty-two thought that one year in the shop and round-house, with two to three years’ firing, was necessary to make a competent engineer; many recommended that young men, while firing, read and study books that would give them a general knowledge of the locomotive, such as Forney’s Catechism of the Locomotive, and several other works of that kind. Many of the replies admitted that machinists would make the best runners if they would consent to fire one year after having learned their trade, as they would then have the advantage of knowing all about the construction of the locomotive. Of course, when speaking of that class of men, they meant bright, intelligent young machinists, men with nerve and energy, and quick to act in cases of emergency. Of course, there are some who would never make engineers, no matter what opportunities were given them. If young men of this kind would consent to run one year or more as firemen, we could select our locomotive engineers from among that class; but they will not do it, from the belief that they are just as competent to run a locomotive as the best engineer on the road for which they are working: and, if they are given an opportunity to run an engine, they are certain to make a failure. This being the fact, we are compelled to select our engineers from among the ranks of the firemen, as the best and safest runners. Now, this being the class of men from which we have to select our engineers, some uniform mode of instructing them for the responsible position that many of them27 will have to fill in the future, will have to be adopted by the different railroads in America. Your committee would therefore recommend the following:—

“All master mechanics should have full control of the engineers and firemen in the employ of their respective roads, with full power to hire and discharge the same,—of course, recognizing the rights that the general managers or superintendents have to order the discharge of any engineer or fireman for neglect of duty.

“1st, The qualifications for the position of fireman on all the railways in America should be as follows: The applicant should be from eighteen to twenty-four years old, able-bodied, and in good health, with a good common-school education, and a fair knowledge of arithmetic, and of sober and steady habits. All applicants should be required to make application in their own handwriting, signing it in the presence of the master mechanic, or the person he may appoint to hire that class of men. In selecting men for firemen, great care should be exercised. The master mechanic should endeavor, so far as lies in his power, to select energetic, smart, and active young men,—men of nerve, and presence of mind, quick to act in cases of emergency which may occur in the position they may be selected to fill in the future. If we select men of that kind, there will be very little difficulty in educating them up to the proper standard to fill the place of engineers.

“2d, There should be three grades of firemen, classed as junior, intermediate, and senior firemen,—the young man just commencing, to be classed as junior fireman, and so on up to senior fireman; the senior fireman receiving the highest pay for his services, the others in28 proportion. When a fireman has fired four years, and is worthy of promotion, and fully competent to run a locomotive, there may be no vacancies in the engineer force on the road by which he may be employed. In that case we recommend that he receive a small amount more per day than the senior fireman (say from fifteen to twenty cents per day more), and be ranked as veteran fireman. On the road which one of your committee represents in this convention, this custom has been in vogue for a number of years, and has worked exceedingly well. All the engineers on this road have been educated under this rule, and to-day no engineers in the country rank higher than they do.

“Proper care should be taken, in selecting young men for firemen, as to their ability to distinguish colors in a practicable, common-sense way. We recommend that all railroads having a sufficient number of employés to justify them in so doing, have a reading-room and library for their firemen and engineers, in which the other employés could participate. The library, to some extent, should consist of works on the locomotive engine that a man with a fair education could understand. While we do not think it essentially necessary, still we believe it would be beneficial to some extent to let firemen work one year out of the four in the shop and round-house, so that they might obtain a more perfect knowledge of all the parts of the locomotive.

“Young men consisting of the class we have mentioned, are certain to make good runners; and there will be no difficulty, at the proper time, in selecting good junior engineers from among that class of men. All opportunities possible should be given firemen to get such knowledge29 of the theory and movements of the different parts of the locomotive as would be beneficial to them when they enter on their career as engineers. To accomplish this end, monthly lectures might be given in the reading-room by men of good practical common sense, who fully understand what they are talking about. If possible, these lectures should be given by one of the engineers. The firemen would learn more from him, as they would better understand what he was saying; he having formerly been one of them.

“Your committee is convinced, that, if the mode recommended by them is adopted generally throughout the country, a large majority, if not all, of the firemen, would be educated to a point from which there would be no difficulty in selecting men who will make good and reliable engineers.

