UNITED STATES DEPARTMENT OF AGRICULTURE

BULLETIN No. 404

Contribution from the Bureau of

Plant Industry

WM. A. TAYLOR, Chief

Title: Hemp Hurds as Paper-Making Material

Author: Lyster H. Dewey

Jason L. Merrill

Release date: February 25, 2006 [eBook #17855]

Language: English

Credits: Produced by K.D. Thornton and the Online Distributed

Proofreading Team at http://www.pgdp.net

PROFESSIONAL PAPER

By Lyster H. Dewey, Botanist in Charge of Fiber-Plant Investigations, and Jason L. Merrill, Paper-Plant Chemist, Paper-Plant Investigations.

| Page | Page | ||

| The production and handling of hemp hurds. | The manufacture of paper from hemp hurds. | ||

| by Lyster H. Dewey: | by Jason L. Merrill: | ||

| What hemp hurds are | 1 | Introduction | 7 |

| Pith, wood, and fiber | 2 | Factors justifying an investigation of hemp hurds | 8 |

| Character of hurds affected by retting | 2 | Character of the material | 11 |

| Proportion of hurds to fiber and yield per acre | 3 | Character of the tests | 12 |

| Hurds available from machine-broken hemp | 3 | Operations involved in a test | 13 |

| Present uses of hemp hurds | 4 | Description of tests | 16 |

| Present supplies of hurds available | 5 | Comparison of the tests and commercial practice | 21 |

| Baling for shipment | 5 | Physical tests of the papers produced | 24 |

| Cost of baling | 5 | Conclusions | 25 |

| Summary | 6 | ||

In preparing the report on the manufacture of paper from hemp hurds it became evident that a short discussion of the agricultural aspects of this material should be included in the publication. Such an article was prepared, therefore, and the two reports are here presented together.

Note. —This bulletin should be useful to all persons who are interested in the economic phases of paper making, especially to print and book paper manufacturers. It also should be of interest to scientific investigators and chemists.

By Lyster H. Dewey, Botanist in Charge of Fiber-Plant Investigations.

The woody inner portion of the hemp stalk, broken into pieces and separated from the fiber in the processes of breaking and scutching, is called hemp hurds. These hurds correspond to shives in flax, but are much coarser and are usually softer in texture.

-2- The hemp stalk grown in a broadcast crop for fiber production is from one-eighth to three-eighths of an inch in diameter and from 4 to 10 feet tall. The stalk is hollow, with a cylindrical woody shell, thick near the base, where the stalk is nearly solid, and thinner above, where the hollow is relatively wider.

In the process of breaking, the woody cylinder inside of the fiber-bearing bark is broken into pieces one-half of an inch to 3 inches long and usually split into numerous segments. The thicker lower sections are split less than the thin-shelled upper ones, and they are often left quite solid.

The inner surface of the hurds usually bears a layer of pith, consisting of thin-walled cells nearly spherical or angular, but not elongated. They are more or less crushed and torn. They are probably of little value for paper, but they constitute less than 1 per cent of the weight of the hurds. The principal weight and bulk consist of slender elongated woody cells. The outer surface is covered with fine secondary fibers composed of slender elongated cells, tougher than those of the wood but finer and shorter than those of the hemp fiber of commerce. No method has been devised thus far which completely separates from the hurds all of the long fiber. From 5 to 15 per cent of the weight of the hurds consists of hemp fiber, in strands from 3 inches to 8 feet in length. Some fragments of the bark, made up of short cubical cells, usually dark in color, cling to the strands of fiber.

Nearly all of the hemp in the United States is dew retted. The stalks are spread on the ground in swaths as grain is laid by the cradle. The action of the weather, dew, and rain, aided by bacteria, dissolves and washes out the green coloring matter (chlorophyll) and most of the gums, leaving only the fibrous bark and the wood. The plants in this process lose about 60 per cent of their green weight, or about 40 per cent of their air-dry weight.

The stalks are sometimes set up in shocks to cure before retting, and after retting they are set up in shocks to dry. Each time the stalks are handled they are chucked down on the ground to keep the butts even. In these operations sand and clay are often driven up into the hollow at the base of the stalks, and this dirt, which often clings tenaciously, may constitute all objectionable feature in the use of hemp hurds for paper stock.

In Italy and in most localities in Russia and Austria-Hungary where hemp is extensively cultivated, it is retted in water, but water retting has never been practiced in the United States except to a limited extent before the middle of the last century. Hurds from -3- water-retted hemp are cleaner and softer than those from dew-retted hemp.

The fiber is sometimes broken from dry hemp stalks without retting. The hurds thus produced contain a small percentage of soluble gums, chiefly of the pectose series. Comparatively little hemp is prepared in this manner in America.

Process retting by means of weak solutions of chemicals or oils in hot water is practiced to a limited extent. The hurds from these processes may contain traces of the chemicals or oils and also soluble gums in greater degree than those of the dew-retted or water-retted hemp.

The yield of hemp fiber varies from 400 to 2,500 pounds per acre, averaging 1,000 pounds under favorable conditions. The weight of hurds is about five times that of the fiber, or somewhat greater from hemp grown on peaty soils. A yield of 2½ tons of hurds per acre may be taken as a fair average.

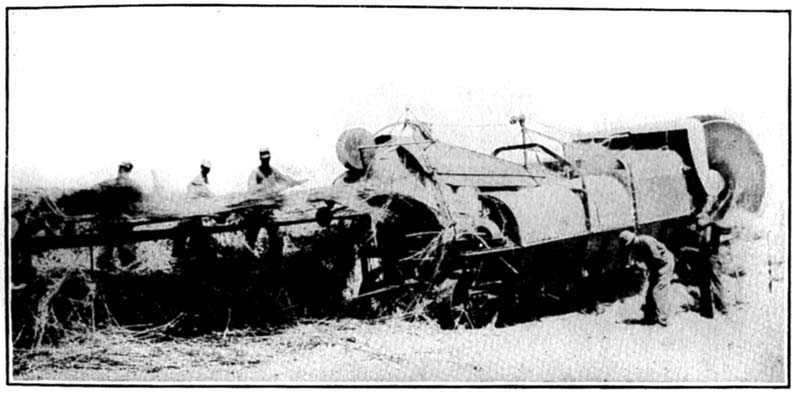

Fig. 1.—Hemp-breaking machine.

The stalks are fed sidewise in a continuous layer 2 to 3 inches thick,

turning out about 4,000 pounds of clean fiber per day and five times

as much hurds.

Hemp hurds are available only from hemp which is broken by machines, when the hurds may be collected in quantity in one place (figs. 1 and 2). Most of the hemp in Kentucky is still broken by hand brakes. These small brakes are moved from shock to shock, so that the hurds are scattered all over the field in small piles of less than 50 pounds each, and it is the common practice to set fire to them as soon as the brake is moved. It would be difficult to collect them at a cost which would permit their use for paper stock.

