Title: The Steam Engine Explained and Illustrated (Seventh Edition)

Author: Dionysius Lardner

Release date: April 26, 2013 [eBook #42602]

Most recently updated: October 23, 2024

Language: English

Credits: E-text prepared by Chris Curnow, RichardW, and the Online Distributed Proofreading Team (http://www.pgdp.net) from page images generously made available by Internet Archive (http://archive.org)

The Project Gutenberg eBook, The Steam Engine Explained and Illustrated (Seventh Edition), by Dionysius Lardner

|

Note: Images of the original pages are available through Internet Archive. See https://archive.org/details/steamengineexpla00lardrich Some characters might not display in the html version. If so, the reader should consult the iso-8859-1 (Latin-1) text file 42602-8.txt (http://www.gutenberg.org/files/42602/42602-8.txt) or 42602.zip (http://www.gutenberg.org/files/42602/42602-8.zip) |

The Drawings for several of the Cuts in this Volume have been taken, by the permission of Mr. Weale, from the admirable Plates annexed to the last edition of Tredgold on the Steam Engine and on Steam Navigation. This acknowledgment is especially due for the Illustrations which abound in this Volume.

London, June, 1840.

Advanced as we are in the art of rendering knowledge popular, and cultivated as the public taste is in the appreciation of the expedients by which science ministers to the uses of life, there is still perhaps but one machine of which such a proposition can be truly predicated: it is needless to say that that machine is the STEAM ENGINE. There are many circumstances attending this extraordinary piece of mechanism which impart to it an interest so universally felt. Whether we regard the details of its structure and operation, the physical principles which it calls into play, and the beautiful contrivances by which these physical principles are rendered available;—or, passing over these means, we direct our attention to the ends which they attain, we are equally filled with astonishment and admiration. The history of the steam engine offers to our notice a series of contrivances which, for exquisite and refined ingenuity, stand without any parallel in the annals of mechanical science. These admirable inventions, unlike other results of scientific inquiry, have also this peculiarity, that, to understand their excellence and to perceive their beauty, no previous or subsidiary knowledge is necessary, save what may be imparted with facility and clearness in the progress of the explanation and development of the machine itself. A simple and clear exposition, divested of needless technicalities and aided by well-selected diagrams, is all that is necessary to render the construction and operation of the steam engine, in all its forms, intelligible to persons of plain understanding and moderate information.

But if the contrivances by which this vast power is brought to bear on the arts and manufactures, be rendered attractive by their great mechanical beauty, how much more imposing will the subject become when the effects which the steam engine has produced upon the well-being of the human race are considered. It has penetrated the crust of the earth, and drawn from beneath it boundless treasures [Pg005] of mineral wealth, which, without its aid, would have been rendered inaccessible; it has drawn up, in measureless quantity, the fuel on which its own life and activity depend; it has relieved men from their most slavish toils, and reduced labour in a great degree to light and easy superintendence. To enumerate its present effects, would be to count almost every comfort and every luxury of life. It has increased the sum of human happiness, not only by calling new pleasures into existence, but by so cheapening former enjoyments as to render them attainable by those who before could never have hoped to share them: the surface of the land, and the face of the waters, are traversed with equal facility by its power; and by thus stimulating and facilitating the intercourse of nation with nation, and the commerce of people with people, it has knit together remote countries by bonds of amity not likely to be broken. Streams of knowledge and information are kept flowing between distant centres of population, those more advanced diffusing civilisation and improvement among those that are more backward. The press itself, to which mankind owes in so large a degree the rapidity of their improvement in modern times, has had its power and influence increased in a manifold ratio by its union with the steam engine. It is thus that literature is cheapened, and, by being cheapened, diffused; it is thus that Reason has taken the place of Force, and the pen has superseded the sword; it is thus that war has almost ceased upon the earth, and that the differences which inevitably arise between people and people are for the most part adjusted by peaceful negotiation.

Deep as the interest must be with which the steam engine will be regarded in every civilised country, it presents peculiar claims upon the attention of the people of Great Britain. Its invention and progressive improvement are the work of our own time and our own country; it has been produced and matured almost within the last century, and is the exclusive offspring of British genius, fostered and sustained by British enterprise and British capital.

The steam engine is a mechanical contrivance, by which coal, wood, or other fuel is rendered capable of executing any [Pg006] kind of labour. Coals are by it made to spin, weave, dye, print and dress silks, cottons, woollens, and other cloths; to make paper, and print books upon it when made; to convert corn into flour; to express oil from the olive, and wine from the grape; to draw up metal from the bowels of the earth; to pound and smelt it, to melt and mould it; to forge it; to roll it, and to fashion it into every desirable form; to transport these manifold products of its own labour to the doors of those for whose convenience they are produced; to carry persons and goods over the waters of rivers, lakes, seas, and oceans, in opposition alike to the natural difficulties of wind and water; to carry the wind-bound ship out of port; to place her on the open deep ready to commence her voyage; to throw its arms around the ship of war, and place her side by side with the enemy; to transport over the surface of the deep persons and information, from town to town, and from country to country, with a speed as much exceeding that of the ordinary wind, as the ordinary wind exceeds that of a common pedestrian.

Such are the virtues, such the powers, which the steam engine has conferred upon COALS. The means of calling these powers into activity are supplied by a substance which nature has happily provided in unbounded quantity in every part of the earth; and though it has no price, it has inestimable value: this substance is WATER.

A pint of water may be evaporated by two ounces of coals. In its evaporation it swells into two hundred and sixteen gallons of steam, with a mechanical force sufficient to raise a weight of thirty-seven tons a foot high. The steam thus produced has a pressure equal to that of common atmospheric air; and by allowing it to expand, by virtue of its elasticity, a further mechanical force may be obtained, at least equal in amount to the former. A pint of water, therefore, and two ounces of common coal, are thus rendered capable of doing as much work as is equivalent to seventy-four tons raised a foot high.

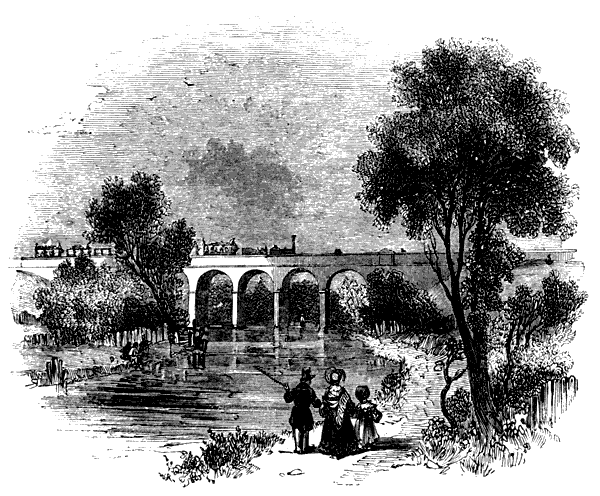

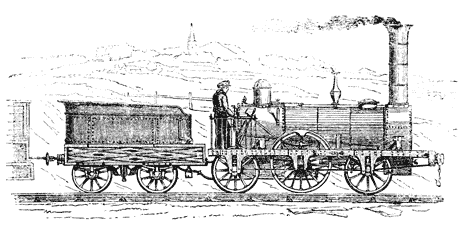

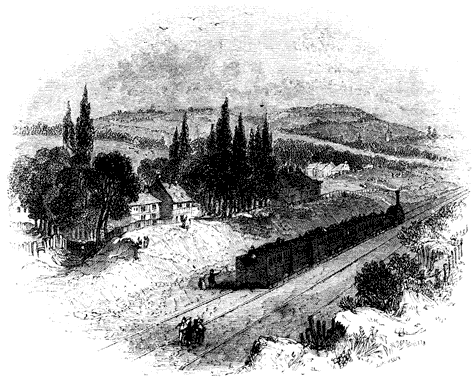

The circumstances under which the steam engine is worked on a railway are not favourable to the economy of fuel. Nevertheless a pound of coke burned in a locomotive engine [Pg007] will evaporate about five pints of water. In their evaporation they will exert a mechanical force sufficient to draw two tons weight on the railway a distance of one mile in two minutes. Four horses working in a stage-coach on a common road are necessary to draw the same weight the same distance in six minutes.

A train of coaches weighing about eighty tons, and transporting two hundred and forty passengers with their luggage, has been taken from Liverpool to Birmingham, and back from Birmingham to Liverpool, the trip each way taking about four hours and a quarter, stoppages included. The distance between these places by the railway is ninety-five miles. This double journey of one hundred and ninety miles is effected by the mechanical force produced in the combustion of four tons of coke, the value of which is about five pounds. To carry the same number of passengers daily between the same places by stage-coaches on a common road, would require twenty coaches and an establishment of three thousand eight hundred horses, with which the journey in each direction would be performed in about twelve hours, stoppages included.

