Title: Armor and Arms

Author: Thomas T. Hoopes

Release date: August 2, 2020 [eBook #62818]

Most recently updated: October 18, 2024

Language: English

Credits: Produced by Stephen Hutcheson and the Online Distributed

Proofreading Team at https://www.pgdp.net

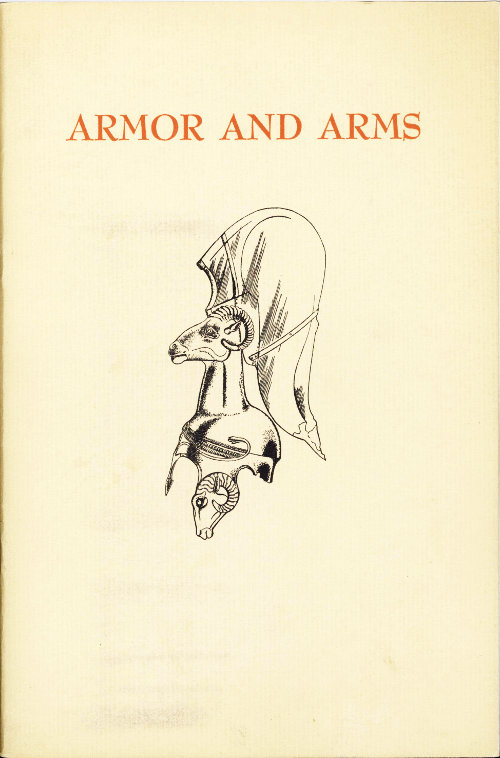

The Helmet of a Commander

Bronze, silver, and ivory. Greek, mid-VI century B.C.

From a Greek colony at Metaponto, Italy

An elementary handbook and guide to the collection in the

City Art Museum of St. Louis, Missouri, U.S.A.

by

Thomas T. Hoopes

Curator of the Museum

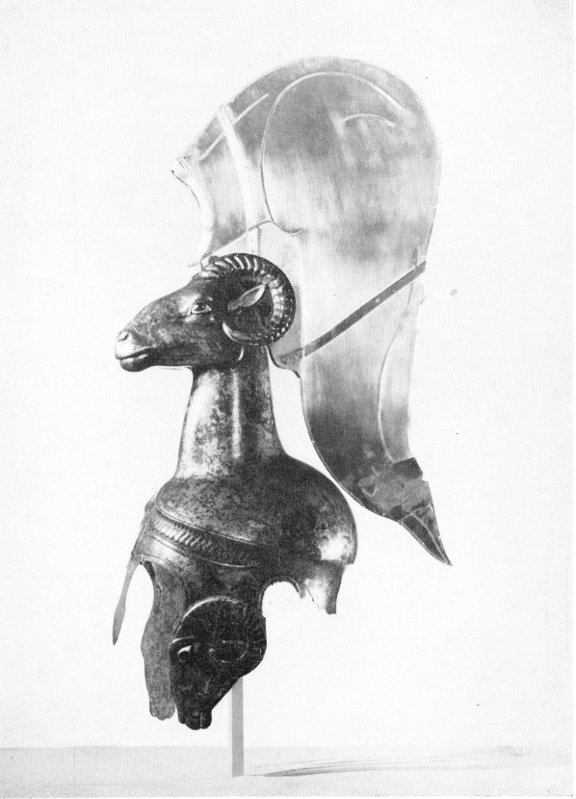

State sword, German, Augsburg, XVI century

St. Louis, Missouri

1954

Copyright 1954 by the City Art Museum of St. Louis, Mo.

This publication is a guide to the armor and arms in the City Art Museum of St. Louis and, incidentally, a very elementary introduction to the history of arms and armor in general. The major part of the Museum’s collection, comprising the European armor and arms of the fifteenth, sixteenth and seventeenth centuries, is displayed in a single armor gallery. Other specimens are shown with the exhibition of their own special cultures.

The City Art Museum is, as its name implies, restricted to objects of art, to objects which, independently of their usefulness, are more or less beautiful by the intention of their makers. There are numerous items in the vast range of armor and arms which do not fill this requirement, and are purely utilitarian. The Museum possesses specimens of some of these. As they are not considered objects of art they are not on exhibition, but have been assembled in a special study collection where they can be seen on application to the Curator.

When individual specimens are illustrated, they are given, in the list of illustrations, their identifying Museum serial numbers. If a reader fails to find on exhibition any such specimen in which he is interested, he has only to ask for it by this serial number at the information desk. If its place of exhibition has been changed he will be told where to find it; if for any reason it has been temporarily removed from exhibition, arrangements will be made, if possible, for him to see it.

The subject of armor and arms is neither short nor simple, and it is quite impossible, in a publication the size of this one, to do more than give the barest kind of outline. Many points of interest are not discussed in detail, some technical terms are unexplained, many fascinating items are not mentioned at all. If the subject interests you, you will find helpful information in the books listed on page 43, most of which will be available at any public library. If specific questions concerning armor and arms are addressed to the Curator, City Art Museum, Forest Park, St. Louis 5, Missouri, accompanied by a self-addressed, stamped envelope, they will be answered as far as practicable, but research problems cannot be undertaken.

| Figure | Acc. No. | Page | |

|---|---|---|---|

| Frontispiece Helmet, bronze with silver crest, Greek, mid-VI century B.C. | 282:49 | ||

| Title Page State sword, German, Augsburg, XVI century | 173:26 | ||

| 1 | Ceremonial axe blade (Ch’i), bronze, Chinese, An-yang, Shang dynasty (ca. 1523-ca. 1028 B.C.), gift of J. Lionberger Davis | 36:51 | 1 |

| 2 | Helmet, bronze, Chinese, Shang dynasty (ca. 1523-ca. 1028 B.C.) | 283:49 | 2 |

| 3 | Ceremonial dagger of a shaman, bronze, Siberian steppes, ca. 1000 A.D. | 34:43 | 2 |

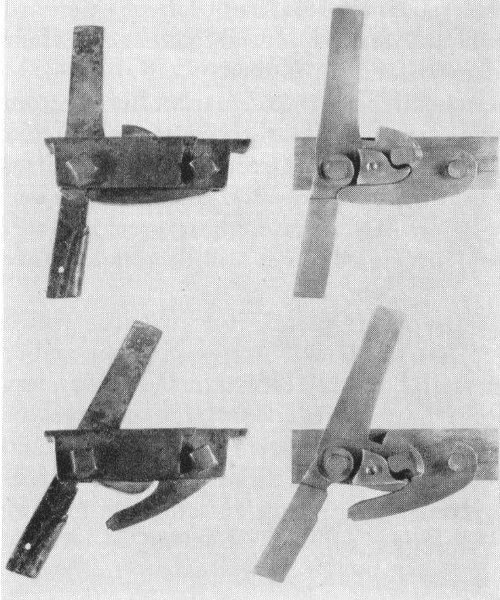

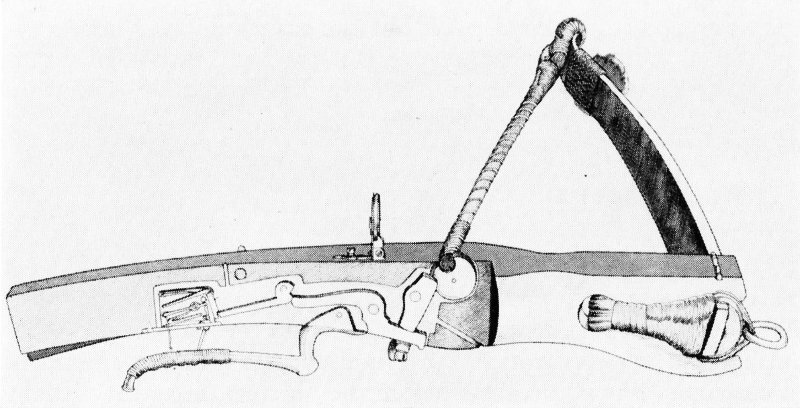

| 4 | Lock of a crossbow, bronze, Chinese, Han dynasty (206 B.C.-220 A.D.), with model to show operation of interlocking interior parts | 1106:20 | 3 |

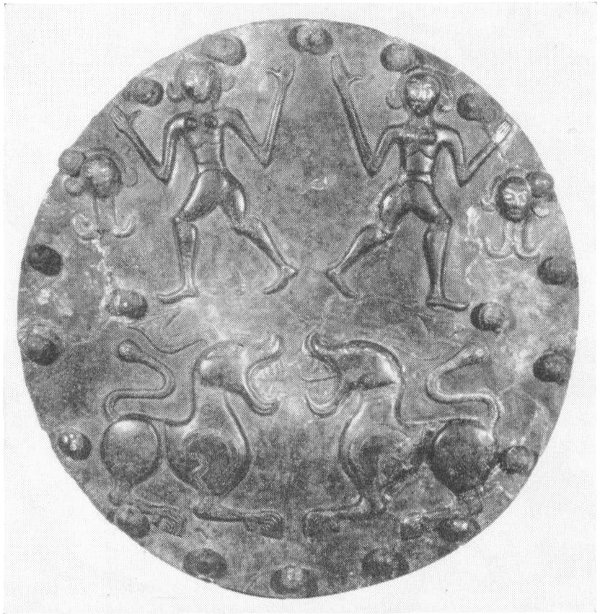

| 5 | Disk, probably the central plate of a shield, bronze, Italian, from Picenum, near Ancona, VII-VI century B.C. | 51:22 | 4 |

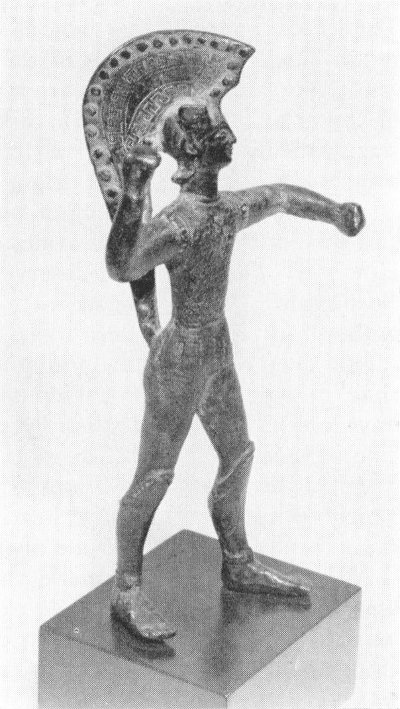

| 6 | Figure of a warrior, bronze, Etruscan, ca. 500 B.C. Gift of J. Lionberger Davis | 40:51 | 4 |

| 7 | Ink rubbing of engraved brass plate on tomb of Sir Roger de Trumpington, a Crusader, in the church at Trumpington, Cambridgeshire, England | 7 | |

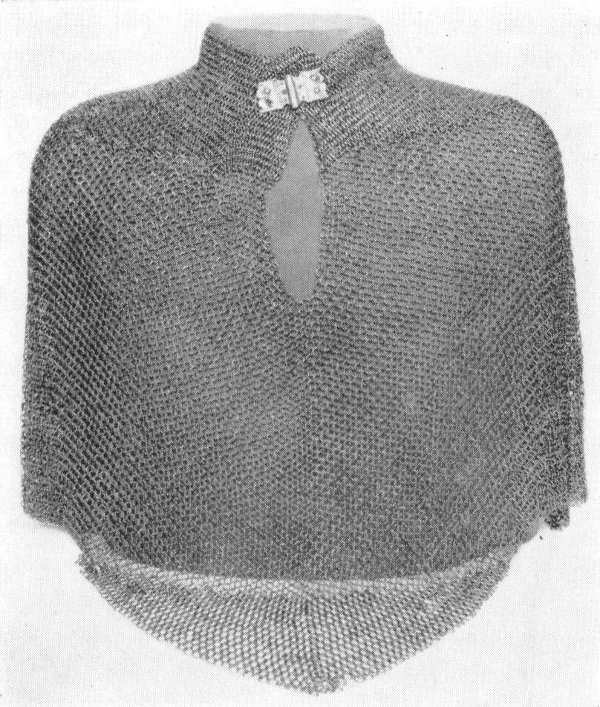

| 8 | “Bishop’s mantle” of chain mail, German or Swiss, XVI century | 87:39 | 7 |