Where machine brakes are used, the hemp stalks are brought to the machine as grain is brought to a thrashing machine, and the hurds -4- accumulate in large piles, being blown from the machine by wind stackers.

Machine brakes are used in Wisconsin, Indiana, Ohio, and California, but to only a limited extent in Kentucky. Five different kinds of machine brakes are now in actual use in this country, and still others are used in Europe. All of the best hemp in Italy, commanding the highest market price paid for any hemp, is broken by machines. The better machine brakes now in use in this country prepare the fiber better and much more rapidly than the hand brakes, and they will undoubtedly be used in all localities where hemp raising is introduced as a new industry. They may also be used in Kentucky when their cost is reduced to more reasonable rates, so that they may compete with the hand brake. Hemp-breaking machines are being improved and their use is increasing. The hemp-growing industry can increase in this country only as machine brakes are developed to prepare the fiber. A profitable use for the hurds will add an incentive to the use of the machine brake.

Fig. 2.—Machine brake and hemp hurds.

Hemp hurds from machine brakes quickly accumulate in

large piles.

Hemp hurds are used to a limited extent for barnyard litter and stable bedding, as a substitute for sawdust in packing ice, and, in rare instances, for fuel. They are not regarded as having a commercial value for any of these uses, though they are doubtless worth at least $1 per ton on the farm when used for stable bedding. They are a waste product, without value for other purposes which might compete with their use for paper stock.

During the last season, 1915, about 1,500 acres of hemp have been harvested outside of Kentucky and in regions where machine brakes are used. Estimating the yield of hurds at 2½ tons per acre, this should give a total quantity of about 3,750 tons. Large quantities of hemp from the crop of 1914, which are still unbroken in these areas, and large piles of hurds undisturbed where the machines have been used during the last two or three years, increase the total to more than 7,000 tons. Hemp is now grown outside of Kentucky in the vicinity of McGuffey, east of Lima, Ohio; around Nappanee, Elkhart County, and near Pierceton, in Kosciusko County, Ind.; about Waupun and Brandon, Wis.; and at Rio Vista and Stockton, Cal.

In Kentucky, hemp is grown in most of the counties within a radius of 50 miles of Lexington. No accurate statistics of the acreage are collected, but the crop harvested in 1915 is estimated at 7,000 acres. A machine brake will probably be used in Bourbon County and also in Clark County, but most of the hemp in Kentucky will be broken on hand brakes.

The hurds will have to be baled to facilitate handling in transportation and to economize storage space at the paper mills. The bales will need to be covered with burlap or some material to keep them from shaking out. They may be baled in the same presses that are used for baling hemp fiber, but care must be exercised to avoid breaking the press, for the hurds are more resistant than hemp fiber. A bale of hemp 2 by 3 by 4 feet weighs about 500 pounds. A bale of hurds of the same size will weigh about one-third less, or approximately six bales per ton.

Rough hemp fiber as it is shipped from the farm is not covered; therefore, the covering material must be purchased especially for the hurds. A piece of burlap about 36 by 48 inches placed on either side of the bale will be sufficient, but these pieces, weighing about 3 pounds each, cost about 40 cents a pair. Baling rope, in addition to jute covering, will cost at least 5 cents per bale, making the total cost of covering and ties $2.70 or more per ton. Possibly chip-board, costing about $33 per ton, or not more than 5 cents for the two pieces for each bale, may be used in place of burlap. Chip-board, burlap, and also rope ties may all be used for paper stock. Burlap covers might be returned, to be used repeatedly until worn out, but chip-board could not be used more than once.

If burlap covers are used the cost of baling, including covering, ties, use of baling press, power, and labor will amount to at least 60 cents per bale, or about $3.75 per ton. If chip-board can be used the cost -6- may be reduced to about $2 per ton. The cost of hauling and loading on the cars will vary from $1 to $3 per ton, depending upon the distance and the roads. The farmer must therefore receive from $4 to $6 per ton for the hurds, baled, on board cars at his home station.

Hemp hurds are the woody inner portion of the hemp stalk, broken into pieces in removing the fiber.

They are not used at present for any purpose that would compete with their use for paper.

Hurds are available only from machine-broken hemp, for the cost of collecting them from the hand brakes would be too great.

About 7,000 tons are now available in restricted localities in Ohio, Indiana, Wisconsin, and California.

The quantity is likely to increase as the use of machine brakes increases.

The hurds may be baled in hemp-fiber presses, with partial burlap covers like those on cotton bales, or possibly chip-board covers.

It is estimated that the farmers may deliver the bales on board cars profitably at $4 to $6 per ton.

By Jason L. Merrill, Paper-Plant Chemist, Paper-Plant Investigations.

The purpose of this paper is to report upon preliminary tests which were conducted to determine the paper-making value of hemp hurds, a crop waste of the hemp-fiber industry.

The search for plant materials capable of being utilized in paper manufacture is a comparatively recent but world-wide activity which has for its object the husbanding of present sources of paper-stock supply by the substitution of new materials for some of those which are rapidly becoming less plentiful and more costly.

The abstract idea of utilizing that which is at present a waste can play no important rôle in such activities, the successful commercial outcome of which must be based on the three fundamental factors—market or demand for product, satisfactory raw material, and cost.

Since hemp hurds are to be treated in this report as a raw material for the manufacture of book and printing papers, the qualities, supply, probable future, and cost of the material will be considered in comparison with wood, with which it must compete. There seems to be little doubt that the present wood supply can not withstand indefinitely the demands placed upon it, and with increased scarcity economy in the use of wood will become imperative. This effect is already apparent in many wood-using industries, and although the paper industry consumes only about 3 per cent of the total forest cut, it is probable that it will be affected through this economy. Our forests are being cut three times as fast as they grow, and as wood becomes more expensive proper growing and reforesting will receive more attention. Thus, naturally, a balance will be established between production and consumption, but as this condition approaches its limiting values the price of wood may rise to such levels that there will be a demand for other raw materials.

The use of waste paper in conjunction with chemical wood pulp has increased to enormous proportions, and it is probable that the increase will continue. Although it is a cheaper raw material than wood, it is reasonable to suppose that as the wood supply decreases and the price of wood pulp advances, the price of waste paper will advance somewhat proportionately.

In view of these conditions it is advisable to investigate the paper-making value of the more promising plant materials before a critical -8- situation arises. To be of substantial value the investigations should include not only a determination of the quality and quantity of pulp and paper which the material is capable of producing, but should embrace a consideration of such relevant factors as agricultural conditions, farm practice, assembling conditions, transportation, and probable future supply.

