Title: The Library of Work and Play: Working in Metals

Author: Charles Conrad Sleffel

Release date: February 24, 2014 [eBook #45004]

Most recently updated: October 24, 2024

Language: English

Credits: Produced by Chris Curnow, Chris Jordan and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

book was produced from images made available by the

HathiTrust Digital Library.)

| Carpentry and Woodwork |

| By Edwin W. Foster |

| Electricity and Its Everyday Uses |

| By John F. Woodhull, Ph.D. |

| Gardening and Farming |

| By Ellen Eddy Shaw |

| Home Decoration |

| By Charles Franklin Warner, Sc.D. |

| Housekeeping |

| By Elizabeth Hale Gilman |

| Mechanics, Indoors and Out |

| By Fred T. Hodgson |

| Needlecraft |

| By Effie Archer Archer |

| Outdoor Sports, and Games |

| By Claude H. Miller, Ph.B. |

| Outdoor Work |

| By Mary Rogers Miller |

| Working in Metals |

| By Charles Conrad Sleffel |

WORKING IN METALS

By CHARLES CONRAD SLEFFEL

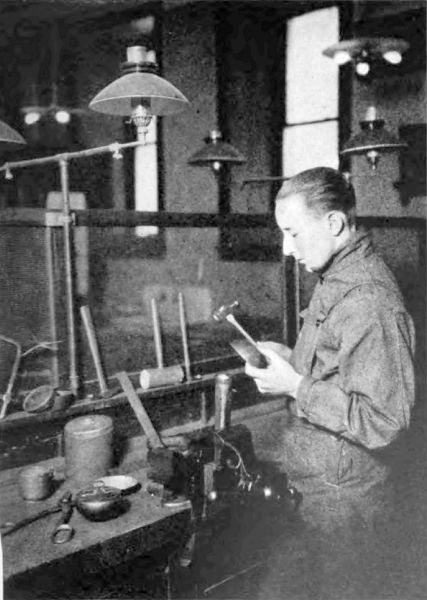

Wide Experience in Practical Shop Work and for 12 years Instructor in Metal Work at the Horace Mann School, Teachers' College, New York

Garden City New York

DOUBLEDAY, PAGE & COMPANY

1916

ALL RIGHTS RESERVED, INCLUDING THAT OF TRANSLATION INTO FOREIGN LANGUAGES, INCLUDING THE SCANDINAVIAN

COPYRIGHT, 1911, BY DOUBLEDAY, PAGE & COMPANY

The publishers wish to acknowledge their indebtedness to the Teachers College of Columbia University for their courtesy in permitting certain of the photographs to be taken for this volume.

PART I

| CHAPTER | PAGE | |

| I. | Introductory | 3 |

| II. | Tools | 5 |

| WORK IN COPPER | ||

| III. | How to Make a Copper Bowl | 19 |

| IV. | Copper Trays | 26 |

| V. | Paper Cutter and Nut Set | 34 |

| VI. | Hard and Soft Soldering | 41 |

| VII. | Candlestick, Sconce, Rose Jar, and Chalice | 47 |

| VIII. | How to Make a Hat Pin | 64 |

| IX. | How to Rivet | 73 |

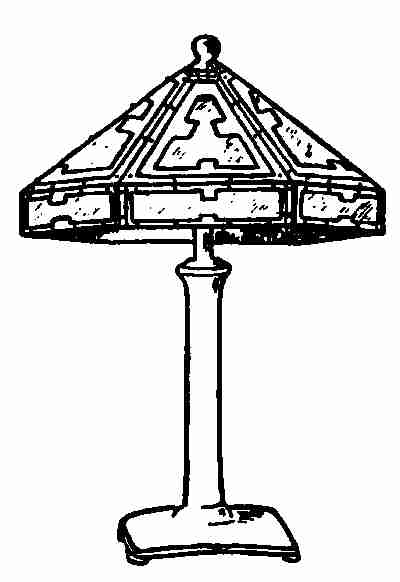

| X. | Lamp (for Electricity), with Shade | 92 |

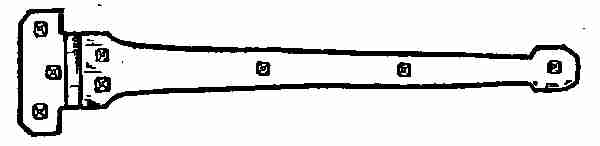

| XI. | Hinges in Copper or Silver | 100 |

| XII. | Jewel Box and Desk Set | 107 |

| BRASS WORK | ||

| XIII. | Finger Bowl, Crumb Tray, Tea Caddy, Vase, Bell and Bracket, Drawer Pulls, etc. | 133 |

| SILVER WORK | ||

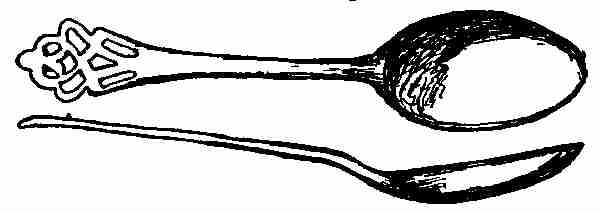

| XIV. | Finger Rings and Scarf Pins | 151 |

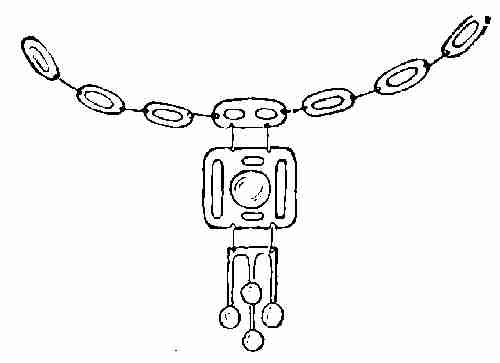

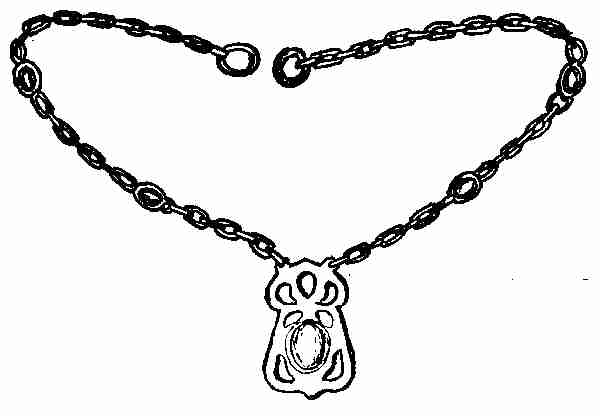

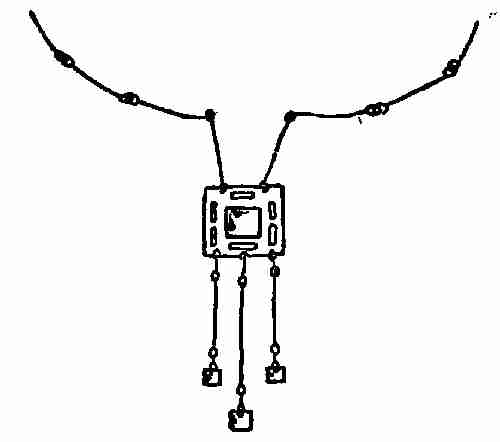

| XV. | Necklaces, Brooches, Bracelets | 166 |

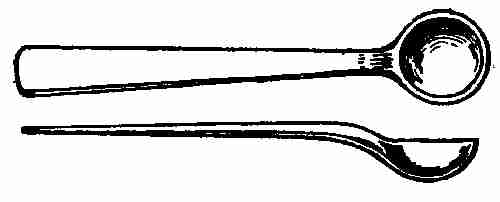

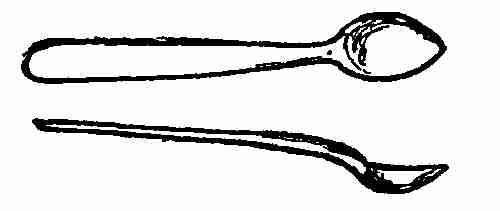

| XVI. | Spoons and Picture Frame | 178 |

| XVII. | Watch Fobs | 187 |

| XVIII. | Napkin Rings, Silver Comb, Belt Buckles | 191 |

| XIX. | Enamelling | 197 |

| THE BLACKSMITH'S SHOP | ||

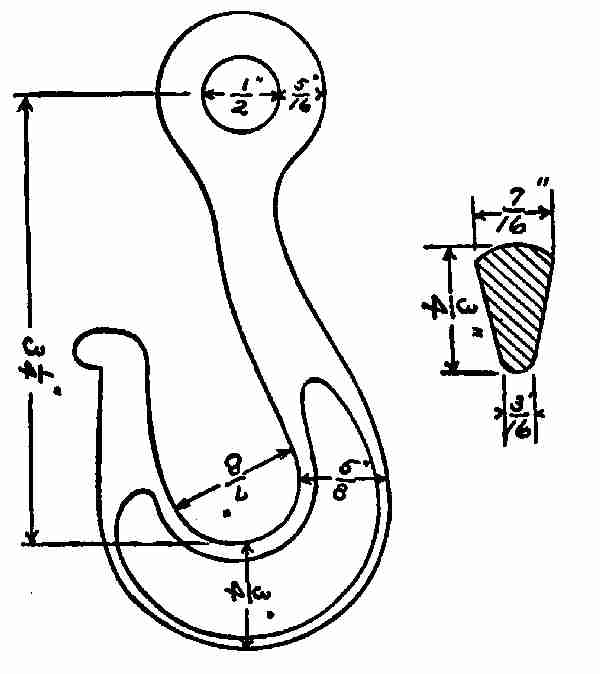

| XX. | Blacksmithing and Tools | 215 |

| XXI. | First Problems in Forging | 233 |

| XXII. | Welding | 247 |

| XXIII. | Mild Steel or Soft Steel | 264 |

| XXIV. | Hardening and Tempering. Tool Making | 289 |

| XXV. | How to Harden, Soften and Stretch Steel | 307 |

| XXVI. | Forging Hand Hammers | 316 |

| XXVII. | Some General Forging Problems | 327 |

| ORNAMENTAL IRON WORK | ||

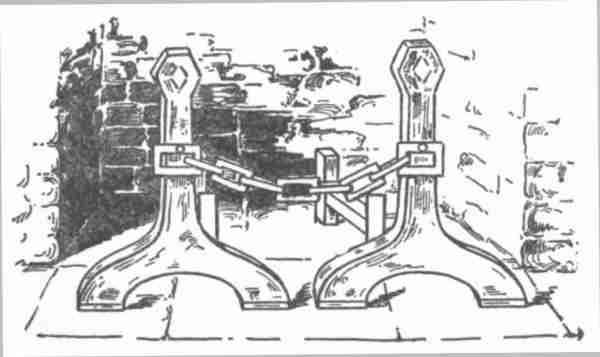

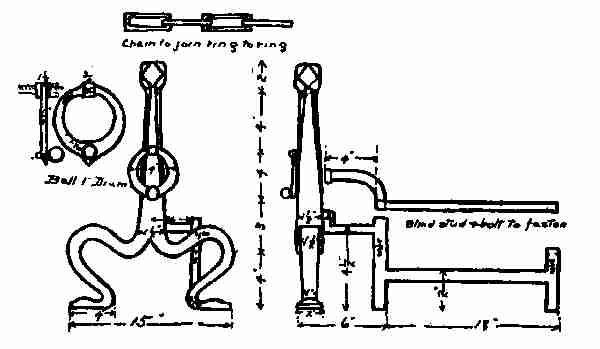

| XXVIII. | Processes, Andirons, Fire Tools | 361 |

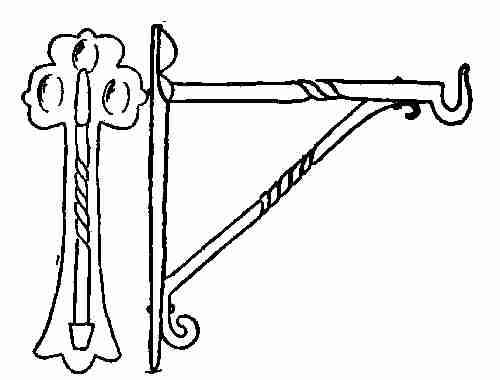

| XXIX. | Candlesticks, Hinges, Iron Brackets | 380 |

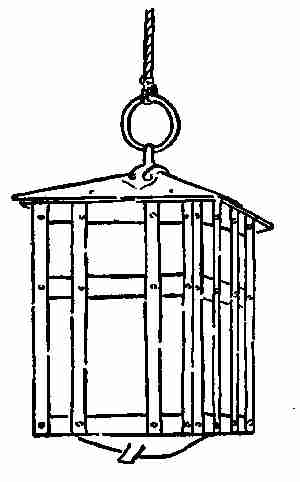

| XXX. | Lamps, Lanterns, Iron Kettle Stand, Umbrella Stand | 396 |

| XXXI. | Door Knockers, Plates, Handles, etc. | 410 |

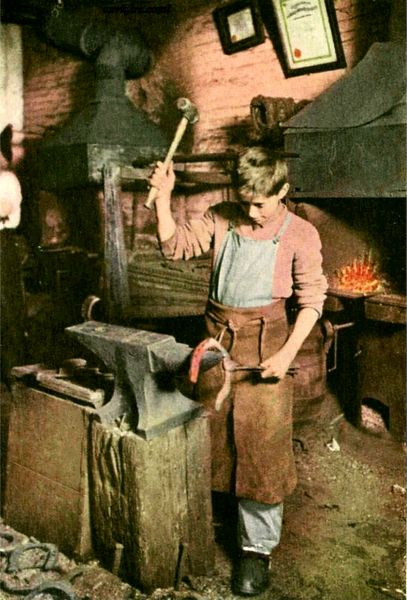

| Even a Boy Can Learn How to Make a Horseshoe | Frontispiece |

| FACING PAGE | |

| A Boy's Workshop | 14 |

| A Group of Boys at Copper Work | 66 |

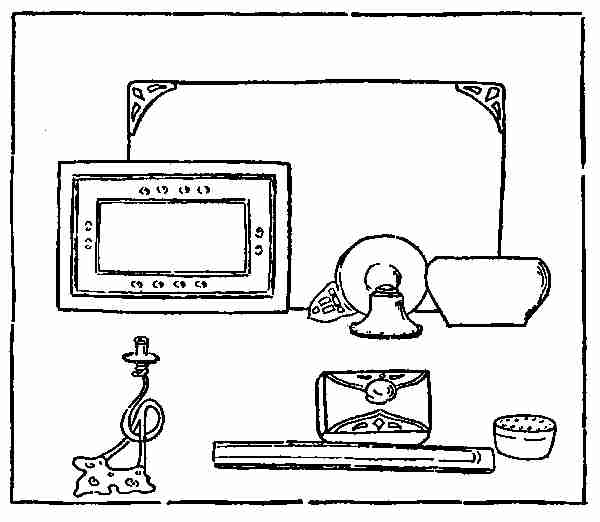

| Some Problems in Copper and Brass Work Made by Boys | 142 |

| Boys from Eleven to Fourteen Years of Age Doing Metal Work in the Country | 194 |

| Splitting and Shaping the Iron in the Making of Andirons | 362 |

| Finishing of an Ornamental Window Grill, and Levelling up of an Old Dutch Candlestick | 388 |

| Making an Iron Lamp | 396 |

| Ornamental Work and the Straightening and Finishing of an Umbrella Stand | 408 |

What a pretty copper box, John. Where did you get it?"

"I made it."

"You made it?"

"Yes, out of sheet copper in my room last night. That's the way I spend my evenings. And such fun as it is! I enjoy every minute of the time. Mother says I'd work all night if she didn't stop me.

"I'd like to do something like that. Do you think I could learn to do it?"

"I'm sure you could. Do you know the blacksmith around the corner? He taught me how to do this work, and ever so much more. He got me the tools, too. He says every boy can learn to work with metals, so I thought I'd try it. I'll take you around to see him sometime. Come up to my room and I'll show my workshop and all the tools I use."

"It would be mighty nice to know how to do something else besides running an elevator all day.[4] I get so tired of that. How long would it take me to make a box like this one?"

"Not very long if you begin in the right way. I've worked at it only since I left school. The manual training I got there helped me to know how to handle the tools. You had that training, too, and I know it will help you. Here we are, this is my workshop and bedroom. Let's work here together and I'll teach you all I know: how to use the tools and just what to do."

So began two boys to do work that one had done—metal work which any boy can do if he will but take the trouble to get the tools and have the patience to learn the way step by step.

"You don't need a large room for your workshop, you see," said John. "The table here is my work bench and all the tools can be put into a box out of the way when you are not using them.

"Here are my sketches of the tools one needs to make almost anything out of copper, brass, or silver. The blacksmith made the drawings for me and taught me how to make some of the tools myself. He says every boy should learn to make his own tools and I shan't be satisfied until I can make them all. Then I can make them as I need them and only those that fit the work best. But I had to buy most of them to start with. Here they are."

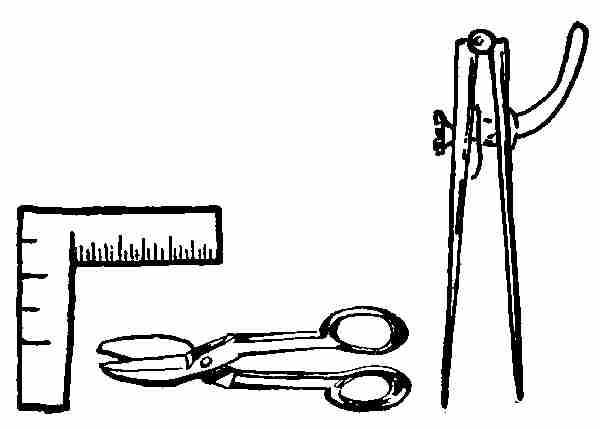

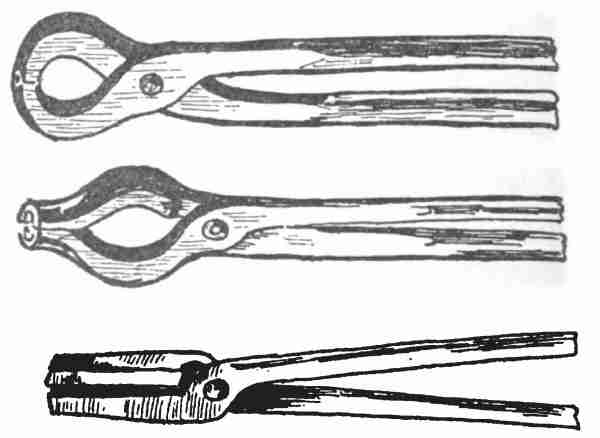

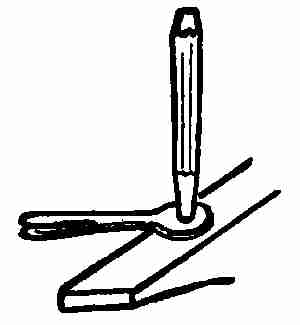

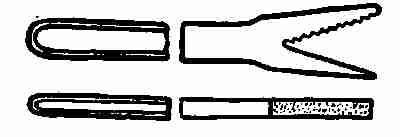

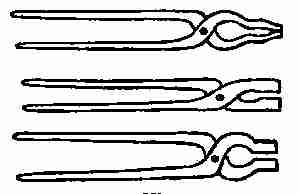

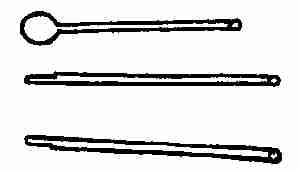

These are my shears. They are sometimes called jewellers' snips. I use them for cutting copper, wire, and my designs. You can buy them at any hardware store. But be sure to get a good pair, as they are needed for so many things.

I do all my measuring with a steel square. You see it takes the place of a two-foot rule. It's useful for squaring up, too. See, it has the 1⁄16, 1⁄4, 1⁄2, 3⁄4, and 1-in. spaces.

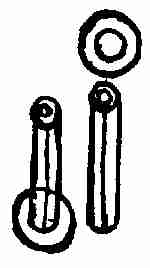

My dividers are my compasses. I draw circles, mark pieces, and find centres with them.[6] The pliers are used to twist the binding wire and to hold the metal when it is to be heated, or soldered, etc.

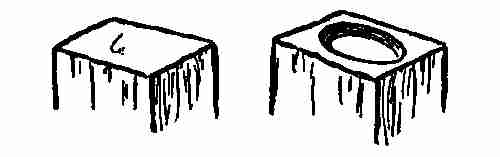

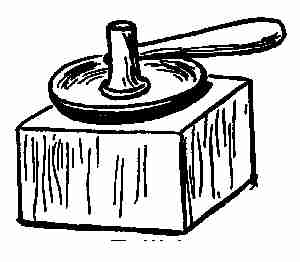

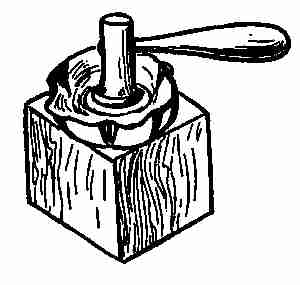

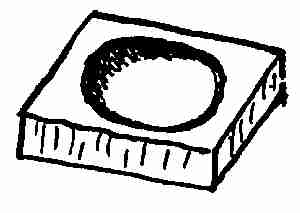

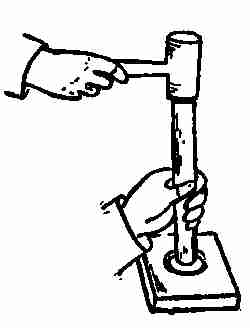

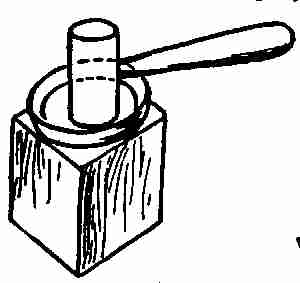

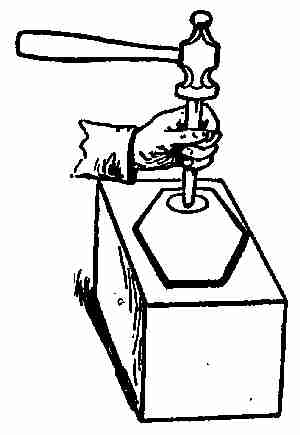

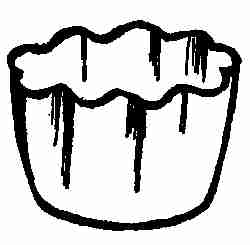

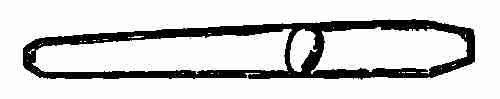

You can get a wooden block like this anywhere. Hard wood is best. This block is 6 × 4 × 4 ins. You see, I cut out a hollow bowl-shaped place in the top. When I want to work a flat piece of copper into a rough bowl shape, I hammer it into the depression. The opposite end of the block, which is flat, is useful in many ways, too.