| 9 | Salade, Gothic, German, ca. 1475 | 58:39 | 8 |

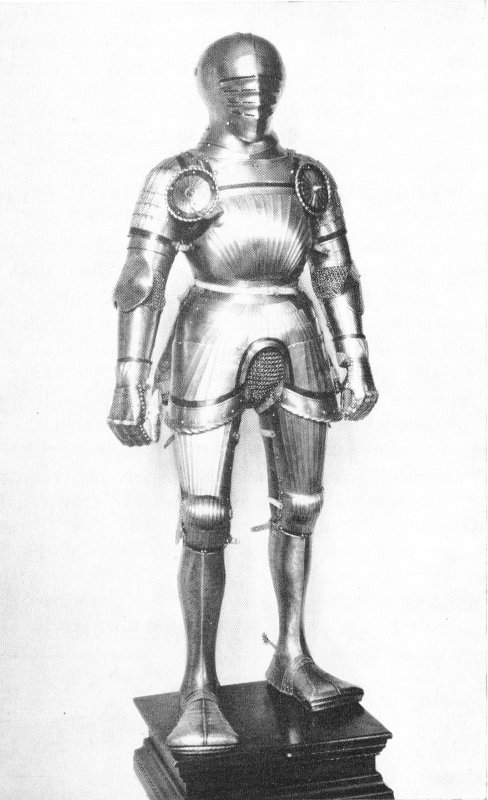

| 10 | Full suit of Maximilian armor, German, ca. 1510 | 171:26 | 10 |

| 11 | Breastplate, Italian, Pisan style, ca. 1575 | 170:26 | 11 |

| 12 | Morion, Italian, ca. 1560 | 319:25 | 11 |

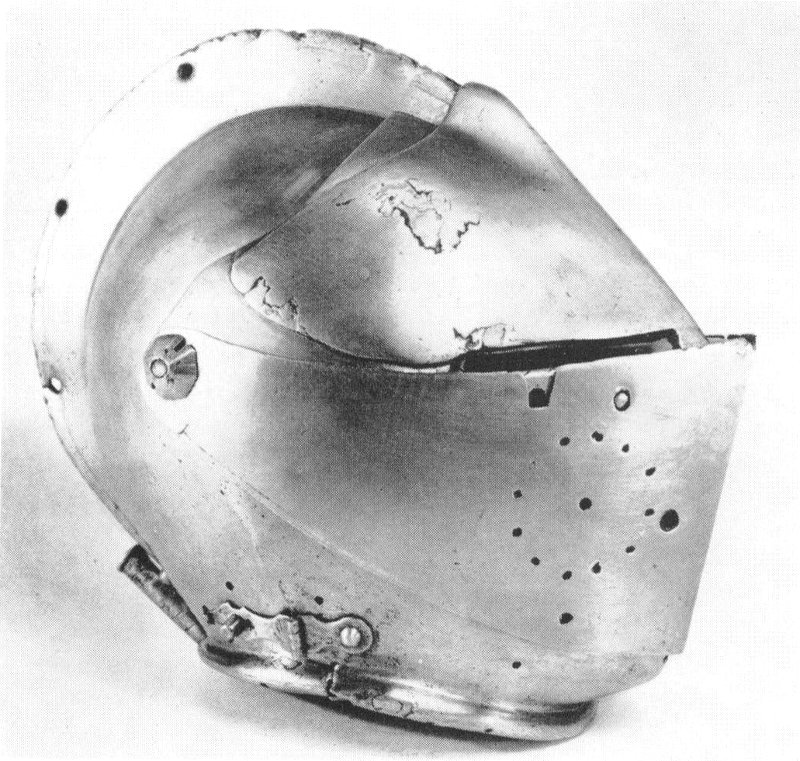

| 13 | Closed helmet, German, ca. 1575 | 79:39 | 12 |

| 14 | Tilting helmet, Spanish, ca. 1580 | 444:19 | 13 |

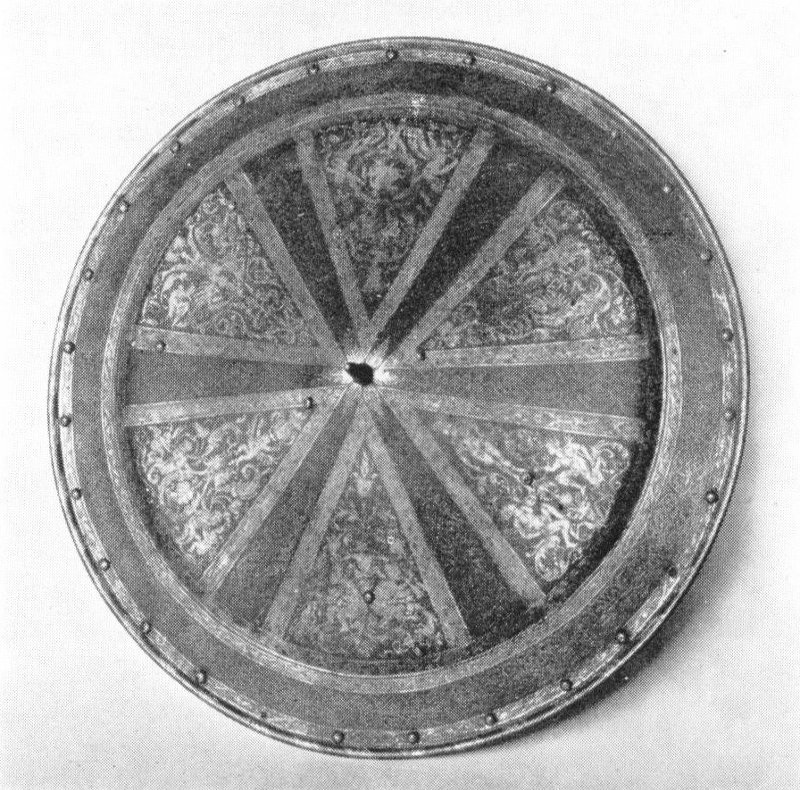

| 15 | Parade shield, Italian, XVI century | 47:27 | 14 |

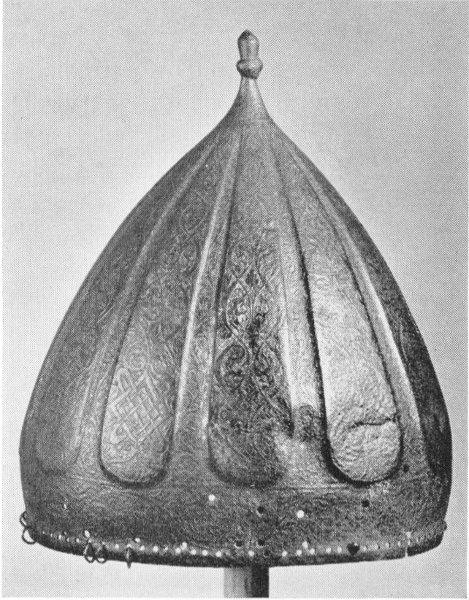

| 16 | Helmet, German, made for Hungarian or Polish market, XVI century | 71:42 | 14 |

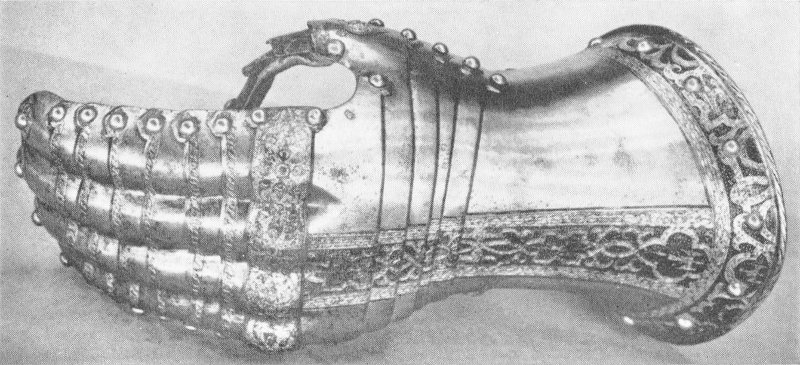

| 17 | Mitten gauntlet for left hand, English, Greenwich school, second half of XVI century | 80:39 | 14 |

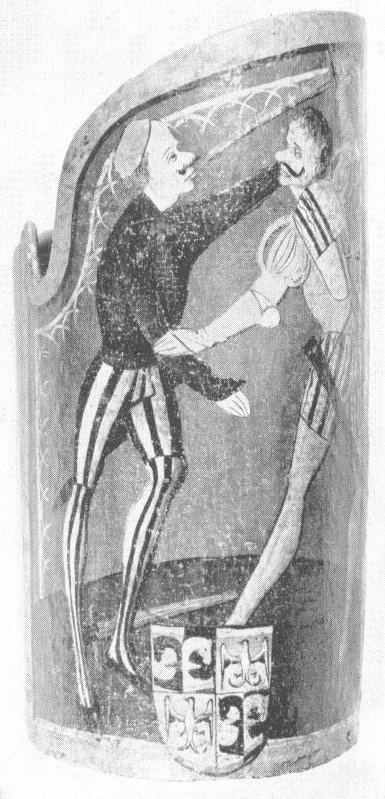

| 18 | Parade shield, wood, painted, Hungarian, XV century | 88:42 | 15 |

| 19 | Stirrups, pair, bronze gilt, French, early XVII century | 54:26 55:26 | 16 |

| 20 | Three-quarter suit of armor, South German, ca. 1620 | 172:26 | 17 |

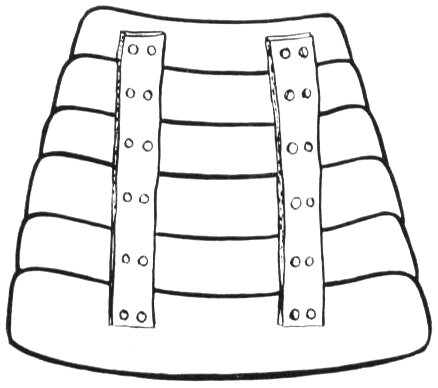

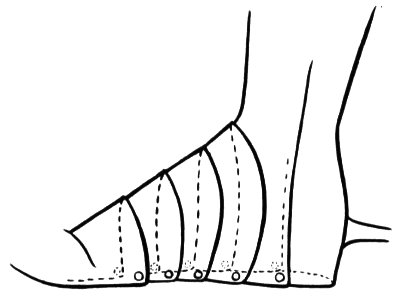

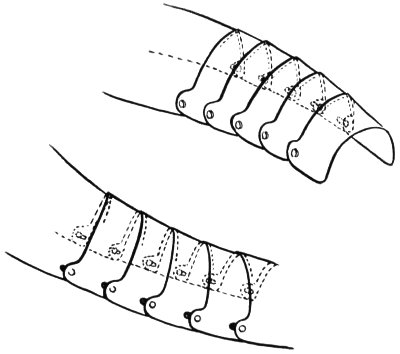

| Drawings to illustrate methods of attaining flexibility in plate armor: | |||

| 21 | By use of leather straps | 19 | |

| 22 | By use of ordinary rivets at pivot points | 19 | |

| 23 | By use of rivets and slotted holes, (so-called Almain or sliding rivets) to allow motion in two directions | 19 | |

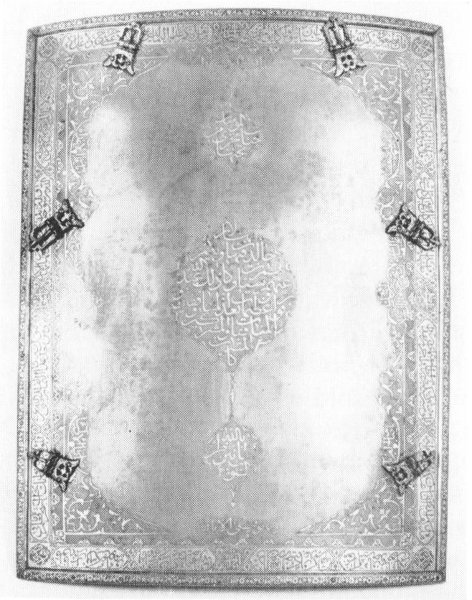

| 24 | Breastplate of char aina, Persian, Ispahan, XVI-XVII century | 34:15 | 20 |