Certain cultivated plants seem particularly promising, because in the harvesting of the regular crop that portion which might be utilized for paper manufacture necessarily is either wholly or partially assembled. To this class of plants belong corn, broom corn, sorghum, sugar cane, bagasse, flax, hemp, and the cereal straws. [1]

It is generally conceded that the employment of different raw materials would probably yield products of a somewhat different quality than those now prevailing in the markets, but the qualities of papers and the public demands are so diversified and numerous that this possible objection should not be serious. Ten years ago sulphite manufacturers would not accept consignments of spruce logs if they contained over 5 per cent of fir, while to-day many manufacturers tolerate 50 per cent. Rope papers are found to contain not only jute, but when this raw material is not plentiful, chemical pulp of various kinds. "Linen paper" is often no more than a trade term. Not long ago printing papers were made entirely from chemical wood pulp, but to-day if it is desired to secure paper which is free from ground wood the specifications must so stipulate. Writing papers, formerly made entirely from rags, now are likely to contain either chemical or even ground-wood pulp unless the specifications prohibit it. Without doubt, many paper manufacturers have maintained certain papers up to a fixed standard for a long series of years, but it is equally true that competition has lowered the standard of a great many papers, some of which had acquired a distinctive recognition. The employment of plant fibers will not necessarily lower the present quality of papers, but if their employment does result in products whose qualities are somewhat different from our so-called standard papers it does not necessarily follow that such papers will not find a ready market.

Hemp hurds form a crop waste, in that they necessarily are produced in the raising and preparation of hemp fiber, and their present use and value are comparatively insignificant.

The assembling of the hurds may be effected with economy, since the area in which hemp is handled with the use of machine brakes is restricted. Although it must be stated that the present annual -9- supply would not be sufficient to justify the installation of a pulp mill nor would its transportation to existing mills appear feasible, it is expected that the available annual tonnage, especially in certain general sections, will increase, due to the increased use of the machine brake. The present tonnage per annum is approximately as follows: In the region of Ohio and Indiana, 2,500 tons; in the Wisconsin section, 1,000 tons; in the California region, 1,400 tons.

In years of adverse weather conditions there are often large areas of hemp which are not harvested on account of its poor quality; there are also large areas of cut hemp which become overretted, due to inclement weather. It has been suggested by some of the hemp raisers that this large amount of material might be utilized as a paper stock. In these cases the cost of the whole material would probably be somewhat higher than that of the hurds, because either all or part of the cost of harvesting and the total cost of breaking would have to be borne by the paper maker. Moreover, the quality of this material would be so very irregular and the supply so uncertain that it probably would not appeal to the paper manufacturer.

Without doubt, hemp will continue to be one of the staple agricultural crops of the United States. The wholesale destruction of the supply by fire, as frequently happens in the case of wood, is precluded by the very nature of the hemp-raising industry. Since only one year's growth can be harvested annually the supply is not endangered by the pernicious practice of overcropping, which has contributed so much to the present high and increasing cost of pulp wood. The permanency of the supply of hemp hurds thus seems assured.

The favorable location geographically of the hemp regions in relation to the pulp and paper industry is a factor of considerable importance. The Kentucky region is not at present in a position to supply hurds, as machine methods have not been adopted there to any appreciable degree. The Ohio and Indiana region, which at present has the greatest annual tonnage, with the prospect of an increase, is situated south of the Wisconsin and Michigan wood-pulp producing region and at a distance from the eastern wood-pulp producing regions; therefore, it is in a favorable position to compete in the large Ohio and Indiana markets. Since, as will be shown, the hurd pulp acts far more like soda poplar stock than sulphite stock, competition would be strongest from the eastern mills; in fact, the hurd stock might very possibly meet with favor as a book-stock furnish in the Michigan and Wisconsin paper mills, which are within the sulphite fiber-producing region. Because of its very close proximity to paper mills, this latter possibility applies with far greater force to the Wisconsin hemp region, where a considerable extension of the hemp industry is anticipated.

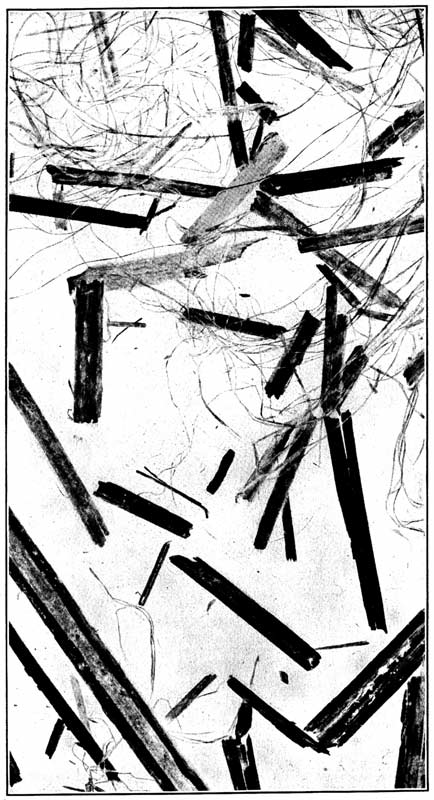

Fig. 3.—A representative sample of hemp hurds,

natural size, showing hemp fiber and pieces of wood tissue.

As received from Pierceton, Ind., the hurds consisted of a mixture of tangled hemp bast fibers and pieces of broken wood of the hemp stalk. (Fig. 3.) No reliable data were secured as to the proportion of bast fiber in the total shipment of 4 tons, although two hand separations of small representative samples gave results averaging 8 per cent. The chemical character of the material was such and the quantity was so small that any appreciable variation of the proportion should not affect materially the treating processes finally adopted, yet its presence in varying proportions undoubtedly would modify to some extent the quality of the resulting paper product. Since the length of the ultimate bast fiber averages about 22 mm. and the length of the ultimate hemp wood fiber averages 0.7 mm., it is natural to assume that the bast fiber would tend to increase the strength of paper produced from the hurds. (Fig. 4.)

Fig. 4.

—Fiber derived from the woody portion of the hurds. ×75.

From a microphotograph.

The broken pieces of wood contained in the hurds varied in length from mere particles which were somewhat finer than sawdust to pieces about 3½ inches long, exceptional pieces being found which measured 6 inches in length. The majority of the long pieces were between 2 and 3 inches in length. In thickness the pieces ranged from one-eighth of an inch, in case they were derived from the base of the hemp stalks, to about one sixty-fourth of an inch in those pieces which were derived from the top and branches of the stalks. In cross section the -12- pieces often were found to be a quarter or half of the rounded rectangular woody shell of the stalk, although there appeared to be no regularity in this respect.