“3d, The fireman now being competent to run a locomotive, and being placed in charge of one, has yet some few things to learn that he did not have the opportunity of learning, from the fact that he was not running the engine. While he may run carefully, and avoid accidents, he has to learn to run his engine with economy in the consumption of fuel and the cost of repairs. To learn this, and to give the young engineer an opportunity to become a first-class man in his occupation, we recommend there be three grades of engineers,—first, second, and third grades,—and that the remuneration they receive be according to grade; the fireman just promoted ranking in the third grade; after one year’s service he enters the second grade; when two years have passed, he enters the first grade, and becomes a first-class locomotive engineer.”

On railroads where the system of “long runs” for locomotives prevails, there is a locomotive inspector employed, whose duty it is to thoroughly examine every available point about every engine that arrives at his station, and find out what repairs are needed, and to detect the incipient defects which lead to disaster on the road. Some roads that do not practice long runs have an inspector who examines every engine. This plan is very effectually used on the elevated railroads of New York, and has much to do with the immunity from accident of their engines. These inspectors are not employed to exempt engineers from looking over their engines, but merely to supplement their care. In some cases engineers are brought sharply to task if they overlook any important defect which is discovered by the inspector.

The engineer who has a liking for his work, and takes pride in making his engine perform its part, so as to show the highest possible record, does not require the fear of an inspector behind him as an incentive to properly examine his engine, and keep it in the best31 running-order. He recognizes the fact, that upon systematic and regular inspection of the engine while at rest, depends in a great measure his success as a runner, and his exemption from trouble.

The man who habitually neglects the business of inspecting his engine, and leaves to luck his chances of getting over the road safely, soon finds that the worst kind of luck is always overtaking him on the road. A careful man may have a run of bad luck occasionally, but the careless man meets with nothing else. Among a great many men who have failed as runners, I can recall numerous cases where carelessness about the engine was the only and direct cause which led them to failure. One of the most successful engineers that ever pulled a throttle on the Erie Railroad was asked by a young runner to what cause he attributed his extraordinary good fortune. His reply was, “I never went out without giving my engine a good inspection.” This man had been running nearly half a century, and never needed to have his engine hauled to the round-house.

When a locomotive is thundering over a road ahead of a heavy train in which may be hundreds of human beings, the engineer ought to understand that the safety of this freight of lives depends to a great extent upon his care and foresight. As the train rushes through darkened cuttings, spans giddy bridges, or32 rounds curves edged by deep chasms, no one can understand better than the engineer the importance of having every nut and bolt about the engine in good condition, and in its proper place. The consciousness that every thing is right, the knowledge that a thorough inspection at the beginning of the journey proved the locomotive to be in perfect condition, give a wonderful degree of comfort and confidence to the engineer as he urges his train along at the best speed of the engine.

Between the time of an engine’s return from one trip and its preparation for another, a thorough examination of all the machinery and running-gear should be made while the engine is standing over a pit. Monkey-wrench in one hand, and a torch in the other if necessary, the engineer ought to enter the pit at the head of the engine, and make the inspection systematically. The engine-truck, with all its connections, comes in for the first scrutiny. Now is the time to guard against the loss of bolts or screws, which leads to the loss of oil-box cellars on the road. This is also the proper time to examine the condition of the oil-box packing. The engineers of my acquaintance who are most successful in getting trains over the road on time, attend to the packing of the truck-boxes themselves. Nothing is more annoying on the road than hot boxes. They are a fruitful source of delay and danger, and nothing is better calculated to prevent such troubles than good packing and clear oil-holes. The shop-men who are kept for attending to this work are sometimes careless. They can hardly be expected to feel so33 strongly impressed with the importance of having boxes well packed as the engineer, who will be blamed for any delay. He should, therefore, know from personal inspection that the work is properly done.