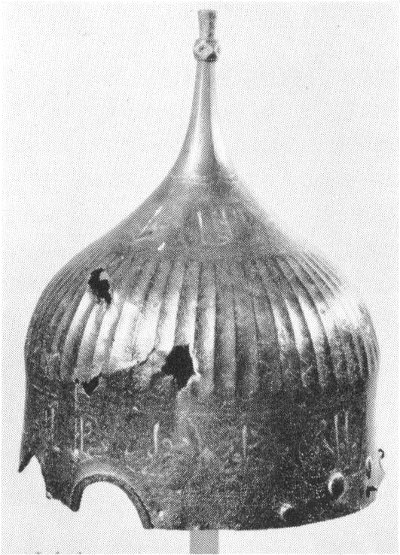

| 25 | Helmet, Persian, late XVI century | 16:22 | 21 |

| 26 | Helmet, Turkish, XV century | 36:42 | 21 |

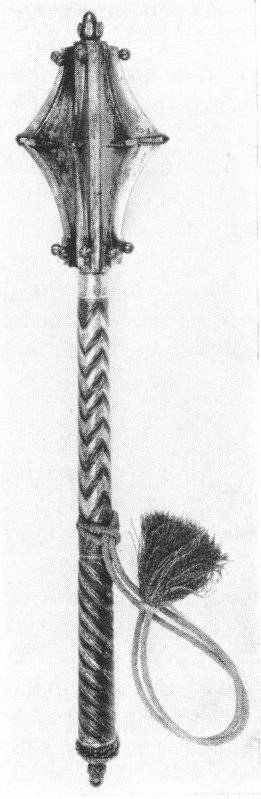

| 27 | Mace, Italian, second quarter XVI century | 231:23 | 22 |

| 28 | Sword, bronze, Chinese, Han dynasty (206 B.C.-220 A.D.) | 1108:20 | 22 |

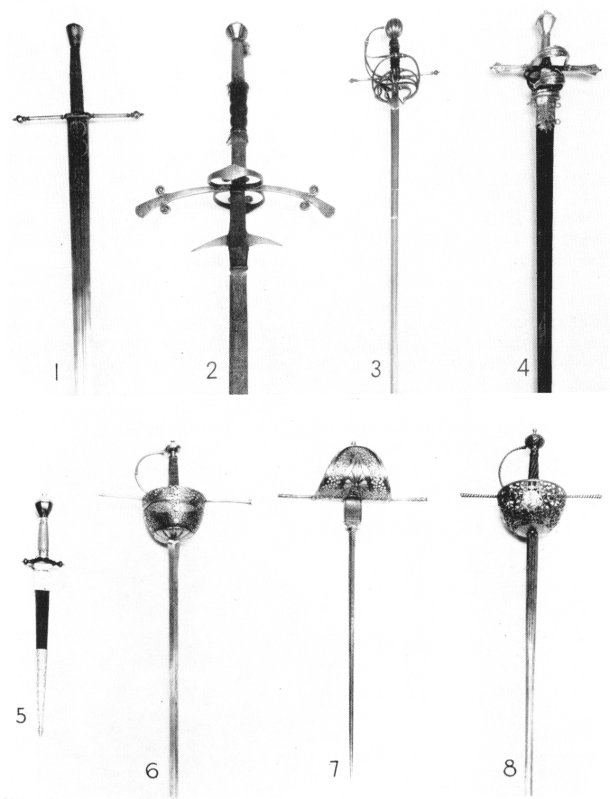

| 29 | Group of swords, as displayed | 23 | |

| 1. State sword, German, XVI century | 173:26 | ||

| 2. Two-handed landesknecht sword, Swiss, dated 1617 | 60:39 | ||

| 3. Swept-hilted rapier, Italian, late XVI century | 430:19 | ||

| 4. Dress sword, German, Saxon, ca. 1620 | 62:39 | ||

| 5. Left-hand dagger, companion to No. 4 | 63:39 | ||

| 6. Cup-hilted rapier, Italian, XVII century | 49:25 | ||

| 7. Left-hand dagger, Italo-Spanish, XVII century | 81:39 | ||

| 8. Cup-hilted rapier, Spanish, XVII century | 233:23 | ||

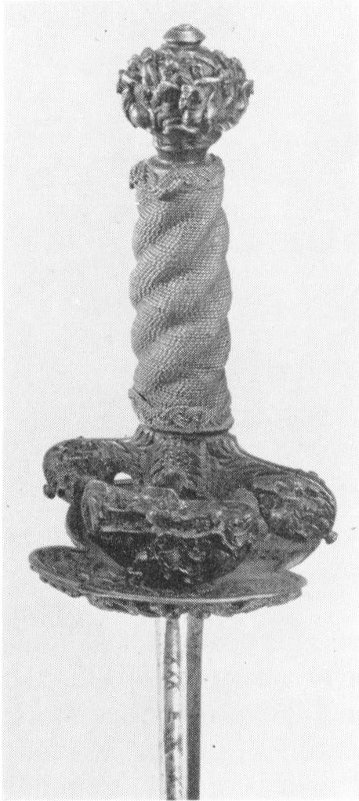

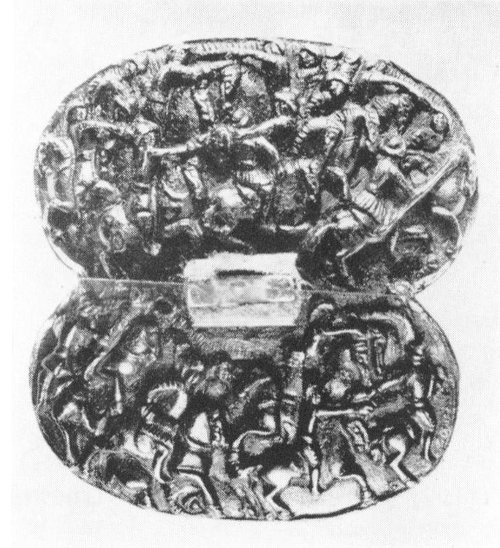

| 30 | Hilt and guard of court sword, Italian or Spanish, XVII century | 174:26 | 24 |

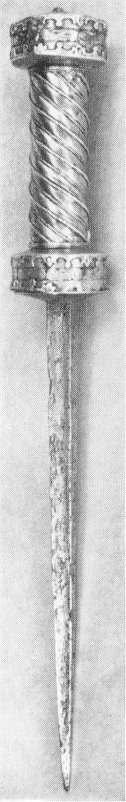

| 31 | Rondel dagger, Italian, XV century | 82:39 | 25 |

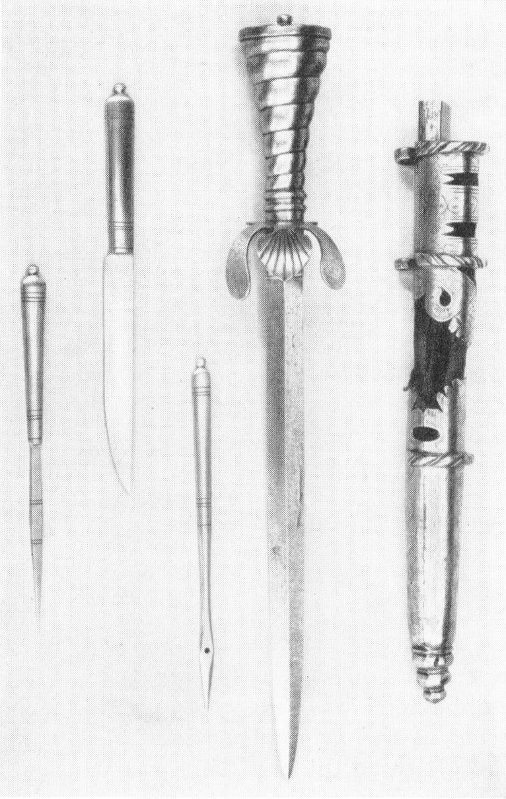

| 32 | Trousse, German, XVI century | 65:39 | 25 |

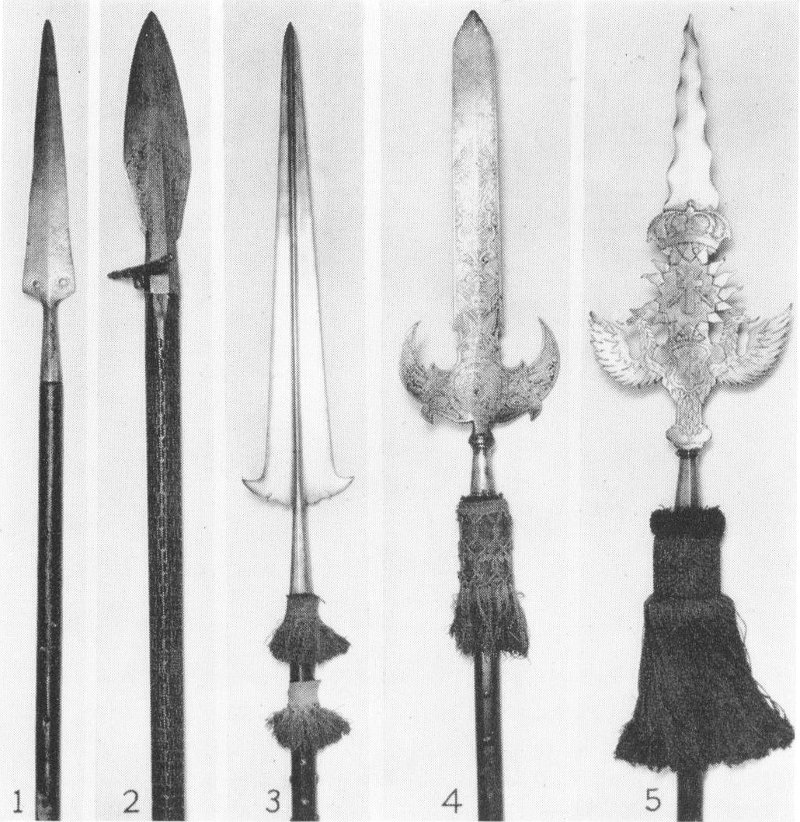

| 33 | Group of spear-type pole arms, XV-XVII centuries | 27 | |

| 1. Ox-tongue pike, Austrian, Salzburg, ca. 1500 | 433:19 | ||

| 2. Hunting spear, Italian, XVI century | 42:19 | ||

| 3. Partisan, Italian, XVI century | 450:19 | ||

| 4. Partisan of State Guard of William V of Bavaria, ca. 1615 | 169:26 | ||

| 5. Partisan of State Guard of Augustus the Strong of Saxony, King of Poland, ca. 1597 | 166:26 | ||

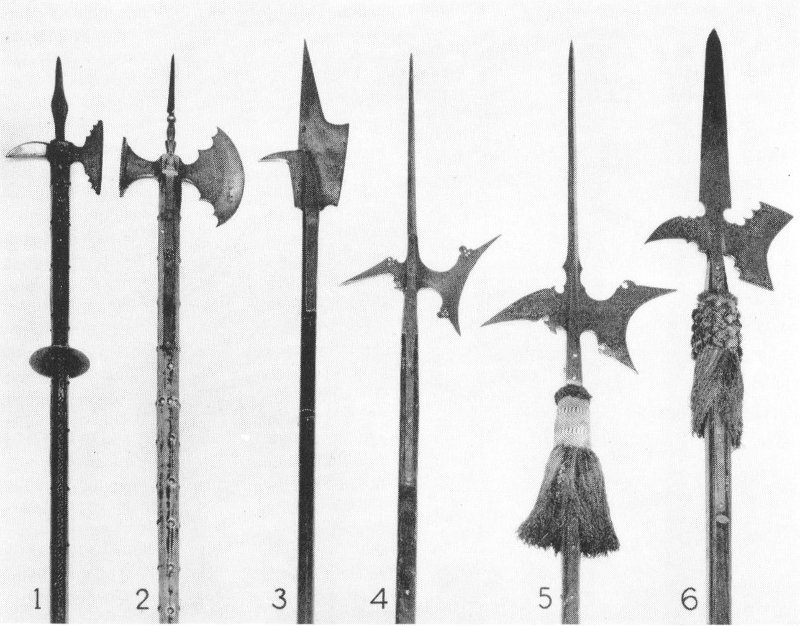

| 34 | Group of axe-type pole arms, XV-XVII centuries | 28 | |

| 1. Military axe, Spanish, XVI century | 43:19 | ||

| 2. Military axe, Italian, XVI century | 44:19 | ||

| 3. Halberd, Swiss, XV century | 67:39 | ||

| 4. Halberd, North Italian, XVI century | 451:19 | ||

| 5. Halberd of State Guard of Christian II of Saxony, ca. 1590 | 167:26 | ||

| 6. Halberd of State Guard of the Princes of Liechtenstein, XVII century | 168:26 | ||