From the pulp-maker's standpoint the great irregularity in thickness, length, and mass of the woody pieces militates decidedly against economy in pulp production. The smaller pieces reduce by chemical treatment sooner than the larger fragments and are thereby overtreated, which results in a lower yield of cellulose fiber and a product composed of undertreated and overtreated fibers, the production and use of which are not satisfactory or economical. It probably would be found more satisfactory, therefore, to screen or sort the hurds and treat the various sizes separately and differently.

Associated with the hurds was a small quantity of chaff and dirt, composed chiefly of sand, soil, particles of hemp leaves and flowers, and other extraneous matter. The sand and soil were present because of the practice of placing the stalks in shocks in the field, the butts of the stalks being in contact with the soil. It is a simple matter, however, to remove the chaff and dirt by sieving, and this practice was followed in most of the paper tests conducted with this material.

Because of the similarity of hemp hurds to other materials which have been tested by the Office of Paper-Plant Investigations, semicommercial tests were conducted in cooperation with a paper manufacturer without preliminary laboratory tests. Laboratory pulp and paper tests are regarded only as a preliminary to semicommercial tests and therefore are not employed unless the material in question presents new features which should receive investigation before larger sized tests are undertaken.

The advantages of cooperative mill tests are many, among which may be mentioned the counsel and advice of the mill management and employees, the services of specialized and skilled labor, facilities for comparing the processes and the results of tests with commercial processes and results, and the use of commercial or semicommercial types and sizes of machinery. Tests conducted in this manner and on this scale are of a different quality than is possible in those conducted in a laboratory, and the results are susceptible of commercial interpretation with a fair degree of reliability. It is found, in general, that the cost of securing such equipment and service for a complete and comprehensive test does not exceed $500, while the installation of an equally satisfactory equipment alone would cost at least $50,000 and in many cases very much more. Tests conducted in this manner constitute a direct demonstration to the manufacturer, and the results obtained are found to carry more weight when presented to other manufacturers for consideration.

-13- It is well known that the method of conducting tests necessarily varies with the size of the test. In the matter of yield determination, for example, laboratory tests may be on such a small scale that the weighing and sampling of the resulting cellulose fibers may be conducted by means of chemical laboratory apparatus and analytical balance, while in tests involving a matter of 5 to 10 pounds of material larger and different types of equipment are necessary. When the tests are so increased in size as to employ 300 or 400 pounds, still other types of equipment are necessary for the treatment of the material and for a determination of the yield of fiber. In tests involving tons of material the equipment involves the use of machines. Accuracy in degree of control and in results will vary materially with the size of the test. As the size of the test increases, certain factors will vary in a beneficial manner, while others will vary in a detrimental manner, so it is a question for each investigator to decide, after taking all factors into consideration, as to the size of test which will give the most satisfactory results. In work of this nature it is found, on the whole, that better results are obtained in large tests, although the control of the factors and the determination of the yield of fiber are more difficult than in smaller tests.

In the tests described in this bulletin, the Department of Agriculture employed a rotary digester of its own design,[2] comprising a shell 5 feet 5 inches in length by 4 feet in diameter, capable of holding about 300 pounds of air-dry hurds. It is believed that a test of this size is large enough to give satisfactory results and that the results are susceptible of commercial interpretation, while at the same time they are sufficiently small for complete control and to afford fiber-yield figures which are both accurate and reliable. Two such rotary charges gave enough fiber for one complete paper-making test.

A complete test on hurds comprises seven distinct operations, and the method will be described, operation by operation, in the order in which they were conducted.

Sieving.—The hurds for the first test were not sieved to remove sand and dirt, but the resulting paper was so dirty that sieving was practiced in all subsequent tests. The hurds were raked along a horizontal galvanized-iron screen, 15 feet long and 3 feet wide, with 11½ meshes per linear inch, the screen being agitated by hand from below. Various amounts of dirt and chaff could be removed, depending on the degree of action, but it was found that if much more than 3 per cent of the material was removed it consisted chiefly of fine pieces of wood with practically no additional sand or dirt; in most of the tests, therefore, the material was screened so as to remove -14- approximately 3 per cent. It became apparent that a finer screen would probably serve as well and effect a saving of small but good hurds.

Cooking.—Cooking is the technical term for the operation by which fibrous raw materials are reduced to a residue of cellulose pulp by means of chemical treatment. In these tests about 300 pounds of hurds were charged into the rotary with the addition of a caustic-soda solution, such as is regularly employed in pulp mills and which tested an average of 109.5 grams of caustic soda per liter, or 0.916 pound per gallon, and averaged 85 per cent causticity. Sufficient caustic solution was added to furnish 25 or 30 per cent of actual caustic soda, calculated on the bone-dry weight of hurds in the charge. After closing the rotary head, it was started rotating at the rate of one-half revolution per minute, and in about five minutes steam at 120 pounds per square inch was admitted at such a rate that the charge was heated in one hour to 170° C., which is the theoretical equivalent of 100 pounds of steam pressure per square inch. It was found, however, that when the temperature reached 170° C. the pressure was usually 115 or 120 pounds instead of 100 pounds, due to air and gases inclosed in the rotary. At this point the rotary was stopped and steam and air relieved until the pressure dropped to 100 pounds, or a solid steam pressure. The temperature was maintained at this point for the number of hours required to reduce the hurds, which was found to be about five, after which the rotary was stopped and steam relieved until the pressure was reduced to zero, when the head was removed and the stock was emptied into a tank underneath, measuring 5½ by 6 by 2 feet deep, where it was drained and washed. Samples of waste soda solution or "black liquor," which were taken from some of the "cooks" for analysis, were drawn while the stock was being thus emptied into the drainer.

Determination of yield.—For determining the yield of cellulose fiber the stock in the drain tank was washed with water until free from waste soda solution, when, by means of a vacuum pump communicating with the space between the bottom and the false perforated bottom, the water was sucked from the stock, leaving the fiber with a very uniform moisture content throughout its entire mass and in a condition suitable for removing, sampling, and weighing for a yield determination. Tests have shown that it is possible to sample and calculate the yield of bone-dry fiber within 0.05 per cent of the actual amount.

It has been found that stocks from different materials vary greatly in their ability to mat in the drain tank, thereby enabling a good vacuum to be obtained, some stocks permitting a 25-inch vacuum to be obtained, while others will not permit more than 5 inches. For this reason the moisture content of the stock will vary from 65 to 85 per cent.