When the engineer is satisfied that the truck, pilot-braces, center-castings, and all their connections, are in proper condition, he passes on to the motion. His trained eye scans every bolt, nut, and key in search of defects. The eccentrics are examined, to see that set screws and keys are all tight. Men who have wrestled over the setting of eccentrics on the road are not likely to forget this part. Eccentric-straps are another point of solicitude. A broken eccentric-strap is a very common cause of break-down, and these straps very seldom break through weakness or defect of the casting. In nearly all cases the break occurs through loss of bolts, or on account of oil-passages getting stopped up. The links are carefully gone over, then the wedges and pedestal braces come in for an examination which brings the assurance that no bolts are missing, or wedge-bolts loose. Passing along, the careful engineer finds many points that claim his attention; and, when he gets through, he feels comfortably certain that no trouble from that part of the engine will be experienced during the coming trip. The runners who do not follow this practice are not aware of how much there is to be seen under a locomotive when the examination is undertaken in a comprehensive manner.

In going round the outside of the engine, the most important points for examination are the guides and34 the rods. Guide-bolts, rod-bolts, and keys, with the set screws of the latter, are the minutiæ most likely to give trouble if neglected. In going about the engine oiling, or for any other purpose, it is a good thing to get in the habit of searching for defects. When a man trains himself to do this, it is surprising how natural it comes to make running inspections. As he oils the eccentric-straps, he sees every bolt and nut within sight; as he drops some oil on the rods, he identifies the condition of the keys, set screws, or bolts; while oiling the driving-boxes, the springs can be conveniently examined; and, when he reaches the engine-trucks with the oil-can, he is sure to be casting his searching eyes over the portions of the running-gear within sight.

The oil-cups should be carefully examined, to see that they are in good feeding-order. A great many feeders have been invented, which guarantee to supply oil automatically; but I have never yet seen the cup which could long dispense with personal attention. And this does not apply to locomotives alone, but to all kinds of machinery. The worst sort of oil-cup will perform its functions fairly in the hands of a capable man, and the most pretentious cup will soon cease to lubricate regularly if the engineer neglects it. The oil-cups should be cleaned out at regular intervals: for mud, cinders, and dust work in; and they sometimes retain glutinous matter from the oil, which forms a sticky mixture that prevents the oil from running. The eccentric-strap cups and the tops of the driving-boxes should receive similar attention.

In looking round an engine, it is a good plan to watch35 the different oil-cups to see that they are not working loose. Many cups that are strewed over the country could be saved by a little more attention. A cup flying off a rod when an engine is running fast becomes a dangerous projectile. I have known several cases where cups went back through the cab-window. I have also seen several cases where cups worked off the guides or cross-head, and got between the guides, doing serious damage. One instance was that of an engine out on the trial-trip. It smashed the cross-head to pieces, and let the piston through the cylinder-head.

A sharp tap with a hammer on the tread of the cast-iron wheel will produce a clear, ringing sound if the wheel is in good order. The drivers can generally be effectively inspected by the eye. If oil be observed working out between the wheel and axle, attention is demanded; for the wheel may be getting loose. Moisture and dirt issuing from between the tire and wheel indicate that the former is becoming loose, and this is a common occurrence when the tires are worn thin. When a wheel is running so that the flange is cutting itself on the rail, something is wrong, which also demands immediate attention. Oblique travel of wheels may be produced by various causes. If the axles of the driving-wheels are not secured at right angles to the frames, and parallel with each other, the wheels will run tangentially to the track, according to the inclination of the axles. Violent strains or concussions, such as36 result from engines jumping the track about switches, sometimes spring the frames, and twist the axle-box jaws away from their true position enough to cause cutting of flanges without disabling the engine. Tires wearing unevenly in consequence of one being harder than the other, produce a similar effect. Where there are movable wedges forward and aft of the boxes, the wheels are often thrown out of square by unskillful manipulation of these wedges. Engineers running engines of this kind should leave the forward wedges alone. Sometimes the center-pin of the engine-truck gets moved from the true central position, leading the drivers towards the ditch. Diagnosing the cause of wheel-cutting is no simple matter, and it is a wise plan for engineers to allow the shop-men to devise a remedy.