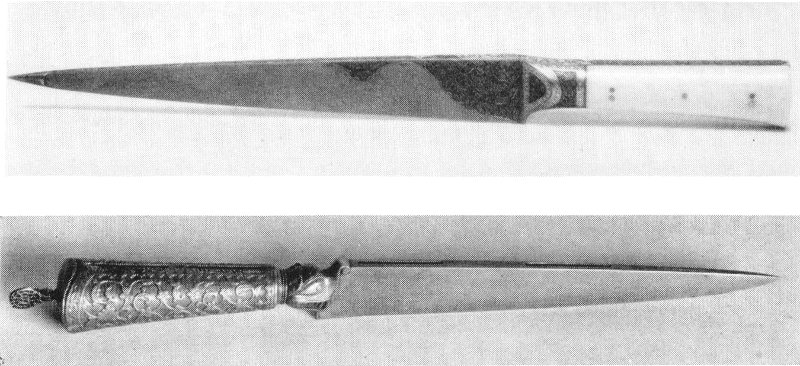

| 35 | Two dagger-knives | 29 | |

| 1. Persian, Ispahan, XVII century | 13:22 | ||

| 2. Persian, Shiraz, XVII century | 14:22 | ||

| 36 | Sword hilt, gold, Persian, XIII-XIV century | 45:24 | 29 |

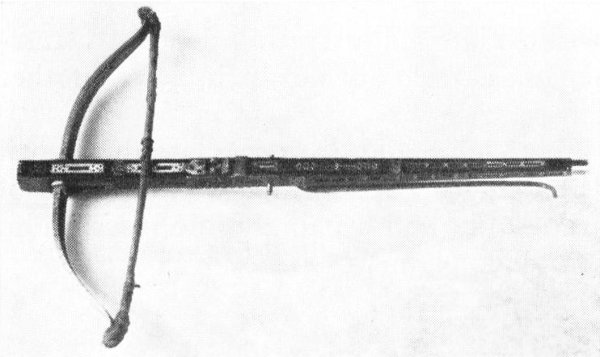

| 37 | Crossbow, Flemish, XV century | 41:19 | 30 |

| 38 | Prodd, Italian, XVI century | 69:39 | 30 |

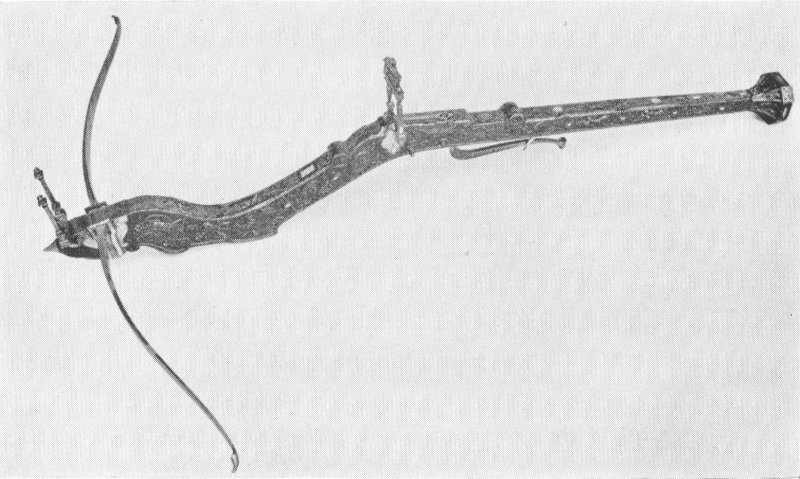

| 39 | Crossbow and cranequin, Swiss, XVII century | 68:39 | 31 |

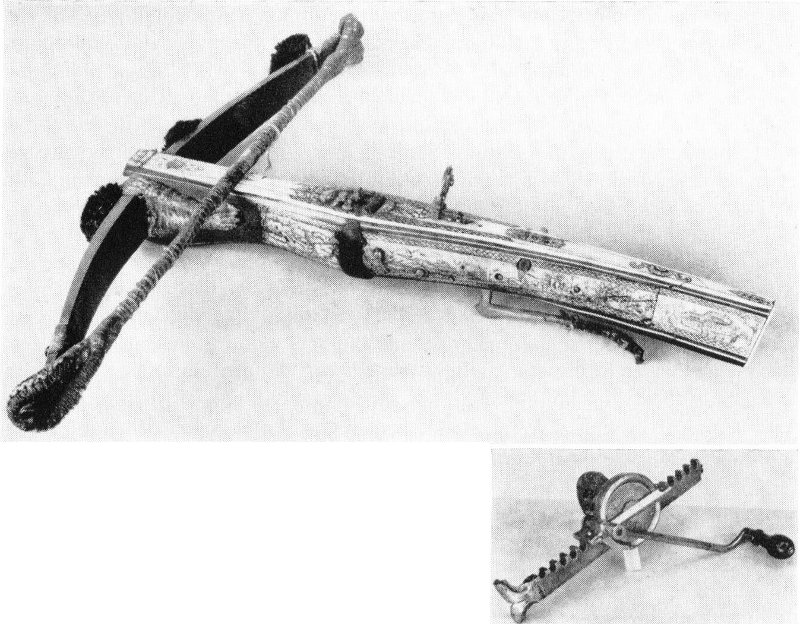

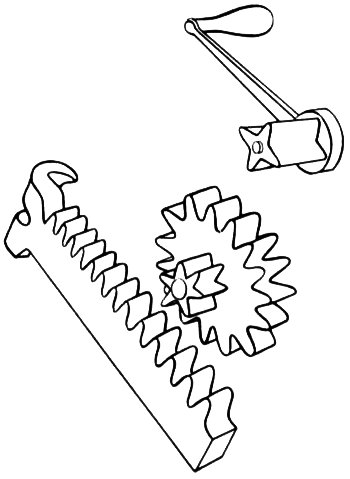

| 40 | Drawing, mechanism of cranequin | 31 | |

| 41 | Drawing, mechanism of crossbow lock | 31 | |

| 42 | Engraving after de Gheyn, 1606: musketeer about to give fire | 31 | |

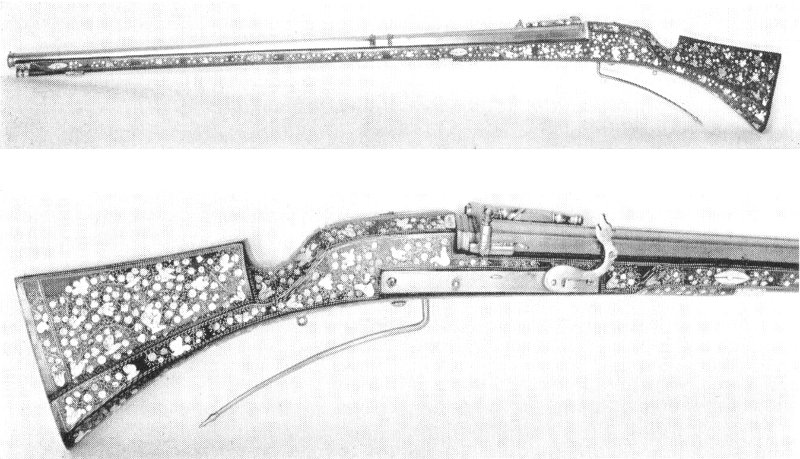

| 43 | Matchlock musket, Dutch, XVII century, and detail of its decoration. Gift of the John M. Olin Trust | 302:51 | 33 |

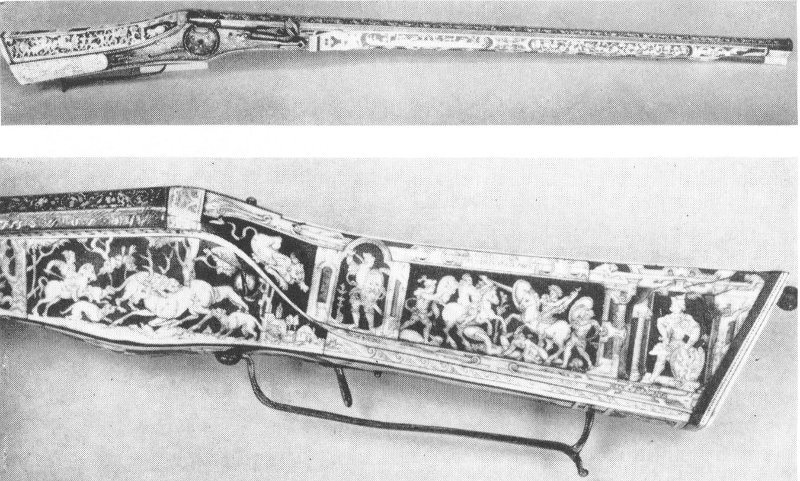

| 44 | Wheellock gun, German, ca. 1550 and detail of engraved inlays after Beham | 74:39 | 34 |

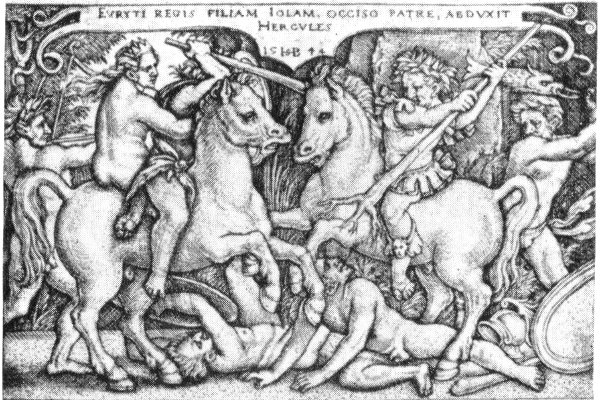

| 45 | Engraving by Hans Sebald Beham, (1500- ca. 1550) The Rape of Iole | 58:14 | 35 |

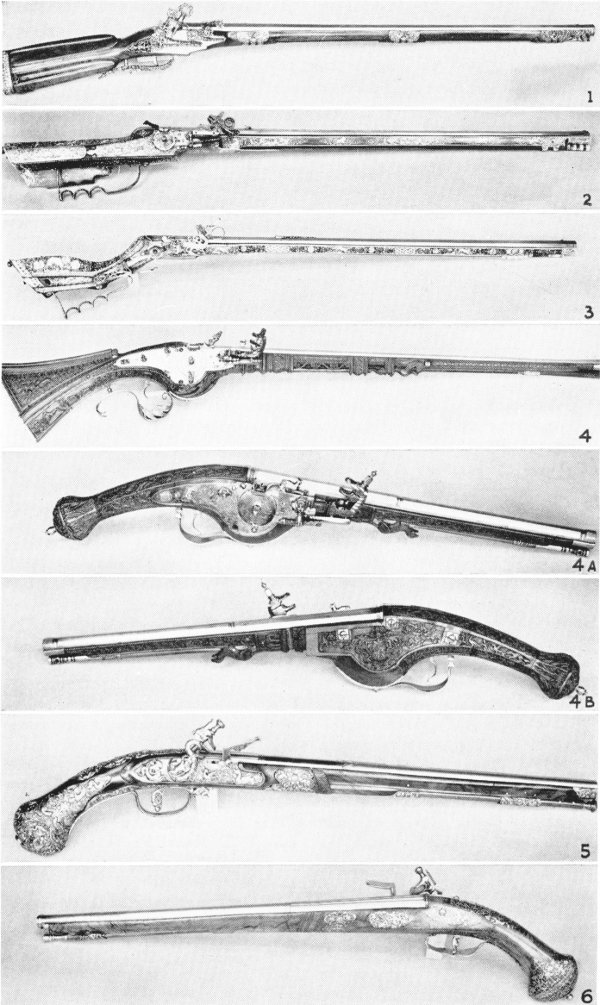

| 46 | Group of hand firearms of the XVII century | 37 | |

| 1. Miguelet lock gun, Italian, Brescia, for the Balearic trade, by Lazari Cominaz, XVII century | 76:39 | ||

| 2. Wheellock rifle, German, Dresden, by Martin Süssebecker (1593-1668), gunmaker to the Saxon court, ca. 1635 | 75:39 | ||

| 3. Wheellock tschinke, German-Silesian, XVII century | 73:39 | ||

| 4. Wheellock rifle, French, Épinal (Vosges), by Claude Thomas, 1623 | 70:39 | ||

| 4A,B. Pair of wheellock pistols. Companions to No. 4 | 71:39 72:39 | ||

| 5. Flintlock pistol, Italian, Brescia, by Lazaro Lazarino, XVII century | 77:39 | ||

| 6. Flintlock pistol, Italian, Brescian, by Lazarino Cominazzo; Giovanni Bourgognone, mid-XVII century | 85:39 | ||

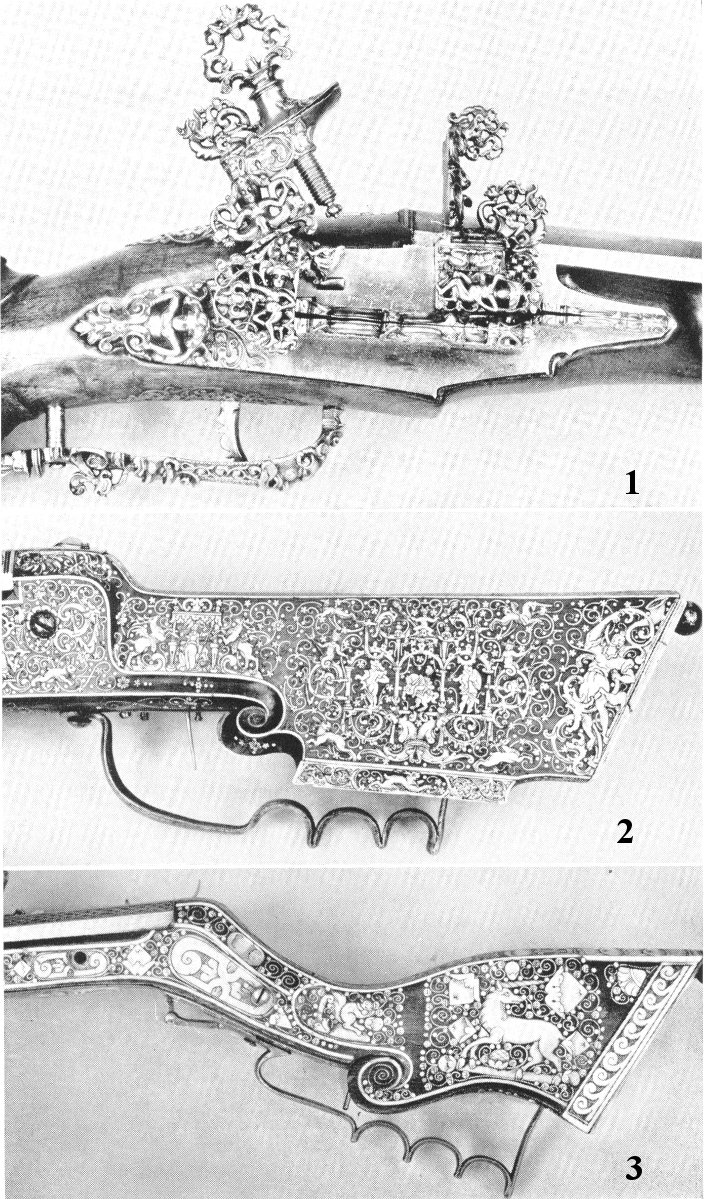

| 47 | Details of decoration of guns: | 39 | |

| 1. Miguelet lock gun, Italian, Brescia, for the Balearic trade, signed “Lazari Cominaz”, XVII century | 76:39 | ||

| 2. Wheellock rifle, German, Dresden, by Martin Süssebecker (1593-1668), ca. 1635 | 75:39 | ||

| 3. Wheellock tschinke, German-Silesian, XVII century | 73:39 | ||

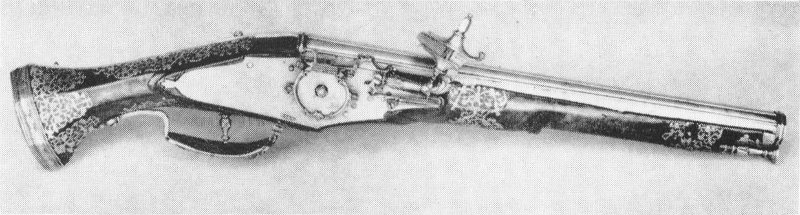

| 48 | Wheellock pistol, Italian, Brescia, ca. 1630 | 84:39 | 40 |

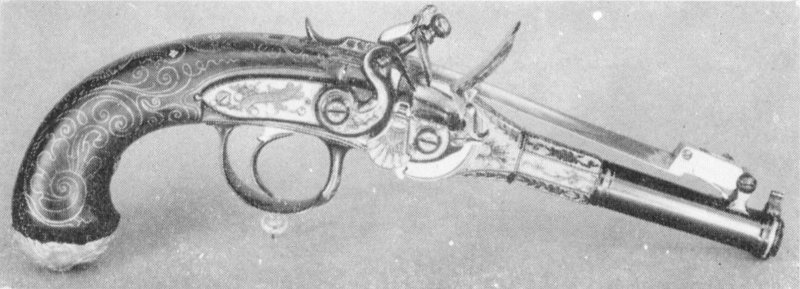

| 49 | Flintlock powder tester, German, ca. 1690 | 24:25 | 40 |

| 50 | Flintlock pistol set (two brace) with accessories, Portuguese, Lisbon, by Jacinto Xavier, 1799 | 185:42 | 41 |

| 51 | Flintlock repeating pistol, French, Paris, by Derby, late XVIII century | 43:39 | 42 |

Once upon a time there probably were men who had neither armor nor arms. They did not last long, for wild animals or other men with stones or sticks in their hands killed them and ate them up. The first men about whom we know anything definite already had weapons of stone. Arms and, later, armor have accompanied man throughout his history.