-15- Washing and bleaching.—Washing and bleaching were performed for the purpose of bleaching the brown-colored cooked stock to a white product, since it was regarded as highly probable that the fiber would be suitable for book-paper manufacture. The colored stock was charged into a 400-pound beating and washing engine of regular construction and washed about one hour, the cylinder washer being covered with 60-mesh wire cloth in order to remove fine loose dirt and chemical residues. The washer was then raised, the stock heated by steam to about 40° C., and a solution of commercial bleaching powder was added in the quantity judged to be necessary, after which the stock was pumped to a large wooden tank, to remain and bleach over night. If the stock was bleached sufficiently white it was drained and washed from bleach residues, and if not more bleach was added until a good color was obtained. The bleaching powder used was estimated to contain 35 per cent of available chlorin, as this is the commercial practice, and the amount required was calculated to the bone-dry weight of the unbleached stock. More bleach is required for undercooked stock than for stock which is properly cooked or overcooked; therefore, the percentage of bleach required is an indication of the quality of the cooked stock. Since bleaching is usually more expensive than cooking, it is desirable to cook to such a degree that the consumption of bleach will be held within certain limits, depending on the raw materials used and the quality of paper to be produced. In these tests it was desirable so to cook the hurds that the consumption of bleach would not be over about 10 per cent of the fiber.

Furnishing.—Furnishing is the operation of charging the beating engine with the desired kind or kinds of fiber in the proper proportion and amount and the adding of such loading and sizing agents as may be necessary. As shown in the record of results, the furnish in these tests consisted of hurd stock alone and of various proportions of hurds, sulphite fiber, and soda fiber. The percentages to be given in the record of the furnishes refer to the percentage of the total fiber furnish, and this likewise applies to the loading and sizing agents. In case sulphite or soda fiber was used, the commercial product in the dry state was charged into the beating engine and disintegrated, after which the hurd stock was added in the wet condition.

Beating.—Beating is that operation concerning which the paper makers often say "there is where the paper is really made," and although the statement may not be literally true it contains a great deal of truth. It is the operation whereby the fibers are separated from each other, reduced to the proper lengths, and put in such a physical or chemical condition that they felt properly and form into a satisfactory sheet. It is probable that the quality of the sheet depends more upon the proper beater action than upon any other single operation. The action consists in drawing a water suspension of the fiber between two sets of rather blunt knives, one set being -16- located in the bottom of a circulating trough and the other set on the periphery of a roll revolving just above the former set of knives. It is during this operation that the loading and sizing agents are incorporated and the whole furnish is tinted either to produce a satisfactory white or the desired color.

The term "paper making," as used in this publication, means the operation of forming the finished sheet of paper from stock which has been furnished and prepared in the beater. In these tests a 30-inch Fourdrinier machine of regular construction was used, a machine which often is used for the production of paper for filling regular commercial orders. The machine is designed to cause the water suspension of fibers to flow on to a traveling wire cloth, whereby the water drains away. More water is removed by passing the wet sheet through a series of press rolls, after which the sheet is dried on steam-heated drums and passed through polished iron rolls, which impart a finish to the sheet. A Jordan refining machine was employed in conjunction with the machine to improve further the quality of the fiber, and a pulp screen was used in order to remove coarse and extraneous materials from the fiber.

The nature of each complete paper test and the dependence of each operation on the others were such that it does not seem advisable to submit the results of the seven tests in tabular form. The numerous cooks, however, which furnished the pulp for the paper tests are presented in Table I in all essential detail.

TABLE I.—Data on cooking hemp hurds.

| Cook No. | Caustic soda used (percentage of bone-dry hurds). | Strength of caustic soda (grams per liter). | Causticity of soda solution. | Cooking | Yield of bone-dry fiber (percentage of bone-dry unsieved hurds). | |

| Time (hours). | Temperature (°C.) | |||||

| 293 | 20.6 | 100 | 75.3 | 3 | 166 | |

| 294 | 21 | 100 | 75.3 | 3 | 166 | |

| 295 | 21.6 | 100 | 75.3 | 3 | 166 | |

| 296 | 20.3 | 100 | 75.3 | 3 | 166 | |

| 301 | 21.9 | 100 | 82.5 | 4 | 166 | [3] |

| 302 | 24.4 | 100 | 82.5 | 4 | 166 | |

| 303 | 24.2 | 100 | 84.3 | 4 | 166 | 44.1 |

| 304 | 25 | 100 | 84.3 | 4 | 170 | 39.5 |

| 305 | 25 | 100 | 84.3 | 5 | 170 | 39.4 |

| 306 | 27.8 | 107.5 | 84.3 | 4 | 166 | 36.5 |

| 307 | 26.7 | 107 | 84.4 | 5 | 170 | 38.1 |

| 308 | 26 | 107 | 84.4 | 5 | 170 | } 37.3 |

| 309 | 27.3 | 107 | 84.4 | 5 | 170 | |

| 310 | 27.1 | 107 | 84.4 | 6 | 170 | 37.0 |

| 311 | 27.2 | 107 | 84.4 | 6 | 170 | 36.8 |

| 312 | 28.3 | 116.5 | 85.5 | 5 | 170 | 35.9 |

| 313 | 29.1 | 113.1 | 84.9 | 5 | 170 | } 35.2 |

| 314 | 29.1 | 109 | 83.9 | 5 | 170 | |

| 315 | 29.4 | 109 | 83.9 | 5 | 170 | 34.9 |

| 316 | 30 | 109.5 | 84.9 | 5 | 170 | 37.2 |

| 317 | 29.6 | 109.5 | 84.9 | 5 | 170 | 37.0 |

| 318 | 29.6 | 107 | 84.8 | 5 | 170 | 37.7 |

| 319 | 29.4 | 107.5 | 84.2 | 5 | 170 | } 35.4 |

| 320 | 29.3 | 107.5 | 84.2 | 5 | 170 | |

-17- Discussion of the various cooks will be given in connection with the descriptions of those paper tests in which the stocks from the cooks were used, since a stock and its cooking condition can be judged adequately only after it has been put through the various processes and into the finished sheet of paper.

The first test consisted in making four separate cooks, Nos. 293, 294, 295, and 296, of approximately 300 pounds each, dividing the total stock into two parts and making two separate paper tests. The first test was made primarily in order to learn some of the qualities and characteristics of the stock and to get the machinery equipment adjusted properly. The yield of fiber was not determined in this preliminary test, since the knowledge of it was not essential at this stage of the work. The cooked stock which was emptied into the drainer to be washed free from black liquor was composed largely of whole pieces of hurds, but only slight pressure between the fingers was required to crush the pieces. In the case of wood, this condition ordinarily would indicate undercooking, but might not in the case of hurds. Further observation on the action of the cooked stock during subsequent processes was necessary in order to judge of its quality or the suitability of the cooking conditions. The total cooked stock, about 500 pounds, was divided into two portions of 200 and 300 pounds, respectively, and work was continued on them separately. The 200-pound test, designated as run No. 135, was put into a 350-pound washing engine, washed one hour, and given a total light brush of 2¼ hours. The washing removed a great amount of dirt, but the engine did not reduce the hurd stock as much as was desired. After heating the stock in the beater to 40° C., it was bleached with bleaching-powder solution, 94 gallons at 0.418 pound bleach per gallon, equivalent to 19.7 per cent of the fiber. This percentage of bleach is regarded as too high for stock intended for book-paper manufacture, and subsequent cooks therefore were given harder treatment in order to reduce this figure. After draining and washing free from bleach residues, the stock was furnished in the beater with 13 per cent of clay, 1 per cent of resin size, and 2.5 per cent of alum, was tinted blue, given one hour's light brush, and pumped to the stock chest. When running it on the paper machine, the Jordan refiner seemed to have little effect in reducing shives of undertreated wood, which indicated further the necessity of harder cooking. The furnish acted well on the paper machine at 70 feet per minute, but appeared somewhat too "free" on the wire. The paper produced from this test is of very low quality, due to the improper preparation of the stock, lack of sufficient bleach, the use of too small an amount of blue tinting, and the presence of an excessive amount of dirt, sand, and shives. The excessive amount of dirt and sand suggested the sieving of the hurds before cooking, and this was performed in all subsequent cooks. -18- The finish of the sheet is very poor, due to the fact that the calender stack was composed of very light rolls which did not have a satisfactory surface, yet the stack is known to be able to produce better finishes if the proper stock is employed.