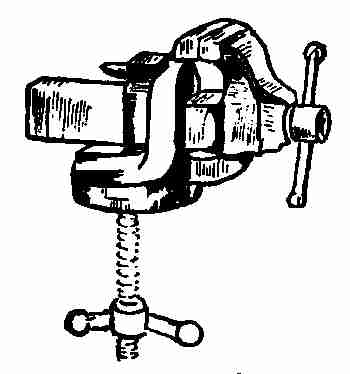

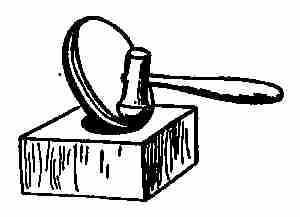

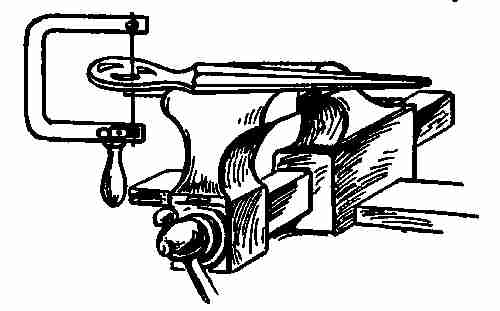

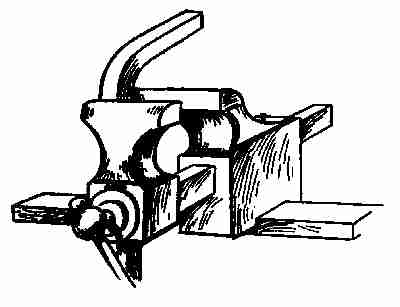

I couldn't get along without my bench vise. Here it is; made of metal. It can be fastened to a table as well as to a bench. It holds any tool used for shaping and also the metal when I wish to file it.[7]

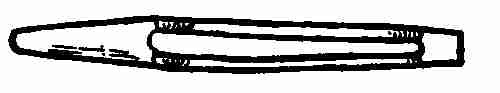

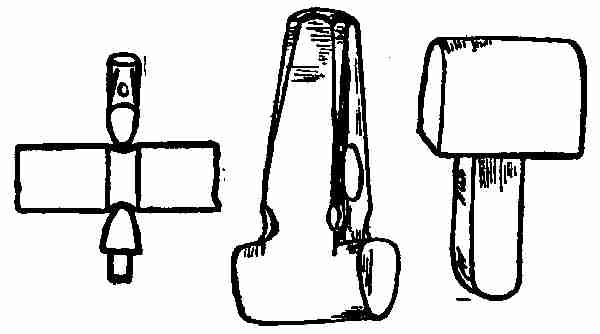

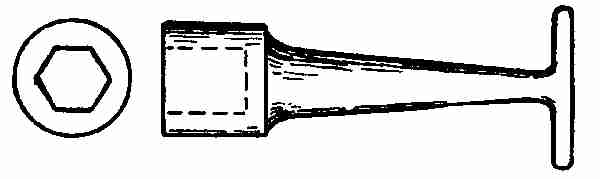

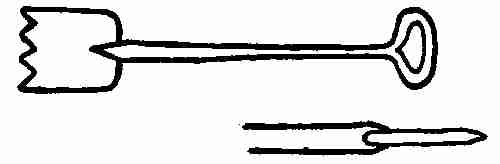

This piece of 3⁄8-in. hexagonal steel, 5 in. long, tapered at one end down to 1⁄16-in., is a punch for making or pressing holes in copper or silver. The size of the hole depends upon the length you drive the punch into the metal.

The centre-punch is made like this one, but the end is ground to a point.

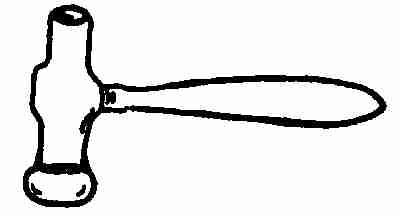

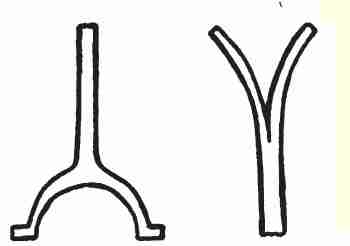

Here are my hammers. I have three and a wooden mallet. The raising hammer is used for many things which you will learn as you get on. You see one end is somewhat rounded. You can pound away on the copper with this hammer and have no fear of driving holes into the metal. It's the first hammer I use to shape up the metal bowl with.

The shaping or driving hammer is flat at one end[8] and rounded at the other. Its bent head is shaped so that you can use it in places where a straight headed hammer won't go. It's the only hammer to use when you work on the outside of boxes or bowls to shape them up.

Sometimes lumps are left on the surface of the copper after the raising hammer has been used. These are smoothed away with the planishing hammer. Its broad end flattens these rough places and makes the surface perfectly level before going on with the work.

A wooden mallet is often used in place of the heavier hammer. If a light stroke is needed it can be used without danger[9] of marring the metal, as wood is so much softer than the metal itself.

You'll need some files to reduce the metal to certain sizes. I have four: a bastard, 12-in.; a mill cut, 8-in.; a half round mill cut, and one round 1⁄2-in. mill cut. Then I have one half dozen jewellers' files of different sizes. Supply houses will always tell you the best kind to buy.

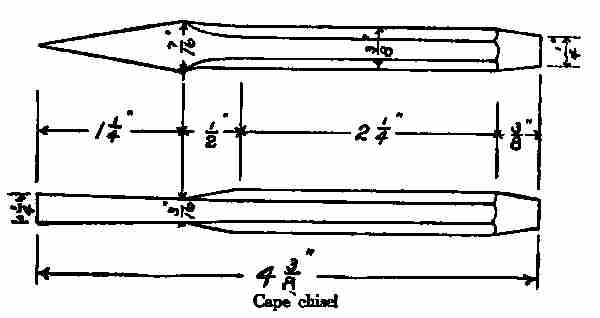

The cold chisel is used in many places for cutting off material, especially for metals that are too heavy for the shears.

A carpenter's gouge chisel will be found useful for cutting impressions in wooden blocks.

The drill press is used to bore holes into the copper or silver when you wish to rivet or saw. You will need a half dozen drills for your work. The 1⁄16-in. drills are the size I like best.

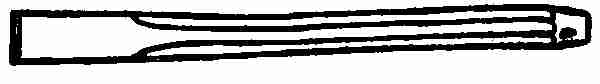

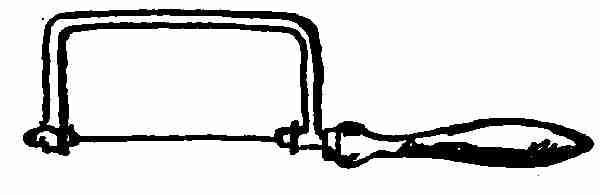

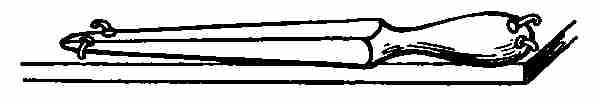

With a jewellers' saw frame like this[10] you can cut any design out of copper or silver. The fine saws are very cheap and one will last you a long time if you take care of it.

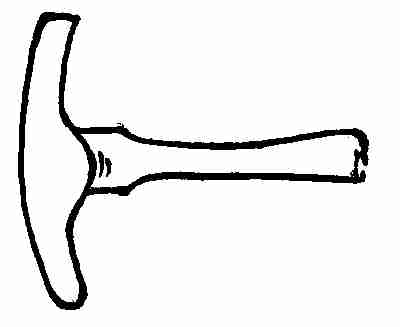

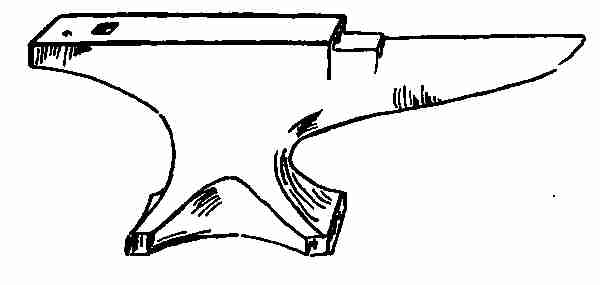

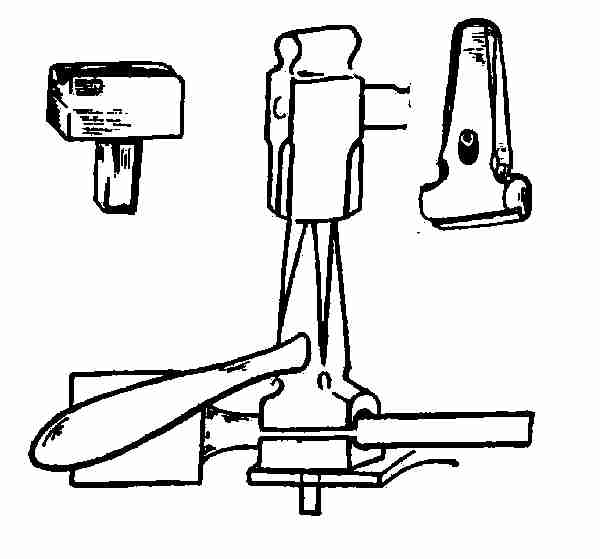

Here are the tools I use to finish shaping my bowls on. This round top stake is put into my bench vise, where it is held tight. Then I put my bowl on it after I have shaped it as much as I can on the hard wood block. I can then go on shaping it as I choose, but if the bowl is very deep you must use the anvil stake instead of the round top stake.

Here is a tool which is a combination of anvil[11] stake and riveting tool. I use it for drawing out pieces of copper into different shapes; flattening round pieces, rounding up flat ones, and for riveting pieces of metal together, as you must do when you make a piece of work like my box.

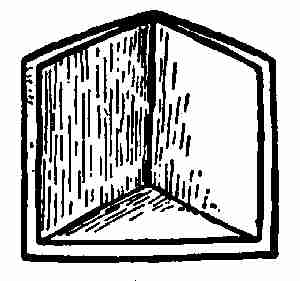

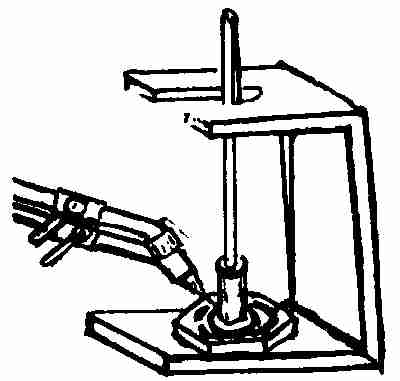

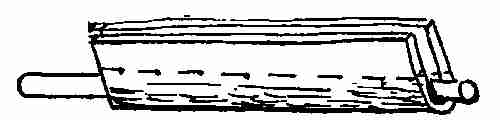

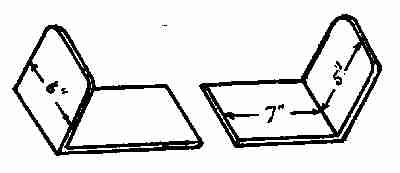

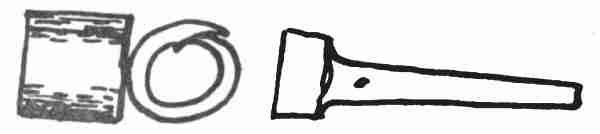

Here is a little fire screen I made myself. You need one, you know, to put your metal in, at times, for annealing and soldering. It's a safe way to prevent the blaze burning the table or setting fire to anything. I take two pieces of board, each 6 × 12 × 7⁄8 ins. (any kind of lumber will do). Nail the two 12-in. edges of the boards together, at right angles to each other. Nail this to a base and line the whole inside with asbestos. You can place any piece of metal you wish to heat in this corner and direct a flame upon it with perfect safety.

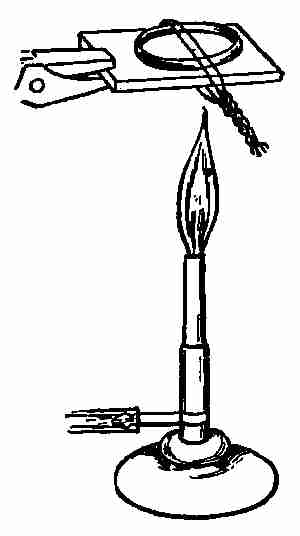

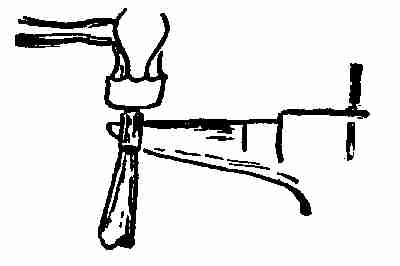

All the heat I need comes from a gas burner. Here I have a bunsen burner, and for such work as I do on rings, scarf pins, hat pins, etc., or for any work that doesn't need lots of heating in the process, the bunsen burner will do. But for annealing, which you have to do when you make bowls, or for[12] soldering, when you make boxes, you must have a stronger flame. Then I use the gas range in the kitchen or the bellows blower and blow pipe. If you happen to be where you can't get a gas flame, an alcohol lamp with a mouth blow pipe can be used.

Fill the alcohol lamp with denatured alcohol (bought at any drug store). Light it. With the large end of the blow pipe in your mouth and the small end about 1⁄4 in. above and a little to the right of the flame, blow gently. This little blue flame will give you heat enough to solder small pieces. Even a small wood fire would give you heat enough to anneal any size pieces you wish.[13] "Must I learn to make all these tools before beginning?"

"Oh, no, you'd better buy your tools; they don't cost very much. Then we can start to make something right away. The first thing you must do is to design the piece of work you are going to make. I made a bowl first."

"But I can't design."

"Neither could I when I began. You won't find it hard after you have once made a start."

"Let's begin now, John, I want to make something."

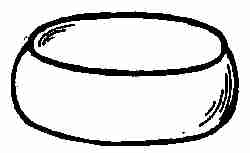

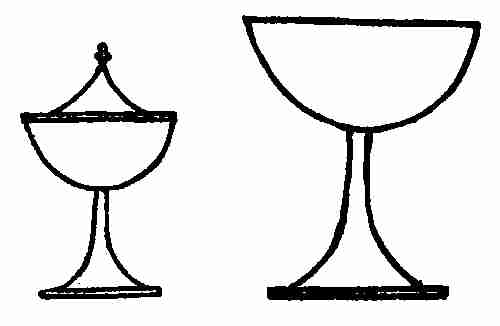

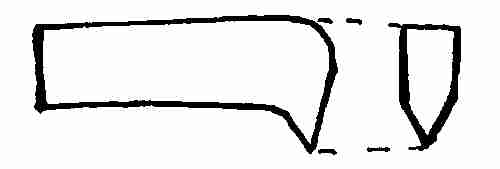

"I know you do," said John. "That's the way I felt. Now, I'm the teacher and you must do as I tell you until you can plan for yourself. Here are pictures of a lot of things we can[14] choose from: bowls, boxes, trays, etc. If a boy can make all these models he can go on and make nearly anything in copper, or even silver, he would like to make. Here are the bowl designs I have drawn. Of course there are bowls of different shapes, and some have covers to them. But we will try to get the shape that's most pleasing. Let's take this wrapping paper and draw a number of shapes on it, keeping the diameter and depth of each bowl the same. This model is 4 ins. in diameter and 11⁄2 ins. deep. Let's make all our drawings of bowls that size."

"Which do you like best?"

"I like the first one."

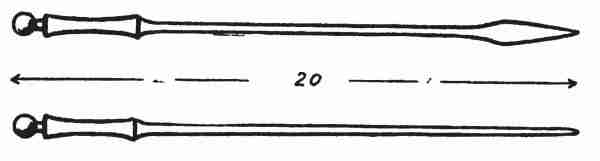

"Now that we've decided on the size and shape of the bowl, I must tell you something about the copper to be used. All sheet copper is sold by number, the higher the number the thinner the metal. Number 20 is a good size to use for most bowls and boxes. I use size 20 for mine. If you want a bowl to be lighter, use size 22 or 24. [15]You can buy the sheet copper at any hardware store."

"Now you know how to make your design and you know something, too, about the tools and copper in general. We are ready now to begin the bowl."

Here are the tools and the material that we need to make our first piece of work:

Material: 1 Sheet of copper, 20 gauge. Powdered pumice stone.

Tools: Hard wood block, dividers, shears, round headed hammer, planishing hammer, round top stake, mallet, files.

Directions: Take the sheet of copper, and with the dividers mark on the copper a circle having a diameter a little longer than the contour of your bowl design. Cut this circle out with your shears.

With the round headed hammer, using the rounded end, beat the metal disc into the hollow of the[20] wooden block until it takes on a fairly even bowl shape. Keep turning the metal with the left hand while you hammer it with the right.

You soon have a rough shaped bowl full of bumps and wrinkles around the outer edge.

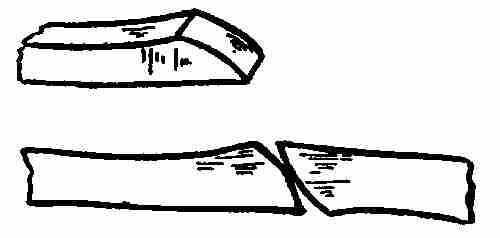

These wrinkles must come because the circumference of the metal disc decreases as it takes on the bowl shape. So long as these wrinkles are long regular curves, they will work out all right. If they should take short, sharp shapes there is danger of the metal splitting. In order to avoid this be sure to keep the[21] wrinkles hammered out flat as you work along.

If you went on hammering too long after your bowl is shaped, the bowl would crack or perhaps break, for hammering leaves copper hard and springy. So you must soften it before you can safely hammer any more. To do this I hold the bowl over a gas range until it is red all over, then I plunge it into cold water. This heating to soften up the copper is called annealing. Repeat the hammering[22] until the bowl takes on the shape of the design.

Now take your round top stake and put it into the vise. Place the bowl over the round top stake, and with the planishing hammer, beat the surface until it is perfectly smooth, driving the metal just hard enough to flatten the bumps made by the hammering in the wooden block. If carefully done the surface will be true and bright and covered over with brilliant facets. A skillful hammer-man can really drive the metal in any direction he may wish. In this way you make a bowl out of one piece of copper. The top of the bowl will be ragged. Cut this rough edge with a pair of shears.[23] File the top with a smooth file until it is perfectly true. A good test to make sure of this is to lay the bowl down on a plate of glass, or hold it up against the window pane. If there are still any tiny openings[24] left in the edge the light will be easily seen through them. More filing must be done until no light comes through from the smallest space. This done, take a piece of emery cloth and rub the edge of the bowl until the file marks disappear. If you lap the cloth over the edge your rubbing will leave a rounded edge, which is just the finish it should have.

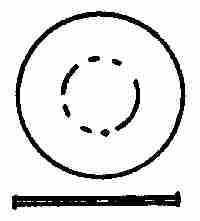

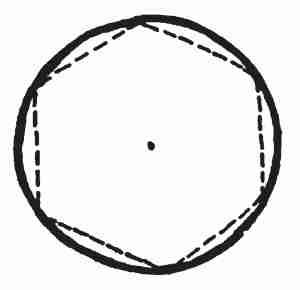

To flatten the bottom of a bowl: Turn the bowl upside down on a bench. With a pair of dividers find the centre of the bottom of the bowl. This is done by placing one leg of the dividers against the side of the bowl and with the other making a light scratch as near the centre as you can. Change the position of the dividers to the opposite side and do the same, but be careful that the scratch is light. Repeat this until you have done it on the four sides.

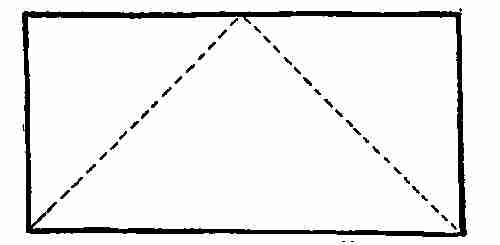

Where these lines cross is the centre. With one leg of the dividers on the centre draw a circle having a diameter of about two inches. Take a wooden mallet and strike down on the centre of the circle. This will flatten the bottom. Work from both sides of the circle and keep the rounding edge just touching[25] the circle made by the dividers. If the strokes are too heavy the bottom will bend in like the dotted lines in the sketch.

In that case, turn the bowl up and hammer from the inside. The bowl is now ready for polishing. Mix some powdered pumice stone with water. With a woollen cloth that has been wet and then dipped into the mixture, rub the bowl. This both cleans and polishes and at the same time gives a beautiful lustre to the surface of the metal.

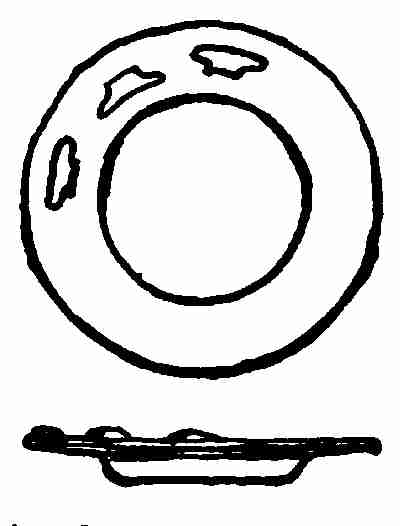

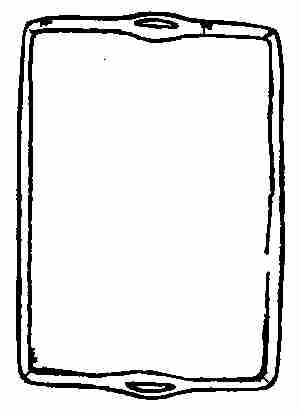

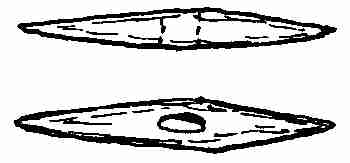

How to make copper trays (used for pins, hair pins, cards, etc.).

(1) Round. (2) Square or oblong.

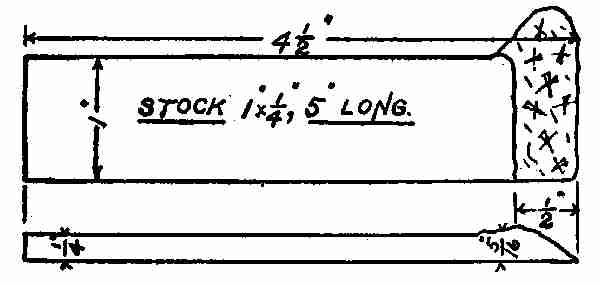

Material: Piece of copper about 7 ins. square, No. 20 gauge. A hard wood block, 10 × 10 × 2 ins. thick.[27] Tools: Carpenters' gouge chisel, dividers, steel punch, shears, round peg of wood, 6 ins. long and 1 in. in diameter.

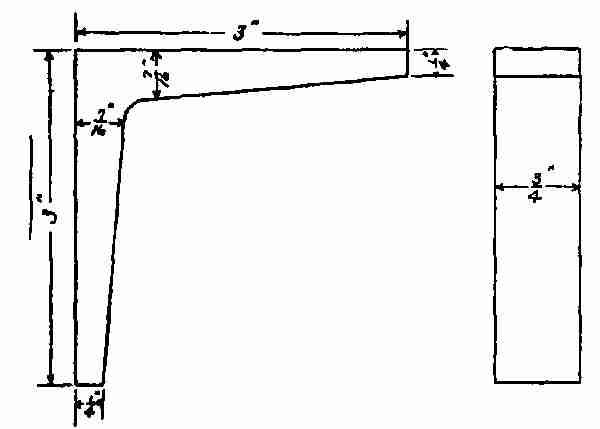

Design: Take a large sheet of plain paper. Draw on it a 3-in. circle. Using the same centre, draw a 5-in. circle. This gives you the plan or top view of the tray. Below this view on the same sheet, draw the elevation, or edge view of the tray. You can make the tray as deep in the centre as you wish. Let's make this one 1⁄2 in. deep, that's a good proportion.

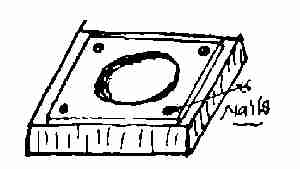

This is what we call a working drawing. If you are pleased with the design, you can go right on with the work, if not, you can change it to suit. You can see by the design that the tray is made by driving the centre of this square plate of copper down into a depression. In order to do this we must make a mould the exact size and shape of the tray centre. This is what the square hard wood block is used for.[28]

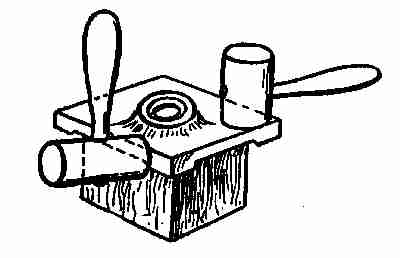

Take your hard wood block. Draw diagonal lines across one face. Where these lines intersect is the centre. With your dividers, using this centre, draw a 3-in. circle. Place the carpenters' chisel anywhere on the circle and strike with a hammer, driving the chisel down into the wood about 3⁄8 in. Do this all around the circle. Gouge out the loose wood until you have cleaned out the whole depression, being careful not to go below 1⁄2 in. in depth (the depth of your design). Smooth this up nicely with sand-paper. The mould is now ready for the metal plate. With the steel punch, make holes in each corner of the copper plate about 1⁄2 in. from the edge and just large enough to fit the wire nails. Place this plate over the mould so that the centre of the plate comes right over the centre of the mould. Fasten the four corners down with the wire nails. To drive the metal into the depression we must use something softer than a steel hammer. A hard wood peg has been found to do this best. Cut a piece about 6 in. long from the end of a broom[29] handle. Round one end up, using a file or a carpenters' chisel to do so.