The first obvious weapons were stones, roughly shaped to make them more effective. Such are not to be found in the City Art Museum, but we do have examples of the next type to develop, the weapons of the bronze age.

Bronze is a mixture of copper and tin, and it was invented a very long time ago, and in many different places. It was known in ancient Egypt, in the Far East and in Europe. Two thousand years before Christ the Chinese were making bronze arms and domestic and ceremonial objects of all sorts, and were making them so beautiful that such objects are considered proper exhibits for an art museum. We have a very fine collection of ancient Chinese bronzes, exhibited in the Museum’s Chinese galleries, and among them are numerous weapons. The earliest include axes and dagger-axes (Fig. 1). These date from the Shang Dynasty, (ca. 1523-ca. 1028 B.C.) This too is the period of a bronze helmet (Fig. 2) in the form of a hood with smooth sides which come down well over the cheeks, while leaving the front of the face exposed. Helmets of almost precisely this form, but made of steel, were worn in Italy in the fifteenth century, more than two thousand years later! This helmet has a small plume-holder at its very top, and is peculiar in having, as its only decoration, a pair of eyes embossed in relief on the forehead.

Fig. 1. A Chinese bronze axe more than 3000 years old, with a crouching monster in relief.

From the Ordos region of Siberia, where a primitive culture lasted for 2 a very long time, comes a particularly fine ceremonial dagger (Fig. 3) of bronze with inlays of turquoise. From China again, dating throughout the thousand years before Christ, come numerous bronze weapons now in the Museum’s Study Collection, including swords, daggers, and, from about the beginning of the Christian Era, most ingenious mechanisms for the crossbow (Fig. 4) a weapon which was not known in Europe until many centuries later.

An Etruscan grave has yielded the large bronze disk of Fig. 5. On stylistic grounds it is believed that this originated not in Etruria, but on the other, Eastern, shore of Italy in Picenum, in the second half of the seventh century before Christ. It was probably the central reinforcement of a large leather shield.

Fig. 2. A bronze helmet as old as the axe in Fig. 1, but in form closely resembling Italian steel helmets of the fifteenth century.

Fig. 3. The thin flat-bladed ceremonial bronze dagger of a shaman or sorcerer from the steppes of Siberia.

But of all the specimens of antique armor and arms in this (and possibly in any other) museum, none surpasses the helmet shown in our frontispiece. This helmet, together with fragments of armor, a shield rim and a spear point, all now in the Museum, was found in a tomb near Metaponto, in Southern Italy, where once there was a Greek colony. It is believed to 3 date from about the middle of the sixth century B.C. The helmet is of bronze, the upper part of the bowl formed as the neck and head of a ram. This is surmounted by a great crest of silver, resting on a support of ivory. The cheek pieces of the helmet have rams’ heads in profile embossed in relief. The eyes, the horns of the main ram’s head, the ivory crest holder and part of the silver crest are restorations, but enough original fragments of the crest were found with the helmet to indicate exactly how the crest was shaped. Moreover the existence of such metallic crests is verified by a bronze statuette of similar origin (Fig. 6).

Fig. 4. A crossbow lock two thousand years old, with a model to show how the parts interlock. An ingenious bit of early mechanical engineering.

At first glance, the helmet proclaims itself a great work of sculpture, and proves that arms and armor can properly belong in a museum of art. How very well this piece deserves its place here is still more apparent on close examination. It seems incredible that so long ago a craftsman could, without any of our modern tools, have formed from a single plate of bronze such a deep and difficult forging as this helmet bowl. It is equally amazing that, in a period still considered as archaic, his artistic imagination could have produced so naturalistic yet so noble a rendition of an animal form. The technical skill and taste of the engraving and embossing are also noteworthy: the suggestion of locks of hair around the forehead, the eyebrows which terminate as snakes’ heads, the suggestions of skin texture on the rams’ heads. It is indeed one of the world’s masterpieces of armor.

Although the Greeks made their armor out of bronze, they did have knowledge of iron, at least as early as the fifth century B.C. But it was extremely difficult for them to prepare, as they had not yet discovered efficient methods of smelting it from iron ore, so that what little they had was very precious. It could not be spared for making armor, but was 4 restricted to edged weapons where a relatively small amount of this hard new metal could be most effective. The Romans too used iron, and as their technical skill improved they used more and more of it.

After the Roman empire was overwhelmed by the barbarian hordes from the North the making of fine arms languished. It did not cease; occasionally discoveries are made of beautifully inlaid sword pommels and shield bosses belonging to the so-called “dark ages”. Sword blades too turn up occasionally, skillfully constructed of many layers of alternately hard steel and soft iron, so that they may retain a keen cutting edge yet still be tough rather than brittle.

Fig. 5. Embossed bronze disk, probably the central reinforcement of a leather shield, from Picenum, East-Central Italy, second half VII century B. C.

Fig. 6. An Etruscan warrior in battle dress. Note the rivets on the helmet crest.

(Steel, you will remember, is not a separate metal; it is just iron which contains from about .5% to about 2.5%, of carbon. This gives it the peculiar property that if it is heated to redness and quickly cooled, it becomes much harder than before. It also becomes more brittle. If hardened steel be heated a second time, not red hot but to a much lower temperature, and again chilled, the hardness is reduced somewhat, while the brittleness is reduced a great deal; the metal becomes tough and suitable for making into tools. This second heating and chilling is called “tempering”. Contrary 5 to popular belief, “to temper” steel does not mean “to make it harder”. It means “to make fully hardened steel somewhat softer and much tougher”. If the iron has too much or too little carbon it cannot be hardened at all; if there is too little it is very soft and malleable and is called “wrought iron”. If there is too much carbon it is harder than mild steel, but is very brittle indeed; this is called “cast iron”.)

Except for the rare finds just mentioned, we know little about the armor and arms of the period from the fall of Rome to about the twelfth century. The paintings, drawings, and statues which have survived suggest, but give no clear information. We have reason to believe that armor was made of small plates of iron attached to cloth or leather garments, or of chain mail, a fabric made of interlinked rings of iron wire. Towards the end of this period we know that chain mail was extensively employed, for it often appears, especially in England, on the engraved brass plates attached to the tombs of important people of the time (Fig. 7). The Museum has a small collection of paper impressions of these “brasses” which are well worthy of study by anyone interested in early armor. Some are exhibited on the walls of the armor gallery.

Chain mail is more interesting than it appears at first glance, and the Museum’s specimens deserve to be looked at carefully. In the first place, it was made of wire. Nowadays wire is so common that we think nothing of it; it is produced by the mile with automatic machinery. But in medieval times wire was scarce and valuable, for every bit of it had to be made by hand. At first this was done with the hammer: a billet of iron was pounded with a hammer held in one hand, while the other kept the billet rotating so that its diameter became less and less until it was small enough to be made up into links of mail. Of course, only short bits of wire could be made in this way and the diameter was naturally irregular. It was slow and tedious work, but the earliest mail was so made. Later it was found that a rod of iron could be pulled by tongs through a hole in a hardened steel plate, thus reducing its diameter and giving it a uniform thickness. By drawing it through a number of holes of progressively smaller diameter, the wire could be made quite thin and entirely uniform. Then such wire could be wound in a coil around an iron rod, and the coil then cut lengthwise with a chisel or saw giving a large number of links all of the same size. All later chain mail was so made. Such links were interlaced, each link with four others, to form a fabric much like that of a lady’s mesh bag. However, if the ends of the links were simply brought together the fabric would not be very strong. An arrow or dagger point could easily spread open a link, and penetrate to the wearer’s body. So all good chain mail was strengthened by having the ends of every link overlapped, slightly flattened, and then riveted. In that part of the world we now call “Middle East”—where the 6 Mohammedan and Hindu cultures flourished—the rivet was a separate piece of fine wire. European chain mail is more of a mystery—principally because there is so very little old European chain mail still in existence. The probability is that a separate rivet was used as in the Eastern mail, but that its insertion was more skillfully performed. However, some scholars feel that European chain mail was welded or was riveted by a swaging process, that a special tool in the form of tongs or a pair of dies forced a small part of the lower end of the link of chain mail through a slit in the upper end and then riveted it over. Careful microscopical research on sections of links of mail could doubtless solve this problems, but who wants to cut off links from a rare and precious genuine, documented piece? As yet it may be said that no such ingenious swaging tool has been discovered, nor have we any unquestionably contemporary illustrations which would prove this theory.

In places where special strength was required, as around the throat, the rings were made of the same size but of heavier wire, which was flattened by hammering in the neighborhood of the rivet. In this way the overlapping of the rings became so close that not even a needle could penetrate the fabric (Fig. 8). In other cases, unflattened rings were used, but strands of leather were drawn through the rows, giving additional rigidity and protection. It is believed that this practice accounts for the appearance of what is known as “banded mail” in numerous monuments and engraved brasses.

Chain mail was a good protection against cuts and stabs, but it had a number of serious disadvantages. In the first place, it was expensive. Even the most skillful armorer could make it but slowly. The mail cape of Fig. 8 contains about 44,235 links, each separately forged and riveted; some complete coats of mail contain over 200,000! Forgeries of antique chain mail are practically non-existent, for they would cost more to make than genuine specimens, rare as they are, would be worth today.

Again, chain mail was very easily attacked by rust, and, once it was rusted, was most difficult to clean. (The usual way was to put a rusted mail shirt in a barrel with some oily sawdust and to set an apprentice to rolling the barrel around for hour after hour.) Consequently very little early mail is left—most of it just rusted away to nothing. It was heavy and uncomfortable, for the whole weight hung from the shoulders.

But its worst disadvantage lay in its flexibility. It would resist a cut, but was of little protection against a blow. To make it of any use in battle against heavy swords, maces, and battle axes it was necessary to wear beneath it a very heavily padded garment which, of course, was hot. How the Crusaders in their chain mail must have sweated in the hot sun of the Holy Land! And how many mail-clad knights must have been pounded to death without necessarily losing one drop of blood!

Fig. 7. An ink rubbing taken from the engraved brass plate on the tomb of Sir Roger de Trumpington, an English knight who died in 1289. Note the complete suit of chain mail, the supplementary knee defenses and big pot helmet attached by a chain, the cloth surcoat, and the shield with his punning badge of a trumpet.

Fig. 8. Cape of chain mail, with extra wide links at the collar, and ornamental links of brass around the lower edge.

To protect against blows, therefore, it became necessary to produce a rigid protection. The primitive state of iron metallurgy did not permit the making of more than small pieces of iron at a time. Nevertheless, iron head coverings were already in use by the eleventh century, and from that time on pieces of plate armor increased in size and number. After the head defense, the most vulnerable part of a rider’s body (for remember that only knights could afford mail, and knights fought on horseback) was the knees. Have you ever had a really hard bump on the kneecap, and, if you remember one, should you have liked to go on fighting just after receiving it? The knight represented in the brass of Fig. 7, who died in 1289, wears knee-guards, and rests his head on his great “pot-helm”, which was normally attached to his body by a chain, so that it could not easily be lost if he took it off to get a breath of air. The City Art Museum has no specimens of plate armor of this early period.

Fig. 9. A helmet called a salade: made like a deep salad bowl, with a slit to see through.

During the thirteenth and fourteenth centuries it became the fashion to wear a long cloth garment, called a surcoat, over armor. Pictures and statues of this period show armored figures only with such surcoats, and it is, therefore, impracticable to follow the exact development of the pieces of plate armor which were added to reinforce the chain mail. By the beginning of the fifteenth century complete outfits of plate armor were in use, but the earliest surviving suits of the so-called “Gothic” armor date from about 1460. They are exceedingly rare. The City Art Museum possesses only a gauntlet of about 1450 and a helmet (Fig. 9) from about 1475, yet we feel lucky to have these two pieces, for “Gothic” armor is not only rare: 9 it is very beautiful. It was at this period that armorers did their best work, from every standpoint. It was best metallurgically, with inner surfaces of pure soft iron, but with outer surfaces skillfully converted into almost glass-hard steel. It was best functionally, for its simple clean curved lines were admirably designed to turn a blow harmlessly aside, with no unnecessary decorative forms to catch descending edge or point. It was best artistically (as is usually the case with things that function perfectly), depending for beauty on its own pure sculptural lines rather than on extraneous ornament.

The helmet of Fig. 9 is of a type called salade. It is a simple steel hat, like that of a modern soldier, and originally had a padded lining. Unlike the modern military helmet, however, it covers the head down to the end of the nose; there is a narrow slit in front of the eyes which permits surprisingly good vision while leaving the eyes quite well protected. The lines of this helmet are clean and elegant, typical of the “Gothic” style. This type of helmet was often worn in combination with an upstanding guard for the lower part of the face which was attached to the top of the neck-defense. The lower edge of the helmet overlapped the upper edge of this face-guard; thus the entire face was protected, yet the wearer had reasonable ventilation and could obtain more when circumstances permitted by taking off his helmet.

At the beginning of the sixteenth century the most important single personality in Europe was probably King (later Emperor) Maximilian I of Germany and Austria. A contemporary of Leonardo da Vinci, he lived at a time when versatility was one of the characteristics of an educated man, and as sovereign he set his subjects a good example in this respect. He wrote books on genealogy, hunting and woodsmanship, horse breeding, architecture, and landscape gardening. He was greatly interested in arms and armor, and frequently visited his court armorer in his workshop. It is not surprising, therefore, that he had a great influence on the design of armor, and that the new and sharply different fashion which appeared at this time became known as the “Maximilian”. It was characterized by parallel, or almost parallel, fluting, especially on breastplate and thigh guards, by broad-toed foot guards (sollerets) as compared with the long pointed toes of the Gothic period, and by strongly roped edges of the plates. The City Art Museum has an excellent suit of Maximilian armor (Fig. 10). The breastplate, thigh guards (tassets) and main shell of the helmet illustrate the characteristic flutings, while the sollerets are fully developed Maximilian style. The suit was made in Nuremberg in the first quarter of the sixteenth century, and was formerly in the armory of Prince Liechtenstein.