The circumference of the earth measures twenty-five thousand miles; and if it were begirt with an iron railway, such a train as above described, carrying two hundred and forty passengers, would be drawn round it by the combustion of about thirty tons of coke, and the circuit would be accomplished in five weeks.

In the drainage of the Cornish mines the economy of fuel is much attended to, and coals are there made to do more work than elsewhere. A bushel of coals usually raises forty thousand tons of water a foot high; but it has on some occasions raised sixty thousand tons the same height. Let us take its labour at fifty thousand tons raised one foot high. A horse worked in a fast stage-coach pulls against an average resistance of about a quarter of a hundred weight. Against this he is able to work at the usual speed through about eight miles daily: his work is therefore equivalent to one thousand tons raised one foot. A bushel of coals consequently, as used in Cornwall, performs as much labour as a day's work of one hundred such horses. [Pg008]

The great pyramid of Egypt stands upon a base measuring seven hundred feet each way, and is five hundred feet high, its weight being twelve thousand seven hundred and sixty millions of pounds. Herodotus states, that in constructing it one hundred thousand men were constantly employed for twenty years. The materials of this pyramid would be raised from the ground to their present position by the combustion of about four hundred and eighty tons of coals.

The Menai Bridge consists of about two thousand tons of iron, and its height above the level of the water is one hundred and twenty feet. Its mass might be lifted from the level of the water to its present position by the combustion of four bushels of coal.

The enormous consumption of coals produced by the application of the steam engine in the arts and manufactures, as well as to railways and navigation, has of late years excited the fears of many as to the possibility of the exhaustion of our coal-mines. Such apprehensions are, however, altogether groundless. If the present consumption of coal be estimated at sixteen millions of tons annually, it is demonstrable that the coal-fields of this country would not be exhausted for many centuries.

But in speculations like these, the probable, if not certain progress of improvement and discovery ought not be overlooked; and we may safely pronounce that, long before such a period of time shall have rolled away, other and more powerful mechanical agents will supersede the use of coal. Philosophy already directs her finger at sources of inexhaustible power in the phenomena of electricity and magnetism. The alternate decomposition and recomposition of water, by magnetism and electricity, has too close an analogy to the alternate processes of vaporisation and condensation, not to occur at once to every mind: the development of the gases from solid matter by the operation of the chemical affinities, and their subsequent condensation into the liquid form, has already been essayed as a source of power. In a word, the general state of physical science at the present moment, the vigour, activity, and sagacity with which researches in it are prosecuted in every civilised [Pg009] country, the increasing consideration in which scientific men are held, and the personal honours and rewards which begin to be conferred upon them, all justify the expectation that we are on the eve of mechanical discoveries still greater than any which have yet appeared; and that the steam engine itself, with the gigantic powers conferred upon it by the immortal Watt, will dwindle into insignificance in comparison with the energies of nature which are still to be revealed; and that the day will come when that machine, which is now extending the blessings of civilisation to the most remote skirts of the globe, will cease to have existence except in the page of history.

In explaining the different forms of steam engine which have been proposed in the course of the progressive improvement [Pg010] of that machine from its early rude and imperfect state to its present comparatively perfect form, it will be necessary to advert to various physical phenomena and mechanical principles, which, however obvious to those who are conversant with matters of science, must necessarily be at least imperfectly known by the great majority of our readers. To refer for information on such topics to other works on Mechanics and general Physics, would be with most readers ineffectual, and with all unsatisfactory. In former editions of the present work, we consigned these necessary general principles of physics and mechanics to a preliminary chapter; but it appears, on the whole, more convenient not to remove the exposition of the principle from the place where its application is required. We shall therefore pause as we proceed, where these difficulties occur, to give such explanation and illustration as may seem best suited to render them intelligible and interesting to the unscientific reader.

The history of the arts and manufactures affords no example of any invention the credit for which has been claimed by so many different nations and individuals as that of the steam engine. The advocates of the competitors for this honour have urged their pretensions, and pressed their claims, with a zeal which has occasionally outstripped the bounds of discretion, and the contest has not unfrequently been tinged with prejudices, national and personal, and characterised by a degree of asperity altogether unworthy of so noble a cause, and beneath the dignity of science.

"When a question is clearly proposed, it is already half resolved." Let us see whether a careful attention to this maxim will aid us in the investigation of the origin of the steam engine. The source of the power of that machine is found in the following natural phenomena.

Such are the natural phenomena in which are found the original sources of all steam power. In some forms of steam engine one of these is used, and in some another, and in some the application of all of them is combined; but in no existing form of steam engine whatever is there any other source of mechanical power.

Neither these nor any other natural forces can be applied immediately to any useful purpose. The interposition of mechanism is indispensable; on the invention and contrivance of that mechanism depends altogether the useful application of these natural forces.

The world owes the steam engine then partly to discovery, and partly to invention.

He that discovered the fact, that mechanical force was produced in the conversion of water into steam, must be justly held to be a sharer in the merit of the steam engine, even though he should never have practically applied his discovery. The like may be said of him who first discovered the source of the mechanical power arising from the expansion of steam.

The discoverer of the fact, that steam being reconverted into water greatly contracted its dimensions, and thereby produced a vacuum, is likewise entitled to a share of the credit. [Pg012]

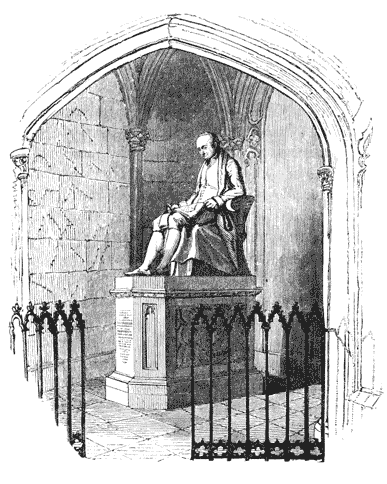

The mechanism by which these natural forces have been rendered so universally available as a moving power, is very various and complicated, and cannot be traced to one inventor. "If a watchmaker," says M. Arago, "well instructed in the history of his art, were required to give a categorical answer to the question, Who has invented watches? he would remain mute; but the question would be divested of much of its difficulty if he were required separately to declare who discovered the use of the main spring, the different forms of escapement, or the balance wheel." So it is with the steam engine. It is a combination of a great variety of contrivances, distinct from each other, which are the production of several inventors. If, however, one name more than the rest be entitled to special notice; if he is entitled to the chief credit of the invention who by the powers of his mechanical genius has imparted to the steam engine that form, and conferred upon it those qualities, on which mainly depends its present extensive utility, and by which it has become an agent of transcendant power, spreading its beneficial effects throughout every part of the civilised globe, then the universal voice will, as it were by acclamation, award the honour to one individual, whose pre-eminent genius places him far above all other competitors, and from the application of whose mental energies to this machine may be dated those grand effects which render it a topic of interest to all for whom the progress of civilisation has any attractions. Before the era rendered memorable by the discoveries of James Watt, the steam engine, which has since become an object of such universal interest, was a machine of extremely limited power, inferior in importance and usefulness to most other mechanical agents used as prime movers; but, from that epoch, it is scarcely necessary here to state, that it became a subject not of British interest only, but one having an important connection with the progress of the human race.

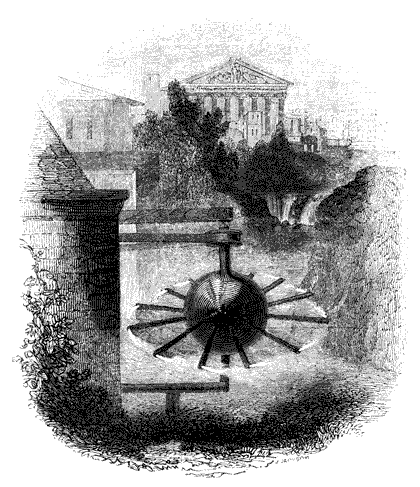

Hero of Alexandria, 120 B. C.

After having been allowed to slumber for nearly two thousand years, this machine has recently been revived, and engines constructed similar to it are now working in these countries. In the proper place we shall describe Avery's Rotatory Engine, which it will be seen is, not only in its principle, but almost in its details, the machine of Hero of Alexandria.