Place the rounded end of the peg on the circle of the copper plate and, with a hammer, drive the copper into the depression below it. As constant hammering hardens copper so that it ceases to respond to the blows, it is necessary to soften up the metal by annealing as the work goes on. Take the sheet off the block. To do this, place the point of the chisel under the copper sheet close to the nail head and pry the nails out, lifting both copper and nail up at the same time.

After annealing, nail the copper plate in the same place as before. With the wooden peg continue driving until you fill the depression, at the same time flattening all parts of the metal that may push up. Be careful not to mar the copper at any time. When everything is perfectly flat and smooth take it off as before.

We are now ready to draw the 5-in. circle on the copper. The centre for this circle is the centre[30] of the depression; and that is found with the dividers in the same way as you found the centre for the bottom of the bowl. Make the circle on the copper. With the shears cut along a little on the outside of this line. Smooth up and round the edges of the tray with a mill file. Rub out file marks with a little piece of emery cloth. If the hammering has been uneven some parts of the copper will have stretched more than other parts and the tray will not lie flat when placed on a table. To level this up, place the tray top side down upon a bench or table and strike gently with a mallet on the surface. Holding the mallet near the head one can control the blows and be able to strike gently. But if it is held toward the end of the handle the blows will not be uniform. This applies to all hammers, whether of wood or steel. You will notice as you do your hammering the high spots will settle down and gradually flatten. The tray is now ready for cleaning and polishing. This is done in the same way as you treated the bowl.

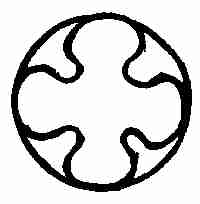

Decoration: Round trays may be decorated in many simple ways by drilling holes in the rim, and then sawing out designs to suit one's fancy, or they may be notched at intervals. Nothing is more decorative though, than the embossed or repoussé design,[31] made by beating from the back and raising the metal on the face above the level. One of the designs given here shows the embossed, and the other shows a combination of the embossed and sawed out work.

The value of the mould: It may seem to you like a lot of work to make a mould just for this round tray, but it can be used many times for making this kind of tray and also for trays of similar shape, like bowl covers, etc. Most of the jewellery nowadays is made in moulds, wood, steel, or lead. Copper, silver, and gold medals, pins, rings, tea and dinner sets are all made by the mould or die method. This mould you have just made is only a simple one; however, complex ones are made in the same way. The skill all lies in making a very good design first and then in making a very smooth mould to fit the design. After one or two trials it comes easy enough. The chapter at the end of the book will explain die and mould making in modern copper, silver, and goldsmith shops.

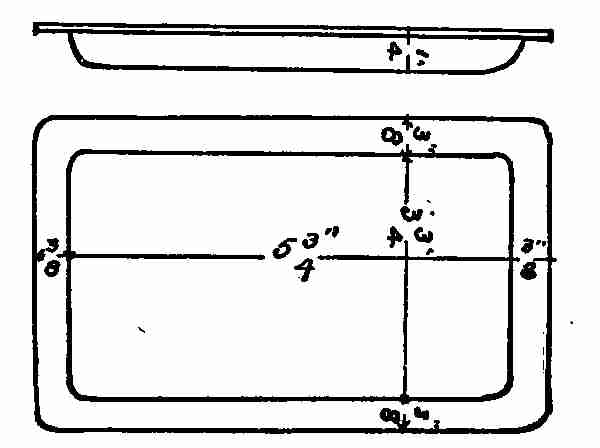

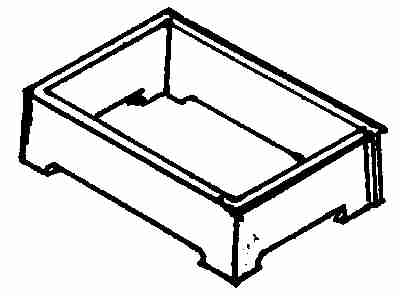

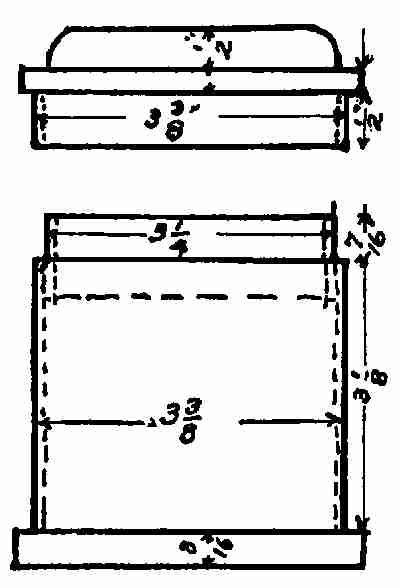

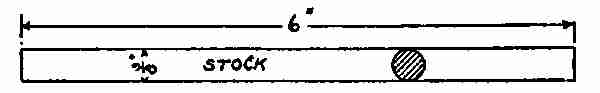

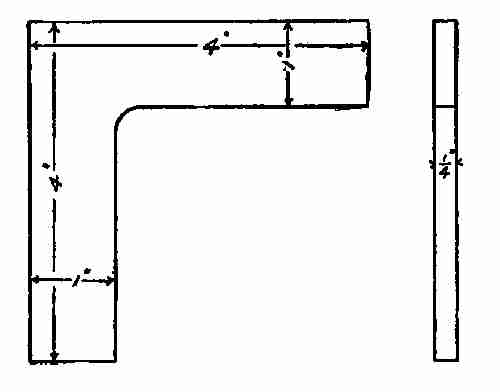

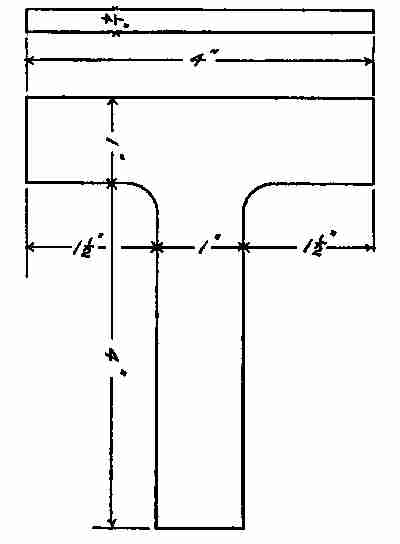

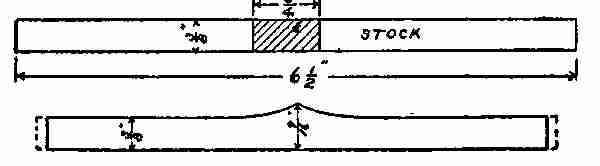

Material: Copper, 61⁄2 × 41⁄2 ins. No. 20 gauge.

Tools: Shears, square, bench vise, round hard wood peg; dividers, copper vise jaws.

Design: Determine first whether the tray is to[32] be oblong or square. This material makes a tray 61⁄2 × 41⁄2 in. Draw this size oblong on a sheet of paper. The rim of the tray should be 3⁄8 in. wide. Draw an inner line all around, 3⁄8 in. from the outside. Below this draw your elevation, or edge view, showing the depth of the tray. In this design it is 1⁄4 in. deep.

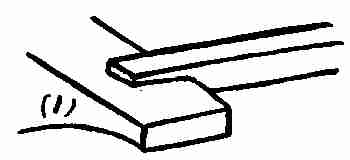

First see that your 6-1⁄4 × 41⁄2-in. piece of copper is squared. Now draw your inner rectangle on the metal. To do this, set the dividers 3⁄8 in., and with one leg against the edge of the copper, draw all around the four sides, marking the lines on the metal. You now have a flat sheet marked ready for[33] bending. Place the sheet of copper between the vise jaws, the inner line even and on a line with the vise.

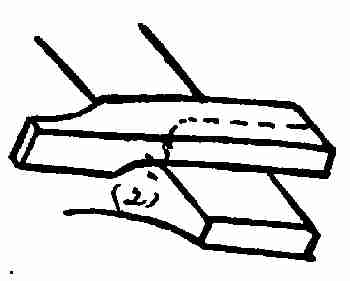

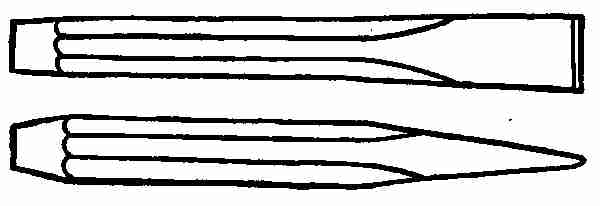

The hard wood peg should be cut to a flat tapered end. This flat end of the peg is held at an angle of about 45° against the copper plate, just above the vise jaw and against the line of the rectangle. With the mallet drive gently. By doing this the body of the tray is pushed in, but the rim is kept straight in the vise. Repeat this all around. You'll have a tray like the sketch. If the body of the tray is not deep enough put it into the vise again and keep driving it until you get the depth you want. The inner corners will be found to be rounded, as they should be. Round off the outside corners to match. File the edges round and finish with an emery cloth, clean and polish as explained before.

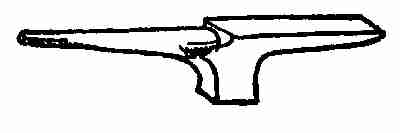

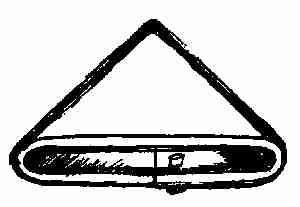

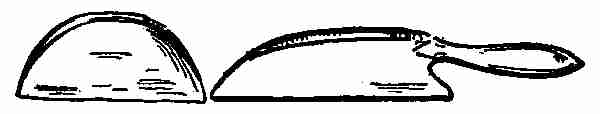

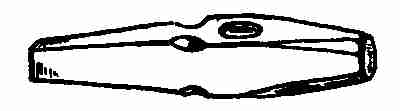

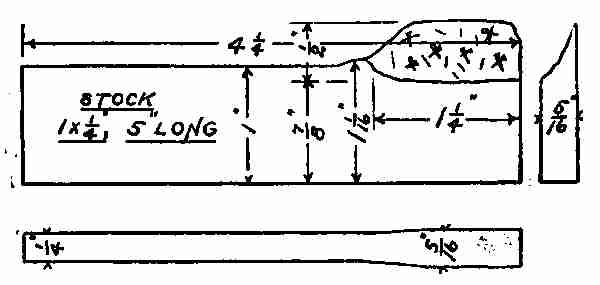

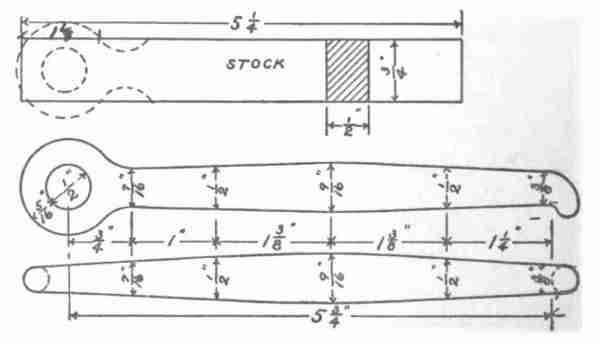

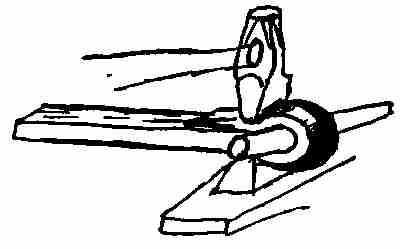

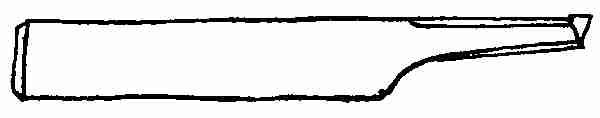

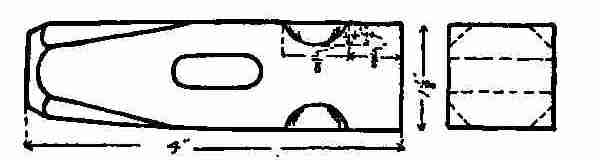

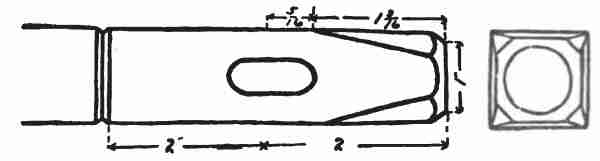

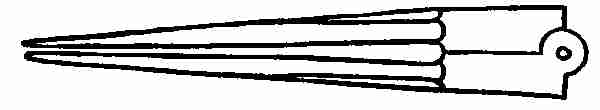

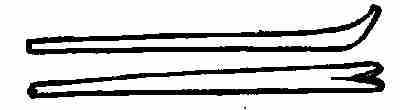

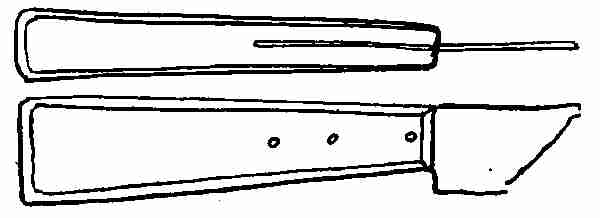

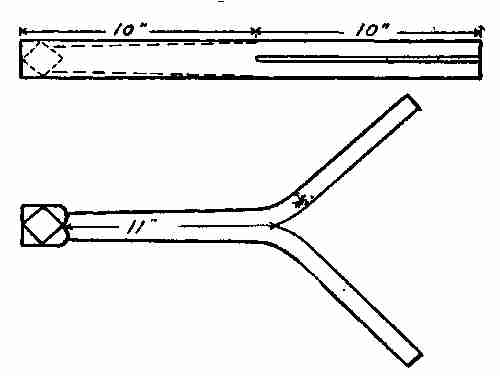

Let's make a paper cutter like this sketch. We can draw the design on paper first and then cut it out. Here is what we need to make it.

Material: Heavy copper, No. 8 gauge, 10 inches long by 11⁄4 inches wide.

Tools: Drill press and drills, jewellers' saw frame, cold chisel, files, vise, emery cloth, few wire nails (1⁄2 in.) two blocks of hard wood, one, 10 × 11⁄4 × 11⁄4 ins., and the other, 6 × 2 × 1⁄2 ins.

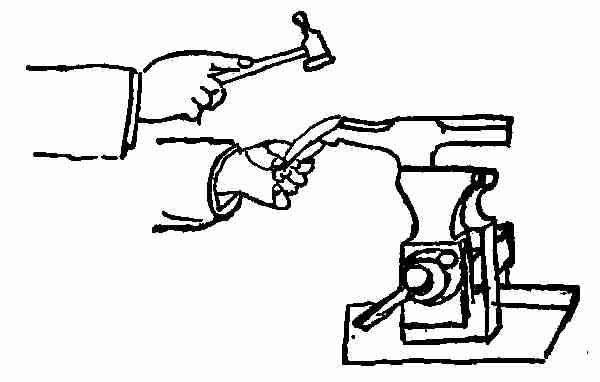

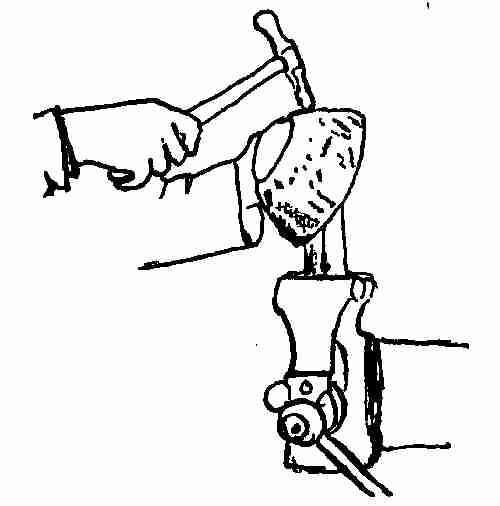

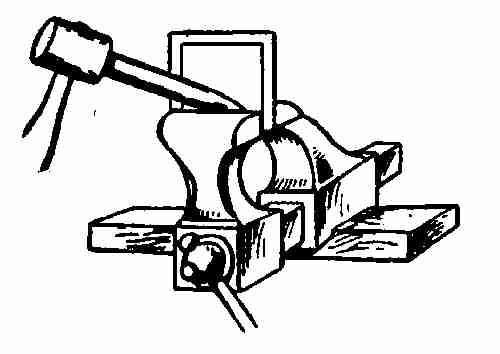

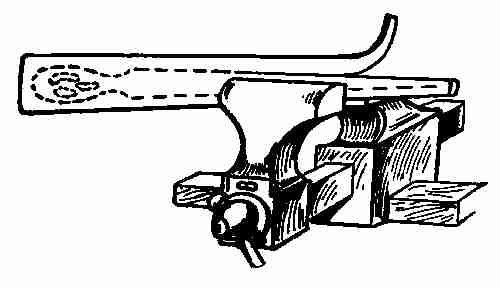

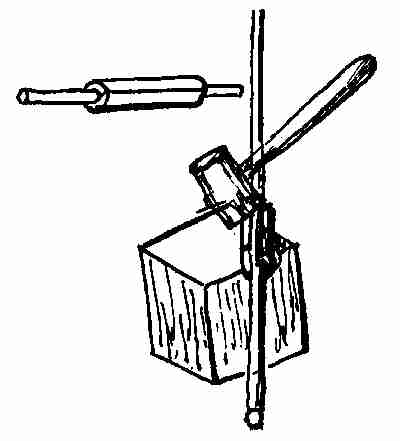

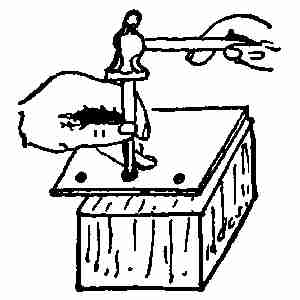

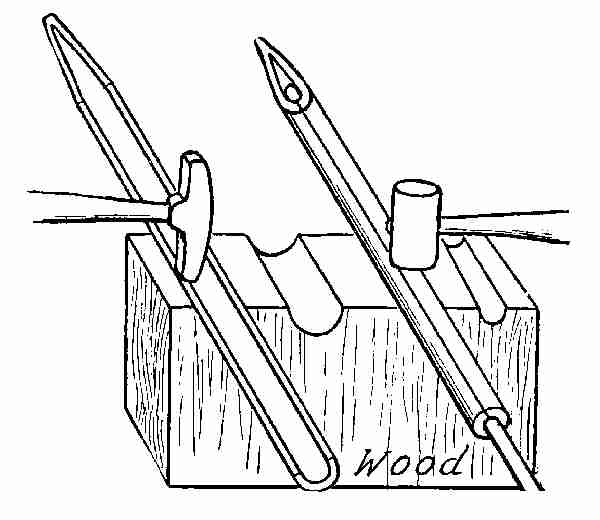

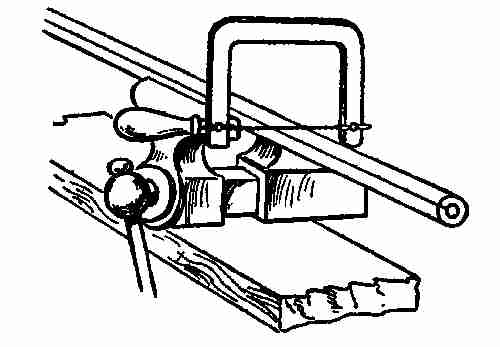

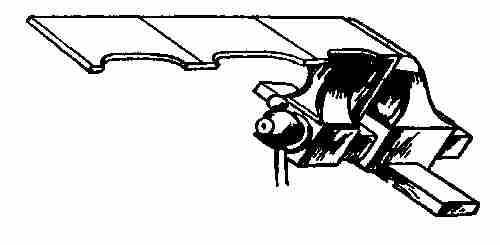

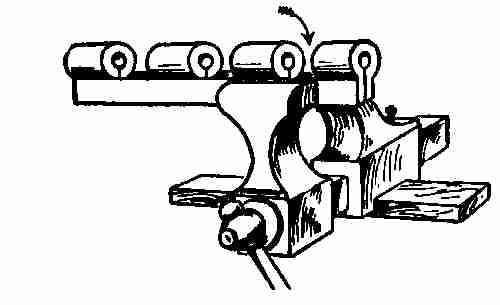

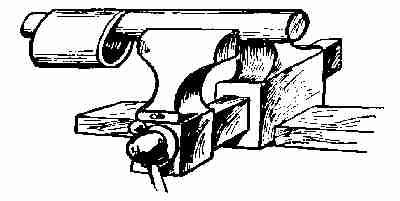

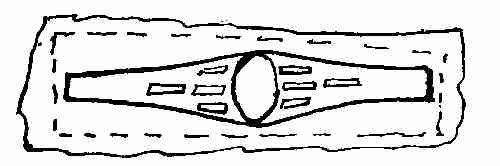

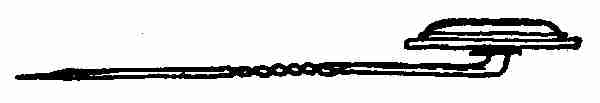

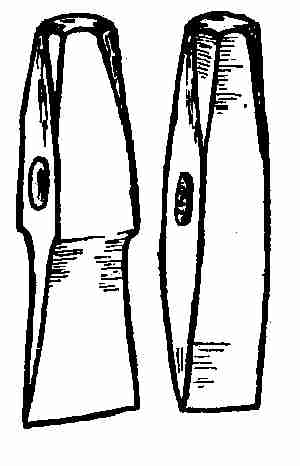

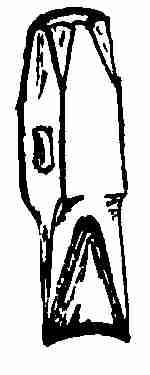

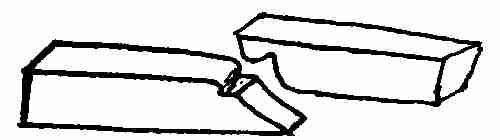

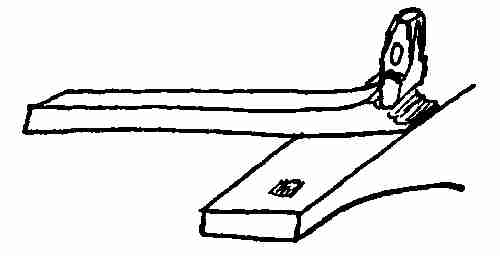

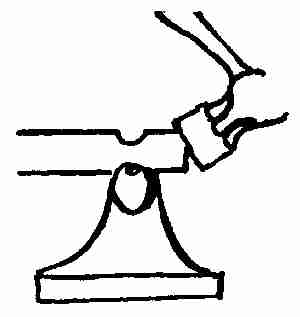

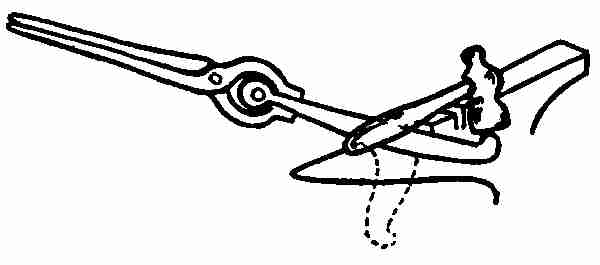

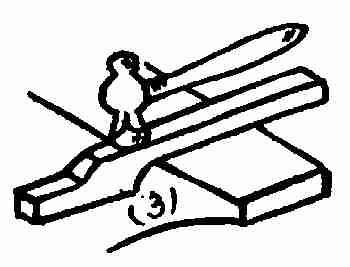

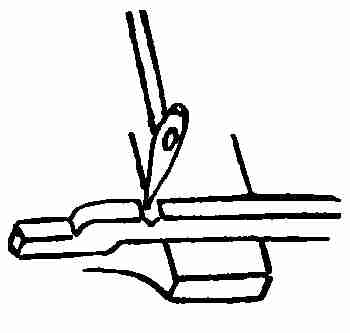

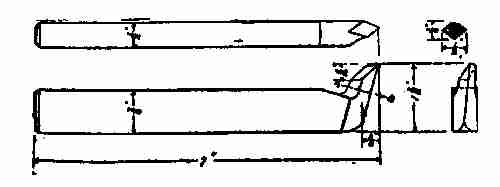

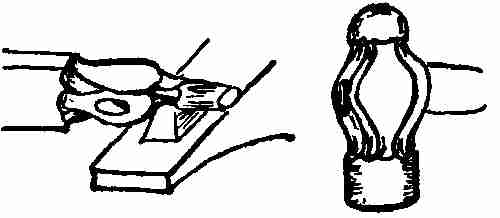

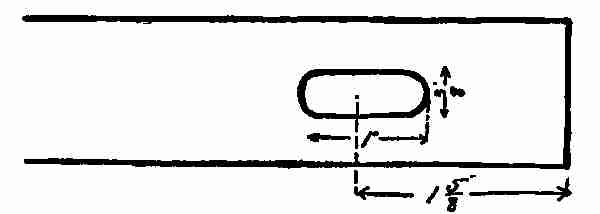

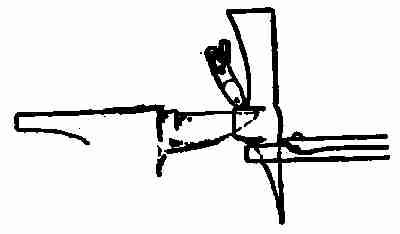

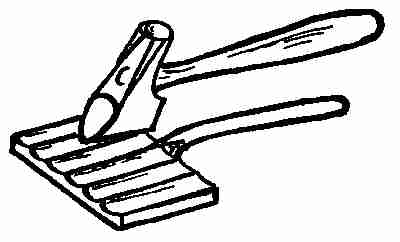

Cut out the design and paste it on the copper plate. If our shears could cut copper as heavy as this we would have little trouble to cut our design out. But the shears can't do this work, so we have to put the copper into the vise and cut the design out with a cold chisel and hammer.[35] Place the copper into the vise with the line of design to be cut flush with the top of the vise. With hammer and chisel, cut along this line. The back part of the vise will act as a shear and help in the cutting and will prevent the copper breaking away and leaving the edge rough. When this is done, place the paper knife in the vise and file all the edges smooth. Now that it's cut out and smoothed up we are ready to saw out the design in the handle. To do this drill holes in the design as a starting point for the sawing. Take the drill press and put a 1⁄16-in. drill into the chuck. Drill a hole in any part of the design. Take the jewellers' saw frame and fasten one end of the small saw into one of the legs of the frame; push the loose end through the hole made by the drill. Fasten the loose end to the other leg of the saw frame so[36] the saw is fairly tight. In order to saw properly, we must have something to support the piece while we are working on it. This is best done by taking a block of wood 6 × 2 × 1⁄2 ins. and cutting out a V-shaped notch in one end. Place this in the vise, or nail one end of it to a bench so that the V-shaped end will extend over the bench or vise to be free to work upon. Put the handle to be sawed out on this block so that it will be supported on both sides of the parts to be sawed out (see sketch of work in vise). The saw will play freely up and down in the notch. All sawed work is done in the same way.

