The cover image was created by the transcriber and is placed in the public domain.

Title: The Story of Milk

Author: Johan Ditlev Frederiksen

Release date: August 14, 2021 [eBook #66061]

Language: English

Credits: Charlene Taylor, Barry Abrahamsen, and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive/American Libraries.)

The cover image was created by the transcriber and is placed in the public domain.

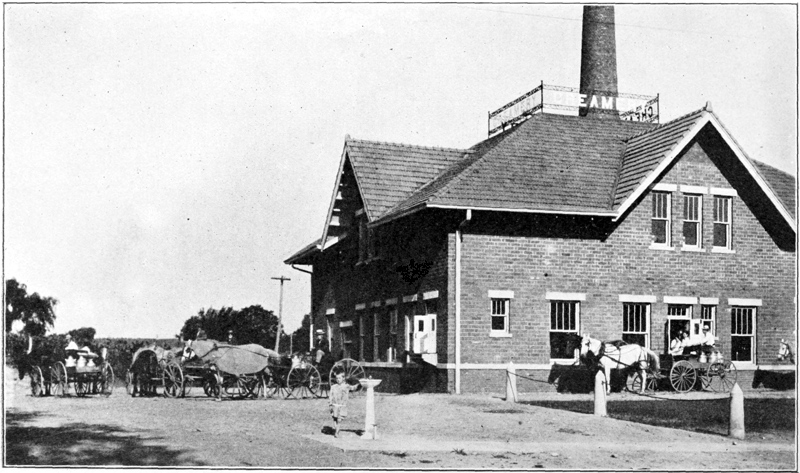

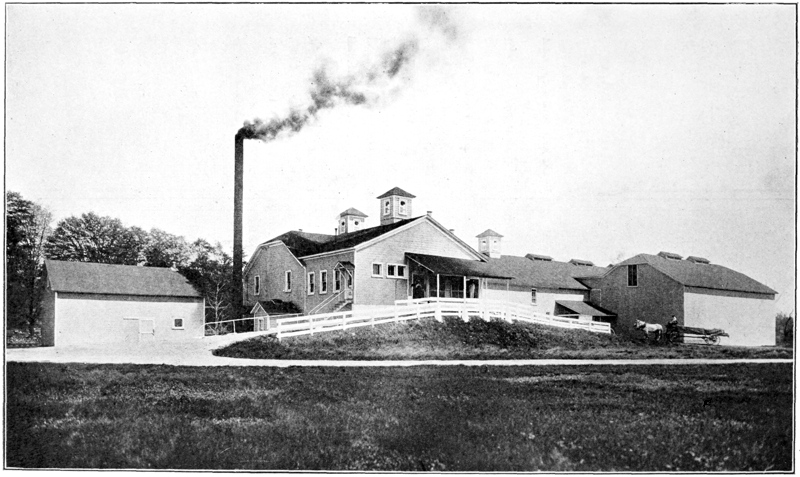

Well kept creamery with attractive surroundings

| PAGE | |

| Production, Composition and Characteristics of Milk | 1 |

| Milk Ferments | 1 |

| —Pasteurization | 1 |

| Dairy Cattle | 1 |

| —Milk-Breeds | 1 |

| —Beef-Cattle | 4 |

| —Food and Water | 5 |

| —The Barn | 9 |

| —Milking | 10 |

| —Test the Cows | 11 |

| —Healthy Cows | 12 |

| Composition of Milk | 13 |

| —Butter-fat | 13 |

| —Casein and Albumen | 14 |

| —Milk-Sugar | 14 |

| —Mineral Matters | 15 |