Although the elastic force of steam was not reduced to numerical measure by the ancients, nor brought under control, nor applied to any useful purpose, yet it appears to have been recognised in vague and general terms. Aristotle, Seneca, and other ancient writers, accounted for earthquakes by the sudden conversion of water into steam within the earth. This change, according to them, was effected by subterranean heat. Such tremendous effects being ascribed to steam, it can scarcely be doubted that the Greeks and Romans were acquainted with the fact, that water in passing into vapour exercises considerable mechanical power. They were aware that the earthquakes, which they ascribed to this cause, exerted forces sufficiently powerful to extend the natural limits of the ocean; to overturn from their foundations the most massive monuments of human labour; to raise islands in the midst of seas; and to heave up the surface of the land of level continents so as to form lofty mountains.

Such notions, however, resulted not as consequences of any exact or scientific principles, but from vague analogies derived from effects which could not fail to have been manifested in the arts, such as those which commonly occurred in the process of casting in metal the splendid statues which adorned the temples, gardens, and public places of Rome and Athens. The artisan was liable to the same accidents to which modern founders are exposed, produced by the casual presence of a little water in the mould into which the molten metal is poured. Under such circumstances, the sudden formation of steam of an extreme pressure produces, as is well known, explosions attended with destructive effects. The Grecian [Pg015] and Roman artisans were subject to such accidents; and the philosopher, generalising such a fact, would arrive at a solution of the grander class of phenomena of earthquakes and volcanoes.

Before natural phenomena are rendered subservient to purposes of utility, they are often made to minister to the objects of superstition. The power of steam is not an exception to this rule. It is recorded in the Chronicles, that upon the banks of the Weser the ancient Teutonic gods sometimes marked their displeasure by a sort of thunderbolt, which was immediately succeeded by a cloud that filled the temple. An image of the god Busterich, which was found in some excavations, clearly explains the manner in which this prodigy was accomplished by the priests. The head of the metal god was hollow, and contained within it a pot of water: the mouth, and another hole, above the forehead, were stopped by wooden plugs; a small stove, adroitly placed in a cavity of the head under the pot, contained charcoal, which, being lighted, gradually heated the liquid contained in the head. The vapour produced from the water, having acquired sufficient pressure, forced out the wooden plugs with a loud report, and they were immediately followed by two jets of steam, which formed a dense cloud round the god, and concealed him from his astonished worshippers.[1]

Among other amusing anecdotes showing the knowledge which the ancients had of the mechanical force of steam, it is related that Anthemius, the architect of Saint Sophia, occupied a house next door to that of Zeno, between whom and Anthemius there existed a feud. To annoy his neighbour, Anthemius placed on the ground floor of his own house several close digesters, or boilers, containing water. A flexible tube proceeded from the top of each of these, which was conducted through a hole made in the wall between the houses, and which communicated with the space under the floors of the rooms in the house of Zeno. When Anthemius desired to annoy his neighbour, he lighted fires under his boilers, and the steam produced by them rushed in such quantity and with [Pg016] such force under Zeno's floors, that they were made to heave with all the usual symptoms of an earthquake.[2]

Blasco de Garay, A. D. 1543.

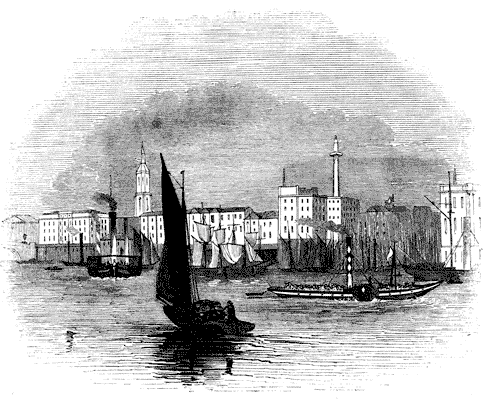

Blasco de Garay, a sea captain, proposed in that year to the Emperor Charles V. to propel vessels by a machine which he had invented, even in time of calm, without oars or sails. Notwithstanding the apparent improbability attending this project, the Emperor ordered the experiment to be made in the port of Barcelona, and the 17th of June, 1543, was the day appointed for its trial. The commissioners appointed by Charles V. to attend and witness the experiment were Don Henry of Toledo, Don Pedro of Cardona, the treasurer Ravago, the vice chancellor and intendant of Catalonia, and others. The vessel on which the experiment was made was the Trinity, 200 tons burthen, which had just discharged a cargo of corn at Barcelona. Garay concealed the nature of his machinery, even from the commissioners. All that could be discovered during the trial was, that it consisted of a large boiler containing water, and that wheels were attached to each side of the vessel, by the revolution of which it was propelled. The commissioners having witnessed the experiment, made a report to the king, approving generally of the invention, particularly on account of the ease and promptitude with which the vessel could be put about by it.

The treasurer Ravago, who was himself hostile to the project, reported that the machine was capable of propelling a vessel at the rate of two leagues in three hours; but the other commissioners stated that it made a league an hour at the least, and that it put the vessel about as speedily as would be accomplished with a galley worked according to the common [Pg017] method. Ravago reported that the machinery was too complicated and expensive, and that it was subject to the danger of the boiler bursting.

After the experiment was made, Garay took away all the machinery, leaving nothing but the framing of wood in the arsenals of Barcelona.

Notwithstanding the opposition of Ravago, the invention was approved, and the inventor was promoted and received a pecuniary reward, besides having all his expenses paid.

From the circumstance of the nature of the machinery having been concealed, it is impossible to say in what this machine consisted; but as a boiler was used, it is probable, though not certain, that steam was the agent. There have been various machines proposed, of which a furnace and boiler form a part, and in which the agency of steam is not used. The machine of Amontons furnishes an example of this. It is most probable that the contrivance of Garay was identical with that of Hero. The low state of the arts in Spain in the sixteenth century would be incompatible with the construction of any machine requiring great precision of execution. But the simplicity of Hero's contrivance would have rendered its construction and operation quite practicable. As to the claims to the invention of the steam engine advanced by the advocates of De Garay, founded on the above document, a refutation is supplied by the admission, that though he was rewarded and promoted by the government of the day, in consequence of the experiment, and although the great usefulness of the contrivance in towing ships out of port, &c., was admitted, yet it does not appear that a second experiment was ever tried, much less that the machine was ever brought into practical use.

Solomon de Caus, 1615.

The treatise commences with definitions of what were then considered the four elements: earth, air, fire, and water. Air is defined to be a cold, dry, and light element, capable of compression, by which it may be rendered very violent. He says, "The violence will be great when water exhales in air by means of fire, and that the said air is enclosed: as, for example, take a ball of copper of one or two feet diameter, and one inch thick, which being filled with water by a small hole, which shall be strongly stopped with a peg, so that neither air nor water can escape, it is certain that if we put the said ball upon a great fire, so that it will become very hot, that it will cause a compression so violent, that the ball will burst in pieces, with a noise like a petard."

The effect which is here described is due to the combined pressure of the heated air contained in the ball and the high pressure steam raised from the water, but much more to the latter than to the former. It is evident, however, from the language of De Caus, that he ascribes the force entirely to the air, and seems to consider that the force of the air proceeded from the water which exhaled in it.

The first theorem is, "that the parts of the elements mix together for a time, and then each returns to its place" (the elements here referred to being apparently air and water). Upon this subject the following is an example: "Take a round vessel of copper, soldered close on every side, and with a tube, whereof one end approaches nearly to the bottom of the vessel, and the other end, which projects on the outside of the vessel, has a stop-cock; there is also a hole in the top of the vessel, with a plug to stop it. If this vessel will contain three pots of water, then pour in one pot of water, and place the vessel on the fire about three or four minutes, leaving the hole open; then take the vessel off the [Pg019] fire, and a little after pour out the water at the hole, and it will be found that a part of the said water has been evaporated by the heat of the fire. Then pour in one pot of water as before, and stop up the hole and the cock, and put the vessel on the fire for the same time as before; then take it off, and let it cool of itself, without opening the plug, and after it is quite cold pour out the water, and it will be found exactly the same quantity as was put in. Thus we see that the water which was evaporated (the first time that the vessel was put on the fire) is returned into water the second time when that vapour has been shut up in the vessel, and cooled of itself."

In the description of these experiments, the processes of evaporation and condensation are obscurely indicated; but there is no intimation that the author possessed any knowledge of the elastic force of steam. His theorem is, that the parts of the element water mix for a time with the parts of the element air; that fire causes this mixture, and that on removing the fire, and dissipating the heat, then the parts of the water mixed with air return to their proper place, forming again part of the water. There is no indication of a change of property of the water in passing into vapour. It is difficult to conceive, if De Caus had been aware that the vapour of water possessed the same violent force which he distinctly and in terms ascribes to air, or if he had been aware that in effect the vapour of the water produced by the fire was a fluid, possessing exactly the same mechanical qualities, and producing the same mechanical effects as air, that he would not have expressed himself clearly on the subject.