Fig. 10. A full suit of Maximilian armor from the early sixteenth century.

By the middle of the sixteenth century the techniques of the armorer were fully developed. From the smelters he was able to obtain iron in good-sized lumps, and he had learned so to weld it as to produce plates of any desired size. He could keep it soft and malleable or could add minute amounts of carbon and thus convert it into steel, which he could, by heat treatment, give any desired degree of hardness. He no longer bothered to harden the surface of his breastplate and helmets to the glassy hardness 11 which was the pride of the Gothic armorers, but he made good, reasonably homogeneous mild steel which was hard enough for sword or dagger blades, yet tough enough to avoid brittleness. He could hammer his metal into even the most fantastic shapes, could color or gild it, or could inlay it with precious metals. Armorers began to vie with one another to produce magnificent and elaborate armor; many and strange were the results. Instead of only one kind of armor, as in the past, there were three: military, tournament and parade armor.

In the military armor, intended for actual fighting, taste was usually conservative. Extravagances, such as excessively wide or narrow sollerets, over-elaborate elbow guards, or extremely large shoulder guards, were avoided. A moderate amount of decoration was considered quite permissible, provided it did not lessen the functionality of the armor; such decoration most frequently was in the form of etching.

Fig. 11. A breastplate decorated with etched ornament against a black background.

Fig. 12. A morion with etched decoration. Handsome, but rather top-heavy.

Although we are accustomed to think of etching primarily in connection with pictures on paper, the process seems to have originated with the armorers. They would take a helmet or breastplate, paint it all over with a heavy acid-proof varnish, scratch a design through this varnish with a sharp needle, then place the metal in a bath of acid. The acid would eat away the steel where the varnish had been scratched, but not elsewhere. After the plate had been taken from the acid and the varnish removed, the etched part would show dark against the polished surface of the steel. This contrast could be heightened by rubbing in a little black pigment, and the early armorers discovered that they could readily keep a record of their work or a sample sheet to show other customers, by simply placing a piece of paper against the etched and blackened surface and rubbing it. The 12 fresh black would stick to the paper, giving a clear impression of the etched design. Masters of etching like Rembrandt used and modern etchers still use essentially the same process.

Fig. 13. A closed helmet with etching. Though heavier, it is more comfortable than Fig. 12, since its weight rests partly on the shoulders.

The Museum has a number of good examples of etched armor. In Fig. 11 we see a breastplate with etched designs of military trophies and mythological figures. Fig. 12 shows a helmet, formerly in the collections of the Baron de Cosson and Henry G. Keasbey, of the type called morion, with an exceedingly high comb and similar etched decoration. Fig. 13 shows a typical closed helmet of the mid-sixteenth century. Like the morion, it has a high, elaborately etched comb. The wearer’s face was protected by two plates, an upper one called the vizor, which has a narrow horizontal slit for vision like the salade described on page 9, and a lower called the ventail which has holes and vertical slits for ventilation. Both are pivoted at the ears, so that the vizor could be raised alone or vizor and ventail together, 13 yet at the appearance of danger both could be snapped down into position with a single sweep of the gauntleted hand. The etching on this helmet shows floral arabesques and leaping stags against a background, not blackened, but gilt. Such gilding was done by rubbing the freshly etched surface with a mixture of gold and mercury, then heating the metal to evaporate the mercury and leave behind the gold firmly attached to the steel.

Fig. 14. A heavy helmet especially designed for the tournament. The man who wore this was about as safe as armor could make him.

Tournament armor, used in the toughest, most exciting sport that man has ever invented, was worn for comparatively short periods of time, and could, therefore, be considerably heavier than the military armor which a man might have to wear continuously. Decoration on the armor itself was reduced to a minimum, although elaborate trappings of cloth and feathers were often added to it. Fig. 14 shows a helmet for use in a form of tournament conducted according to Italian rules, in which the contestants were separated by a fence which prevented their horses from colliding, thus permitting unrestricted speed of attack. The helmet is very solid and sturdy, with plain polished surfaces to deflect the opposing lance-point. Notice the circular hollow rim at the neck. This closed over an outward-turned rim on the throat defense (colletin) so that although the helmet could be turned to either side following the motion of the wearer’s head, it could not separate from the body armor at the throat and leave an opening for hostile spear or sword point.

Fig. 15. A parade shield, etched and gilded. Italian, XVI century.

Fig. 16. A parade helmet, probably made in Germany for the Hungarian or Polish market.

Fig. 17. A gauntlet of solid steel which is almost as flexible as chamois skin.

Parade armor was the lightest yet the most elaborate of all. Not intended for actual combat in either war or sport, it did not require the fundamental functionality of the other types; the armorers were free to follow their fancy and make the decoration as elaborate as they pleased. All methods were used. Etching and gilding were extensive and in addition the metal was embossed or chased in the most fanciful forms. In addition to the flat mercury gilding, gold was applied by the damascene process, either the “true” damascene in which plates or wires of gold (or silver) were actually inlaid into undercut grooves in the steel much as a dentist would fill a tooth, or the “false” damascene in which the precious metal was applied in the form of foil and rubbed onto the steel surface which had previously been roughened by tool work to produce innumerable tiny sharp points which could be burnished down to hold the foil firmly in place.

Fig. 18. A painted shield for a pageant or fancy-dress parade. Hungarian, XV century.

Specimens of the simpler parade armor, with etched and gilded ornament against a background colored a warm brown, are the shield shown in Fig. 15 and the helmet of Fig. 16. A mitten-gauntlet of the second half of the sixteenth century from the Clarence Mackay collection and formerly from the Imperial Russian Collection in the Hermitage Museum of St. Petersburg (Fig. 17) is an example of the work of the British Royal Armory at Greenwich, which made numerous finely decorated suits of armor for the nobles of the court of Queen Elizabeth. This gauntlet is a magnificent specimen of engineering skill as applied to the design of armor; its construction allows complete freedom to the wrist, knuckle, and finger joints, yet keeps the hand perfectly protected in any position. The gauntlet is decorated with an etched design of rising eagles in interlaced medallions against a dotted background; the latter is partly black, partly gilded.

An entirely different type of parade armor is the shield of Fig. 18. It is made of wood, covered on the inside with leather, on the outside with 16 canvas painted with a small coat of arms and a large representation of two unarmored men in mortal combat. This shield also was formerly in the Clarence H. Mackay collection.

Fig. 19. These stirrups are made of carved bronze, completely gilded.

Another example of parade equipment in a different medium is a pair of stirrups (Fig. 19) made of bronze and elaborately carved and gilded. They were formerly in the Spitzer collection.

As the sixteenth century drew to a close armor began to deteriorate. No single influence was responsible. Do not think that firearms were invented and armor was therefore suddenly made obsolete. As a matter of fact, firearms were in use before plate armor really received general acceptance, and firearms were in use all the time that plate armor was being worn in Europe. But the gradual improvement in the efficiency of firearms undoubtedly caused armor to be made heavier and heavier, and thereby contributed greatly to its decline. For just when armor was thus increasing in weight there developed a new school of cavalry tactics based upon the use of lightly armed troopers on fast horses who, instead of directly attacking the enemy, could dash around his flank and cut off his supplies from the rear. The tendency was, therefore, to make the armor light and very flexible, directly contrary to the need for solid, bullet-stopping protection. Even fashion had a deteriorating effect on armor. Fig. 20 shows a late suit 17 of armor which has a multitude of small plates to give extreme flexibility, and has extra wide leg protectors to cover the extravagant wide-topped trousers which were then the vogue. But what a clumsy suit this is compared to the Maximilian suit of Fig. 10!

Fig. 20. “Three-quarter” suit of armor for a young German of the early XVII century.

During the seventeenth century armor shrank away piece by piece, much as a tired soldier might have been tempted to discard it on a long march. The choking face defenses vanished from the helmet. The sollerets went, then the shin guards or greaves, then the thigh guards. The arm guards were discarded, then the gauntlets. Finally the armored man was left with only breastplate, backplate, and helmet, and even these deteriorated in the following century into the decorative but inefficient trappings of the cuirassier. The two world wars, with their steel helmets and flak suits (the design of which was strongly influenced by ancient models) have revived the use of armor, but it is a machine-made product and, well-designed though it be, must be considered a reproduction rather than an original work of art.

Let us turn back to the armor of the fifteenth and early sixteenth centuries, and consider some of the questions which naturally arise in our minds as we contemplate these relics of the past. In the first place, was it practical? How could men possibly wear such a mass of metal upon their bodies and engage in long military campaigns, interspersed with violent battles? Isn’t it true that an armored man, once fallen, could not get up again until he was hoisted with a derrick? No, that isn’t true. The comical scenes in the moving pictures of frustrated knights floundering about in search of hoisting engines were put in strictly for laughs. Armor was practical; it was worn by about all the most important men of more than three centuries; if they had not worn it they would not have lived long enough to become important! As a matter of fact armor is not as heavy as one might think. A good military suit weighs no more than the pack carried by a modern soldier, sixty pounds or less, and is a great deal more comfortable to carry. The pack hangs from the shoulders, but a good suit of armor, carefully made (as all good armor had to be made) to fit the individual body of the wearer, has its weight distributed over the entire body. The helmet rests partly on the head and partly on the shoulders. The breast and backplates rest partly on the shoulders and partly on the hips. The arm and leg guards are laced to the special undergarment which had always to be worn with armor, and each limb supports its own protection. The joints come at exactly the right places to correspond with the natural motions of the body, and every one of these motions is provided for. A man wearing a properly fitting suit of armor over the correct undergarment could do anything that a modern man can do wearing a winter overcoat, and probably, due to his special training, a number of things that the modern man could not. He could certainly walk, run, climb a wall, lie down and get up quickly, and mount his horse without help. To test the truth of these statements and the implications of the romantic novels of the past, the writer donned a suit of armor which fitted him only approximately, yet found himself able to perform all the actions above mentioned and, in addition, to descend two stories on a rope, hand under hand.

Two particular devices aided in making such flexibility possible. Where the body needed protection combined with motility it could be covered with a series of narrow, overlapping steel strips, each of which was riveted in turn to one or more leather straps, the ends of which were fastened to the solid main defense. Then as the body was flexed the steel strips or lames would slide over one another without exposing the body beneath them (Fig. 21). It was also possible to join a series of lames by not more than two rivets for each pair; these would act as pivots, allowing one lame to rotate slightly relative to the other (Fig. 22). However, if rivets were used with rather large heads with a washer under the burred end of each, and if the holes for the rivet in one lame were round while that in the other had the form of a slot, in addition to the pivoting motion, a certain 19 amount of sideways motion between the lames would be possible (Fig. 23).

Fig. 21. The leathering of a tasset, from the inside.

Fig. 22. The pivot rivets of a solleret.

Fig. 23. The wrist plates of a gauntlet with sliding (Almain) rivets.

Who wore armor? Every man who could afford it. Armor was always very much of a luxury. Its making required the services of consummate craftsmen, men who were not only expert metal workers, but also skilled draughtsmen, expert tailors, and keen students of human anatomy. Armorers were the aristocrats of all mediaeval craftsmen, the most highly respected and by far the best paid. It required a great deal of their time; the completion of a full suit of armor might take a year or more. Armor was, therefore, in the class of the modern automobile. A wealthy monarch might have a large wardrobe of beautifully decorated armor, as a millionaire to-day owns a fleet of expensive imported motor cars. A simple knight would be proud to possess a single suit, plain, but nevertheless made exactly to fit him and no other person. A minor soldier was lucky if he could secure a simple ready-made breastplate and helmet.

What was the physical character of the men who wore armor? Why do the suits seem so small? Were people smaller in those days? Yes and no. It is true that the nature of their life tended to develop men of the cowboy type, wiry rather than massive. Men who spend their lives on horseback are likely to have a broad shoulder and narrow waist, strong thigh and slender calf. It is true too that with primitive medicine and sanitation man died young; the average age of adult males was less than it is now.

However the principal reason for the small average size of preserved suits of armor lies in its inextensibility. A suit of armor cannot be “let out”. 20 As has been pointed out, it had to be made exactly to fit the wearer. Men had to learn their military duties very young, they had to have and to wear armor while they were still growing. Consequently they usually outgrew their first suit of armor, and it was this suit, unmarked by the scars of serious fighting, which was most likely to be preserved. By the time a man reached his full growth his armor showed wear and tear; when he died he was buried in it, or it was discarded after his death as too battered to be worth keeping. The suits of armor in the world’s collections are largely the outgrown suits of young men.

In addition to the armor of Europe, consideration should be given to that of the Middle East, of which the City Art Museum displays a number of fine specimens in a special gallery. Armor was worn in Persia and in India long after it had been abandoned in Europe; it is even possible that among isolated tribes armorers may still be plying their trade. However, as in Europe, the later work tended to deteriorate, and the earlier an Eastern armor is, the better will it probably be.

The Indian and Persian smiths had two specialties: Damascus steel and damascened steel, which are often and not unnaturally confused, both having presumably originated at Damascus. Damascene work has already been described on page 15; both the “true” and the “false” variety were practised throughout the Middle East. Damascus steel, on the other hand, is a type of metal especially suitable for armor and sword blades, made by the intimate combination, in innumerable layers, of two kinds of metal, one extremely hard, the other soft and tough. As billets of this composite steel were twisted, bent, and reformed, the superimposed layers made intricate patterns like those in watered silk. Such Damascus steel patterns can be best observed in sword and dagger blades like those illustrated in Fig. 35, page 29.