On our well-regulated roads, engineers are not required to inspect their boilers; as expert boiler-makers, who can readily detect a broken stay-bolt, or broken brace, have to make periodical examinations. But a prudent engineer will keep a sharp lookout for indications that show weak points about any part of the boiler or fire-box. This department can not receive too much vigilance. A seam or stay-bolt leaking is a sign of distress, and should receive immediate attention. Leaks under the jacket should never be neglected, although they are hard to reach; for they may proceed from the beginning of a dangerous rupture. A leak starting in the boiler-head should make the engineer ascertain that none of the longitudinal braces have broken. I once had some rivet-heads on my boiler-head37 start leaking, and presently the water-glass broke. After shutting off the cocks, I found that the boiler-head was bulged out. I reduced the pressure on the boiler as quickly as possible. When the boiler was inspected, it was found that two of the longitudinal braces were broken, and the head-sheet was bent out two inches.

If an engineer is going to take out an engine the first time after it has been in the shop for repairs, it is a good plan to examine the tank to see if the workmen have left it free from bagging, greasy waste, and other impediments, which are not conducive to the free action of pumps or injectors. Keeping the tank clean at all times saves no end of trouble through derangement to feeding-apparatus. The smoke-box door should be opened regularly, and the petticoat-pipe and cone examined. These things wear out by use, and it is better to have them renewed or repaired before they break down on the road. A cone dropping down through failure of the braces makes a troublesome accident on the road. I have known of several cabs being badly damaged by fire through the cone dropping down, and closing up the stack. Where engines have extended smoke-boxes, the nettings and deflectors must be inspected at frequent intervals.

To go over an engine in the manner indicated, requires perseverance and industry. The work will, however, bring its full reward to every man who practices38 the care and watchfulness entailed by regular and systematic inspection. It is the sure road to success. He who regards his work from a higher plane than that of mere labor well done, will experience satisfaction from the knowledge, that, understanding the nobility of his duties, he performed them with the vigor and intelligence worthy of his responsible calling.

It used to be the universal custom, that, when an engine arrived from a trip, the fire was drawn, and the engine put into the round-house for ten or twelve hours before another run was undertaken. During this period of inaction, the boiler partly cooled down. When the engine was wanted again, a new fire was started in time to raise steam. The system of long runs, introduced on many roads, has changed this; and engines are now generally kept hot, unless they have to be cooled down for washing out, or repairs. When an engine comes in off a trip, the fire is cleaned from clinker and dead cinders, and the clean fire banked. It is found that this plan keeps the temperature of the boiler more uniform than is possible with the cooling-down practice, and that the fire-box sheets are not so liable to crack, or the tubes to become leaky.

Where it is still the habit to draw the fire at the end of each trip, a supply of good wood is kept on hand for raising steam. To raise steam from a cold boiler, some theorists recommend the starting of a fire mild enough to raise the temperature about twenty degrees an hour. The exigencies of railroad service prevent this slow40 method from being practicable, and the ordinary practice is to raise steam as promptly as possible when it is wanted.

The first consideration before starting a fire in a locomotive, is to ascertain that the boiler contains the proper quantity of water. The men who attend to the starting of fires should be instructed not to depend upon the water-glass for the level of the water, but to see that it runs out of the gauge-cocks. I have known several cases where boilers were burned through those firing up being deceived by a false show of water in the glass, and starting the fire when the boiler was empty. If the boiler has been filled with water through the feed-pipes by the round-house hose, care should be taken to see that the check-valves are not stuck up. Where there is sand in the water, it frequently happens, that, in filling up with a hose, all the valves get sanded, and do not close properly. When there is steam on the boiler, this source of danger will generally be indicated at once by the steam and water blowing back into the tank; but, where the boiler is cold, the water flows back so silently and slowly, that the crown-sheet may be dry before the peril is discovered.

The water being found or made right, the next consideration is the grates. Before throwing in the wood, all loose clinkers left upon the grates should be cleaned off: care should be taken, to see that the grates are in good condition, and connected with the shaker levers.41 This is also the time to see that no accumulation of cinders is left on the brick arch, the water-table, or in the combustion chamber, should the engine be provided with either of these appliances. In starting the fire, it is considered the best plan to put enough wood in the fire-box to raise sufficient steam to operate the blower before the fire needs replenishing. To do the job in a clean, workman-like manner, the fire should be started from below: otherwise every part of the cab will be veneered with soot and dust, and the bright work tarnished.