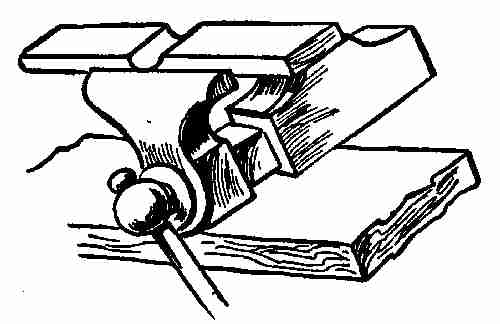

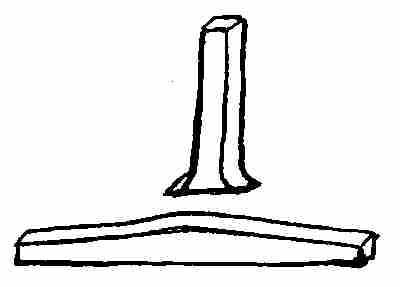

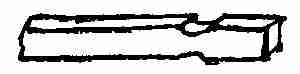

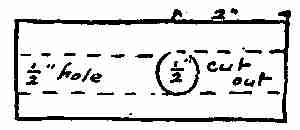

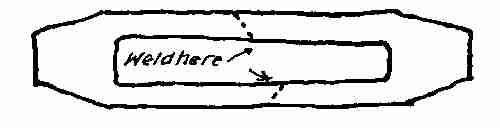

To file the edges sharp: Take your hard wood block, 10 × 11⁄4 × 11⁄2 ins.; fasten the cutter down tight by driving two short wire nails half their[37] length into the wood at each end of the cutter. Place the cutter between these nails, bend the ends over, and fasten down (see sketch). Place all into the vise jaw and tighten it up. With a rough flat file, file the edges down, working from the centre line both ways. When one side is filed about half the thickness of the copper, bend the nails, take off the cutter. Reverse it, put it back, and file as before. Do this until the edges become sharp.

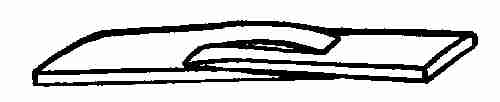

To finish this piece of work as it should be done, we must do some draw filing. The draw filing is done in this way: Take hold of both ends of the flat file, the handle in one hand and the end of the file in the other. Stand lengthwise of the piece. Place the file flat down on the blade with the teeth of the file pointing in the same direction as the blade. Push it from you and pull it toward you, at the same time pressing down on the blade. This is draw filing and it is the only way to make a piece of metal true, and free from the marks of the cross filing which was done in the beginning. Repeat this on the other side until the whole paper cutter[38] including the handle is smooth. Wrap a piece of emery cloth around a block and rub all over the surface. Polish and finish as before described.

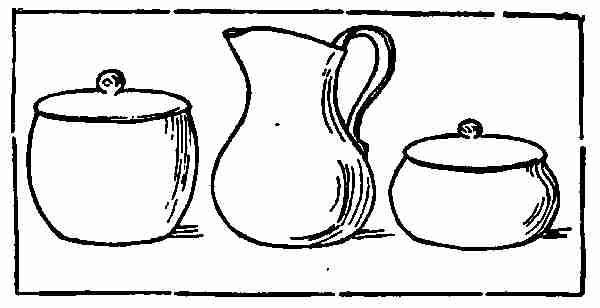

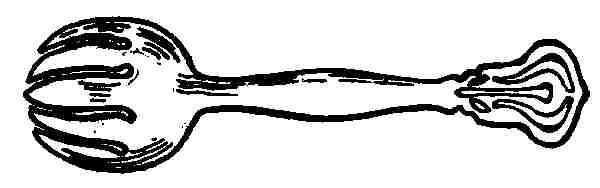

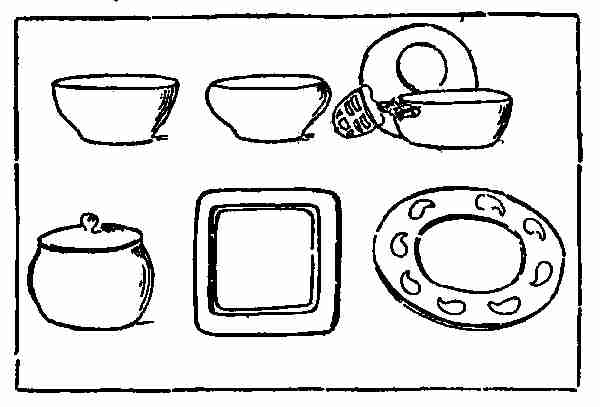

A very beautiful nut set consisting of a bowl, four plates, and a nut spoon or a shovel, can be made out of copper. One uses the same tools to make this set as were used for the copper bowl, and the work of making it is done in much the same way.

Material: 9-in. disc of No. 20 copper (bowl). Four 5-in. discs (for plates). Piece of copper 2 × 3 ins. (No. 8).

Take the 9-in. disc and hammer it into the desired bowl shape, on the hard wood block. The plate should be hammered up in the same way, keeping the depression in the centre of the plates about 1⁄2 in. deep. A very beautiful finish can be made on[39] these bowls and plates by the use of the round end of the raising hammer and a flat-iron. Place the handle of the iron between your knees, face up. Put the bowl or plate, face up on the flat-iron and go over every part with the rounded end of the hammer. This produces a surface covered with oval facets, giving a mottled effect. The edges of the bowl and plates may be left straight or they may be rounded, according to the design.

Draw the design on paper. Cut the design out and paste it on the copper. This piece of No. 8 copper is too heavy to be cut with the shears, so it must be placed in the vise. See that the outline is even with the top of the vise jaws. With the cold chisel and hammer cut along the top of the vise as you did when making the paper knife. Now you have a shovel-shaped metal of the same thickness all over. Where the handle joins the bowl the metal[40] should be left thicker than in any other place, otherwise the spoon will bend in the using. To thin out the metal of the bowl, hammer it. Begin where the handle joins the bowl and thin out to the edge. The handle is shaped by working from the bowl out toward the handle end, constantly widening and flattening it. Cut off the surplus metal, keeping to the original design. The handle may be left plain or some simple sawed out design may be put on. File up, rounding the edges off so that the spoon feels smooth and is comfortable to handle. Place the whole on a hard wood block and beat the bowl and handle into shape. Many nut spoons have designs sawed out in the bowl to lighten the weight.

Soldering is a process of joining two metals together. It is not hard to learn to do. If you are careful when you do the work to have the materials to be used perfectly clean, you may be sure of success, for, after all, it's one of the easiest and simplest of all the operations done with metals.

Material: 1. Borax: bought in lumps, wrapped in tin foil, or pulverized.

2. Borax slate: a square piece of slate with a small depression in one side. Any piece of clean slate will do. This is used to grind the lump borax, or to mix the pulverized borax to a pasty condition on.

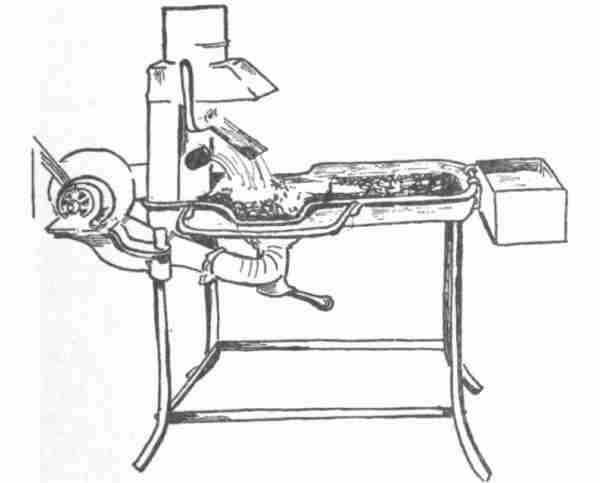

3. Solder: silver solder, sometimes called hard solder. It can be bought by the sheet in large or small quantities. Bunsen burner, or either one of[42] the following: blowpipe and foot bellows with gas flame, a blacksmiths' fire with coke or charcoal.

Directions: The parts of the metals to be joined should, first of all, be scraped or filed bright. This prepares them best for the solder. Take a lump of borax, grind it up and mix with a little water, on the slate, until it is like a paste. Take a sheet of silver solder, cut a number of slits lengthwise down the sheet and then cut them crosswise. You will have a number of pieces about 1⁄16 in. square. These bits are dropped into the borax solution until they are completely covered with the paste. With a camels' hair brush, wash the edges of the metal to be joined, with the solution of the borax. Tie the pieces together with an iron binding wire, taking care to have the edges to be joined close together and in the proper position. If you don't, the solder will not fill up all the openings and cracks, and parts will be left unsoldered. Now, wash all around the joint with the borax solution. Place bits of solder at intervals along the joint, fairly close. Warm the work gently in the flame. This drives off the water in the borax solution. When the borax is quite dry in the joint direct a stronger flame over the whole work. Heat it gradually, but be careful that no part of the metal, except[43] that around the joint, becomes red-hot, and that both sides of the joint get red-hot at the same time. If you don't guard this, the solder will climb to the hotter side and leave the other, and the edges will not unite. Cool it off in water and file the joint perfectly smooth.

For mending teakettles, tin cans, tin cups, or anything made of tin, galvanized iron, or lead.

Material: Lead solder, comes in small bars. Flux (1.) Resin and sweet oil. (2.) Muriatic acid. (3.) Tallow candle.

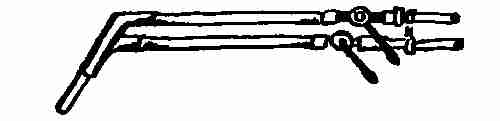

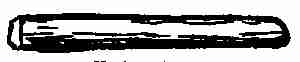

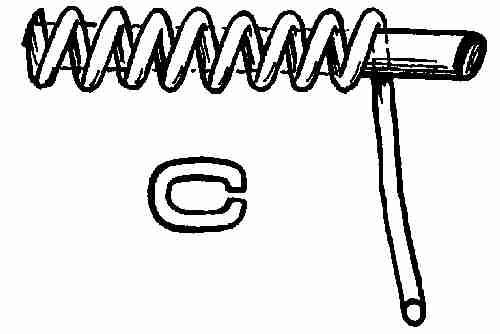

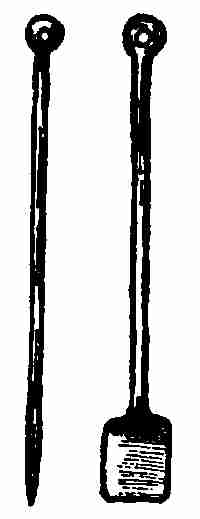

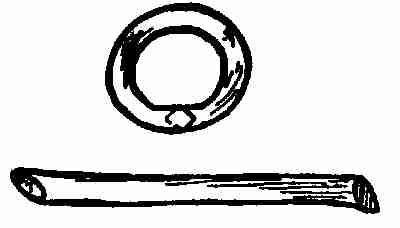

Tool: Soldering iron (can be made out of a piece of half-inch round copper.)

How to solder: Soft solder is a mixture of tin and lead in even proportions. This solder melts at a very low temperature. That is why we can do the work with the soldering iron. I find I can solder many things at home with the soft solder, and I'm going to tell you how I mended a leak in the teakettle the other day. First, I took a pocket knife and cleaned all around the hole or leak, scraping the dirt off both inside and out. Then I mashed a little resin up fine and mixed a little sweet oil[44] with it. Then I washed inside and outside of this leak with the mixture. After heating my soldering iron in a stove (any kind of fire will do) I took a bar of solder, held it over the leak, and melted off a bit with the hot iron. You can make the solder flow over the leak by pressing the iron right on the hole. You see, the heat of the iron melts the solder and at the same time it heats the tin hot enough to make the solder cling to it. Before the part got cold I rubbed off the oil and resin with a woollen cloth. This left the work nicely cleaned. You can mend any leak in anything made of tin, in this way.

Galvanized iron utensils are soldered in exactly the same way, but you must use muriatic acid in place of the resin and sweet oil. But if you wish to solder anything made of lead or pewter a tallow candle is rubbed over the place to be mended, instead of resin and sweet oil or muriatic acid. In every other way the work is just the same. But lead, you know, melts at a very low temperature, so you must be careful when working on it that your soldering iron is just hot enough to melt the solder and not hot enough to melt the lead.[45] And now I am going to tell you how you can make your own soldering iron out of copper.

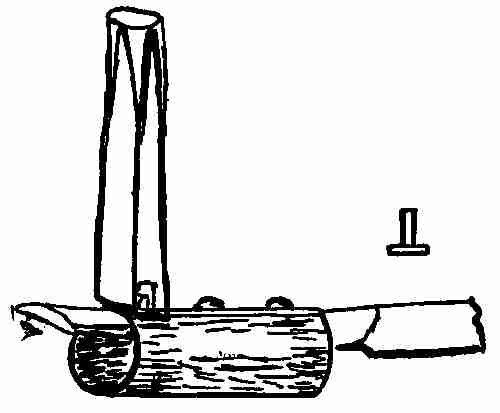

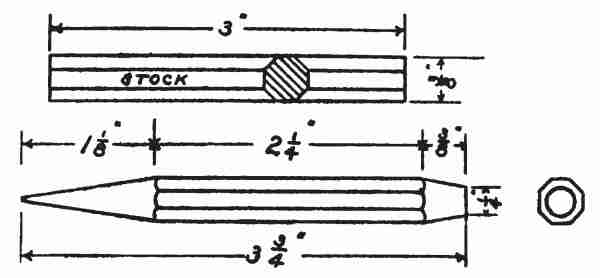

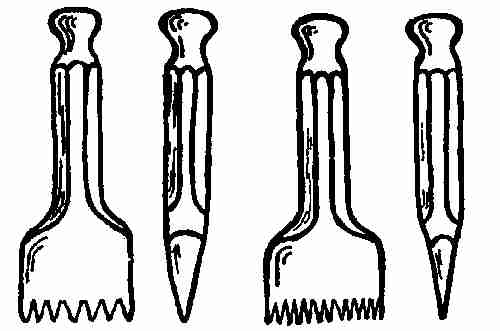

Material: A piece of 1⁄2-in. round copper, 3 ins. long, a piece of No. 8 wire, 18 ins. long, or a piece of light telephone or telegraph wire will do. Some soft solder. Resin and sweet oil. Small piece of clean tin. Manufactured fluid for soldering (used sometimes in place of muriatic acid).

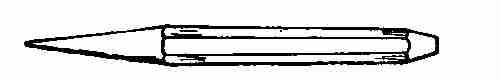

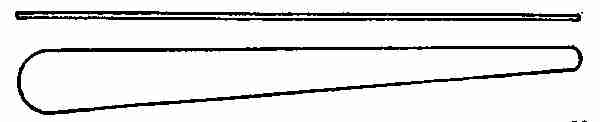

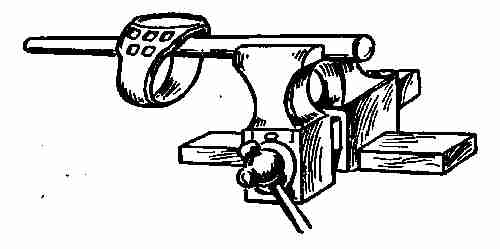

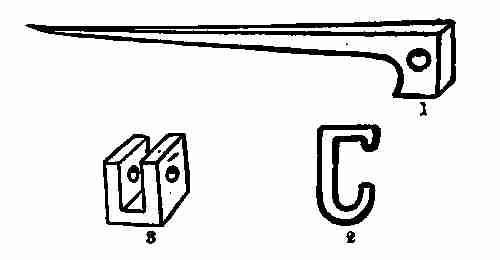

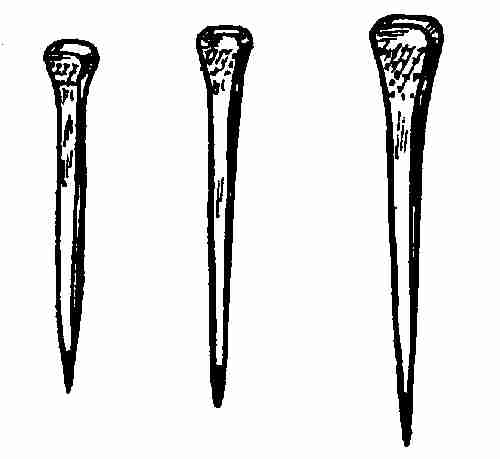

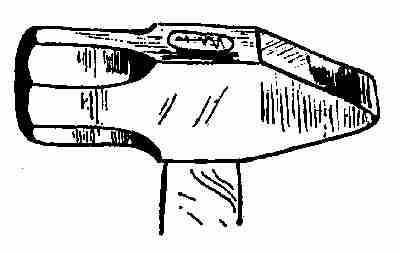

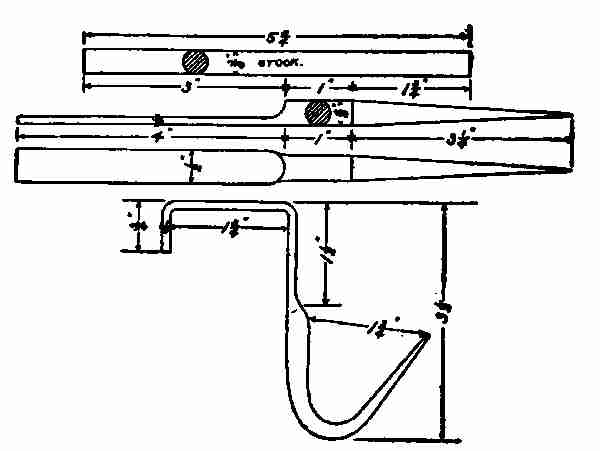

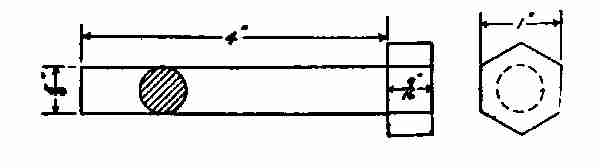

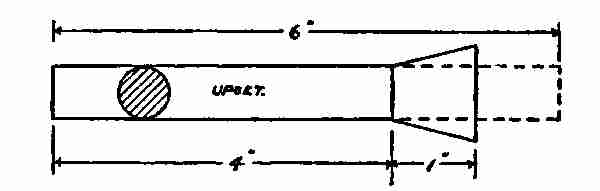

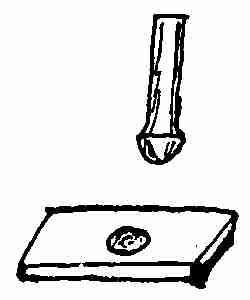

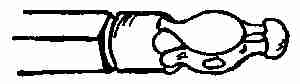

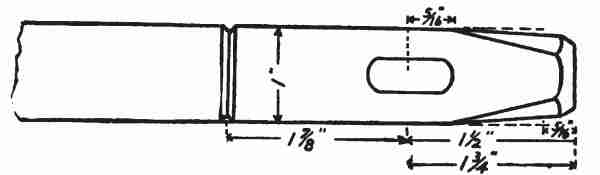

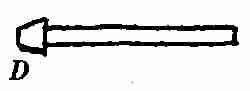

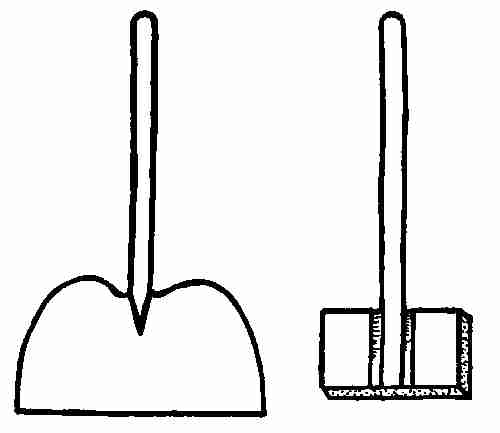

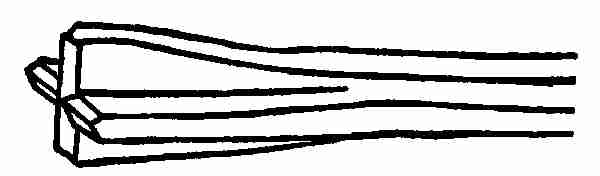

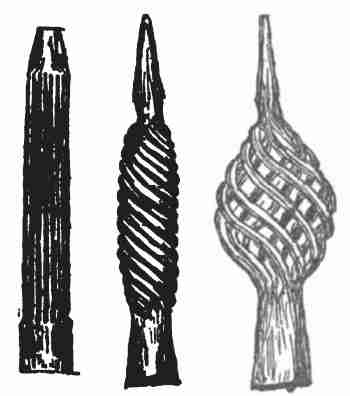

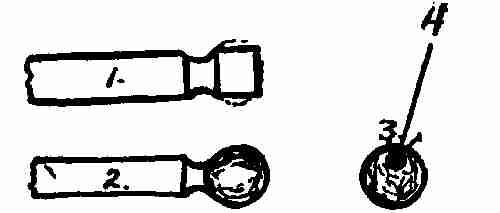

Tools: Punch, vise, file, hammer.