He proceeds to give another demonstration that heat will cause the particles of water to mix with those of air.

"After having put the measure of water into the vessel, and shut the vent-hole, and opened the cock, put the vessel on the fire, and put the pot under the cock; then the water of the vessel, raising itself by the heat of the fire, will run out through the cock; but about one sixth or one eighth part of the water will not run out, because the violence of the vapour which causes the water to rise proceeds from the [Pg020] said water; which vapour goes out through the cock after the water with great violence. There is also another example in quicksilver, or mercury, which is a fluid mineral, but being heated by fire, exhales in vapour, and mixes with the air for a time; but after the said vapour is cooled, it returns to its first nature of quicksilver. The vapour of water is much lighter, and therefore it rises higher," &c. &c.

In this second demonstration there appears to be some obscure indication of the force of steam in the words "because of the violence of the vapour which causes the water to rise," &c.

The fifth theorem is the following:—

"Water will mount by the help of fire higher than its level," which is explained and proved in the following terms:—

"The third method of raising water is by the aid of fire. On this principle may be constructed various machines: I shall here describe one. Let a ball of copper marked A; well soldered in every part, to which is attached a tube and stop-cock marked D, by which water may be introduced; and also another tube marked B C, which will be soldered into the top of the ball, and the lower end C of which shall descend nearly to the bottom of the ball without touching it. Let the said ball be filled with water through the tube D, then shutting the stop-cock D, and opening the stop-cock in the vertical tube B C, let the ball be placed upon a fire the heat acting upon the said ball will cause the water to rise in the tube B C."

In the apparatus as here described, the space enclosed in the boiler above the surface of the water is filled with air. By the action of the fire, two effects are produced: first, the air enclosed above the water, being heated, acquires increased elasticity, and presses with a corresponding force on the surface of the water. By this means a column of water will be driven up the tube A B at such a height as will balance the elasticity of the heated air confined in the boiler; but besides [Pg021] this the water contained in the boiler being heated, will produce steam, which being mixed with air contained in the boiler, will likewise press with its proper elasticity on the surface of the water, and will combine with the air in raising a column of water in the tube A B. In the above description of the machine, the force which raises the water in the tube A B is ascribed to the fire, no mention being made of the water, or of the vapour or steam produced from it having any agency in raising the water in the tube A B.

Antecedently to the date of this invention, the effect of heat in increasing the elastic force of air was known, and so far as the above description goes, the whole operation might be ascribed to the air by a person having no knowledge whatever of the elasticity of steam. M. Arago, however, who, on the grounds of this passage in the work of De Caus, claims for him a share of the honour of the invention of the steam engine, contends that the agency of steam in this apparatus was perfectly known to De Caus, although no mention is made of steam in the above description, because in the second demonstration above quoted he uses the words, "the violence of the vapour which causes the water to rise proceeds from the said water; which vapour goes out from the cock after the water with great violence." By these words M. Arago considers that De Caus expresses the quality of elasticity proper to the vapour, and that the context justifies the inference, that to this elasticity he ascribed the elevation of the water in the tube C B.

There appears to be some uncertainty attending the birthplace of De Caus. In the Biographie Universelle he is said to have been born and to have died in Normandy. M. Arago assigns Dieppe, or its neighbourhood, as his birthplace.

There was another engineer and architect, Isaac De Caus, a native of Dieppe, who published a work in folio, entitled "Nouvelle Invention de Lever l'Eau plus haut que sa Source, avec quelque Machines mouvantes, par le Moyen de l'Eau, et un Discours de la Conduite d'Icelle." This volume is without a date, but from the nature of its contents it would appear to have been published before the work of Solomon De Caus already cited. The drawings and machines described in both [Pg022] are exactly the same; but the definitions and theorems quoted above on raising water by fire are not given in the work of Isaac. It seems, therefore, that Solomon De Caus re-published, with additions, the work of Isaac De Caus. From the same birthplace being assigned to both these authors, as well as from the similarity of their pursuits, it is likely they were members of the same family, and from their christian names they were probably Jews.

The work cited above, was dedicated to Louis XIII., and in the dedication Solomon De Caus calls himself the subject of that monarch; and in the privilege prefixed to the work he is designated, "Our well-beloved Solomon De Caus, master engineer, being at present in the service of our dear and well-beloved cousin, the Prince Elector Palatine, has made known to us," &c.—"we, desiring to gratify the said De Caus, he being our subject," &c.

It is therefore certain, whatever may have been the birthplace of De Caus, that he was at least a subject of France. The circumstance of his work being written in French, though published beyond the Rhine, is also an argument in favour of his being a native of that country.

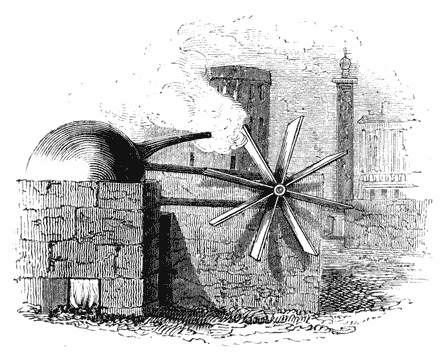

Giovanni Branca, 1629.

This method of applying the force of steam has no analogy to any application of steam in modern engines.

Edward Somerset, Marquis of Worcester, 1663.

Lord Worcester having been engaged on the side of the Royalists in the civil wars of the revolution, lost his fortune, and went to Ireland, where he was imprisoned. He escaped from thence, and reached France; from that country he ventured to London, as a secret agent of Charles II., but was detected, and imprisoned in the Tower, where he remained until the restoration, when he was set at liberty. Tradition has connected the invention of the steam engine with the following anecdote:—One day, during his imprisonment, Lord Worcester observed the lid of the pot in which his dinner was being cooked, suddenly forced upwards by the vapour of the water which was boiling in it. Reflecting on this, it occurred to him that the same force which raised the cover of the pot might be rendered, when properly applied, a useful and convenient moving power. After he recovered his liberty, he accordingly proceeded to carry into effect this conception. The contrivance to which he was ultimately led is described in the following terms in the sixty-eighth invention, in the work above named:—

"I have invented an admirable and forcible way to drive [Pg024] up water by fire; not by drawing or sucking it upwards, for that must be, as the philosopher terms it, infra sphœrum activitatis, which is but at such a distance. But this way hath no bounder if the vessels be strong enough. For I have taken a piece of whole cannon whereof the end was burst, and filled it three quarters full of water, stopping and screwing up the broken end, as also the touch-hole, and making a constant fire under it; within twenty-four hours, it burst and made a great crack. So that, having a way to make my vessels so that they are strengthened by the force within them, and the one to fill after the other, I have seen the water run like a constant fountain stream forty feet high. One vessel of water rarefied by fire driveth up forty of cold water, and a man that tends the work has but to turn two cocks; that one vessel of water being consumed, another begins to force and refill with cold water, and so successively; the fire being tended and kept constant, which the self-same person may likewise abundantly perform in the interim between the necessity of turning the said cocks."

Since the date of the publication of the "Century of Inventions" was the year 1663, the experiments here mentioned must have been made before that year. The description of the machine here given, as well as others in the same work, was intended by the author, not to convey a knowledge of the nature of the mechanism which he used, but only to express the effects produced, and to indicate the physical principle on which they depended. It should also be observed, that an air of mystery was thrown by Worcester over the accounts of all the machines which he described; and therefore any obscurity in the above description ought not to be regarded as an evidence against his claim to the discovery of the mechanical agency of steam, so far as that agency is indicated by the effects said by him to be produced. The above account is, however, sufficiently distinct and explicit to enable any one possessing a knowledge of the mechanical qualities of steam to perceive the general nature of the machine described. To render this machine, and that of De Caus, previously described, intelligible to those who are not familiar with physical science, we must here explain some general principles on which their agency depends. [Pg025]

These two species of fluids are each distinguished by peculiar mechanical properties.

Now let us suppose this solid mass of lead to be rendered liquid by being melted. The constituent particles will then be deprived of that cohesion by which they were held together; they will accordingly have a tendency to separate, and fall asunder by their gravity, and will only be prevented from actually doing so by the support afforded to them by the sides, [Pg026] A B, D C, of the vessel. They will therefore produce a pressure against the sides, which was not produced by the lead in its solid state. This pressure will vary at different depths: thus a part of the side of the vessel at P will receive a pressure proportional to the depth of the point P below the surface of the lead. If, for example, we take a square inch of the inner surface of the side of the vessel at P, it will sustain an outward pressure equal to the weight of a column of lead having a square inch for its base, and a height equal to P A. And, in like manner, every square inch of the sides of the vessel will sustain an outward pressure equal to the weight of a column of lead having a square inch for its base, and a height equal to the depth of the point below the surface of the lead.