Run No. 136 was made on the 300-pound portion of stock from cooks Nos. 293, 294, 295, and 296, and in essentially the same manner as run No. 135. The stock was washed one hour, but given a brush of three hours, and this brush was harder than in run No. 135. Bleach to the extent of 19.8 per cent of the fiber was used, assisted by 1 pint of oil of vitriol, and the resulting color was an improvement over that of run No. 135. After adding 13.5 per cent of clay and sizing with 1.1 per cent of resin size, the furnish was given one-half hour's light brush, tinted, and run on the machine, which was set at 70 feet per minute. This stock acted better on the wire and gave no trouble on the machine, but it still seemed to be impossible to reduce the wood shives by manipulation of the Jordan refiner. The resulting sheet is an improvement over that produced by No. 135, but is far from satisfactory.

Run No. 138 was made from hurds which, as in all subsequent tests, were sieved on a 11½-mesh wire screen until practically all the loose dirt and sand was removed, which operation caused a loss averaging 3 per cent of the hurds. Stock from cooks Nos. 302 and 303 was used for this run and the increased amount of caustic soda and the increase in the time of cooking gave a stock of better appearance than those of preceding tests.

The stock, amounting to 231 pounds dry weight, was washed and at the same time given a light brush for one hour only, after which it was bleached with 17 per cent of bleach without the addition of acid. Since the preceding paper appeared somewhat weak and had a low tearing quality, it was decided to use a furnish of 15.7 per cent bleached sulphite and 84.3 per cent bleached hemp-hurd stock. After loading with 13.1 per cent of clay and sizing with 1.1 per cent of resin size, the furnish was given a medium brush for one hour, tinted, and run on to the machine at 70 feet per minute. The stock gave no trouble on the machine, but it was impossible to judge the effect of the Jordan refiner, because through an oversight the machine chest had not been cleaned since previous use on an unbleached yucca material. It is believed, however, that sheet No. 138 shows improvement in the preparation of the hurd pulp.

Run No. 139 was made from stock of cooks Nos. 304 and 305, in which still more caustic soda was employed and the time and temperature of cooking were increased, giving a yield of total fiber of 40.7 per cent of the sieved or 39.4 per cent of the unsieved hurds. The cooked stock still seemed to be undertreated, but it must be remembered that in working with any new raw material it is impos -19- sible to know in advance how the properly treated material should appear. A washing of one hour was given while the roll was lowered from a light to a medium brush, after which the stock was bleached with 17.1 per cent of bleach without the aid of acid. Since sulphite stock improved the previous paper, this bleached stock was used in a furnish of 16.6 per cent sulphite and 83.4 per cent hurds, loaded with 16.7 per cent clay, sized with 1.4 per cent resin size, given a medium brush of two hours, tinted, and run on to the machine at 70 feet per minute. The Jordan refiner seemed to have little effect in reducing shives and was therefore left "just off." No trouble was experienced with the stock on the machine, and the sheet is an improvement over previous samples.

Run No. 140 was made from cooks Nos. 306 and 307, in which more caustic soda was employed than in any previous cooks and at a higher concentration, the fiber yields of which averaged 37.3 per cent of the unsieved hurds. Not much improvement was apparent in the cooked stock, in spite of the increased severity of cooking. The stock was washed and given a medium brush for one hour, bleached with 11.9 per cent of bleach, assisted with one-half pint of oil of vitriol, and made into a furnish of 14.9 per cent sulphite and 85.1 per cent of the hurd stock. After loading with 14.7 per cent of clay and sizing with 1.28 per cent of resin size, the furnish was given two hours' medium brush, tinted, and run on to the paper machine at 70 feet per minute. Again the Jordan refiner did not seem to reduce the wood shives sufficiently, and it was left "just off." No trouble which could be attributed to the stock was experienced on the paper machine. The color of the resulting paper is due to the use of too little blue in tinting and probably in some measure to the use of too low a percentage of bleach.

Run No. 141 was made from the stock of cooks Nos. 308 and 309 in practically the same manner as run No. 140. The stock was washed and brushed one hour, bleached (the record of the amount of bleach was lost), made into a furnish of 14.7 per cent of sulphite and 85.3 per cent of hurd stock, loaded with 14.9 per cent of clay, sized with 1.26 per cent of resin size, given one hour at a medium brush, tinted, and run on to the machine. The Jordan refiner was able to reduce the wood shives to a somewhat greater degree than in previous runs and was held at a medium brush. The stock acted well on the machine and produced a sheet of better quality than any preceding, with the exception of the color, which was due to using too small a quantity of blue.

Among the cooks made for run No. 142 are Nos. 312 and 313, in which the concentration of the caustic soda was raised to 113 and 116 grams per liter and the percentage employed was also increased. In spite of these increases the stock from these two cooks did not -20- show any appreciable improvement when dumped from the rotary. Stock from cooks Nos. 310, 311, and 312 was given a medium brush and washing of one hour, bleached with 10.95 per cent of bleach, made into a furnish consisting of 15.2 per cent of sulphite and 84.8 per cent of hurd stock, loaded with 15.2 per cent of clay, sized with 1.28 per cent of resin size, given a medium brush for one hour, tinted, and pumped to the stock chest. Stock from cooks Nos. 313 and 314 was treated in exactly the same manner, except that 11.4 per cent of bleach was used. It was pumped to the stock chest and mixed with the furnished stock from cooks Nos. 310, 311, and 312. A medium Jordan brush was given the stock and it acted well on the paper machine, which was speeded to 75 feet per minute. There seems to be a tendency in the hurd stock to crush a little at the "dandy roll," and although the marks are not removed by the calender stack which was employed in those tests it was found that one "nip" on the supercalenders renders them practically imperceptible and it is believed that the proper size and weight of calender stack would entirely remove these marks. All of the papers produced up to this point are somewhat lacking in the bulk desired in a book paper; therefore, in the two following runs soda-poplar stock was included in the furnishes.