Fig. 24. This is the breastplate of a Persian suit of armor. The buckles are for the straps which attach the side and back plates.

The Persian armorers did not follow the European custom of forging body armor exactly to fit the wearer, but instead made the 21 principal defense of four rectangular plates known as char aina or “the four mirrors”. Two were worn as breast- and backplate respectively, the other two, made concave on the upper edge, were worn at the sides, the concavity fitting under the arm. Chain mail was always used in the East, even more extensively than in Europe, to protect all areas of the body not covered by the char aina or other defenses of solid plate. Fig. 24 shows a plate of such a four-piece armor. It is made of fine Damascus steel (the pattern is too fine to show in the photograph), and is decorated with damascene inlay of floral arabesques in gold. This is work of the late sixteenth or early seventeenth century, and combines adequate functionality with oriental elegance. A Persian helmet (Fig. 25) of the same period shows skillful forging of the fluted ornament.

Fig. 25. The chain mail which now looks rather ragged originally hung evenly around the rim of this Persian helmet.

Fig. 26. Although corroded, this fifteenth century Turkish helmet demonstrates the wonderful skill of Middle Eastern armorers.

But the helmet in Fig. 26, probably a century or more earlier, shows a much greater appreciation of sculptural form. With a row of parallel vertical flutings around its domed upper part, it resembles closely the Maximilian armor of contemporary Europe. It is doubtful, however, if many European smiths could have forged the minaret-like pinnacle which terminates the dome. The helmet is decorated with damascene work of silver in calligraphic inscriptions and arabesques. Its owner’s neck was protected by chain mail attached around the lower edge of the helmet. Probably because of the warmer climate, the Saracenic warriors never adopted the closed helmet of European lands, but preferred to leave the face exposed, or protected only by a nasal bar which was often so arranged that it could be slid upwards and clamped.

Man’s first weapon was probably a club, and the simple club has always retained a certain popularity. Even in the middle of the sixteenth century, when arms of all kinds attained great elaboration, the mace, or short one-handed club, was the accepted weapon of military men in holy orders who, forbidden to shed blood, found no such prohibition against the bloodless cracking of skulls. Fig. 27 shows such a mace, of heavy steel, carved and gilded, a formidable though beautiful weapon. Related arms are short-handled military axes and hammers.

But the accepted symbol of man as a fighting creature has always been the sword, and the sword, perhaps more than any other item of man’s warlike panoply, has experienced the full range of his artistic and technical initiative. Space does not here permit a discussion of the innumerable types of swords; only a brief resumé of the general development can be given. This is supplemented by a display of some typical forms along one side wall of the armor gallery.

Fig. 27. A mace or one-handed club, made of steel carved and gilded. A beautiful implement for smashing heads!

Fig. 28. A Chinese bronze sword from about the time of Christ. Not very sharp, but it could still do quite a lot of damage.

Fig. 29. Typical swords of the sixteenth-seventeenth centuries, as displayed in the armor gallery.

Stone Age man could not make any true swords, for the flint and obsidian which he had to use were too brittle to be available in large pieces. But bronze could be cast into swords both effective and beautiful. A number of Chinese bronze sword blades from the Han Dynasty (206 B.C.-220 A.D.) (Fig. 28) are available in the study collection. They are rather short, double edged blades, adapted primarily for thrusting, but not without cutting ability too. The Greeks and Romans used swords of rather similar 24 form, and also another type which tended to broaden near the point, bringing the weight forward and adding impetus to both the thrust and the cut.

Mention has already been made, (p. 4), of the rare but beautiful swords of the dark ages, made in whole or in part of laminated metal resembling the Damascus steel of the Middle East, (cf. p. 20). Such swords were carried by the Vikings who harried the coast of Britain and extended their voyages even to North America. These swords had long, straight, symmetrically double-edged blades, a short hilt, and a short crossbar guard between blade and hilt. They were very powerful in a downward slash, but too heavy to be manipulated easily as thrusting weapons.

By the fifteenth century the crossbar and the hilt had become longer, giving the weapon a better balance, but the general character of the arm remained the same. With the longer hilt, both hands could be used, considerably increasing the power of the weapon (Fig. 29 [1], also title page illustration). This tendency continued in the sixteenth century until it culminated in the enormous two-handed swords used by the professional mercenary soldiers, or landesknechts (Fig. 29 [2]). Such swords were over five feet long, with immense drooping guards and long leather-wrapped hilts.

Fig. 30. How many figures are carved in the solid steel of this court sword hilt?

As the sixteenth century advanced, sword blades became narrower, lighter, and more adapted for thrusting, while guards developed rings and curved knuckle-guards to protect the out-thrust hand (Fig. 29 [4], [3]). The new method of fighting had definite advantages over the old slashing 25 system, which required the sword to be raised high, exposing the body, before a blow could be struck, and soon the thrusting sword, or rapier, was used everywhere. The system of rings which formed the guard grew more complicated and finally coalesced into a solid metal cup, which completely shielded the hand within it (Fig. 29 [6], [8]). Sometimes a dagger (Fig. 29 [5], [7]) was held in the left hand to parry the opponent’s sword blade, but eventually this was abandoned and fencers learned to parry with the rear portion of their own blades, before making a second thrust (riposte) with the point. Action grew faster and faster, and swords lighter and more manageable, until by the seventeenth century the customary weapon was the court sword, with a short, single-handed hilt, a small flat guard often magnificently decorated in chiselled steel, and a relatively short, light blade having a needle-like point, and often without any sharp cutting edge at all (Fig. 30).

Fig. 31. A rondel dagger with a silver handle.

Fig. 32. An outfit for a hunter: dagger, knife, awl, and larding needle, all fitting into one scabbard.

In addition to the sword, the dagger was often used as a supplementary weapon which could still be carried for self-protection when courtesy or convenience made the wearing of a sword impracticable. Daggers were made in a number of special shapes, varying with changes of fashion. In the fifteenth century two popular forms were the rondel dagger (Fig. 31) which had guard and pommel in the form of disks, and the kidney dagger (then known by a less-printable name and worn, with the naive exhibitionism of pre-Victorian days, directly below the belt buckle) which had a straight, simple hilt and a short guard of ball-like form. Italians of the sixteenth century liked the anelace, with its drooping guard and short, wide, sharply tapering blade. Mention has already been made of the left-hand daggers of the seventeenth century. The stiletto, without a guard other than a short cross-bar, was also popular at this time. Hunters and landesknechts often carried a complete outfit of small tools in the scabbard with their dagger; such a trousse (Fig. 32) was very convenient when preparing freshly-killed venison for the cook or when eating around a camp fire.

The chief arm of the mounted knight was the lance, a weapon having a long and often quite heavy wooden shaft and a steel point. Near the butt its diameter was reduced to provide a comfortable hand grip, and just in front of this grip there was applied a vamplate or conical hand guard of steel. Behind the grip there was attached a thick iron ring called a graper, which, when the lance was in use, rested against the hook or lance-rest projecting from the right side of the knight’s breastplate. The graper thus served as a thrust bearing, and put directly behind the point of the lance the entire momentum of horse and rider. When such a projectile made a direct hit upon an opponent something had to give. Either the opponent was knocked completely off his horse, or his back was broken, or the lance was shattered.

Foot soldiers also employed arms with long wooden shafts, of which by far the commonest was the pike, which had a very simple steel point and butt ferrule respectively on the ends of a slender rod of wood about fourteen feet long. This was the arm of the great bodies of mercenary infantry which did so much of the fighting of the seventeenth century. A company of such men, formed into a square or circle, the front rank kneeling, the second standing, and both holding their pikes with the butts against the ground and the points projecting outward, was almost invulnerable to cavalry, whose horses would not charge against the forest of pike-points. The one effective maneuver against them was for some of the cavalry to dismount and attack swinging great two-handed swords, which could beat down the pike points and allow the cavalry to ride in.

Lance and pike were simple utilitarian tools; few have survived. But there are other pole arms, from the fifteenth century on, which offered 27 more opportunity to individual taste in form and decoration; a number of these are present in the Museum’s collection. Some (Fig. 33) were developments of the simple spear point, as for example (1) the type called an ox-tongue or (2) a boar spear provided with a toggle to prevent a wounded animal from charging right up the shaft of the weapon which transfixed him. In (3), now a well-developed partisan, the toggle has been replaced by a projecting spur at each side of the base. In (4) these spurs have become large and ornamental, the weapon is decorated with etching, and has become a ceremonial object rather than a weapon for actual fighting. (5) is a partisan of the state guard of Augustus the Strong, Elector of Saxony and King of Poland (1697-1733), and is even more noticeably designed for display purposes only.

Fig. 33. Spear-type pole arms, XV-XVII centuries. Developing from a simple tool for stabbing to a decorated badge of office.

Other pole arms are developments of the axe. Military axes (Fig. 34 [1], [2]) had handles somewhat shorter than those of pikes, spears or partisans but longer than the short-handled axes used on horseback. They were particularly popular for use in judicial combats or “trial by battle”. Each contestant in a law suit would swear to the truth of his claim, and call upon God to prove its truth. The two men, armed with such axes, would fight until one was killed or driven out of the ring. The victor was thus proven 28 to have told the truth, while the unsuccessful contestant, if still alive, was executed for perjury. Such axes, capable of defending the right, were made with special care, and were highly valued by their surviving owners.

Fig. 34. Axe-type pole arms, XV-XVII centuries. The earlier ones, at the left, were used in judicial duels, the later, at the right, were held by warders of the doors of princes.

Axes with longer shafts were known as halberds, and were usually provided with a sharpened hook at the back of the axe blade to permit a man on foot to catch and cut the bridle rein of an attacking horseman. Like the partisans, halberds developed from plain functional military types, (Fig. 34 [3], [4]) of the fifteenth and sixteenth centuries respectively to highly decorated types carried as badges of authority by the state guards of Christian II of Saxony (Fig. 34 [5]) and of the Princes of Liechtenstein (Fig. 34 [6]) respectively.

The chief characteristic of the blades of the Middle East is the beautiful watered pattern of the Damascus steel, discussed on page 20. Unfortunately this pattern is too delicate to show well in reproduction, but it may readily be observed in the actual objects, exhibited in the gallery of Middle 29 Eastern Art. Two knives are shown in Fig. 35, illustrating delicate Damascene work in gold and similar ornament carried out not by inlay of another metal, but by chiselling in low relief.

Fig. 35. Persian dagger-knives of the seventeenth century, equally useful as tool and as weapon, and beautiful too!

Fig. 36 shows a Persian sword hilt of solid gold, from the late thirteenth or fourteenth century. The ends of its guard are formed as the heads of lions. It is engraved with floral arabesques and a calligraphic inscription. The engraved lines are filled in with black pigment (niello).

Fig. 36. A Persian sword hilt of solid gold, XIII-XIV century, inscribed: “Salute to Mohammed”.

Ever since a hairy primitive first picked up a stone and threw it, man has tried to find better and better ways to strike from a safe distance. The devices which he has produced for this purpose have been many and varied, yet, strangely enough, remarkable similarities often occur between inventions of widely separated areas. In ancient Peruvian graves have been found cord slings for hurling stones almost identical with those used by herd boys in Palestine today, as in the time of David and Goliath. Bronze arrowheads from prehistoric Japan are much the same as those excavated from Roman Britain. The bow has several different characteristic forms distributed throughout the world, but its fundamental principle is everywhere the same.

Fig. 37 (Left). A light crossbow like this would be used by a young man or an athletic girl. Flemish, XV century.

Fig. 38 (Below). Made a little lighter. A prodd or bullet-shooting crossbow, probably for a lady.

The first projectile-throwing arm appropriate to an art museum is the crossbow, which is simply a bow mounted on a wooden stock provided with a catch and trigger, so that the bow could be carried ready to shoot. This was a great convenience in hunting or war, because otherwise the time lost in drawing the bow might give the victim opportunity to escape. Moreover, it was soon found that the application of mechanical devices permitted the use of a bow much stronger than any man could draw unaided.

Fig. 39. It took a powerful man to wind and shoot this heavy Swiss hunting crossbow, even with the cranequin to help wind!

Fig. 40. If you take off the outer case, these three parts make up the entire mechanism of the cranequin.

Fig. 41. Mechanism of a crossbow lock, complicated but effective.

Fig. 37 shows a light Flemish crossbow of the fifteenth century. Its wooden stock is inlaid with white and with green stained bone in openwork patterns. This type of crossbow required mechanical assistance to pull the string back to the catch which would hold it until the moment should arrive to shoot; the instrument employed was called a goat’s foot lever.

The crossbow of Fig. 38 is Italian work of the sixteenth century. The bow is light enough to be pulled by the hands alone, without mechanical assistance. It had a double string, with a little pouch attached between the two strands, and shot small bullets, instead of arrows. The wooden stock is beautifully carved and the metal parts are damascened with arabesques in gold. This type of light crossbow was especially popular with aristocratic ladies who are frequently represented shooting it in hunting tapestries of the period.

In Fig. 39 is shown a very powerful hunting crossbow of the seventeenth century. The bow is of steel, two inches wide and a third of an inch thick. The bowstring resembles a piece of heavy rope. To pull this string, bending a steel spring as massive as this, requires a tremendous power and an immense strength in the mechanism which will hold the fully-drawn bow until the moment for its release.

The pulling power is supplied by a device, also shown in the illustration (Fig. 39) called a cranequin or cric. It is in mechanical respects essentially identical with a modern geared automobile jack, although, of course, it pulls instead of lifts (Fig. 40). A force of fifty pounds applied to the handle generates on the claw which grasps the bowstring a pull of more than two tons! Fig. 41 shows the mechanism for holding and releasing the string. (These parts are, of course, normally invisible, being hidden inside the wooden stock).