| How to Test Milk | 15 |

| —The Babcock Test | 16 |

| —Sampling | 17 |

| —The Lactometer | 18 |

| —Acidity Test | 19 |

| Ferments | 20 |

| Enzymes | 21 |

| —Rennet | 20 |

| —Pepsin | 21 |

| VIBacteria | 21 |

| —Lactic Acid Bacilli | 21 |

| The Control of Bacteria | 22 |

| —Cleanliness | 22 |

| —Heat | 22 |

| —Cooling | 22 |

| —Disinfectants | 25 |

| Pasteurization | 25 |

| Pure Cultures | 30 |

| —Starters | 32 |

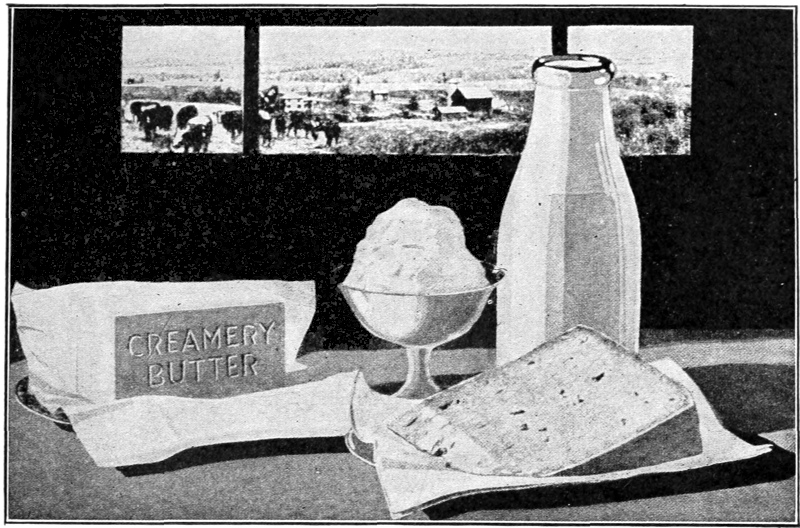

| Milk Supply and Creamery Products | 35 |

| Milk Supply | 35 |

| —Bovine Tuberculosis | 35 |

| —Milk as a Disease Carrier | 36 |

| —Bacteria Count | 36 |

| —Certified Milk | 36 |

| —The Sanitary Code | 38 |

| —New York State Milk Grading | 38 |

| —City Delivery | 39 |

| —Milk Stations | 41 |

| —Skim Milk | 44 |

| Cream | 44 |

| —The Separator | 46 |

| —Percentage of Butter-fat | 48 |

| —Standardizing Cream | 48 |

| —Pasteurized Cream | 49 |

| —Whipped Cream | 49 |