Thus if we suppose any mechanical cause producing a pressure on the surface A D amounting to ten pounds on each square inch, the effect which would be produced, if the lead were solid, would be an additional pressure on the base B C amounting to ten pounds per square inch. But if the lead were liquid, besides this pressure on each square inch of the base B C, there would likewise be a pressure of ten pounds on every square inch of the sides of the vessel.

All that has been here stated with respect to a square or a cubical vessel will be equally applicable to a vessel of any other form. [Pg027]

If such a cover, or lid, had been placed upon a liquid, the cover would sustain no pressure from the fluid, nor would any mechanical effect be produced, save those already described in the case of the open vessel; but when the fluid contained in the vessel is elastic, as is the case with air, then the elasticity (by which name is expressed the tendency of the particles of the fluid to fly asunder) will produce peculiar mechanical effects, which have no existence whatever in the case of a liquid.

It is true that, supposing the fluid to be air or any other gas or vapour, a pressure will be produced upon the bottom B C of the vessel equivalent to the weight of such fluid, and lateral pressures will be produced on the different points of the sides by the weight of that part of the fluid which is above these points; but gases and vapours are bodies of such extreme levity, that these effects due to their weight are neglected in practice.

Putting, then, the weight of the air contained in the vessel out of the question, let us consider the effect of its elasticity. If the vessel, as already described, be supposed to contain atmospheric air in its ordinary state, the tendency of the constituent particles to fly asunder will be such as to produce on every square inch of the inner surface of the vessel [Pg028] a pressure amounting to fifteen pounds; this pressure being, as already stated, quite independent of the weight of the air. In fact, this pressure would continue to exist if the air contained in the vessel actually ceased to have weight by being removed from the neighbourhood of the earth, which is the cause of its gravity.

If the space within which an elastic fluid is enclosed be enlarged, its elasticity is found to diminish in the same proportion. Thus if the air contained in the vessel A B C D (fig. 3.) be allowed to pass into a vessel of twice the magnitude, the elasticity of the particles will cause them to repel each other, so that the same quantity of air shall diffuse itself throughout the larger vessel, assuming double its former bulk. Under such circumstances, the pressure which it would exert upon the sides of the larger vessel would be only half that which it had exerted on the sides of the smaller vessel. If, on the other hand, it were forced into a vessel of half the magnitude of A B C D, as it might be, then its elasticity would be double, and it would press on the inner surface of that vessel with twice the force with which it pressed on that of the vessel A B C D.

This power of swelling and contracting its dimensions according to the dimensions of the vessel in which it is confined, or to the force compressing it, is a quality which results immediately from elasticity, and is consequently one which is peculiar to the gases or elastic fluids, and does not at all appertain to liquids. If the liquid contained in the vessel A B C D were transferred to a vessel of twice the magnitude, it would only occupy half the capacity of that vessel, and it could not by any means be transferred, as we have supposed the air or gas to be, to a vessel of half the dimensions, since it is inelastic and incompressible.

This is a common property of all liquids. If they be exposed for a sufficient length of time to a sufficient degree of heat, they will always be converted into elastic fluids. These are usually distinguished from air and other permanent gases, which never are known to exist in the liquid form, by the term vapour, by which, therefore, must be understood an elastic fluid which at common temperatures exists in the liquid or solid state; by steam is expressed the vapour of water; and by gases, those elastic fluids which like air are never known—at least, under ordinary circumstances—to exist in any other but the elastic form.

These important physical circumstances are now only indicated in a general way. As we proceed with our account of the invention and improvement of the steam engine, they will be developed more fully and accurately.

In the case of the apparatus of De Caus (5.), the heat of the fire acting on the vessel D C (fig. 2.) will raise the temperature of the water contained in it, and also of the air confined within it above the surface of that water. This air, as it is increased in temperature, will also increase in elasticity; it will therefore press on the surface of the water with increased force, and will gradually force the water upwards in the tube; and this effect would continue until all the water in the vessel would be forced up the tube.

But at the same time that the heat acting on the vessel increases the temperature of the air above the water, it also produces a partial evaporation of the water, so that more or less steam is mixed with the air in the vessel above the surface [Pg031] of the water; and this steam possessing elasticity, unites with the air in pressing on the surface of the water, and in raising it in the tube.

Let us now revert to the brief account of the engine of the Marquis of Worcester, described in "The Century of Inventions." We collect from that description that the vessel in which the water was evaporated was separate from those which contained the water to be elevated; also that there were two vessels of the like description, the contents of which were alternately elevated by the pressure of the "water rarefied by the fire;" in other words by steam; and that the water was raised in an uninterrupted stream, by the management of two cocks communicating with these vessels and with the boiler. The following is such an apparatus as would answer this description. Let E (fig. 4.) be the vessel containing the water to be evaporated, placed over a proper furnace A; let S be a pipe to allow the steam produced from the boiling water in E to pass into the vessels where its mechanical action is required. Let R represent a cock or regulator, having in it a curved passage, leading from S to the tube T, when the lever or handle L is in the position represented by the cut; but leading to the tube T′, when the lever L is turned one quarter of a revolution to the right, as represented in fig. 5. By the shifting of this lever, therefore, the steam pipe S may be made to communicate alternately with the tubes T and T′. The tubes T and T′ are carried respectively to two vessels V and V′, which are filled with the water required to be raised. In these [Pg032] vessels tubes enter at C and C′, descending nearly to the bottom: these tubes have valves at B and B′, opening upwards, by which water will be allowed to pass into the vertical tube F, but which will not allow it to return downwards, the valves B and B′ being then closed by the weight of the water above them.

Let G G′ be a pipe entering the sides of the vessels V and V′, for the purpose of filling them with the water to be raised: let K be a cock having a curved passage similar to the cock R, and leading to a tube by which water is supplied from the reservoir or other source from which the water to be raised is drawn. When the cock K is placed as represented in fig. 4., the water from the reservoir will flow through the curved passage in the cock K into the tube G′, and thence into the vessel V′; but when this cock is turned one quarter round, by shifting the lever to the left, it will take the position represented in fig. 6., and the water will flow through the curved passage into the tube G, and thence into the vessel V. Let us now suppose the vessel V already filled with water to be elevated, and the vessel V′ to have discharged its contents. The cock R is turned, so as to allow the steam generated in the boiler E to pass into the tube T, and thence into the upper part of the vessel V, while the cock K is turned so as to allow the water from the reservoir to pass into the tube G′, and thence into the vessel V′. The steam collecting in the upper part of the vessel V′ presses with its elastic force on the surface of the water therein, and forces the water upwards in the tube C; it passes through the valve B, which it opens by the upward pressure received from the action of the steam, and thence into the tube F, its descent into the tube C′ being prevented by the valve V′, which can only be opened upwards. As the steam is gradually supplied from the boiler E, the water in the vessel V is forced up the tube C, through the valve B, and into the tube F, until all the contents of the vessel V above the lower end of the tube C have been raised. In the meanwhile, the vessel V′ has been filled with water, through the cock K: when this has been accomplished, the man who attends the machine shifts the cocks R and K, so as to give them the position represented in fig. 5. and fig. 6. [Pg033] In this position, the steam from the boiler, being excluded from the tube T, will be conducted to the tube T′, and thence to the vessel V′, while the water from the reservoir will be excluded from the tube G′, and conducted through the tube G to the vessel V. The vessel V will thus be replenished and, by a process similar to that already described, the contents of the vessel V′ will be forced up the tube C′, through the valve B′, and into the tube F; its descent into the tube C being prevented by the valve B, which will then be closed. After the contents of the vessel V′ have thus been raised, and the vessel V replenished, the two cocks R and K are once more shifted, and the contents of V raised while V′ is replenished, and so on.

If, having comprehended the apparatus here described, the reader refers to the description of the Marquis of Worcester's machine, he will find that all the conditions therein laid down are fulfilled by it. One vessel (E) of "water rarefied by fire" may by such means "drive up forty (or more) of cold water; and the man that tends the work has but to turn two cocks, that one vessel (V) of water being consumed, another (V′) begins to force and refill with cold water, and so on successively, the fire being tended and kept constant; which the self-same person may likewise abundantly perform, in the interim between the necessity of turning the said cocks."