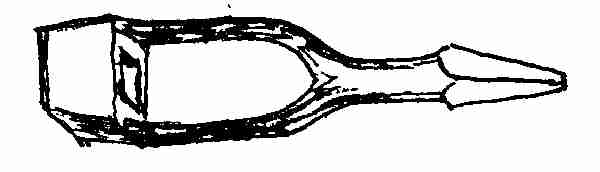

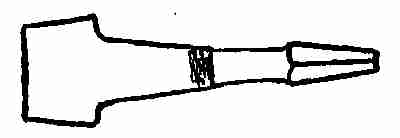

Place the end of the copper rod in the fire and heat it red-hot. Take it out of the fire and punch a hole about 1⁄2 in. from the end of the rod, large enough to allow the No. 8 wire to go through. Push the wire through this hole until half is on one side and half is on the other. Bend the wire close up to the sides to form the handle. In order to make this rigid, place the rod into the jaws of the vise and pinch the wire into the copper rod. This prevents any swinging motion. Take hold of both ends of the wire with the pincers and twist them[46] close to the copper rod. This makes a good handle. Heat the copper end of the rod red-hot, and with a hammer flatten it to a four-sided tapering end about one inch long and ending in a blunt point. (See picture.) Cool off in water and file the end of soldering iron smooth.

Now it must be tinned. On your piece of tin place some soft solder, oil, and resin. Heat the soldering iron hot enough to melt the solder, rubbing it up and down on the tin, mixing all together. Do this on all four sides, and in a little while you'll find the solder has covered the end of the soldering iron. When this is done the iron is ready to be used.

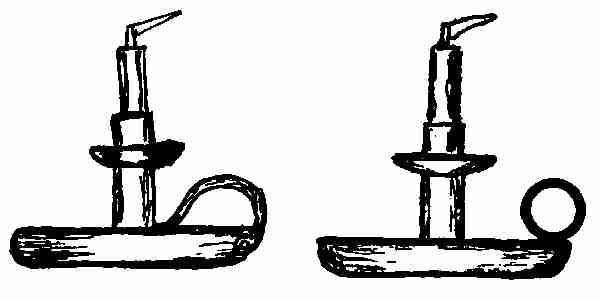

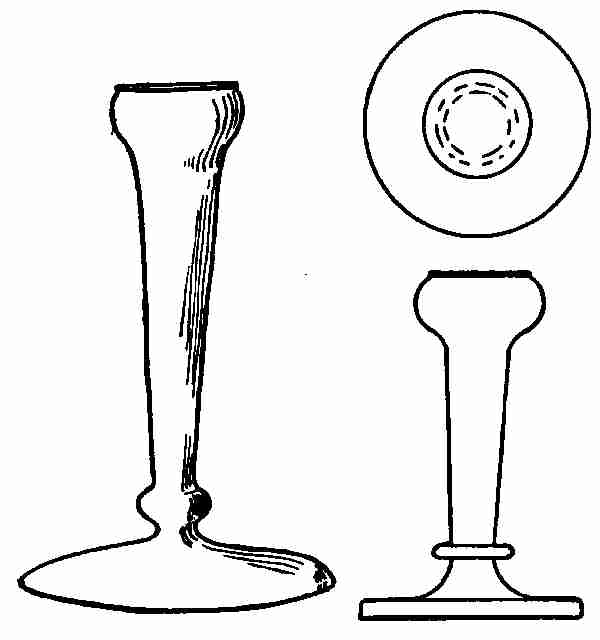

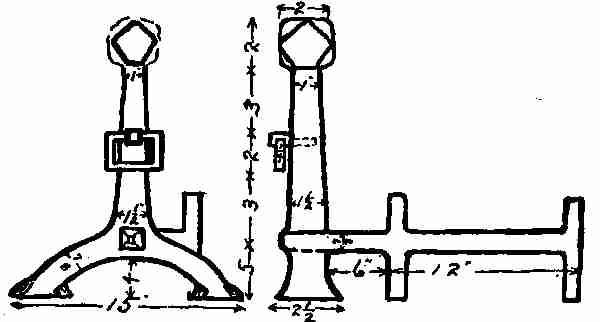

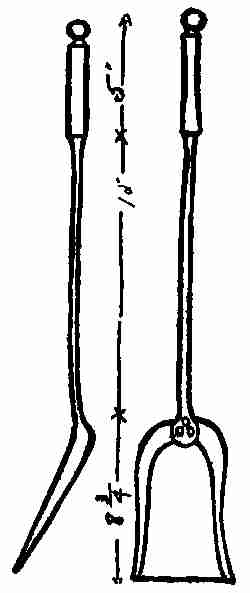

There are many forms of candle holders. Perhaps the one we are all most familiar with is the candlestick. Before the days of lamps and electricity the candle was everywhere. Many different designs of candlesticks have come down to us. Some were large, some small, some plain, while others were highly decorated. But however much the designs vary, there are many points that all have in common. There is the base, large or small, and a cylindrical shaft which rises from the centre of the base. This holds the candle. The drip pan is fastened to this shaft close to the top. It catches the wax as the candle melts. Handles are sometimes soldered on, and sometimes the candlestick is made without one. They are attached to the rim or to the shaft.

Material: Disc of copper, No. 20, 5 ins. in diameter. One piece 3 × 21⁄2 ins., No. 20, (for stem).[48] Disc, 2 ins. in diameter (drip pan). One piece, 3⁄4 × 6 ins. long, No. 16, (for handle).

Tools: Hard wood block, raising hammer, smooth file, dividers, saw, round wood peg, 3⁄4 × 6 ins.

Directions: Beat the copper disc into a saucer shape, for the base. Take the sheet of copper for the stem, fold it around the wooden peg till the edges come together. Scrape and solder the joint with silver solder.

Drip pan: Take the small disc; with the raising hammer, curve it slightly to make a drip pan. With the dividers, describe a circle 3⁄4 in. in diameter in the centre of the drip pan. Cut out this centre[49] circle and make it fit tightly on the stem. Push it down about one inch, scrape the stem, and solder the drip pan to it.

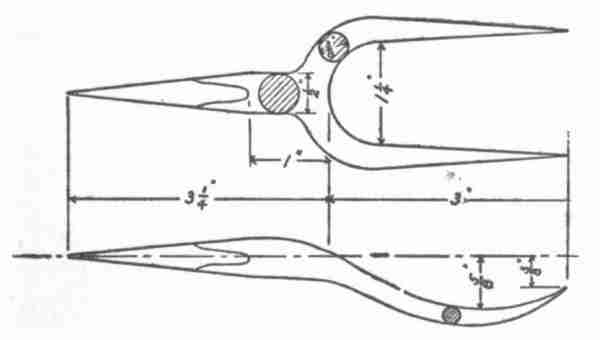

Handle: A strip of copper 3⁄4 × 6 in. long. Cut a tapering slip off each side so that one end will measure 3⁄4 in. and the other 1⁄2 in. Shape with the fingers over the round peg (place the peg in the vise to do this) until you have the shape you wish (see design). The wide end of the handle should fit down on the outside of the rounding part of the base, and the other end against the stem under the drip pan. Bore a hole in each end and rivet the handle in place. If a round handle is desired, take a strip of copper 3⁄4 in. wide and 11⁄2 ins. long, shape round with the fingers. Scrape and solder at the joints, and then solder on the edge of the base. Place and finish up each part as described. This candle design can be greatly varied. It can be[50] made taller, shorter, with various kinds of handles, or with no handle at all.

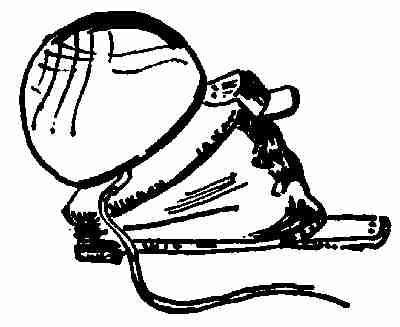

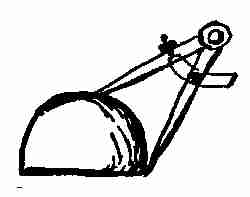

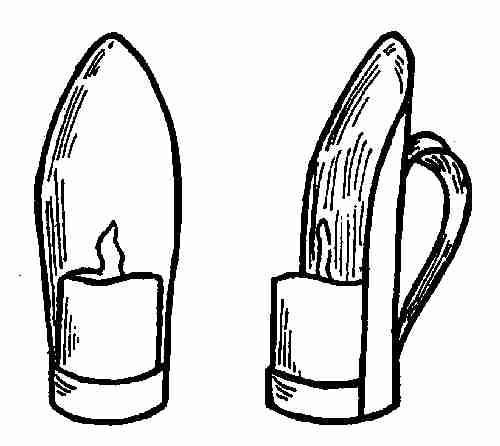

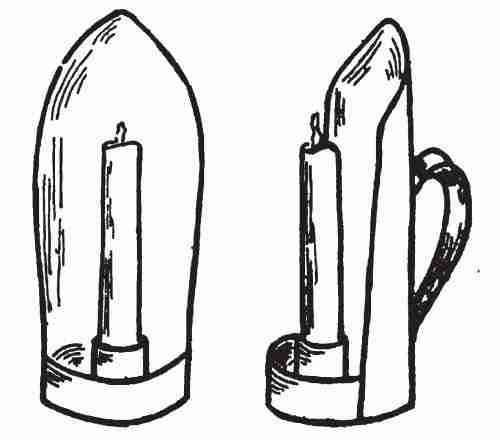

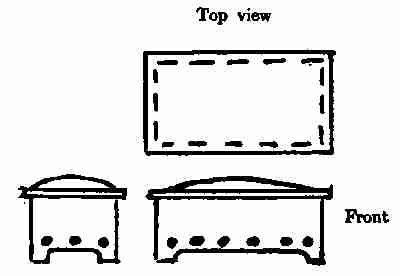

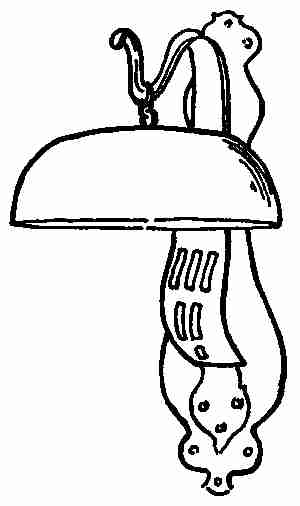

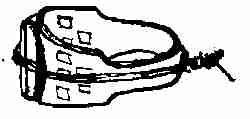

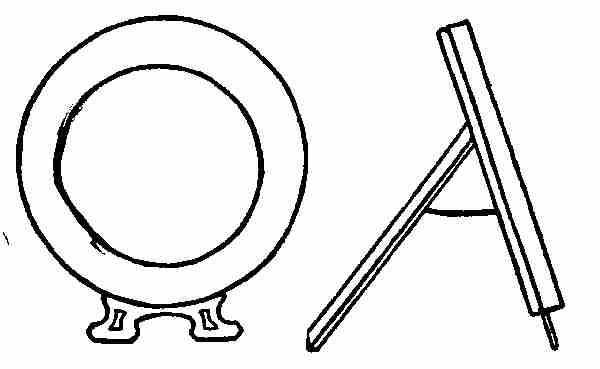

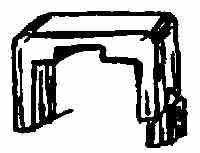

This kind of candle holder, or night light, is made to hold a short, thick candle about 2 ins. in diameter, which will burn from 6 to 10 hours. A round base supports the candle, and a shade with a handle on the back is fastened to the base. It can be adjusted so that the candle burns freely all night, while the shade protects the eyes from the light. Nothing is more convenient than one of these holders, for summer homes or for camping.

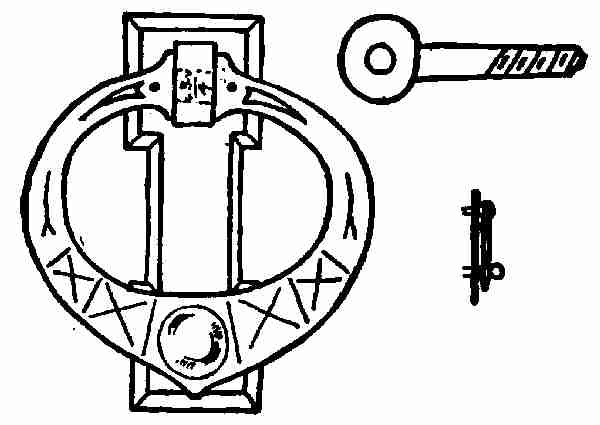

Material: Brass, No. 24, 31⁄2 × 4 ins. for reflector.[51] 61⁄4 × 7⁄8 ins. for cylinder. 2-in. disc for base. No. 20, 6 × 1⁄4 ins. for handle.

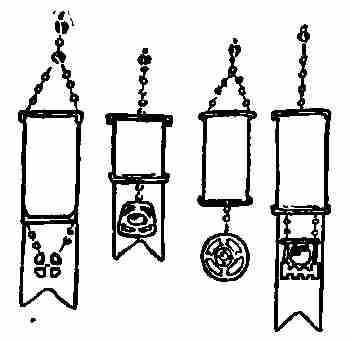

Directions: Picture shows a small night candle made of brass. Cut out a 2-in. disc. Bend the 61⁄4 × 7⁄8-in. strip to fit it. Solder the two ends of the ring and make it perfectly round. Be careful when rounding it up not to stretch it larger than the disc. Push disc into the ring flush with the bottom. Solder the bottom into the ring. Draw the outline of the reflector on the 31⁄2 × 4-in. piece and cut away the corners. Bend it to fit the holder. It should cover about one half of the circle. Solder the reflector on. Soft solder is strong enough for this work. Now bend the handle piece according to the sketch. Rivet or solder it to the back of the reflector. Polish and finish.

The ordinary tallow or wax candle is used in this night candle holder. You will notice from the sketch that the general style is much like that of the small holder. However, in this design, a small cup or stand to fit the candle is soldered on to the base, a little toward the front.

Material: No. 24 brass—A 4-in. disc. 12 × 1⁄2 ins., for band to go around the disc.[52] Reflector, 7 × 7 ins. Cup, 7⁄8 × 23⁄4 ins., and handle piece, 6 × 1⁄4 in.

The reflectors are sometimes left plain, though the facets made by a flat placed hammer reflect the light when the candles are lighted and soften the light by day. The greater the reflecting power of the surface, the better is the effect. If each part is carefully filed and finished before they are all put together there will be nothing but the polishing needed.

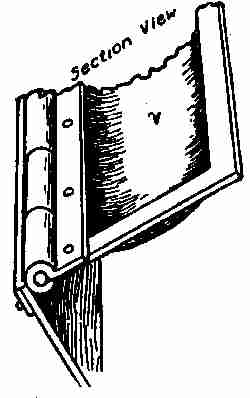

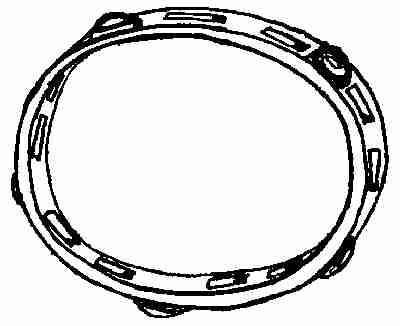

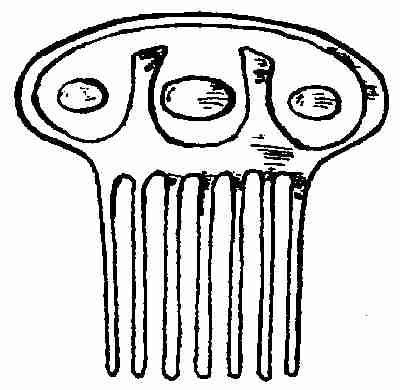

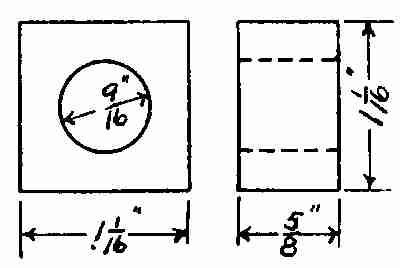

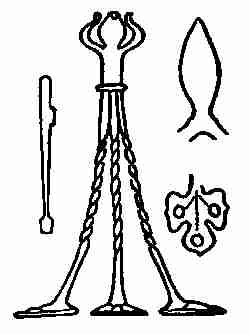

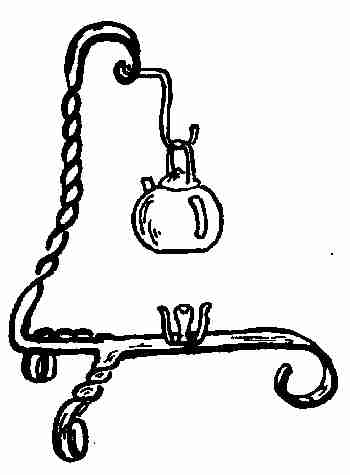

The sconce is a candle holder made to fasten upon any wall. It is both useful and decorative. Some are made to hold but one candle; they can be made,[54] however, for two, three, or four candles. All sconces should have a reflector, a bowl, shaft, and drip pan. But the designs vary to suit the individual taste and surroundings. The design given here is a very simple one and one that works out well in copper or brass.

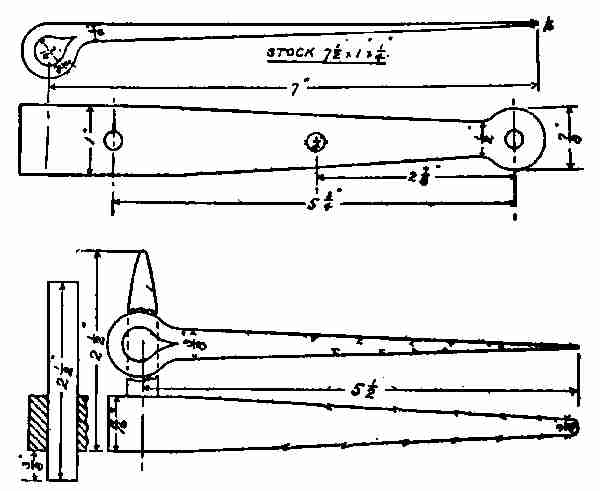

Material: One piece of No. 20 copper, 10 × 31⁄4 ins., for the reflector. One piece of No. 20, 21⁄2 × 1 in., for candle socket. One piece of No. 20 copper, 11⁄2-in. disc. One piece of 1⁄4-in. round copper 4 ins. long.

Directions: Make a drawing like sketch shown here. Place this drawing upon the 10 × 31⁄4-in. sheet of copper and cut the metal to fit the outline. Mark on this sheet of metal the embossed line shown in the sketch. Place the sheet of the copper on the hard wood block and with a chasing tool placed on the line, strike with the planishing hammer on the end of the chasing tool. This, in turn, will drive the metal into the wood. Repeat this till the outline stands out above the face of the reflector[55] about 1⁄32 in. If this is done carefully the raised part will be a true smooth line. The same tool will widen the line any width desired. Cut into a wood block a form like the impression you see back of the candle. Place the sconce over this impression and with a wooden peg drive the metal into it. The dotted line on the sketch will show how deep this should be. Drive out any buckles that may have formed during the working of the metal. This is done by placing the sconce face down on the bench and striking down on the raised parts until it lies flat.

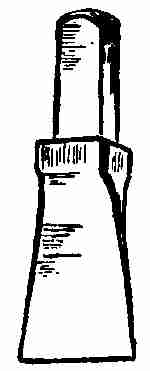

Candle holder: Bend the stock for the holder around a 3⁄4-in. mandrel or wood peg till the two ends meet. Clean and solder these ends. Cut a 3⁄4-in. disc to fit the inside of this and solder in. Place this on the 11⁄2-in. disc and drill a hole through the centre of both.

Bracket for candle: Take the 1⁄4-in. round stock. Put it in the vise with one end projecting above, about 1⁄2 in. Drive down on this end, at the same time bend it as shown in the drawing. File the end flat. Cut a piece of No. 20 copper 1⁄2 in. × 3⁄8 in. and solder it on the end just filed. This plate is drilled with two 1⁄8-in. holes, and filed around. Bend the shape as shown in the drawing and on the other end file a shoulder and 1⁄8-in. pin. This is now placed through the hole of the disc and the candle holder, and both riveted to the bracket. The bracket now is placed on the bottom of the sconce (see drawing), and riveted on. The whole[56] sconce may now be nailed with round head nails to a flat 1⁄4-in. board to give weight, or there may be riveted to the back, angles made of No. 20 metal, 5⁄8 in. wide and bent 3⁄8 in. one way and 1⁄4 in. the other way. These angle pieces are riveted on the sides and on the two ends.

Rivets add much to the decoration of the work if they are placed at intervals and properly spaced. They make a nice finish. A hole can be drilled at the top of the reflector, to hang it upon the wall.

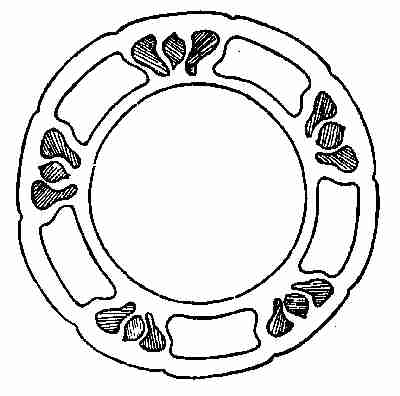

Material: One piece of copper, No. 20, 7 × 7 ins. One piece 4 × 4 ins. (for lid). One piece 3⁄8 in. wide and long enough to go around the opening of the vase or jar.

Tools: Round stake, anvil stake, driving and planishing hammers, dividers, and shears.

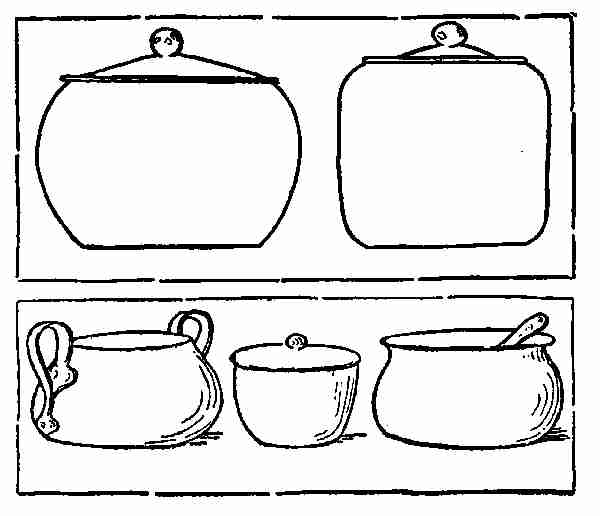

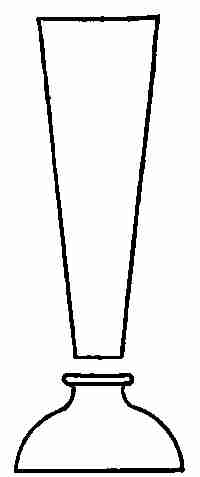

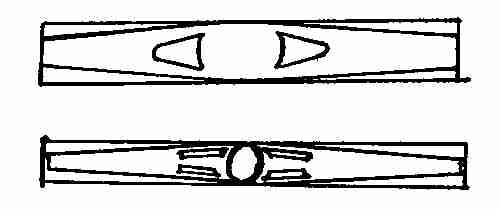

Design: Vase, having a base 21⁄2 ins. in diameter, height 3 ins., 31⁄2-in. opening at the top, and lid to fit. The full height of the vase is 41⁄2 ins.