In run No. 143 stock from cooks Nos. 315 and 316 was given a medium brush and washing for one hour and was medium brushed for one hour more, bleached with 11.3 per cent of bleach assisted with one-half pint of oil of vitriol, made into a furnish of 16.5 per cent of sulphite, 22.3 per cent of soda poplar, and 61.2 per cent of hurd stock, loaded with 22 per cent of clay, sized with 1.38 per cent of resin size, given a hard brush for one hour, tinted very strongly, and pumped to the stock chest. This stock was beaten to a greater extent than in previous runs. The stock was run on the paper machine at a speed of 75 feet per minute, using a medium Jordan brush, and no trouble whatsoever was experienced. Not over 2 pounds of "broke" was produced during the whole run, and that was in the "threading" of the machine. The color of the sheet is entirely satisfactory for many uses. The wood shives apparently were reduced to a satisfactory degree. Experienced paper makers commented very favorably on the running of this furnish and the quality of the paper produced.

Run No. 144 was intended as a duplicate of run No. 143. Stock from cooks Nos. 317 and 318 was given a medium brush and washing for one hour and a further medium brush of one hour, bleached with 11.4 per cent of bleach, and made into a furnish composed of 15.5 per cent of sulphite, 23.5 per cent of soda poplar, and 61 per cent of hurd stock, loaded with 21.4 per cent of clay, sized with 1.17 per cent of resin size, hard brushed for one hour, tinted by the expert colorer -21- of the company, and pumped to the stock chest. Stock from cooks Nos. 319 and 320 was treated in exactly the same manner except that the stock was bleached with 12.1 per cent of bleach and pumped to the stock chest to mix with the former furnish. The stock acted very well on the machine, which was speeded to 75 feet per minute, with the Jordan refiner set at a medium brush. The sheet is as good, if not better, than that of run No. 143, and it is also a good illustration of the extent to which proper tinting will enhance the general appearance of a paper. The poor appearance of the samples of previous runs is due largely to lack of proper tinting. Various degrees of whiteness, however, are demanded by the trade.

In work of this nature and on this scale it is practically impossible to arrive at a cost figure which would be susceptible of commercial interpretation, and in this preliminary publication nothing will be attempted beyond a comparison of the process used with the hurds with that process commercially applied to poplar wood. The process last used with the hurds should not be regarded as final, satisfactory, or most suitable, as it has been shown that progress was being made up to the conclusion of the work.

In comparing the method of using hurds with the method of handling poplar wood, a difference is apparent on the delivery of raw material at the mill. Ordinarily, poplar is received at the mill in the form of logs about 4 feet in length, which may be stored in piles in the open. Hurds very likely would be received baled, and it would seem advisable to store them under cover for the following reasons: (a) Baled hurds would probably absorb and retain more water during wet weather than logs of wood, thereby causing excessive dilution of the caustic liquor; (b) prolonged excessive dampness might create heating and deterioration unless the hemp were properly retted; (c) wet hurds could not be sieved free from sand and chaff. Should further work show that the first two reasons need not be taken into consideration, the third objection might be overcome by sieving the hurds before baling. Even then, it is probable that baled hurds stored in the open would accumulate and retain considerable dirt from factory chimneys, locomotives, and wind. Checked pulp wood exposed in the open invariably suffers from these causes.

In the preparation of the raw material for the digesters there is likewise considerable difference between hurds and poplar wood. The former apparently requires only a moderate sieving to remove sand and chaff, which operation doubtless would require only a small amount of labor and the installation of some simple machinery of low power consumption. In preparing poplar for digestion, the -22- 4-foot logs are chipped by a heavy, comparatively expensive chipper of high power consumption, after which the chips are sorted by sieving, the large pieces being rechipped. There would be a noteworthy difference in the installation, operating, and depreciation costs of the two equipments, and this difference would counterbalance to a considerable extent the difference in cost of raw material storage.

It is possible that in the use of the chip loft more care would have to be exercised in using hurds because of the tendency of the bast fiber to cause lodgments, but this should not be considered a serious difficulty.

The weight of hurds which are capable of being charged into a rotary is a decidedly unfavorable factor. The weight of a cubic foot of hurds varies somewhat with the proportion of bast fiber, but averages about 5.4 pounds, which, compared with a cubic foot of poplar chips at 8.93 pounds, represents a digester charge of 60.5 per cent of the weight of a poplar-wood charge, or, in terms of fiber capacity, the hurds charge would yield 38.6 per cent as much fiber as the wood charge. The hurds upon being baled for transportation may be broken and crushed to such a degree that the weight of the charge may be increased, and it might be found possible to increase the charge weight by steaming or by the employment of tamping devices. This small weight of charge constitutes one of the most serious objections to the use of hurds in paper manufacture.

In those tests in which the most satisfactory results were obtained, the cooking conditions were 29.5 per cent of caustic soda at a concentration of 107 grams per liter and a causticity of 84.0 per cent acting at a temperature of 170° C. for five hours, or a total time of seven hours. The steam condensation in the rotary used for these tests was abnormally high, due to the fact that the steam supply pipe was uncovered for a considerable distance and the rotary was entirely uncovered. It is believed, therefore, that a larger amount of caustic was necessary than would otherwise have been the case. This belief is strengthened by the quality of the waste liquor from one of the later cooks, which gave on analysis 16.85 grams per liter of free caustic soda and showed a causticity of 27.75 per cent. These data show that only 67.3 per cent of the total caustic employed was actually consumed in the cooking operation, which percentage is lower than obtains in practice. The stock from this cook was bleached with 11.5 per cent of bleach. But even as the figures stand, the comparison with poplar cooking practice is as follows: 29.5 per cent caustic soda used as against 22 to 25 per cent; 107 grams per liter as against 100 to 110; 84 per cent causticity is little different than obtains in practice; 170° C. is about commercial practice; five hours at pressure as against four to six hours; seven hours' total time as -23- against possibly six to eight hours; 11.5 per cent bleach as against 8 to 10 per cent. Thus, it is evident that the cooking conditions employed were slightly more severe and expensive than those in commercial use with poplar wood.

The yield of total fiber obtained from the hurds may be placed at 35 per cent of bone-dry fiber calculated on the bone-dry weight of hurds used, or 33.1 per cent of air-dry fiber calculated on air-dry hurds. The yield of bleached fiber was not determined in this preliminary work, but may be safely estimated as 30 per cent, which is low when compared with a yield of about 47 per cent of bone-dry bleached fiber from bone-dry poplar wood. It is believed quite possible that satisfactory cooking conditions may be found which will give a higher yield than was obtained during these tests. The stock should be classed as easy bleaching, and 11.4 per cent of bleach is a satisfactory figure, although a little high.