On comparing this with the contrivance previously suggested by De Caus, it will be observed, that even if De Caus [Pg034] knew the physical agent by which the water was driven upwards in the apparatus described by him, still it was only a method of causing a vessel of boiling water to empty itself; and before a repetition of the process could be made, the vessel should be refilled, and again boiled. In the contrivance of Lord Worcester, on the other hand, the agency of the steam was employed in the same manner as it is in the steam engines of the present day, being generated in one vessel, and used for mechanical purposes in another. Nor must this distinction be regarded as trifling or insignificant, because on it depends the whole practicability of using steam as a mechanical agent. Had its action been confined to the vessel in which it was produced, it never could have been employed for any useful purpose.

Although many of the projects contained in Lord Worcester's work were in the highest degree extravagant and absurd, yet the engine above described is far from being the only practicable and useful invention proposed in it. On the contrary, many of his inventions have been reproduced, and some brought into general use since his time. Among these may be mentioned, stenography, telegraphs, floating baths, speaking statues, carriages from which horses can be disengaged if unruly, combination locks, secret escutcheons for locks, candle moulds, the rasping mill, the gravel engine, &c.

Sir Samuel Morland, 1683.

In 1680, Sir Samuel Morland was appointed Master [Pg035] of the Works to Charles II., and in the following year was sent to France, to execute some waterworks for Louis XIV. In 1683, while in France, he wrote in the French language, a work entitled "Elevation des Eaux par toute sorte de Machines, reduite à la Mesure, au Poids et à la Balance. Presentée à sa Majesté très Chrestienne, par le Chevalier Morland, Gentilhomme Ordinaire de la Chambre Privée, et Maistre des Méchaniques du Roi de la Grande Brétagne, 1683." This book is preserved in manuscript in the Harleian Collection in the British Museum. It is written on vellum, and consists of only thirty-eight pages. It contains tables of measures and weights, theorems for the calculation of the volumes of cylinders, the weights of columns of water, the thickness of lead for pipes, and is concluded by a chapter on steam, consisting of four pages, of which the following is a translation:—

"The principles of the new force of fire invented by Chevalier Morland in 1682, and presented to His Most Christian Majesty in 1683:—

"'Water being converted into vapour by the force of fire, these vapours shortly require a greater space (about 2000 times) than the water before occupied, and sooner than be constantly confined would split a piece of cannon. But being duly regulated according to the rules of statics, and by science reduced to measure, weight, and balance, then they bear their load peaceably (like good horses), and thus become of great use to mankind, particularly for raising water, according to the following table, which shows the number of pounds that may be raised 1800 times per hour to a height of six inches by cylinders half filled with water, as well as the different diameters and depths of the said cylinders.'"

There is nothing in the description here given which can indicate the form of the machine by which Morland proposed to render the force of steam a useful mover. It is, however, remarkable, that at this early period, before experiments had been made on the expansion which water undergoes in evaporation, he should have given so near an approximation to [Pg036] the actual amount of that expansion. It is scarcely supposable that such an estimate could be obtained by him otherwise than by experiment.

The work containing the above description was not printed; but a work bearing nearly the same title, containing, however, no mention of the force of steam, was published by him in Paris in the year 1685. In this he describes various experiments made by him at St. Germains on the weight of the water of the Seine, and gives weights of the columns of water, the contents of cylinders, &c.

Soon after the publication of this work, Morland returned to England, and resided near the court till his death. The celebrated John Evelyn mentioned having paid a visit to him at his house at Hammersmith, in 1695, when he had become aged and blind, but was still remarkable for his mechanical ingenuity. "On the 25th of October," says Evelyn, "the Archbishop and myself went to Hammersmith to visit Sir Samuel Morland, who was entirely blind; a very mortifying sight. He showed us his invention of writing (short-hand), which was very ingenious; also his wooden kalendar, which instructed him all by feeling; and other pretty and useful inventions of mills, pumps, &c.; and the pump he had erected, that serves water to his garden and to passengers, with an inscription, and brings from a filthy part of the Thames near it a most perfect and pure water."[3]

He died at Hammersmith, in January 1696; and before his death, as a penance for his past life, was guilty of the eccentricity of burying in the ground six feet deep a great collection of music which he possessed.[4]

Denis Papin, 1688.

Papin was born at Blois in France. He devoted his youth to the study of medicine, in which he took a degree at Paris. The revocation of the Edict of Nantes having driven him into exile, he went to England, where the celebrated Boyle associated him in several of his experiments with the air-pump, and caused him to be elected a fellow of the Royal Society in 1681. Having been invited to Germany by the Landgrave of Hesse, he discharged during several years the duties of professor of mathematics at the university of Marbourg, where he died in 1710. Notwithstanding his discoveries respecting the agency of steam, he never received any mark of distinction in his own country. The truth is, the importance and value of these investigations were not apparent until long afterwards.

This philosopher conceived the idea of producing a moving power by means of a piston working in a cylinder, in the manner which we shall now briefly explain.

Let A B (fig. 7.) be a cylinder open at the top, and let a piston P be fitted into it, so as to move in it air tight. At the bottom of the cylinder suppose an opening provided, which can be closed at pleasure, by a stop-cock, or otherwise, so that the communication may be opened and closed at will between the interior of the cylinder and the external air. This stop-cock being opened, let the piston be drawn upwards till it reach the top of the cylinder. Let the stop-cock at the bottom be then removed, and imagine that some means can be supplied by which the air within the cylinder can be suddenly annihilated. The piston, now at the top, will have above it the pressure of the atmosphere; and having no air below, it will be resisted in its descent by no force save that arising from its friction with the cylinder. If, then, the force of the air above the piston be greater than the resistance arising from this friction, the piston will descend with the excess of this force, and will continue so to descend until it reach the bottom of the cylinder. Having attained that position, let us [Pg038] suppose the stop-cock in the bottom opened, so as to allow the external air to pass freely below the piston. The piston may now be drawn to the top of the cylinder again, offering no resistance save that of its weight, and its friction with the cylinder. Having reached the top of the cylinder once more, let the stop-cock be closed, and the air included within the cylinder once more annihilated. A second descent of the piston will take place, with the same force as before, and in like manner the process may be continued indefinitely.

Now, if it should appear that means could be provided suddenly and repeatedly to annihilate the air within the cylinder, and that the pressure of the atmosphere above the piston should exert a force compared with which the weight of the piston and its friction are trifling, it is evident that a moving power would be obtained which would be capable, by proper mechanism, of being applied to any useful purpose, but which would more especially be applicable to the working of pumps, the motion of which corresponds with that which has been just ascribed to the piston in the cylinder. Such were the first ideas of Papin. But in order to enable those who are not conversant with physical science fully to appreciate their importance, it will be necessary here to explain some of the mechanical properties of atmospheric air.

A direct demonstration of this may be given by the following experiment:—On the mouth of a flask let a stop-cock be fastened so as to be air-tight. The interior of the flask may then be put into free communication with the external air, or that communication may be cut off at pleasure, by opening or closing the stop-cock. If a syringe be applied to the mouth of the flask, the stop-cock being open a part of the air contained in it may be drawn out. After this, the stop-cock being closed, and the syringe detached, let the flask be placed in the dish of a good balance, and accurately counterpoised by weights in the other dish. This counterpoise will then represent the weight of the flask, and of the air which has remained in it. If the stop-cock be now opened, air will immediately rush in, and replace that which the syringe had withdrawn from the flask; and immediately the dish of the balance containing the flask will sink by the effect of the weight of the air thus admitted into the flask.

If the weight of quantity of air so small as to be capable of being withdrawn by a syringe from an ordinary flask be thus of sensible amount, it may be easily imagined that the vast mass of atmosphere extending from the surface of the earth upwards, to a height not ascertained with precision, but certainly not being less than thirty miles, must be very considerable. Such a force, pressing as it must constantly do, upon the surfaces of all bodies, whether solid or fluid, and resisting and modifying their movements, would play an important part in all mechanical phenomena; and it is, therefore, not sufficient merely to have recognised its existence, but it is most needful to measure its amount with that degree of certainty and precision, which will enable us to estimate its effects on those phenomena which we shall have to investigate.

Take a glass tube, A B (fig. 8.), above 32 inches long, open at one end A, and closed at the other end B, and let it [Pg040] be filled with mercury (quicksilver). Let a glass vessel or cistern C, containing a quantity of mercury, be also provided. Applying the finger at A, so as to prevent the mercury in the tube from falling out, let the tube be inverted, and the end, stopped by the finger, plunged into the mercury in C. When the end of the tube is below the surface of the mercury in C (fig. 9.), let the finger be removed. It will be found that the mercury in the tube will not, as might be expected, fall to the level of the mercury in the cistern C, which it would do were the end B open, so as to admit the air into the upper part of the tube. On the other hand, the level D of the mercury in the tube will be nearly 30 inches above the level C of the mercury in the cistern.