Directions: Take the 7 × 7-in. piece of copper and draw a 7-in. circle. With the dividers set 11⁄4 in., using the same centre, describe a circle. This outlines the 21⁄2-in. circle for the base. Drive[57] up this disc as you did the one for the copper bowl on the wood block, making it as deep as possible. In the same way as you flattened the bottom of the copper bowl, flatten the bottom of this piece of work. Place the bowl over the round head stake. With your hammer drive on the outside. This driving with the hammer on the outside decreases the diameter and increases the length. You will remember that the copper bowl was driven up almost entirely by the use of the raising hammer on the inside and finished by work on the outside with the planishing hammer. This vase or jar calls for the shaping hammer. The vase is placed over the round stake and driven into shape by work on the outside with the shaping hammer. When the rough bowl shape is on the round head stake,[58] drive the sides straight, beginning the strokes at the line of the base circle. Repeat till the sides begin to straighten and take the shape of the design. Take it off the round stake and place it on the anvil stake.

When the sides are symmetrical, mark with lead-pencil a line 3⁄4 of an inch from the top. Work the copper above this line, over toward the centre, until the opening of the vase is about 31⁄2 ins. in diameter. Smooth the work up with a planishing hammer. If the hammer marks made by driving the bowl into shape are carefully done they leave a very beautiful mottled surface of themselves.

To make the rim for the lid to rest upon: Take the 3⁄8-in. strip of metal. Bend it into a circle small enough to fit on the opening left at the top of the vase. Be careful to have this just to fit, otherwise much filing will have to be done, and in this position filing is almost impossible. Cut it the right length, scrape both ends, and solder. Make it perfectly level so that it lies flat when placed upon the bench. Test it by placing it upon the top of the vase. File the top[59] flat, bind the rim in place. Wash, then place bits of solder all around it and heat it until the solder runs. Cool off in water, file off all rough edges left by the solder, clean and polish.

Lid: Take the 4 × 4-in. piece. Cut a 4-in. circle. Place the bowl upside down upon this disc, draw with a pencil all around the rim on this copper plate. This marks the diameter of the rim on the plate, also the line where the copper should be bent to form the lid to fit the rim.

With the anvil stake in the vise, place the disc against the sharp end of the stake, with the line on the edge. Drive with the raising hammer against the part projecting above the stake. Turn the disc, keeping the circle line on the sharp edge of the stake. Repeat this till the sides are at right angles to the top. Place the lid upside down on a wooden block, drive on the inside, shaping it like the drawing. Make it fit the rim, trim off the rough edges, file up smooth, and polish.

Do not forget constant annealing, for you know hammering always makes the metal hard.

Material: 3 pieces of copper, 6 × 6 ins., No. 20. One piece of round rod copper, 1 in. long. One piece of copper, 12 × 1⁄4 ins. (for rim). Solder.

Tools: Hard wood block, round head and anvil stakes, combination stake, shears, dividers, planishing hammer, raising hammer, and shaping hammer, files, emery cloth.

Parts: Bowl, stem, base, lid, ornamental top of the lid.

Directions: Make a working drawing (full size) on drawing paper, plan and elevation.

Bowl: Take the 6 × 6-in. piece of copper. Cut out[61] a 6-in. disc. Drive the bowl up as you did the copper bowl. It should be the same shape as the copper bowl. Do not flatten the bottom. The drawing shows that the bottom should be rounding, to fit the stem.

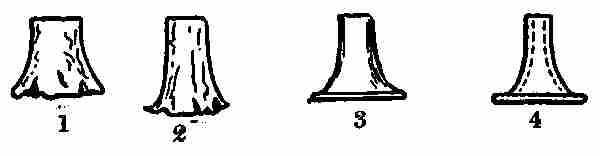

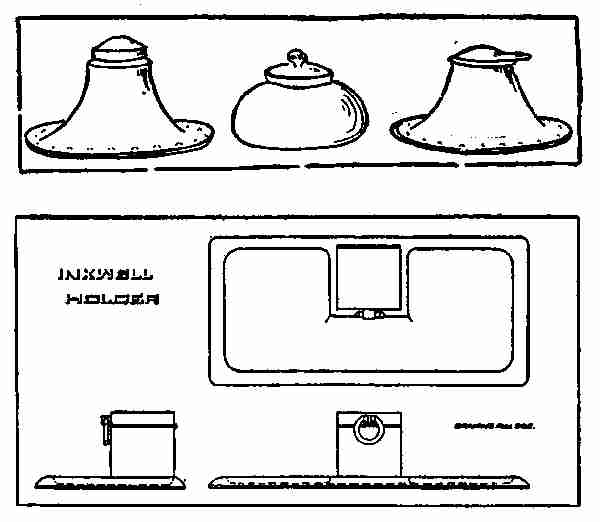

Stem and base: Take another piece of 6 × 6-in. copper. Cut 6-in. disc. With the dividers make a 1-in. circle in the centre of the disc. This inner circle must be beaten up until it becomes the stem. To do this place the disc on the round top stake, with the marked circle touching the edge of the round top. Strike with the raising hammer just above the circle line, turning the disc each time. When you have made one turn of the disc, repeat this twice, hammering just above the part driven up before. Keep repeating this until you have reached within an inch and a half of the outer edge of the disc.

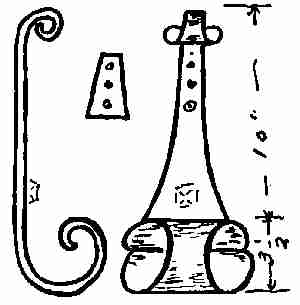

The drawings numbered 1, 2, 3, 4, show the steps in the working up of the copper disc into the stem.[62]

You now have a bell-shaped piece. Anneal the metal and repeat the hammering, beginning at the same place and working up to the same place as before. Anneal whenever the metal seems springy and keep working until the stem is tapered about 3⁄4 in. at the small end, gradually widening into the vase. Place the bell-like stem on the table and flatten it so that it lies perfectly smooth, with the stem perpendicular to the base. Find the centre of the bowl, describe a 3⁄4-in. circle. Scrape both the circle and the small end of the stem. Turn the bowl upside down, place the stem end of the base on the bowl, and solder in the usual way.

To make the lid: Take the 6 × 6-in. piece. Cut a 6-in. disc. Find the centre. Drive the centre down by using the small end of the planishing[63] hammer. This makes a cone-shaped centre, with the sides gradually widening to the edge of the lid. The highest point of the cone is one inch above the level of the lid. Place the lid on the table and tap gently on the outside until it lies flat. Take the small 3⁄8-in. piece of round rod, file a small shaped ornament (to taste) on one end of the rod and a shoulder on the other end. Drill a hole in the cone-shaped part of the lid, push the rod 1⁄8 in. through this hole and rivet it on the inside.

Rim: Strip of copper, 12 × 1⁄4 ins. Bend it into a circle just to fit the outside of the lid. Cut off the proper length and solder. Make it perfectly round and perfectly flat. Place the lid on the chalice bowl so that it overlaps a little all around, evenly. Draw a pencil line all around the edge of the bowl on the under side of the lid. This is where the rim is to go. Before soldering, test, by placing the rim on the face of the lid. Any openings seen must be closed by pressing the rim down to the lid. Bind tightly with binding wire, scrape, and solder. File and finish.

By this time you will have many pieces of scrap copper on hand. These should be kept in a small box and used whenever suitable.

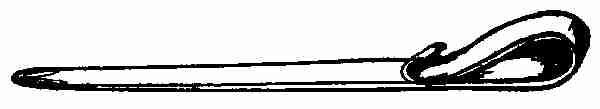

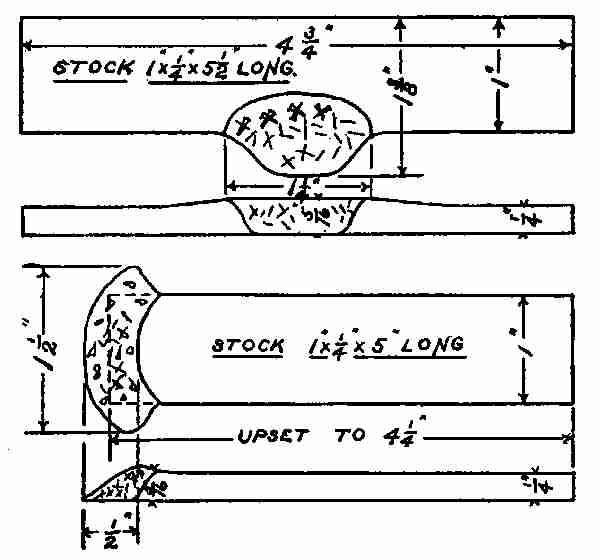

Material: A piece No. 20 gauge, 11⁄2 × 1⁄2 ins., is enough to make the head of a hat pin. The pin part must be of steel, copper is too soft. Buy any cheap hat pin in a dry goods store. (A cent apiece.) Break the glass top or black top and use the pin for the copper head.

Tools: One chasing tool, half moon; shears, dividers, planishing hammer.

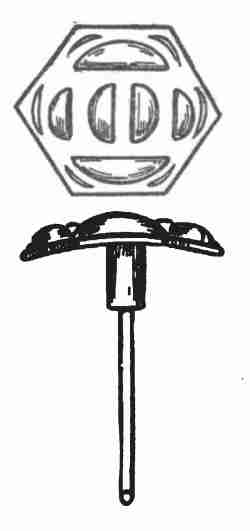

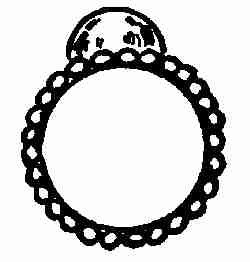

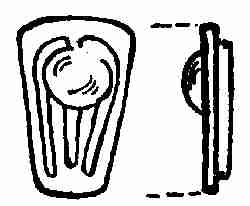

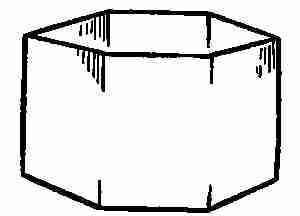

Design: Hat pin with hexagonal top (6 sides) 11⁄2 ins. across. With your dividers draw a circle on the piece of copper, having a diameter of 11⁄2 in.[65] With the radius of the circle, mark off the circumference into 6 equal parts. Draw lead-pencil lines from one point to another, just touching the circle at these points. With your shears cut along these straight lines. Now you have a 6-sided piece of copper 11⁄2 ins. across. Place this piece of copper on the flat end of the hard wood block (the grain end of the wood), and make impressions on it with the half moon tool like your designs. This tool you can make yourself. Take a piece of steel, 5⁄16 in. square or round, heat one end to a red heat and flatten it, like the flat end of a chisel. File the end just flattened blunt and rounding. This end should be hardened to prevent it from wearing rough. To do this[66] heat it to a dark red heat and plunge it into cold water. Place your tool on the upper sides of this plate and drive it with a hammer into the copper, being careful not to drive it through into the wood. If you drive the tool through you will spoil the design and have rough edges. This makes a simple raised or embossed design and is quite easily done.

When this pattern has been stamped in, curve the piece of copper any shape you wish by placing it in the depression in the hard wood block. Place the embossed side down, and with the round end of the planishing hammer, drive with light blows so as not to flatten the design. In this way, you can shape it as you wish. The top could now be soldered right on to the pin itself, but that would not make a strong hat pin. It would be weak and too easily broken from the head. In order to have a strong hat pin we make a little mushroom shaped pin holder which is fastened on the under part of [67]the head of the hat pin and in which the pin itself fits.

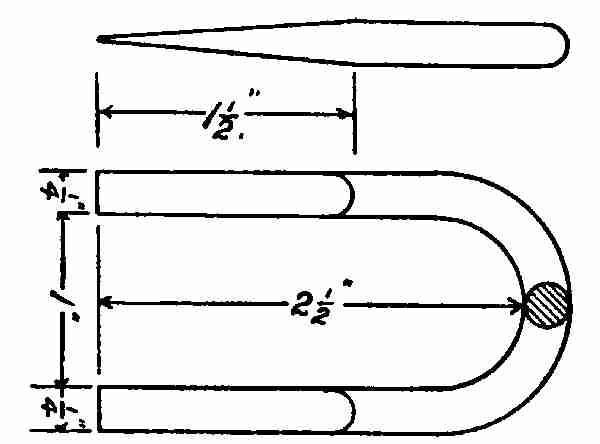

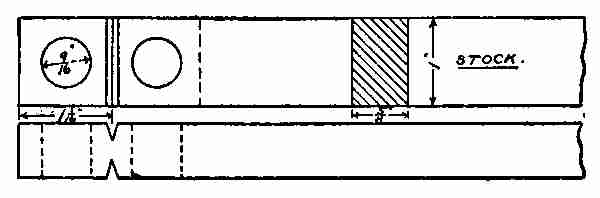

Material: Copper, No. 24, 3⁄8 in. square to make the flat disc. Copper No. 24, 3⁄8 in. length and about 5⁄16 in. wide to make the cylinder.

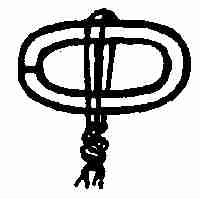

With a pair of dividers draw a circle 3⁄8 in. in diameter. Cut out the circle. Place this little disc on the flat end of the hard wood block and with a punch make a hole 1⁄8 in. in diameter in the middle of the disc. On the same end of the block, file (using round file) a groove right across the corner, about 1⁄8 in. deep. Place the small piece of copper (3⁄4 × 5⁄16 ins.), over the groove. Take the steel wire belonging to the hat pin and place it on top of the copper and over the groove. With the hammer, strike so as to drive the pin, and at the same time the copper, into the depression. The copper sinks into the groove and the two sides lap up on each side of the pin. Drive the two sides down until they lap around the wire, the edges meeting. This makes a copper cylinder which fits exactly around the wire of the pin. Take the cylinder off, fit it into the holes[68] of the small disc. Wash the two pieces with a borax solution, place a little solder on, and solder the disc to the cylinder. After cooling the piece in water, shape the disc so that it fits the under side of the hat pin top. Polish the end of the wire pin with an emery cloth, also the top of the pin holder and the inside of the hat pin top. Push the wire into the little cylinder so that it comes flush with the disc.

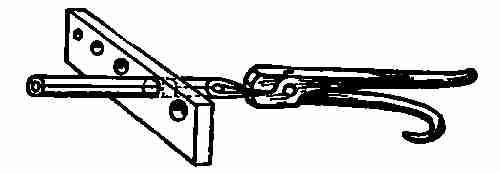

Now the pin is all ready to solder to the head,[69] but there is great difficulty in getting it in straight. In order to do this I make a little device out of copper, which helps me in getting things on straight. Take a piece of copper 1 in. wide and 5 ins. long. Bend each end, one 2 ins. and the other 3⁄4 in., both in the same direction at right angles. With the shears cut a V-shaped piece in the short end. This little stand is good for soldering any upright piece to a flat piece, when they should be at right angles to each other.

Place the top of the pin on the long leg of the stand and, with the pin in the slot, place in proper position and solder.

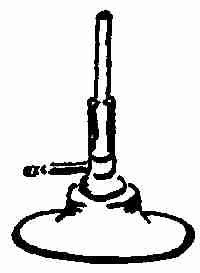

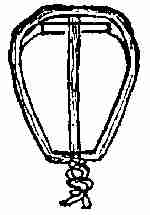

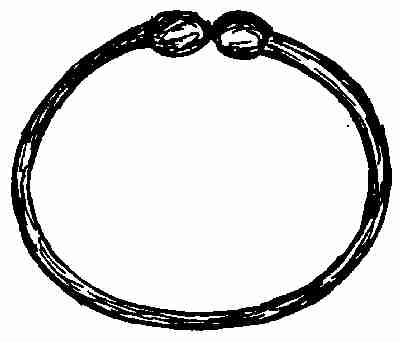

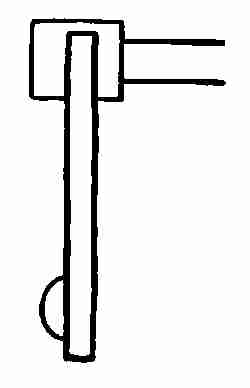

Here is a good design for a hat pin holder, a welcome addition to any dresser. The design is very simple and the holder is easily made if one follows out the directions carefully.

Material: Disc 31⁄2 ins. of No. 20 gauge, for the[70] base. One piece of 3⁄4-in. copper tubing, 4 ins. long for the body. Solder.

Tools: Iron rod, 3⁄8-in. round, 8 ins. long. Hard wood block. Planishing hammer.

Directions: Bore a 3⁄4-in. hole one inch deep in the wooden block. Place the 31⁄2-in. disc over this hole and, with the round end of the planishing[71] hammer, drive the centre of the disc into the hole 1⁄4 in. Be careful not to drive a hole through the copper disc. Turn the piece upside down. Place the iron rod in the vise. Put the bossed end of the disc on the end of the iron rod and flatten the boss down. Shape the base by rounding the edge down all around. See that it lies flat on the table, without rocking.

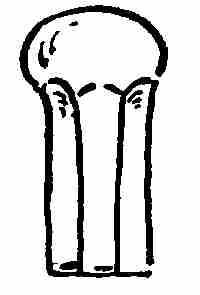

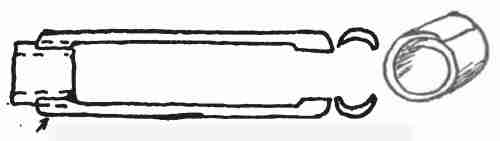

Stem: All copper tubing should be annealed before any work is done on it. After annealing, place the 3⁄8-in. rod through the hole of the tube and with the wooden mallet drive down on the tubing, beginning two inches from the end and using the hard wood block for an anvil. This constant driving and turning reduces the copper to any size required. We must make the end of this tubing fit the 3⁄8-in. rod. The tube must widen toward the other end, which is beaten out. Place it on the small end of the anvil stake. Drive with the raising hammer, turning it all the time. In this way you constantly increase the diameter, making the cup-shaped top like the design. Now the stem and base are ready for soldering. File the ends perfectly[72] smooth and level. Bind in places and solder, as before. The filing, finishing, and polishing must be done as with other copper pieces.

Hat pin holders are usually filled with some soft material. The hat pins are pushed down into this, which helps to keep them in place. Some are covered on the top with a metal disc which has five or six holes bored through, a little larger than the bar of the hat pin. These holes are drilled into the disc and then the disc is soldered on to the top of the holder. The pins cannot fall out with such an arrangement, and they are not likely to gather on one side and tip the holder over.

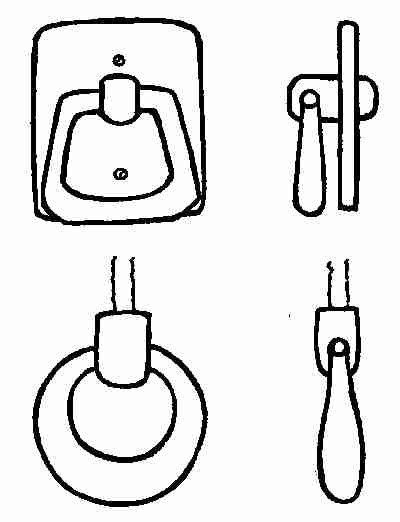

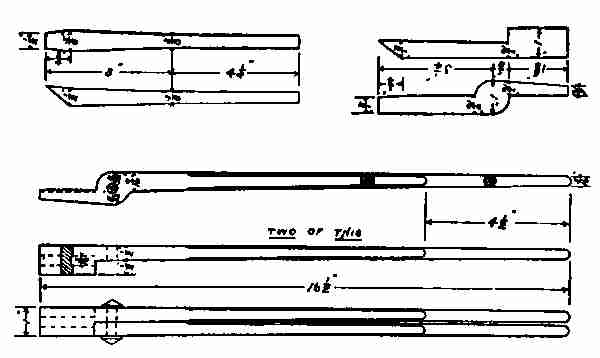

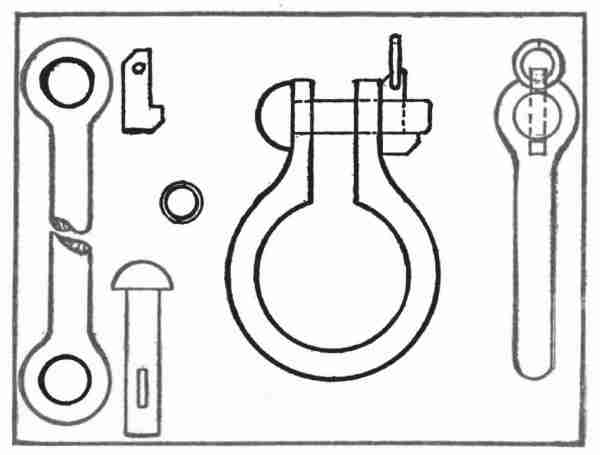

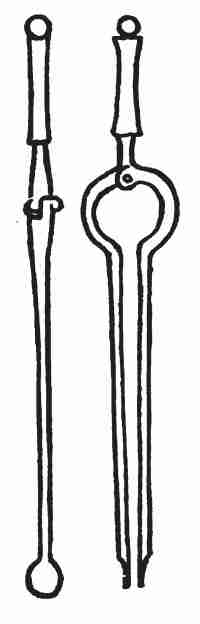

Riveting is one of the processes of joining two pieces of metal together without the use of solder. To rivet, you must first punch or bore holes into the metals along the edges to be joined. Place a rivet through these holes, and either with the hand hammer or rivet set, flatten down the projecting end of the rivet, forming a head similar to the head of the rivet itself. Be careful to have the rivet holes just large enough to let the rivet slip in and leave no extra space. If the holes are too large the rivet will bend instead of flattening.