As to beating cost, in the last two and most satisfactory tests the total washing and beating time was three hours, which may be about an hour more than ordinarily is used in making papers of this grade, although the practice varies to a considerable extent.

In regard to furnish, there is such a diversity of practice that it is difficult to make a comparison, but if the hurd stock can be produced as cheaply as soda-poplar stock, the furnish used in these last two tests should be regarded as satisfactory to the book and printing paper manufacturer.

The finish of the paper was not all that might be desired, but that was due almost entirely to the calender stack available for the work, which was composed of nine light rolls, many of which were about 6 inches in diameter and which had not been reground for some time. From a small test on a large calender stack it was readily shown that the paper produced is capable of taking a satisfactory finish.

This comparison, satisfactory in many respects, develops two factors which are decidedly unfavorable to hemp hurds, namely, raw-material storage and digester capacity, and they must be taken into full account in considering the paper-making value of this material, although it should be recognized that investigation may result in the material improvement of these conditions. Moreover, it is not at all improbable that further investigation would develop more satisfactory treating conditions and more suitable furnish compositions, and the belief in this possibility is strengthened by the fact that material progress was being made at the conclusion of this preliminary work.

Calculations on the raw material and acreage for a permanent supply for a pulp mill producing 25 tons of fiber a day for 300 days per annum, or 7,500 tons per annum, give the comparison between hurds and wood shown in Table II.

-24- Table II.—Comparison between wood and hemp hurds.

| Material. | Pulp yield. | Raw material required per year. | Annual growth per acre. | Acres required for sustained supply. | |

| For 25-ton mill. | For 1 ton of fiber per year. | ||||

| Wood | Two cords yield 1 ton of fiber. | 15,000 cords | 0.37 cord (about 0.55 ton). | 40,500 | 5.4 |

| Hemp hurds | One ton yields 600 pounds of fiber. | 25,000 tons | 2.5 tons | 10,000 | 1.33 |

The most important point derived from this calculation is in regard to areas required for a sustained supply, which are in the ratio of 4 to 1. Every tract of 10,000 acres which is devoted to hemp raising year by year is equivalent to a sustained pulp-producing capacity of 40,500 acres of average pulp-wood lands. In other words, in order to secure additional raw material for the production of 25 tons of fiber per day there exists the possibility of utilizing the agricultural waste already produced on 10,000 acres of hemp lands instead of securing, holding, reforesting, and protecting 40,500 acres of pulp-wood land.

The annual growth per acre, although decidedly in favor of hurds, has little bearing on the project, because the utilization of the hurds is subordinate to the raising of hemp, and the paper manufacturer probably could afford to use only hurds resulting from the hemp industry.

Samples of paper produced in the seven tests were submitted to the Leather and Paper Laboratory of the Bureau of Chemistry. The report of that bureau on its tests is given in Table III.

Table III.—Report of the Leather and Paper Laboratory of the Bureau of Chemistry on papers manufactured from hemp hurds.

| Laboratory No. | Run No. | Ash. | Weight of 500 sheets. | Thickness, 1/10000. | Strength (Mullen). | Strength factor (25 by 40, 500). | Folding endurance. | ||||

| 25 by 38. | 25 by 40. | Average. | Maximum. | Minimum. | Longitudinal. | Transverse. | |||||

| Per ct. | Pounds. | Pounds. | |||||||||

| 31570 | 144 | 13.9 | 48 | 50½ | 33 | 15.0 | 17.0 | 11.0 | 0.30 | 5 | 3 |

| 31571 | 143 | 14.5 | 49 | 51½ | 35 | 14.0 | 14.0 | 13.0 | .28 | 4 | 4 |

| 31573 | 141 | 10.9 | 48 | 50½ | 38 | 19.0 | 20.0 | 19.0 | .37 | 8 | 6 |

| 31572 | 142 | 9.5 | 49½ | 52 | 33 | 16.5 | 18.0 | 11.0 | .33 | 10 | 8 |

| 31574 | 140 | 11.4 | 42 | 44 | 30 | 14.5 | 16.0 | 13.0 | .33 | 7 | 6 |

| 31575 | 139 | 13.4 | 55 | 58 | 40 | 19.5 | 20.0 | 17.0 | .34 | 8 | 5 |

| 31576 | 138 | 10.4 | 56 | 59 | 40 | 20.0 | 20.0 | 19.0 | .34 | 23 | 15 |

There is no system of numerically recording the general appearance and "look through" of a paper, but it can be stated that only papers -25- Nos. 143 and 144 are satisfactory in these respects, the other samples being more or less thickly specked with shives. The general character and tests of these papers correspond very closely with No. 1 machine-finish printing paper, according to the specifications of the United States Government Printing Office, which call for a sheet not exceeding 0.0035 inch in thickness, strength not less than 12 points, free from unbleached or ground wood pulp, and ash not over 10 per cent. The strength factor of such papers is about 0.28. The ash should not be over 10 per cent for this grade of paper, but in spite of the larger amount used the physical tests are sufficiently high. It is to be noted that the physical tests of samples Nos. 138 to 142, inclusive, are higher than in Nos. 143 and 144, in which 23 per cent of soda poplar was used, which shows clearly that hemp-hurd stock imparts strength and folding endurance to a greater extent than does soda-poplar stock. From these preliminary tests it would be concluded, therefore, that hemp-hurd stock acts similarly to soda-poplar stock, but will produce a somewhat harsher and stronger sheet and one of higher folding endurance. Undoubtedly, there is more dirt in the samples than would be tolerated by the trade, but this was to be expected, since in this preliminary work the raw material was sieved by hand screens instead of by automatic machines which would sieve more thoroughly.

There appears to be little doubt that under the present system of forest use and consumption the present supply can not withstand the demands placed upon it. By the time improved methods of forestry have established an equilibrium between production and consumption, the price of pulp wood may be such that a knowledge of other available raw materials may be imperative.

Semicommercial paper-making tests were conducted, therefore, on hemp hurds, in cooperation with a paper manufacturer. After several trials, under conditions of treatment and manufacture which are regarded as favorable in comparison with those used with pulp wood, paper was produced which received very favorable comment both from investigators and from the trade and which according to official tests would be classed as a No. 1 machine-finish printing paper.

[1] For descriptions of investigations of some of these crops, see the list of publications at the end of this bulletin.

[2] For a description of this rotary digester, see Brand, C. J., and Merrill, J. L., Zacaton as a paper-making material, U. S. Dept. Agr. Bul. 309, p. 28, 1915.

[3]Stock not used; dirty.