The cause of this effect is, that the weight of the atmosphere rests on the surface C of the mercury in the cistern, and tends thereby to press it up, or rather to resist its fall in the tube; and as the fall is not assisted by the weight of the atmosphere on the surface D (since B is closed), it follows, that as much mercury remains suspended in the tube above the level C, as the weight of the atmosphere is able to support.

If the section of the tube were equal to the magnitude of a square inch, the weight of the column of mercury in the tube above the level C would be exactly equal to the weight of the atmosphere on each square inch of the surface C.

If the apparatus be transported to any height above its ordinary position, it will have a less quantity of atmosphere above it, and therefore the surface of the mercury in the cistern will be pressed by a less weight, and consequently the [Pg041] column of mercury will fall proportionally. In virtue of this effect, such an instrument has been rendered a means of measuring heights, such as the heights of mountains, the ascents of balloons, &c. &c.

Two cubic inches of mercury weigh very nearly one pound avoirdupois.[6] Hence, when the barometric column measures thirty inches, the weight of the atmosphere resting on each square inch of surface is about fifteen pounds.

Let four glass tubes, A, B, C, D (fig. 10.), be constructed of sufficient length, closed at one end, A, B, C, D, and open at the other. Let the open ends of three of them be bent, as represented in the tubes B, C, D. Being previously filled with mercury, let them all be gently inverted, so as to have their closed ends up, as here represented. It will be found that the mercury will be sustained in all, and that the difference of the levels in all will be the same.[7] Thus, the mercury is sustained in A by the upward pressure of the atmosphere; in B, by its horizontal or lateral pressure; in C, by its downward pressure; [Pg042] and in D, by its oblique pressure: and, as the difference of the levels is the same in all, these pressures are exactly equal.

In the experiments described in (21), the space D B in the top of the barometer-tube, from which the mercury descended, is a vacuum. If, however, it were occupied by a quantity of air in a rarefied state, or any other gas or vapour, such gas or vapour would press on the surface of the mercury at D, with a force determined by its elasticity. In that case, the atmospheric pressure acting on the surface of the mercury C in the cistern, would be balanced by the combined forces of the weight of the mercurial column sustained in the tube, and the elasticity of the gas or vapour in the upper part of it. Now if we know the actual amount of the atmospheric pressure,—that is to say, the height of the column of mercury which it would be capable of sustaining,—we should then be able to determine the pressure of the rarefied air in the space C D.

For example, let us suppose that the barometric column, when B D (fig. 9.) is a vacuum, measures thirty inches: the atmospheric pressure, therefore, would be equal to the weight of a column of mercury of that height. Let us suppose that the elasticity of the gas or vapour occupying the upper part of the tube D B causes the column to fall to the height of twenty-six inches: it is evident, then, that the pressure of the air in the top of the tube would be equal to the weight of a column of mercury of four inches. In fine, to determine the pressure of the rarefied gas or vapour in the top of the tube, it is only necessary to observe the difference between the height of the column of mercury actually sustained in the tube, and the column sustained at the same time and [Pg043] place in a common barometer: the difference of the two will be the column of mercury whose weight will represent the pressure of the vapour or gas in the top of the tube.

It is by such means that water is raised in an ordinary pump. A portion of the air contained between the piston of the pump and the surface of the water below, is withdrawn by the action of the piston, and the pressure of the air remaining under the piston is thereby diminished. The superior pressure of the atmosphere upon the external surface of the water in the well then forces up a column of water in the pump-barrel, and this is continued as the air is more and more rarefied by the action of the piston. By whatever means, therefore, the air can be wholly or partially withdrawn from any space, a mechanical power will be thereby developed, proportional in its amount and efficacy to the quantity of air so withdrawn. If, however, such air be withdrawn by any mechanical process, such as by a syringe, by a common pump, or by an air-pump, the quantity of force expended in withdrawing it is always equivalent to the amount of mechanical power obtained by the vacuum or partial vacuum so produced. Indeed the power expended is greater than the power so obtained, inasmuch as the friction, leakage, &c. of the exhausting apparatus must be allowed for.

The process of filling thermometers with mercury shows one use of producing a high degree of rarefaction by heat. To construct the instrument it is necessary to fill the bulb and a part of the tube with mercury; but the bore of the tube is so small that the mercury cannot be introduced by any ordinary means. It is therefore held over flame until heated to a high temperature. The air within it gradually increasing in pressure as its temperature is raised, is forced through the small bore of the tube, until the pressure of the air within becomes no more than equal to the pressure of the external atmosphere; this air being so rarefied that quantity in the bulb bears a very small proportion to its contents at common temperatures. The mouth of the tube is then plunged into mercury, and as the bulb cools, the air within it loses its elasticity, and the superior pressure upon the external surface forces the mercury into the tube. This continues until the air remaining within the bulb has been so contracted, that its pressure combined with the weight of the mercury, shall balance the atmospheric pressure. The tube is then reversed, and the air which remained rises in a bubble to the surface, and escapes.

It is, however, apparent, from what has been already explained, that such a method of proceeding would amount to a mere transfer of power, and would not, properly speaking, be itself a moving force: the moving power would, in reality, be the force of the water by which the water-wheel would be driven; and the air-pumps, tubes, together with the piston and cylinder, would be merely means of conveying the power of the water-wheel to the objects to be moved, or the machinery to be driven. Papin states, that, long before this, he had attempted to expel the air from his cylinder by means of gunpowder; but, notwithstanding all the precautions which he could take, there always remained a considerable quantity; so much, indeed, as to deprive the vacuum of more than half its proper force. At length he adopted an expedient for the production of a vacuum which forms a most important step in the progressive invention of the steam engine, and which gives to Papin's name a high place in the history of that machine. This method is explained in the following paragraph of a work published by Papin in 1695, at Cassel, entitled "Recueil de diverses Pièces touchant quelques nouvelles Machines", p. 53.

"I have endeavoured," says he, "to attain this end (viz. the production of a vacuum in the cylinder) in another way. As water has the property of elasticity, when converted into steam by heat, and afterwards of being so completely recondensed by cold, that there does not remain the least [Pg046] appearance of this elasticity, I have thought that it would not be difficult to work machines in which, by means of a moderate heat and at a small cost, water might produce that perfect vacuum which has vainly been sought by means of gunpowder."

This remarkable passage is given in the work just cited, as an extract from the "Leipsic Acts," of August, 1690.

Let us pause here to explain more fully this important discovery.

In accordance with these ideas, Papin constructed a model consisting of a small cylinder, in which was placed a solid piston; [Pg047] and in the bottom of the cylinder under the piston was contained in a small quantity of water. The piston being in immediate contact with this water, so as to exclude the atmospheric air, on applying fire to the bottom of the cylinder, steam was produced, the elastic force of which raised the piston to the top of the cylinder; the fire being then removed, and the cylinder being cooled by the surrounding air, the steam was condensed and reconverted into water, leaving a vacuum in the cylinder into which the piston was pressed by the force of the atmosphere. The fire being applied and subsequently removed, another ascent and descent were accomplished; and in the same manner the alternate motion of the piston might be continued. Papin described no other form of machine by which this property could be rendered available in practice; but he states generally, that the same end may be attained by various forms of machines easy to be imagined.[8]

Thomas Savery, 1698.

Savery appears to have been ignorant of the publication of Papin, and stated that his discovery of the condensing principle arose from the following circumstance:—

Having drunk a flask of Florence at a tavern, and flung the empty flask on the fire, he called for a basin of water to wash his hands. A small quantity which remained in the flask began to boil, and steam issued from its mouth. It occurred to him to try what effect would be produced by inverting the flask and plunging its mouth in the cold water. Putting on a thick glove to defend his hand from the heat, he seized the [Pg048] flask, and the moment he plunged its mouth in the water the liquid immediately rushed up into the flask and filled it.

Savery stated that this circumstance immediately suggested to him the possibility of giving effect to the atmospheric pressure by creating a vacuum in this manner. He thought that if, instead of exhausting the barrel of a pump by the usual laborious method of a piston and sucker, it was exhausted by first filling it with steam, and then condensing the same steam, the atmospheric pressure would force the water from the well into the pump-barrel, and into any vessel connected with it, provided that vessel were not more than about thirty-four feet above the elevation of the water in the well. He perceived also, that, having lifted the water to this height, he might use the elastic force of steam in the manner described by the Marquis of Worcester to raise the same water to a still greater elevation, and that the same steam which accomplished this mechanical effect would serve, by its subsequent condensation, to reproduce the vacuum, and draw up more water. It was on this principle that Savery constructed the first engine in which steam was ever brought into practical operation.