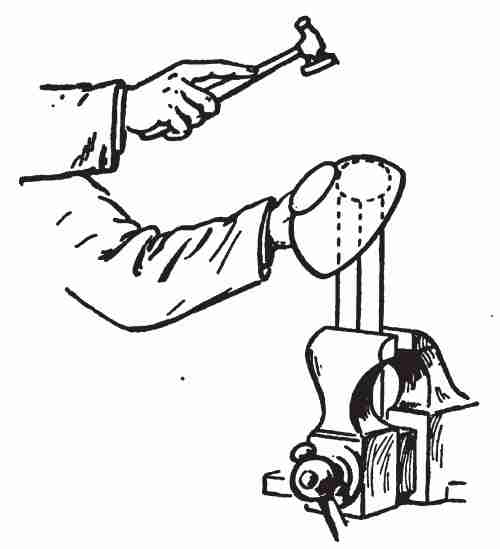

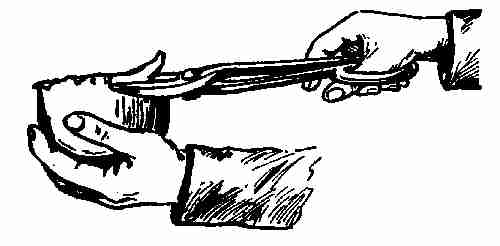

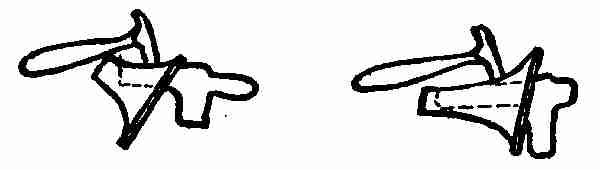

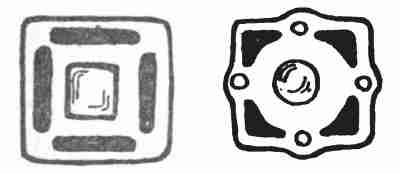

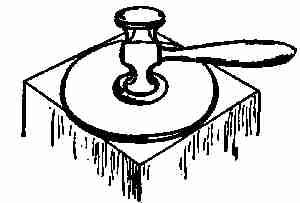

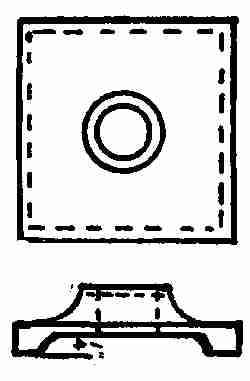

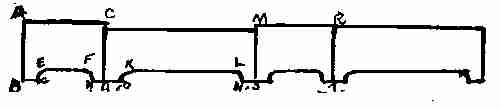

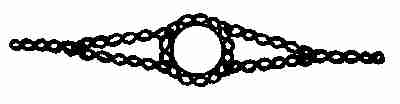

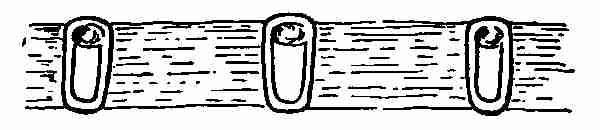

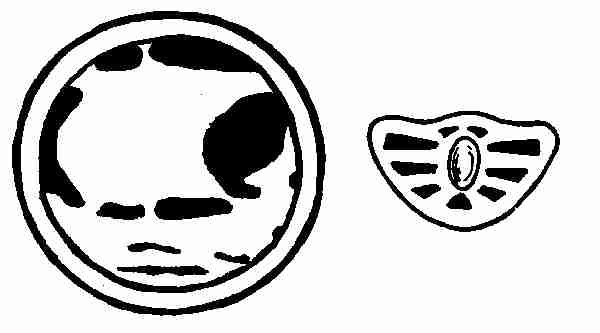

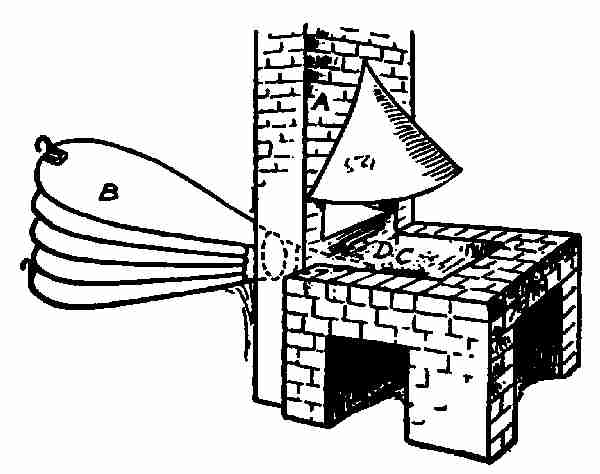

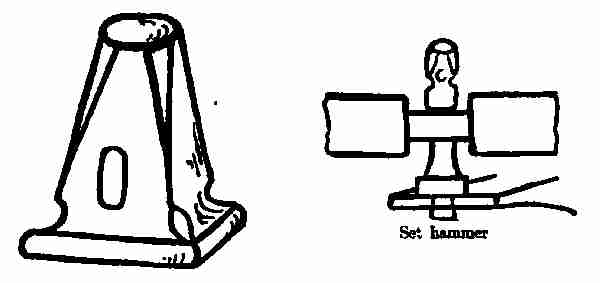

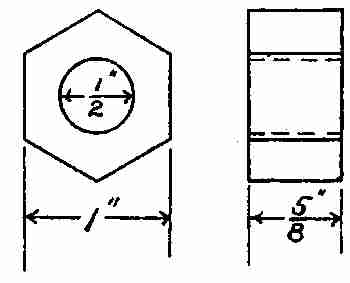

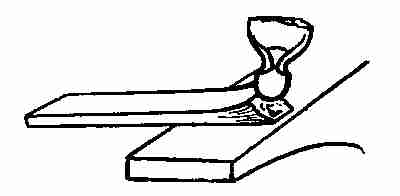

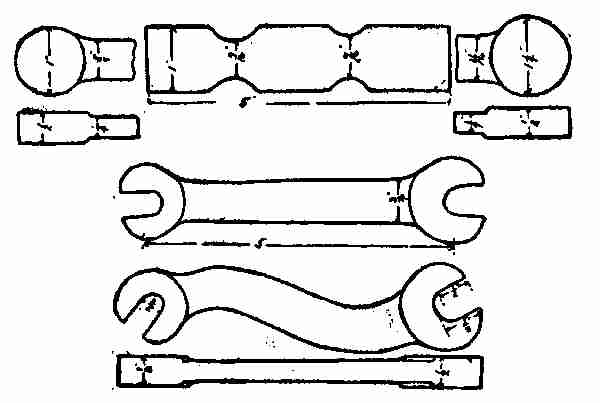

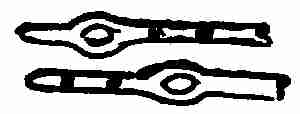

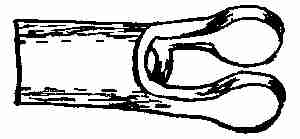

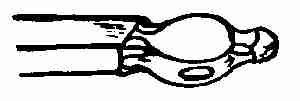

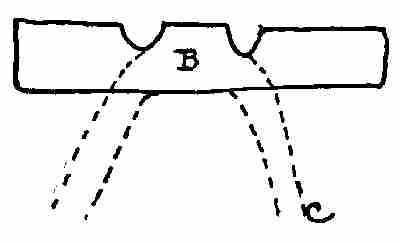

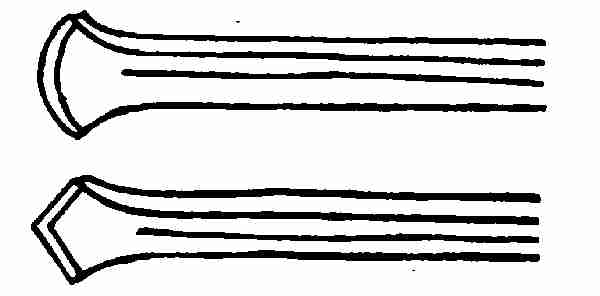

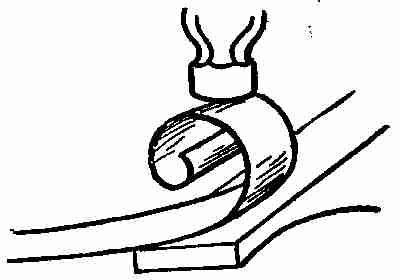

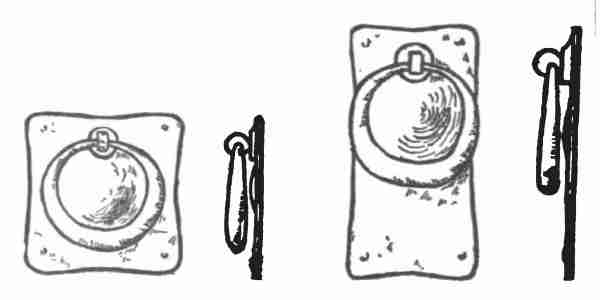

Use of the rivet set: A rivet set is a piece of steel 5 ins. long, 3⁄4 in. wide and 3⁄8 in. thick, tapering a little toward the top end. In the large end of this tool, and to one side, is a 1⁄8-in. hole drilled about 3⁄8 in. deep; on the other side is a counter-sunk[74] hole about 1⁄4 in. in diameter and 1⁄16 in. deep. This hole is used for drawing the rivet up through and closing the openings between the parts to be riveted, previous to flattening the end. (See picture of stove pipe.) The counter-sunk hole is made to shape the head after it is flattened. Tinners use it often for punching holes in thin metal, such as tin and galvanized iron, and it's one of the methods used for punching holes when making or mending stove pipes, and similar shaped pieces.

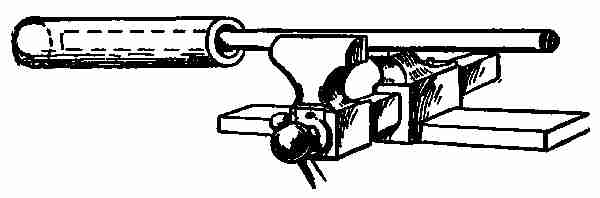

To rivet a stove pipe: Place the rivet on the stake and put the iron pipe over the rivet about where the hole should be. Tip the pipe so it will rest on the rivet. Tap lightly over the rivet. This will mark the spot where the rivet is to go. Drive down the rivet set over this mark and the rivet will be forced[75] through the pipes into the hole of the rivet set. The hole is made and the rivet placed at the same time. Flatten the projecting end, put the counter-sunk hole on the top of this flattened end, and you can shape it up like a round button.

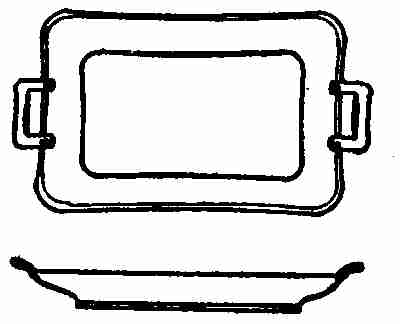

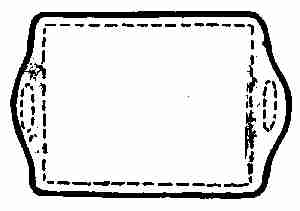

A tray as large as this one is most useful in the home for serving tea, ice cream, etc.

Material: No. 20 copper, 12 × 18 ins. Four pieces of copper, 31⁄2 × 2 ins. Silver wire for rivets 4 × 1⁄8 in. in diameter.

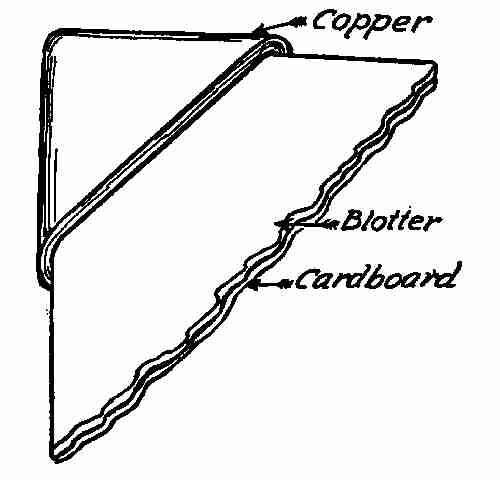

Directions: Perhaps the easiest and simplest way to make this tray is to get a large block of wood, like the end of a building joist, a little longer and wider than the 18 × 12-in. copper sheet. Out of it make a mould the shape of the body of the tray, by cutting the wood away. This mould is made similar to the one you made when making the round tray. If the mould is made carefully and according to the pattern it is a simple matter to nail the sheet[76] of copper over the depression, and drive it in with a wooden peg and mallet, making it fit every part of the mould. Before this is done it may be necessary to anneal the metal two or three times. Do so as often as you need to, it doesn't matter how often it must be done. When the surface is smooth to the touch, take the metal off the mould, and turn up the edges like the design. File off the outer edges perfectly smooth and rub them down with emery cloth. If your wooden peg has made small dents or flat places, leave them as a finish unless they seem too high or too low. The marks made by any wooden tool usually make a beautiful finish.

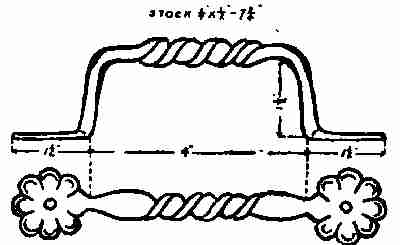

Handles: The handles are hollow. They are made by taking one piece of the 31⁄2 × 2-in. and drawing on this the outline of the handle. Repeat this on the four pieces. This makes four halves. With a pair of shears cut along the sides. Cut the rest out with a chisel. Snip the corners. Put four pieces together and place between the jaws of the vise. File into shape. This makes each piece a duplicate of the others. Place each piece of copper on a hard wood block and with the round end of the raising hammer drive into the block, hollowing it out. Make them in pairs so[77] that when the two parts are put together they make the handles hollow on the inside and oval on the outside. File the edges of the handle so that they meet close. Bind, solder, and file and round them up.

Fastening handles on the tray: Saw the two ends along the soldered joints about 3⁄8 in. Open these out so that they fit over the edge of the tray. Finish the ends off either rounding or square. Now drill a hole through the handle about 3⁄16 in. from the end. Place them again on the tray just where they should be and mark for the hole to be drilled through the tray.

Rivets: Take a piece of silver wire the size of the hole. Place one end of it on the vise so it will stick up about 1⁄8 in. above the surface. With the planishing hammer, hammer a small rounded head on the end of the wire. Cut it off 3⁄8 in. from the head in length. This makes a rivet. You will need four. Place these rivets with the head toward the front part of the tray and fasten the handle on. Polish and finish as you did other pieces of work.

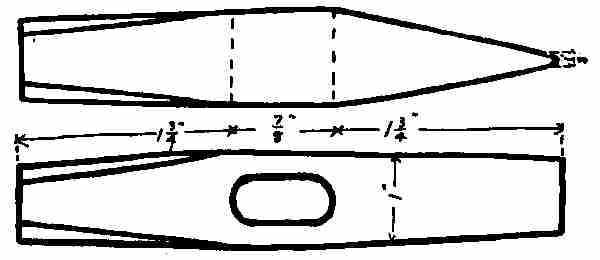

This Dutch bowl looks well made of either silver or copper. It is worked up in the same way as[78] the other bowls described here, the little sawed out handle on the side being an addition which gives to the bowl its Dutch characteristic.

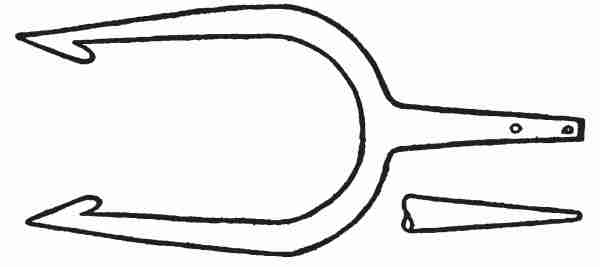

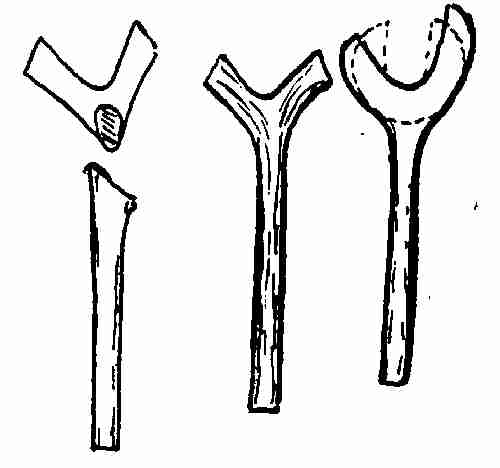

To make the handles: If the bowl is made of copper select a piece of metal thicker than the copper used for the bowl. This piece is 3 × 4 ins. long. Shape it as shown in the sketch. Mark the design and saw it out. Now bend it at right angles about 1⁄2 in. from the end. Before the corners are squared up, round the handle to fit the shape of the bowl. This is best done on a round iron stake. File into shape, drill three holes, and rivet the handles in place. A soldered handle if desired makes a neater piece of work than one riveted in place. Material used is a piece of 3 × 3 ins. The design is sawed out and shaped as before. However, in place of bending the end down we file the circle to fit the bowl. Clean the parts to be soldered, bind[79] the handle in place, wash with borax. Place bits of solder about the joint, heat, and finish. If this soldering makes the bowl very soft stiffen it by hammering it lightly all over the surface.

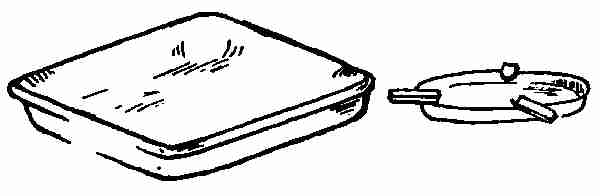

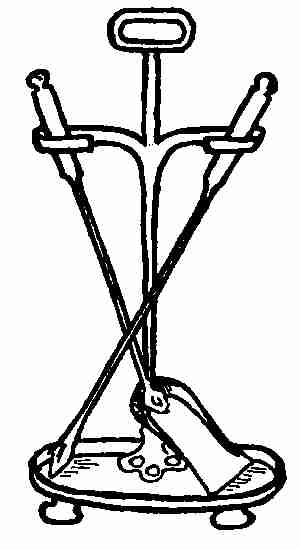

A smokers' set makes a very useful birthday gift or Christmas present and is not hard to make. All the[80] principles involved in the making have been worked out in other problems that have been given. The set consists of five pieces: a large tray, a tobacco jar, match safe, cigar box, and ash tray.

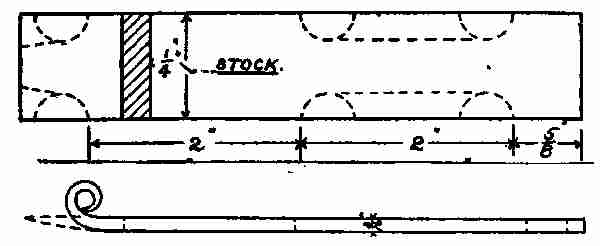

Large tray (copper or brass) oblong: This design shows a large oblong tray with handles sawed out of the sheet metal, not riveted as the handles were on the large serving tray. Draw the design for this tray on a sheet of paper. Mark out the handles like those in the picture. Place the pattern on the copper or brass sheet, and cut out the outline according to the drawing. The handles are not sawed out until the tray has been shaped up and finished. This tray is made out of a piece of No. 20 copper or brass, and is 10 × 12 ins. With the dividers make a half-inch[81] line on the four sides of the sheet as shown by the dotted lines in the sketch. Place this sheet in the vise, the dotted line even with the jaws of the vise. With the wooden peg, drive the sides up as you did the small square tray. Drill the holes in the slot and saw out for the hand-holds. File all around and finish.

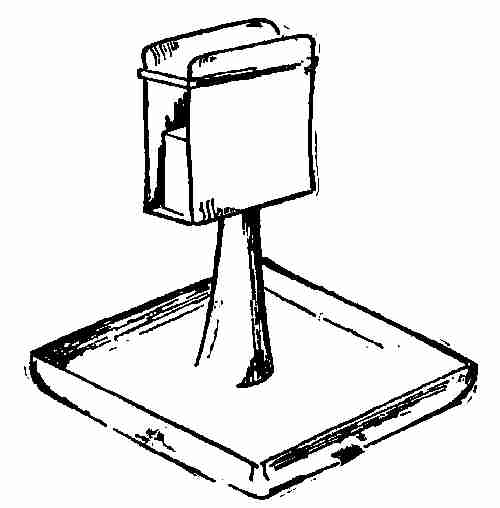

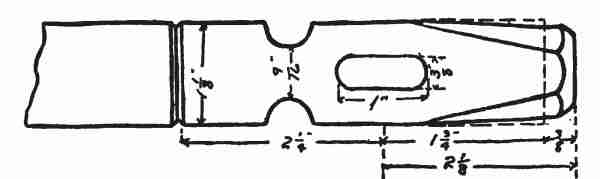

This design shows a very simple arrangement of a match safe holding a match box and a tray to catch the burnt matches.

Material: Copper or brass—No. 20, 5 × 5 ins., for the tray. No. 20, 13⁄4 × 5 ins., for the holder. No. 24, 1⁄2 × 3 ins., for the centre piece. No. 20, 1⁄8 × 51⁄2 ins., for the bar. No. 24, 11⁄2 × 2 ins., for the stem.

This little holder is made up of five parts: base, stem, holder, band, and centre piece for pushing up the matches when the box is pushed down into it.

The base is made by bending all four sides up 1⁄4 in.; corners are made rounding. The stem piece is bent into a cylinder tapered by wrapping it around a 1⁄2-in. tapered stick. Solder the edges, when this is done.[82]

The holder itself is made by taking the 13⁄4 × 5-in. strip and bending it up like the shape of a letter U, so that it is a little longer than the match box itself. The band holds the sides in place. All is soldered together, the stem in the base first, then the holder on the stem, etc. Hard solder is used. The little centre piece is bent, placed in position, and soldered with soft solder. Polish and finish.

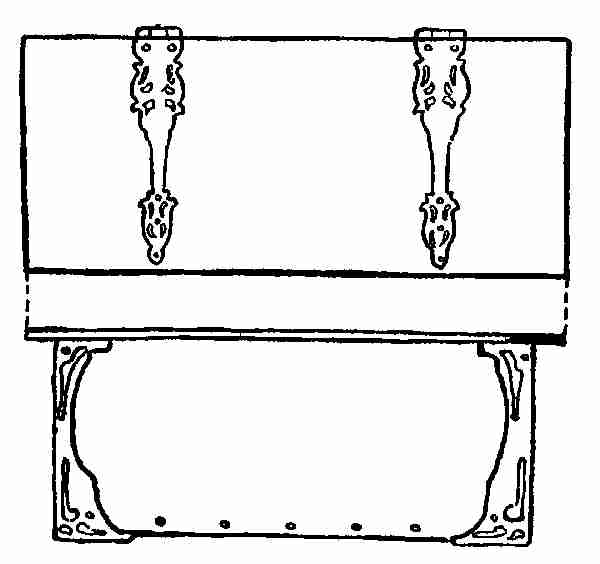

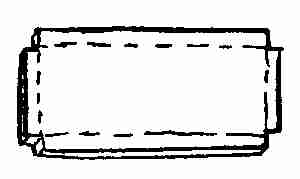

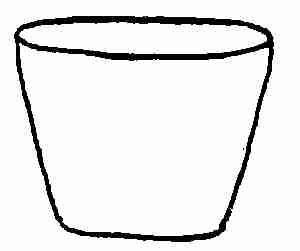

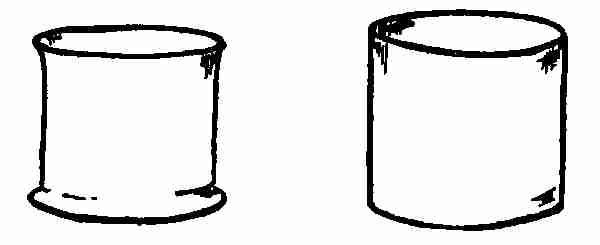

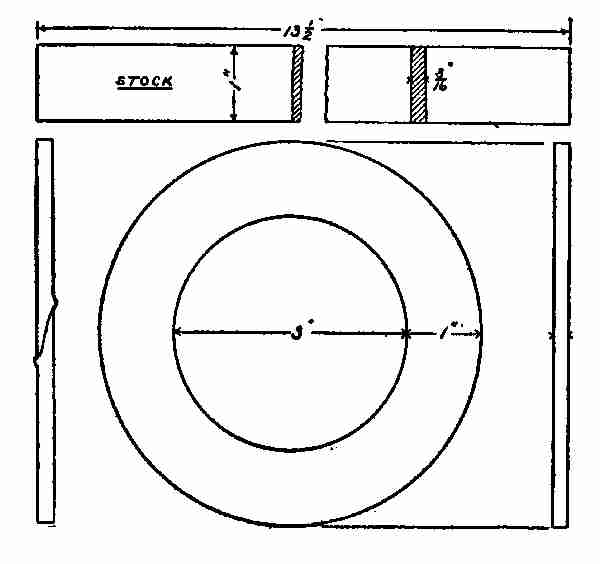

This straight-sided jar is made in three pieces. A disc 5 ins. in diameter is needed for the bottom,[83] a cylinder, 5 ins. deep, to fit the disc, and a lid made from a 5-in. disc turned over to fit the outside.

The disc for the bottom is bent up like the base of the tea caddy. Fit the cylindrical piece around this base and solder where the edges meet.

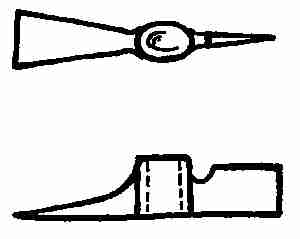

The lid: Cut a disc out of No. 20 copper, 5 ins. in diameter. Find the centre. With the small end of the planishing hammer drive a boss into a hollow wooden block, about 3⁄4 in. in diameter and 1⁄2 in. deep. Out of this boss the knob is made in the following way: Take a piece of 5⁄8-in. square iron and draw about 4 ins. of the end tapered to a 3⁄8-in. round. Bend this up about 1⁄4 in. as shown in the sketch. This is the tool that the knob must be shaped upon. Place this tool in the vise and place the hollow of the lid on this tool. With the thin[84] end of the driving hammer work the knob in shape from the outside. (See sketch.) During the working of this metal it should be annealed three or four times so that it will yield to the extreme tension required to make the knob.