Returning to the artistic aspects of the crossbow of Fig. 39, we observe that the whole of the wooden stock is inlaid with plates of white stag horn engraved with scenes illustrating the legend of William Tell—certainly an appropriate decoration! The bow is quite plain except for the addition of decorative pompoms of colored wool, but the cranequin gear housing is elaborately etched with representations of Biblical and mythological personages, strapwork, and interlace, much of this unfortunately now worn away.

The study of antique firearms is a fascinating one. Contrary to usual belief, firearms are not a late invention. They were in use before complete suits of plate armor were made, and continued in use throughout the entire period that plate armor was worn. Many thousands of different specimens have been classified, but all firearms before the nineteenth century belong 33 to one of four types. These include (1) the cannon or hand cannon in which the charge of gunpowder was set off by direct application of a burning slow match or hot iron held by the shooter; (2) the matchlock in which burning slow match or tinder was held in a clamp attached to the gun and was brought into contact with the gunpowder by a mechanism attached to the gun and operated by the shooter; (3) the wheellock in which fire was not carried about, but was produced by a mechanism like that of a modern cigarette lighter: a rough wheel was spun around in contact with a stone (not flint, but a nodular form of iron pyrite) so that sparks were produced to set off the gunpowder; (4) the flintlock and its variations, in which a piece usually of flint stone held in a clamp attached to a strong spring was moved by the spring to strike a piece of steel, and thereby generate the spark which would set fire to the gunpowder. The Museum’s collection includes interesting and unusual specimens of all but the first of these types.

Fig. 42. This is how a musketeer looked when he was just getting ready to aim his gun. He has more gadgets than even a modern infantryman.

Fig. 43. The Three Musketeers carried muskets like this one in form, but without the elaborate inlaid decoration.

Fig. 44. Was the decoration of the gun copied from the engraving, or the engraving from the gun?

The earliest, simplest form of hand firearm, the hand cannon of the fourteenth and fifteenth centuries, is also the least interesting esthetically. Consisting of a simple tube of iron, it was usually crudely formed, and quite undecorated. Such hand cannon have much archaeological interest, but contribute nothing to the history of art. The first step forward in the mechanization of firearms was the matchlock, and matchlock guns also were usually crude and strictly utilitarian, military pieces (Fig. 42). However, a few specimens of fine quality were made for important personages, and the Museum is fortunate in possessing precisely such a specimen (Fig. 43), the gift of the John M. Olin Trust. The exact date and place of its manufacture are uncertain; it could be English but seems a bit more likely to be Dutch, toward the middle of the seventeenth century.

The lock is the standard seventeenth century matchlock, with the earlier form of trigger resembling that of a crossbow. The serpentine which holds the burning slow match moves upon pressure of the trigger in the rearward direction, from the muzzle towards the butt, bringing the burning slow match (a piece of rope impregnated with saltpeter) into contact with the powder pan, the swiveling cover of which must first have been opened by hand. After the slow match has ignited the priming powder and fired the piece, a release of pressure on the trigger allows a return spring to force the serpentine back to its original position. Notice the shape of the serpentine, suggesting not so much a snake as a double-headed dragon.

Fig. 45. Hercules carries away Iole, daughter of Eurytus. (She shows no strenuous objection.)

Evryti regis filiam Iolam, occiso patre, aedvxit Hercvles

15 HsB 44

The barrel is one-third octagon with finely forged cross mouldings at the change of shape as well as at breach and muzzle. The rear sight is a steel tube, beautifully formed in partly octagonal, partly fluted and molded sections. A flash guard extends from the pan to this rear sight to protect the shooter’s eyes against particles of burning powder from the pan.

It is the stock, however, which is the most remarkable feature of the gun. This is of dark brown wood, completely covered with an elaborate inlay of brass wire and engraved mother-of-pearl in a design of floral scrolls issuing from vases and supporting birds and insects. A few escutcheons are inlaid in engraved bone or white stag horn. The elaborateness of this inlay, combined with its delicacy and taste, make this one of the outstanding matchlock guns of the world.

The wheellock, which for the first time freed gunners from the necessity of carrying around with them a continuously burning coil of slow match, was invented in the early years of the sixteenth century and retained its popularity, in Germany at least, until the very end of the eighteenth. It thus has had a longer period of use than any other firearm with a discharge mechanism. The Museum’s earliest wheellock, from about 1550 (Fig. 44), has its entire octagonal barrel and lock magnificently decorated with damascene of floral arabesques in gold and silver. The stock is inlaid with engraved stag horn showing hunting scenes, Hercules’ capture of Iole (whose hand he had won by conquering her father, Eurytus, in a shooting match), and the figures of Alexander the Great and “Der Nero”. This gun well illustrates the close relationship which, in this day, existed between the various arts, for these inlaid designs are copied almost exactly from a series of engravings by Hans Sebald Beham (1500-ca. 1550), examples of which are in the City Art Museum’s print collection (Fig. 45).

Another, rifled, specimen, from about 1635, formerly in the Liechtenstein collection (Fig. 46 [2]) has a plain barrel, but the lock is finely engraved with a hunting scene, while the stock (Fig. 47 [2]) is most elaborately inlaid 36 with fine filigrees and engraved plates of stag horn representing mythological characters, animals, and monsters against an architectural and arabesque background. The stock bears the mark of Martin Süssebecker, who was born at Liegnitz in 1593, and died in 1668 at Dresden where he was gunmaker to the court of the Electors of Saxony.

A light hunting rifle (Fig. 46 [3]) with a very short stock of the type known as tschinke from the fact that such guns were made at the town of Teschen in German Silesia, dates probably from the latter part of the seventeenth century. It has a peculiar type of wheellock of which the mainspring and most of the other mechanism are exposed on the outside of the lock plate. The barrel is engraved. The lock is ornamented with openwork carving, and the stock (Fig. 47 [3]) is inlaid with mother-of-pearl and engraved stag horn in various designs and animal motives against a background of floral arabesques and scroll work.

A fine Italian wheellock pistol (Fig. 48) was formerly in the collection of H. G. Keasbey. The barrel, ornamented with raised ridges giving it an octagonal appearance, is inscribed “Lazari Cominaz”, an abbreviation of the name of Lazarino Cominazzo, an early gunsmith of Brescia, in northern Italy, whose work became so famous that the name was adopted by his successors practically as a trademark. The simple but finely carved lock and the lace-like openwork steel inlays of the stock are characteristic of the best Brescian workmanship. The piece dates from about 1630.

But the finest wheellocks in the collection are a “suite” consisting of a gun and pair of pistols (Fig. 46 [4], [4A], [4B]). These three pieces differ slightly from one another in their decoration, but they all bear the same signature, “Claude Thomas à Espinal 1623”, and are otherwise so similar that there is no doubt that they were intended to go together. All have wheellocks elaborately ornamented with carving and engraving. The pear wood stocks are magnificently carved in the round, in openwork, and in relief, with plants, animals, and formal ornaments. They all bear a coat of arms which has not yet been identified. On the pistols this is on the side of the stock opposite the lock plate, but on the gun the coat of arms is relegated to the left rear part of the stock, while the region opposite the lock plate is ornamented with a medallion containing the initials “C. T.”. This, together with the extraordinary elaboration of all three pieces, suggests that this set of guns and pistols was not, as was usually the case, made to the order of a wealthy client, but was rather a “masterpiece” produced by a young gunmaker exhibiting all the skill of which he was capable to prove his worthiness to attain the title of “master gunsmith” in the gunmakers’ guild and the right to set up a shop of his own. The coat of arms is presumably that of the noble patron who had supported him in the past and to whom the pieces would eventually come, but as they were made for glory and not for pay, the gunsmith felt quite entitled to place his own initials in a prominent position. It should be noted that though the pistols are both smooth-bored the gun is carefully rifled. It is interesting to speculate about the fate of Claude Thomas. It seems improbable that so skilled a craftsman should not have been successful in his career. Yet, this set of three pieces is the only work of this master known up to the present time. Perhaps he tried experimenting in mechanisms as he had already in decoration, with the result that a magnificent technician was destroyed in the explosion of his invention. Perhaps he succumbed to the plague or to the fortunes of war. All we know is that he could and did make some of the most magnificent guns in the world, and here they are!

Fig. 46. A group of masterpieces of the gunsmith’s art, XVI-XVIII centuries.

A large and heavy gun (Fig. 46 [1]) with a peculiar type of early flintlock having an exposed mainspring and known as a miguelet was probably made in Brescia for a purchaser from the Balearic Islands. The barrel is plain; the lock (Fig. 47 [1]) and steel mountings of the walnut stock, however, are elaborately carved in openwork and in strong relief. Some of the details of this carving, especially that on the trigger guard, evidence the exquisite skill characteristic of the Brescian gunsmiths (compare the wheellock pistol mentioned above). The general style of most of the carving, however, shows a ruggedness of design and a love of the grotesque characteristic of Balearic Island taste. The barrel is inscribed “Lazari Cominaz”.

Another early flintlock variation was the snaphaunce, a form in which the piece of steel struck by the flint was not attached to the cover of the pan holding the priming powder, but was entirely separate from it and could be turned back out of the way as a safety precaution, when immediate use of the arm was not expected. The Museum has a fine snaphaunce pistol in the Brescian style.

Two other pairs of pistols with normal flintlocks are excellent examples of Brescian work. One (Fig. 46 [6]) from about 1640-1660 has barrels with longitudinal ridging about one-third of their length and with the full inscription “Lazarino Cominazzo”. The locks are lightly engraved to give an impression of very shallow relief carving, and bear the signature of “Giovanni Bourgognone in Brescia”. The walnut stocks are ornamented with openwork steel similar to those on the wheellock pistol above described. The other pair (Fig. 46 [5]), possibly somewhat earlier, have barrels octagonal for about one-sixth of their length. These bear the inscription “Lazaro Lazarino” (presumably a son of the great Lazarino Cominazzo or of one of his namesakes). The stocks are of walnut. The locks and the large and numerous mounts on the stock are elaborately chiseled steel in strong relief with designs of animals, monsters, and semi-human figures against a background of floral arabesques.

Not all flintlocks were on firearms. The same mechanism was used on tinder boxes, alarm clocks, and gunpowder testers. The powder tester (Fig. 49) was like a pistol with a friction cover closing the mouth of the barrel. It was loaded (of course without a bullet) and fired. The force of the explosion blew the cover away from the barrel against the friction of a heavy spring; the distance which it moved gave an index of the strength of the gunpowder.

Fig. 47. Details of fine gunsmithing.

Fig. 48. This was what a gentleman carried in a holster at his saddle-bow in mid-seventeenth century Italy.

Fig. 50 illustrates a very complete outfit of pistols and accessories made at Lisbon, Portugal, by Jacinto Xavier in 1799. There are a pair of double barreled holster pistols for rides abroad, and a pair of small but deadly pocket pistols for self defense or card table arguments. With these are the accessories and tools appropriate to them: powder flask, powder measure, bullet molds, oil can, hammer, screw driver, awl, (for cleaning the touch holes), and box for spare flints and bullets. All are enclosed in a handsome mahogany case.

The outfit is definitely that of a dandy, for every piece is beautifully made and exquisitely decorated. The steel parts of the pistols are brilliantly polished or deeply blued. The stocks are delicately inlaid with rococo scrolls of silver wire. The oil can is a dainty hexagonal urn. Even the hammer and screw driver deserve in their own right places in a museum display.

Fig. 49. Not a weapon, but a device to test the strength of gunpowder. Yet just as beautiful as though it were deadly.

Students of the history of arms will delight in the holster pistols, for these have each two barrels side by side, while a single flintlock fires each in turn. The powder pan which catches the sparks from the flint is divided into two parts: that on the right transmits the ignition directly to the right hand barrel; that on the left is covered by a slide operated by a thumb 41 piece on the left side of the pistol. When this slide is pulled back, a second priming charge is exposed, so that the lock may be snapped again to fire the left hand barrel. Both barrels may be unscrewed by means of a wrench attached to the bullet mold; they are loaded from the breach with a slightly oversized bullet which will not move through the barrel until the pistols are fired.

Fig. 50. A gadgeteer’s dream. The big pistols are double barreled, and each of the little ones has three bayonets and a corkscrew!

The little pocket pistols are a gadgeteer’s dream. They have invisible triggers, which are only exposed when the lock is cocked. Each has on the right side a tiny triangular bayonet which springs into position at a touch on a catch. On the left side is a strong, light, knife blade similarly operated. Above each barrel is a second smaller knife blade (just right for trimming a quill pen), which may be pushed forward from a housing which conceals and protects it. And in the butt of each pistol is hidden a small but, effective corkscrew. What more could Beau Brummel himself desire?

The final item for which we have space is a flintlock pistol (Fig. 51) of the late eighteenth or early nineteenth century. It bears the signature “Derby à Paris”. Nothing seems to be known of this gunmaker; whether he was a Frenchman with an English name or an English gunsmith working in France must be left for future research to determine. In any case, he was a master of his craft. The pistol is in beautiful condition, though the blue color of the metal is a later restoration, no doubt based on the original 42 finish of the weapon. The barrel and lock are finely engraved and partially gilt; the walnut stock is fitted with a gilded butt cap and inlaid with silver wire in delicate arabesque scrolls. Attached to the top of the barrel is a short bayonet of bright steel; this is mounted with a spring device in such a way that the bayonet can be folded back when not needed, but at a touch of the thumb upon the spring catch, will fly forward and lock in position for use.

Fig. 51. A repeating flintlock pistol. A thousand of these in one place could have changed the history of the world!