[1] Arago, Eloge historique de James Watt; p. 22.

[2] Ibid., p. 21. note.

[3] Farey, Treatise on the Steam Engine, p. 93.

[4] Arago, sur les Machines à Vapeur, Annuaire, 1829, p. 165

[5] Spiritus, breath or air.

[6] Exactly 15·68 oz. = 0·98 lb.

[7] This experiment with the tube A requires to be very carefully executed, and the tube should be one of small bore.

[8] Recueil de diverses Pièces touchant quelques nouvelles Machines, p. 38.

ENGINES OF SAVERY AND NEWCOMEN.

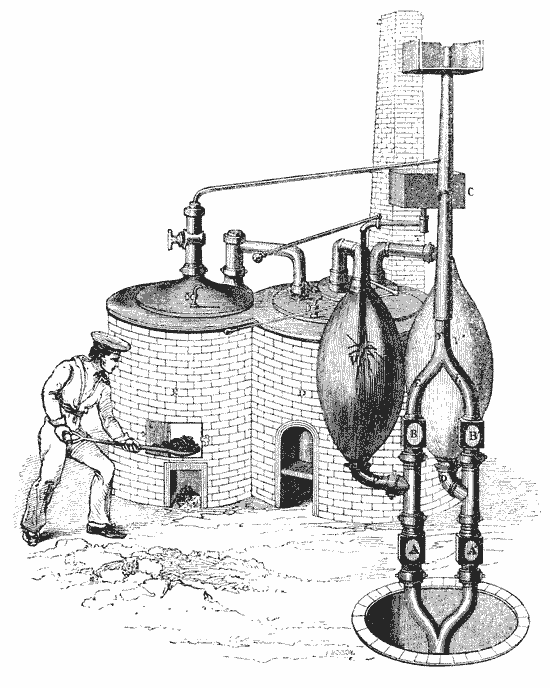

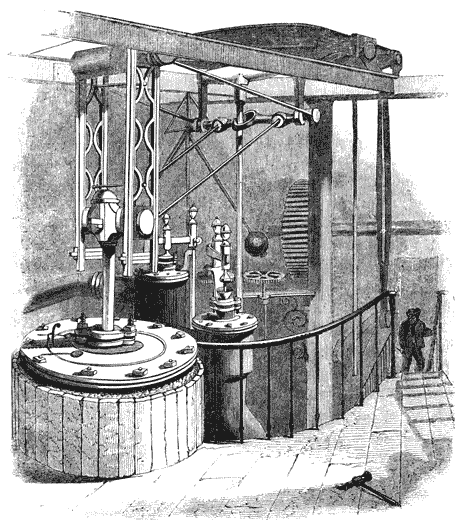

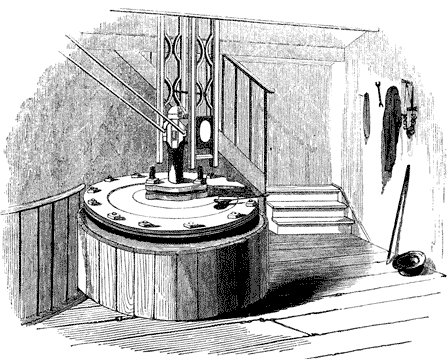

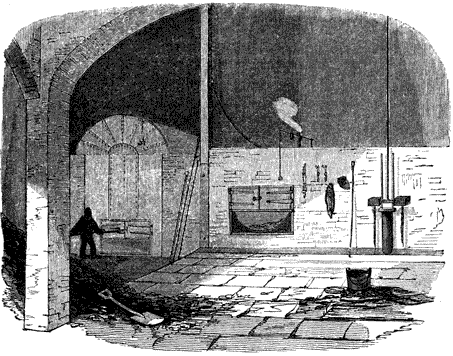

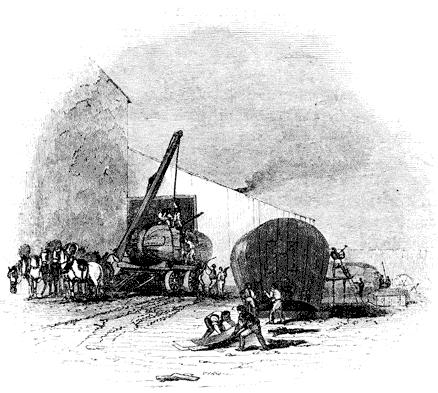

The former apparatus in Savery's engine consists of two strong boilers, sections of which are represented at D and E in fig. 11.; D the greater boiler, and E the less. The tubes T and T′ communicate with the working apparatus, which we shall presently describe. A thin plate of metal R, is applied closely to the top of the great boiler D, turning on a centre C, so that by moving a lever applied to the axis C on the outside of the top, the sliding plate R can be brought from the mouth of the one tube to the mouth of the other alternately. This sliding valve is called the regulator, since it is by it that the communications between the boiler and two steam vessels (hereafter described) are alternately opened and closed, the lever which effects this being moved at intervals by the hand of the attendant.

Two gauge cocks are represented at G, G′, the use of which is to determine the depth of water in the boiler. One, G, has its lower aperture a little above the proper depth; and the other, G′, a little below it. Cocks are attached to the upper ends G, G′, which can be opened or closed at pleasure. The steam collected in the top of the boiler pressing on the surface of the water, forces it up in the tubes G, G′, if their lower ends be immersed. Upon opening the cocks G, G′, if water be forced from both, there is too much water in the boiler, since the mouth of G is below its level. If steam issue from both, there is too little water in the boiler, since the mouth of G′ is above its level. But if steam issue from G, and water from G′, the water in the boiler is at its proper level. This ingenious contrivance for determining the level of the water in the boiler is the invention of Savery, and is used in many instances at the present day.

The mouth of the pipe G should be at a level of a little less [Pg051] than one third of the whole depth, and the mouth of G′ at a level little lower than one third; for it is requisite that about two thirds of the boiler should be kept filled with water. The tube I forms a communication between the greater boiler D and the lesser or feeding boiler E, descending nearly to the bottom of it. This communication can be opened and closed at pleasure by the cock K. A gauge pipe is inserted similar to G, G′, but extending nearly to the bottom. From this boiler a tube F extends, which is continued to a cistern C (fig. 12.), and a cock is placed at M, which, when opened, allows the water from the cistern to flow into the feeding boiler E, and which is closed when that boiler is filled. The manner in which this cistern is supplied will be described hereafter.

Let us now suppose that the principal boiler is filled to the level between the gauge pipes, and that the subsidiary boiler is nearly full of water, the cock K and the gauge cocks G G′ being all closed. The fire being lighted beneath D, and the water boiled, steam is produced, and is transmitted through one or other of the tubes T, T′, to the working apparatus. When evaporation has reduced the water in D below the level of G′, it will be necessary to replenish the boiler D. This is effected thus:—A fire being lighted beneath the feeding boiler E, steam is produced in it above the surface of the water, which, having no escape, presses on the surface so as to force it up in the pipe I. The cock K being then opened, the boiling water is forced into the principal boiler D, into which it is allowed to flow until water issues from the gauge cock G′. When this takes place, the cock K is closed, and the fire removed from E until the great boiler again wants replenishing. When the feeding boiler E has been exhausted, it is replenished from the cistern C (fig. 12.), through the pipe F, by opening the cock M.

Let V V′ (fig. 12.) be two steam vessels communicating by the tubes T T′ (marked by the same letters in fig. 11.) with the greater boiler D.

Let S be a pipe, called the suction pipe, descending into [Pg052] the well or reservoir from which the water is to be raised, and communicating with each of the steam vessels through tubes D D′, by valves A A′, which open upwards. Let F be a pipe continued from the level of the engine to whatever higher level it is intended to elevate the water. The steam vessels V V′ communicate with the force-pipe F by valves B B′, which open upwards, through the tubes E E′. Over the steam vessels and on the force-pipe is placed a small cistern C, already mentioned, which is kept filled with cold water from the force-pipe, and from the bottom of which proceeds a pipe terminated with a cock G. This is called the condensing pipe, and can be brought alternately over each steam vessel. From this cistern another pipe communicates with the feeding boiler (fig. 11.), by the cock M.[9]

The communication of the pipes T T′ with the boiler can be opened and closed alternately, by the regulator R (fig. 11.), already described.