The lid is rounded in the same way as the bottom piece was. There is some shaping to be done on the top of the lid. The picture here shows that[85] plainly. On the inside of the lid are two wires soldered crosswise to hold a damp sponge in place. This sponge keeps the tobacco moist. Finish and polish.

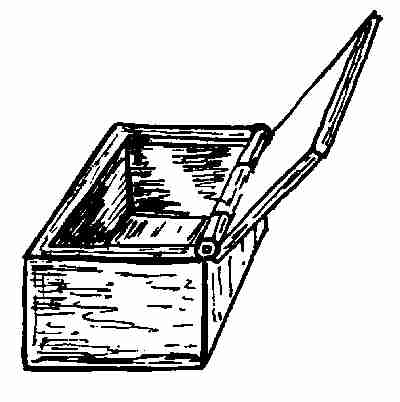

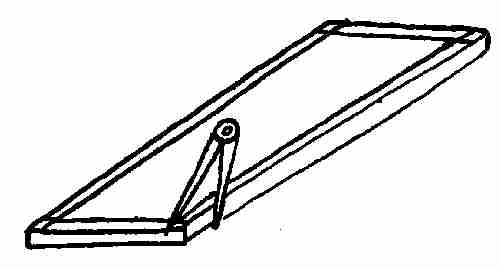

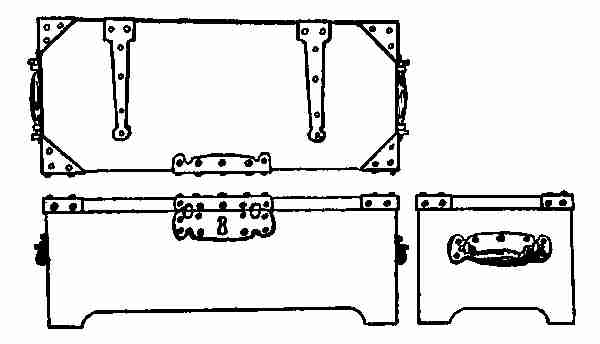

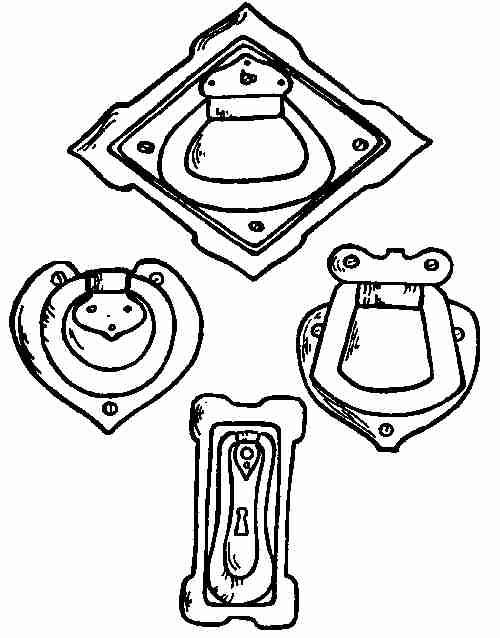

Any wooden cigar box may be decorated very effectively. This picture shows an ordinary cigar box with copper (or brass) trimmings. Corners are sawed out and riveted hinges are placed on the top. Boxes decorated in this way make splendid Christmas gifts. A heavy sheet of brass or copper can take the place of the wooden lid.

Ash trays are of various shapes and sizes. Some are merely a square tray, some are round, while others are half-bowl shaped. Sometimes two or three half-round tube-shaped pieces for holding the cigar are soldered on to the rim of the tray. All ash trays of this style are driven up in the same way[86] as you drive up a square tray or a round one, or a copper bowl. To make the cigar holders, cut a piece of thin copper or brass 1 × 2 ins. rounding on the ends. Place them on a block and round them up in a depression cut out of the wood with a gouge chisel. These are soldered on to the rim of the bowl or tray with soft solder. Polish and finish.

Material: For bowl, copper 123⁄4 × 6 ins., No. 20. For base, copper 41⁄2 × 41⁄2 ins., No. 20. For handles, 2 pieces or 3 pieces of copper 8 × 1 in., No. 20. Solder.

Tools: Combination stake, anvil stake, shears, drill press, drills, rivets, shaping hammer.

Directions—Bowl: Bend the 123⁄4 × 6-in. piece of copper into a cylinder over the combination stake. The two edges should just meet, and fit perfectly along the line. Scrape inside and outside[87] the joint. Wash with borax, bind with binding wire, and solder. Be careful to heat it all over the fire till the solder runs freely and fills every part of the joint. Cool off, then round it up again in the stake, filing off the surplus silver solder inside and outside. Hammer the joint down till flat and true. If carefully done this will show a thin even line of silver.

Base: 41⁄2 × 41⁄2 ins. Cut a 41⁄2-in. disc. Place the cylinder just made on the disc, allowing the surplus to extend out evenly all around. Draw with a pencil the outline of the cylinder on the disc. The rim must be turned up at right angles to the circle so that it fits exactly over the cylinder. To do this, place the edge of the disc on the sharp edge of the anvil stake, driving the edge over. Anneal and repeat until the sides are at right angles to the base. File off the top perfectly even, rounding out the edges. This makes a finish and border to the base. Push the cylinder into the bottom. Prepare, as usual, for soldering. Be careful to put bits of solder both around the edge of the turned up flange, and on the inside bottom edge. Heat and finish.

Handles: Copper pieces, 8 × 1 in. Cut a tapered slip off each side of the handle pieces, until the large[88] end is one inch wide and the small end 3⁄4 in. With dividers draw 1⁄8-in. line parallel to those sides. Bend each side back on this line. Shape the handle (see design) over the combination stake, using the fingers or mallet to do so. The top of the handles should fit up close against the top of the cylinder and should extend down about 2⁄3 of the depth of the bowl. The ends may be rounded off nicely with the shears, and filed. A 1⁄8-in. hole must now be drilled in each side. Place the handle in the proper position on the bowl. Mark the holes and drill them where the marks are made. Place rivets and rivet the handles on. A touch of soft solder will help keep these handles in place and at the same time will prevent any possible chance for leakage through rivet holes, for where you have rivets you are apt to have a leak. Clean, polish, and finish.

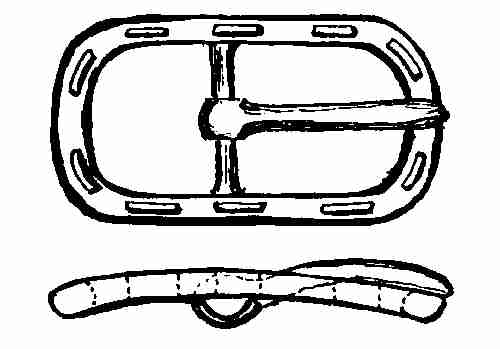

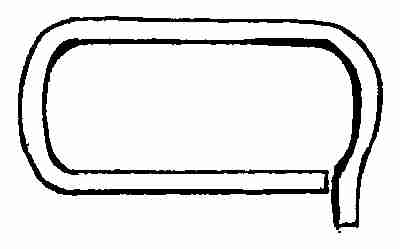

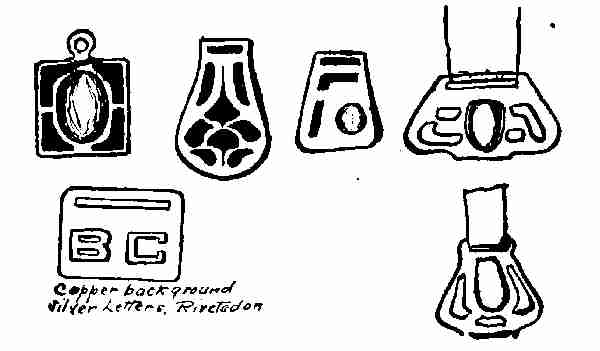

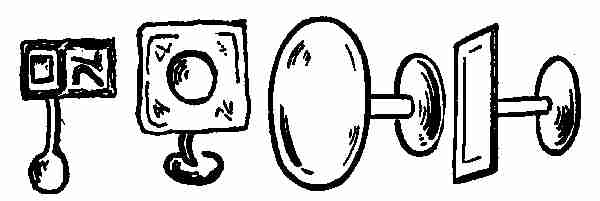

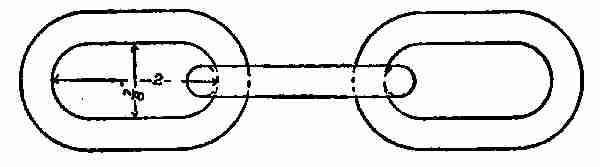

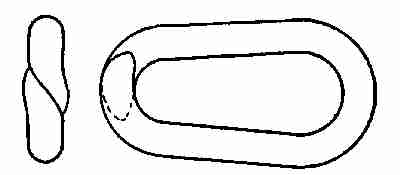

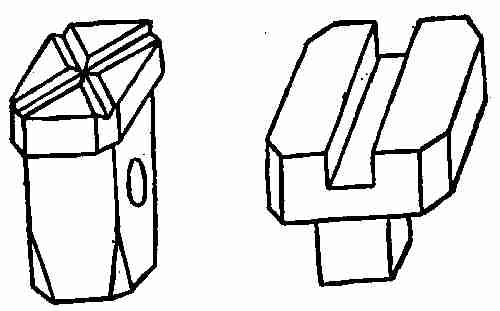

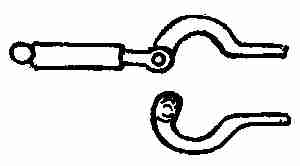

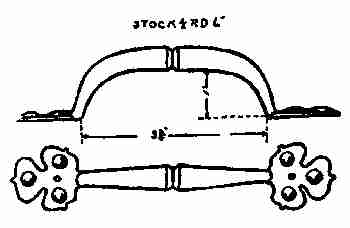

Buckles may be made of copper, silver, or brass, and the process of making them is very simple. This design shows a buckle for a man or a boy.

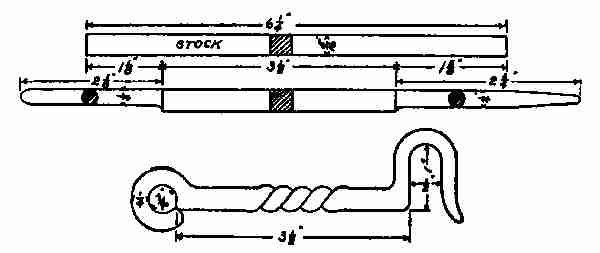

Material: Copper (or brass or silver) 5⁄16 in. square × 8 ins. long for the frame of the belt. One piece 1⁄8-in. round rod × 13⁄4 in. long for the cross[89] piece. One piece 3⁄16-in. square × 2 in. long (pin). Borax and solder.

Tools: Mallet, file, pliers, combination stake, and vise.

Directions: Take the 5⁄16 × 8-in. piece of copper.[90] Put it into the vise and bend it into a rectangular frame like the design. Be careful to make rounding corners and the sides parallel to each other. Cut off the surplus metal. Make the joint in one corner. Solder and file the corner the same shape as the other three.

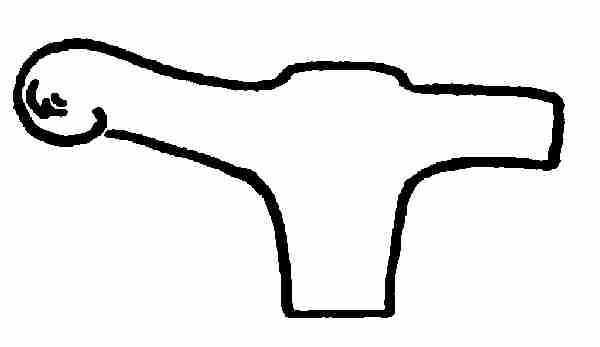

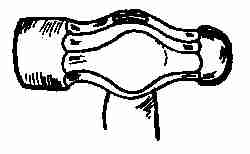

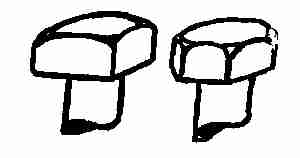

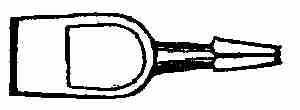

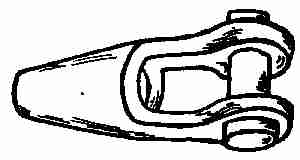

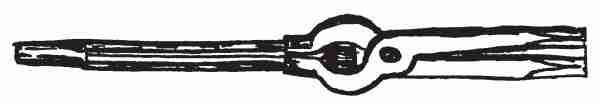

Cross bar: Take the piece of copper, 13⁄4 × 1⁄8 in. Bend the two ends down 1⁄8 in. in the same direction. (See picture.)

Solder this piece to the under side of the frame. The projections throw the cross bar down low enough below the level of the frame to allow the leather strap to come flush with the buckle top.

Pin or tongue: Take the metal set aside for making the pin. Flatten one end of this out to 1⁄16 of an inch thick and long enough to go around the cross bar. (See design.)

Flattening the end piece hardens it so that it must be annealed. With the round pliers, bend this[91] end so it will loop over the cross bar. Shape over the whole buckle according to the design. File, finish, and polish. These buckles may be made very attractive by giving them a smooth finish, or a mottled surface, or by making a sawed out design around the frame.

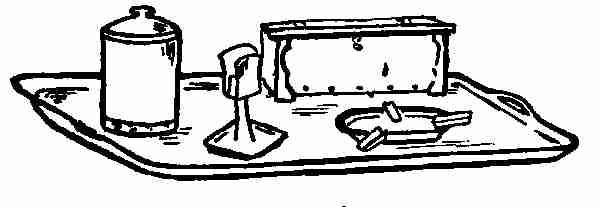

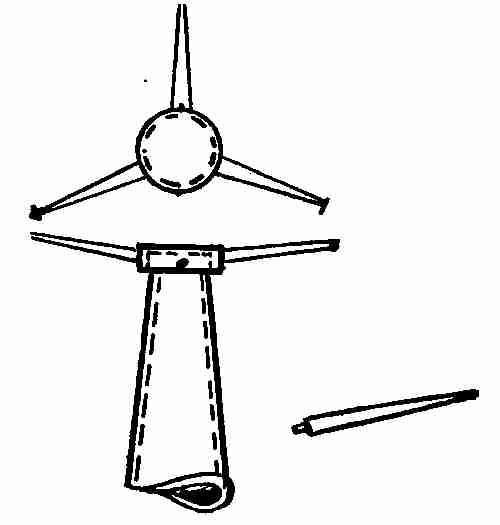

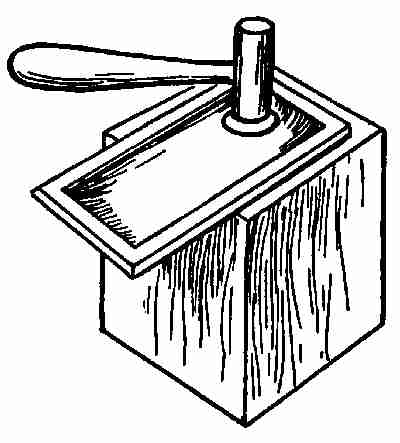

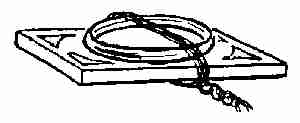

Material: Piece of copper, No. 16, 8 ins. square (base). Piece of copper, No. 24, 10 × 5 ins. (post). Piece of copper, No. 20, 21⁄4 × 21⁄4 ins. (cap). 3 pieces of 1⁄4-in. round copper, 7 ins. long (for shade holder). Solder. Borax.

Tools: Raising hammer, hard wood block, anvil stake, drill press, piece of discarded broom handle, dividers.

Directions: Make a 21⁄2-in. circle in the centre of the 8-in. square plate. Drive this centre up about 1⁄2 in. above the level, tapering on the top to about 11⁄2 in. in diameter. To do this, place the centre over a hole in the wooden block 11⁄2 in. in diameter and drive the metal into the hole to the required depth. (See design.)

Draw a line with the dividers 1⁄2 in. all around the[93] edge. Be sure the line is an equal distance from the centre. Bend the sides down 1⁄2 in. all along this line at almost right angles to the surface. This bending is done in the vise. Measure off 1⁄2 in. in either direction from each corner for the feet, file out a section 1⁄4 in. deep and 7 ins. long, as was done in making the feet for the square box.

Centre post: Take the 10 × 5-in. piece and bend it around the piece of broom handle (or any other piece of round wood the size you wish). The two edges must meet. Scrape and solder, being careful that the solder runs into the joint. File it off flush[94] with the top of the metal and make the column perfectly round. Place the column on the raised part of the base and mark around the column on the base with a pencil. Saw out a hole along the marked line. Push the end of the column in so that it is perpendicular to the base and perfectly true all around. Tie it in place for soldering, with the binding wire, by fastening the wire on the extreme top of the column, and carrying it to the four corners of the base. This centres the column ready for soldering. Wash the joint well, place pieces of silver around the base and column, and heat. The base should be crowned from the centre to the outer edge. To do this, place the centre on any round top wood block. Strike on the outer edges with the wooden mallet until the desired crown is formed. See that it stands plumb and does not rock. If it does rock, tap the base gently on the outer edges with the mallet until it stands firm. File[95] and polish until the surface is perfectly smooth and free from marks of all kinds. The beautiful colours that form on the surface of copper depend much upon the finish. The body of the lamp is now ready for the cap and arms that hold the shade.

Cap: Take a 21⁄4-in. disc. Draw a circle in the centre of this disc, having a diameter equal to the diameter of the top of the column. Place this disc on the edge of an anvil stake and drive the edges of the metal over, forming a cap as described in the[96] making of the lid of the rose jar. Divide this flange equally into three parts, drilling a 1⁄8-in. hole in each one of the three divisions. Take the three pieces of 1⁄4-in. round copper. File the ends of each one, making a shoulder on the end 1⁄8 in. and 1⁄8 in. in diameter to fit the holes in the flange. Put the end of these rods into the vise with the shoulder close to the top of the vise. Put the cap on the projecting pin, and rivet. Repeat this for all three rods. Wash the rivet joints with borax, and solder. File off any projecting parts so that the inside is flush, as this cap must fit over the column. Place the cap over the column and between the projecting arms drill a small hole through both the cap and the column, and rivet as before.

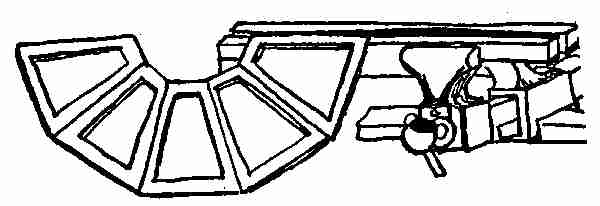

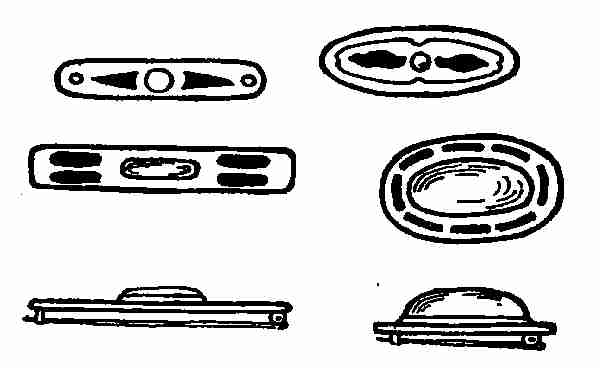

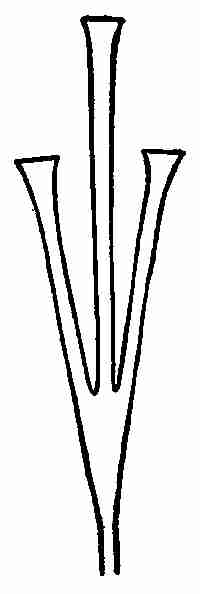

Shade, 4-sided or 6-sided: This design is for 6 sides. That gives a good proportion.

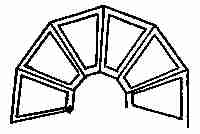

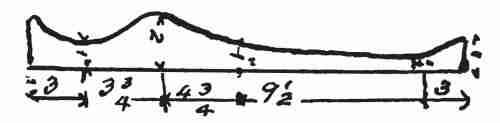

Dimensions of each side: Side (on a slant) 9 ins., top, 21⁄2 ins. Bottom, 8 ins. (See drawing.)[97] Cut out a pattern for one side. Use stiff card board. Lay this design on a piece of copper large enough to cut out the whole lamp shade. Mark around the pattern. Lay the same pattern against one side of the marked design. Make it fit exactly along the margin line. Repeat until you have done six sides. You have now a fan shaped pattern with six divisions. Cut this along the top and bottom lines.

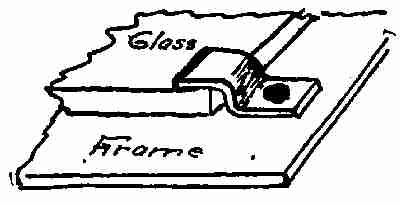

If folded up along these division lines it would shape up into a lamp shade. All lamp shades have glass for light. We provide for the glass by cutting out a section of each of the six faces. Take your card board pattern. Mark a line all around from 3⁄4 in. and parallel to the sides, 1 in. from the top and 1 in. from the bottom. Cut out the inner[98] section made by these lines. Place the pattern on the copper and mark each section. Cut it out with the cold chisel on the wooden block. File up the rough places left, make the edges square and smooth. Bend up each section along the centre line in the following way: Get two pieces of wood, 2 × 1⁄2 × 20 ins. Place the two pieces in a vise and slip the copper between the pieces down to the line where it should be bent. Tighten up on the vise, press the copper over with the hands and tap gently along the lines with the mallet, keeping the angles about 60°. Do this on each of the six sides. If carefully done the shade will have a hexagonal shape. The open parts should come together, one side overlapping about 1⁄4 in. Hammer down the overlapping part and rivet.

Glass: Cut a piece of card board 1⁄4 in. larger all around than the opening in the sections for the glass. Take this to a glazier. Tell the dealer just what is[99] wanted and he will make suggestions as to colour, kinds of glass, etc. Cathedral or opalescent glass is very decorative.

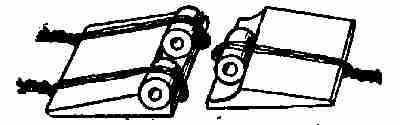

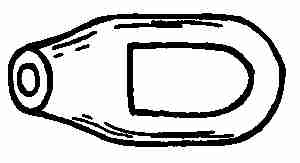

To set the glass: Place one of the panes of glass on the inside of the section, over the open space. Mark all around it. Take 4 pieces of copper (3⁄4 × 3⁄8 in.) and bend them in a double angle.

These are to be soldered or riveted on the rim. One is placed on either side, one at the top and one at the bottom. This glass rests in these brackets and keeps it in place. Repeat for the six sections. Push the brackets down against the glass after it is in place. They hold it firm against the side of the shade.

The design for this shade lends itself to many variations. It may be square, five-sided, six-sided. The edges can be escalloped both top and bottom, and a sawed out design may be made to fit over the glass.

Material: Copper or Silver.

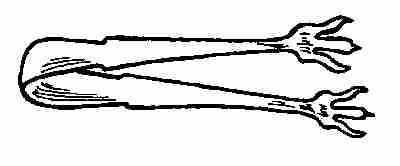

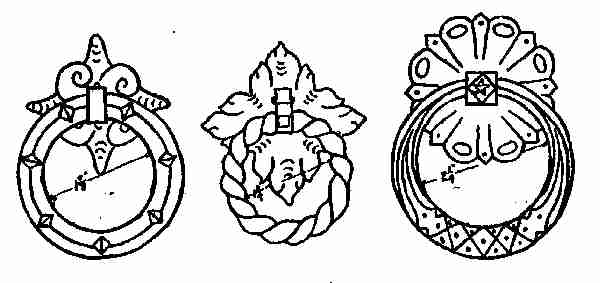

Tools: Hardwood block, 6 × 3 × 1 in. draw plate, tongs, sharp peen hammer, saw frame and saw, round file, shears, small piece of soap.