| —Emulsified Cream | 50 |

| Ice Cream | 52 |

| —Freezers | 52 |

| —Classification of Ice Cream | 56 |

| —Ice Cream Recipes | 56 |

| VIIButter | 69 |

| —Dairy Butter | 70 |

| —Centrifugal Creaming | 70 |

| —Co-operative Creameries | 70 |

| —Ripening the Cream | 71 |

| —Coloring | 74 |

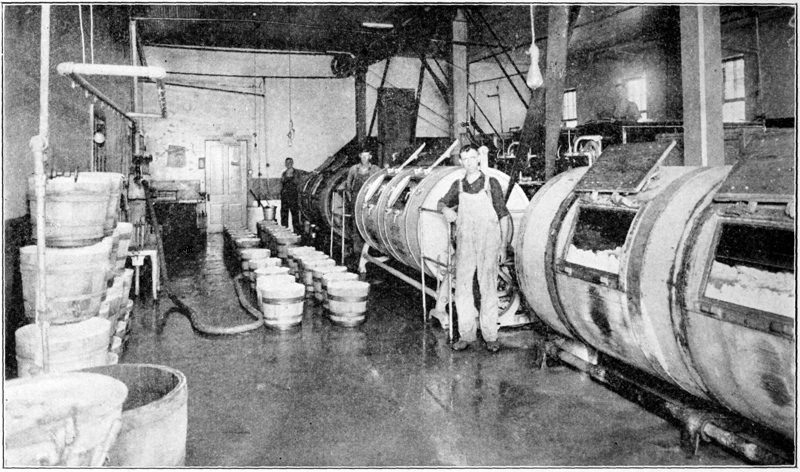

| —Churning | 75 |

| —Working | 78 |

| —Salting | 79 |

| —Composition | 79 |

| —Overrun | 79 |

| —Packing | 79 |

| —Sweet Butter | 79 |

| —Renovated Butter | 80 |

| —Oleomargarine | 80 |

| —Coco-Butter | 80 |

| Buttermilk | 80 |

| —Cooling Essential | 81 |

| —Commercial Buttermilk | 81 |

| —Ripening | 82 |

| —Breaking up the Curd | 82 |

| —Thick Milk | 82 |

| —Yoghourt | 83 |

| Fermented Milk | 83 |

| —Koumis | 83 |

| —Kefir | 85 |

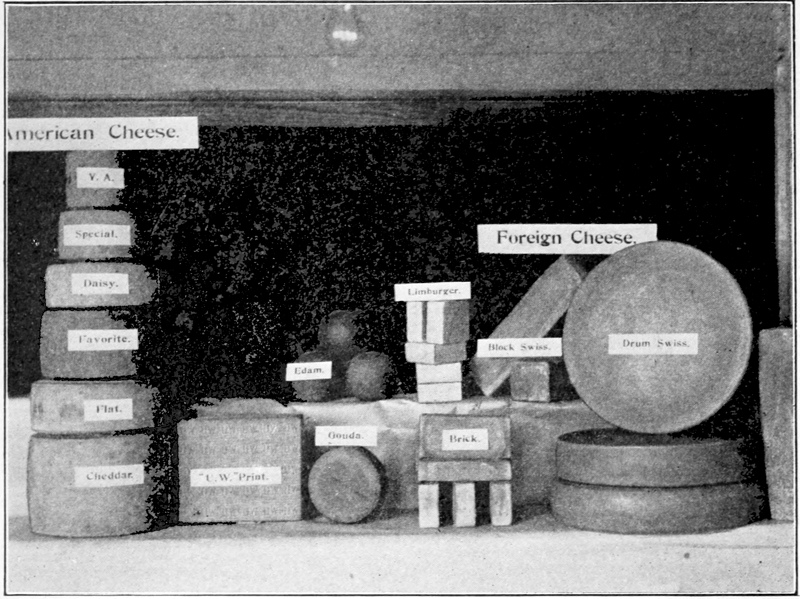

| Cheese | 86 |

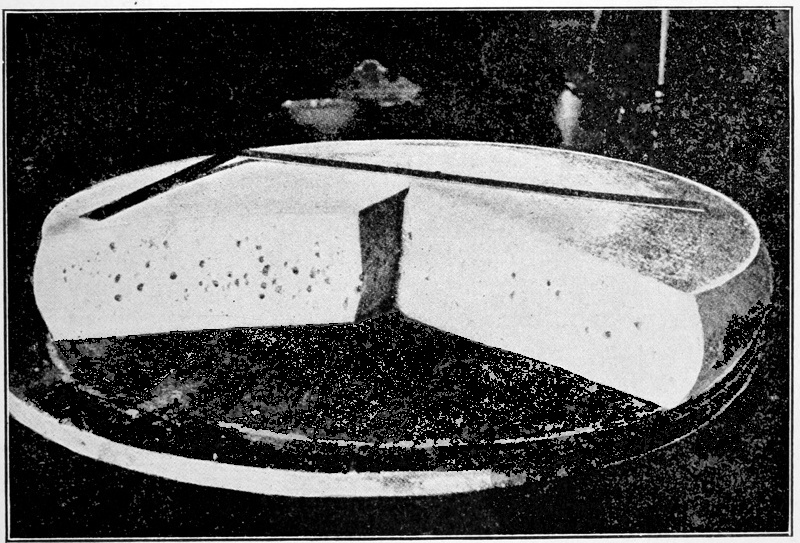

| Cheddar Cheese | 89 |

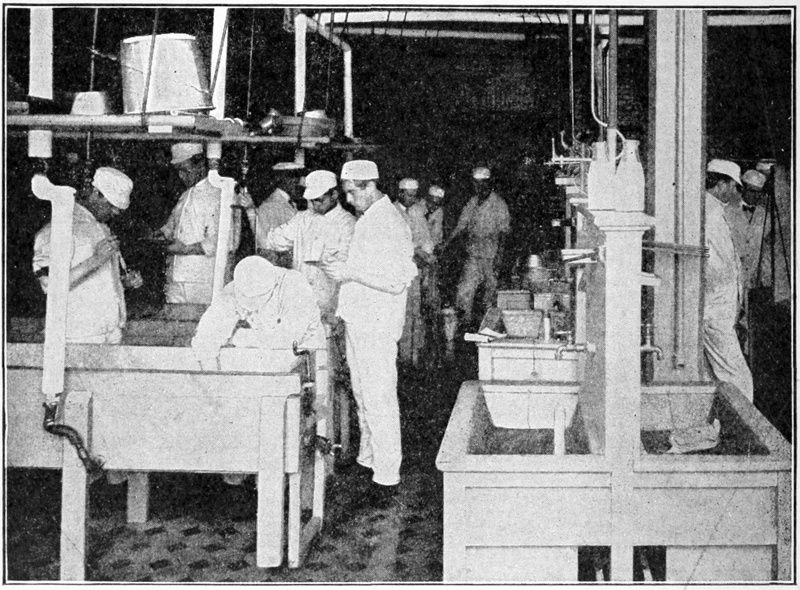

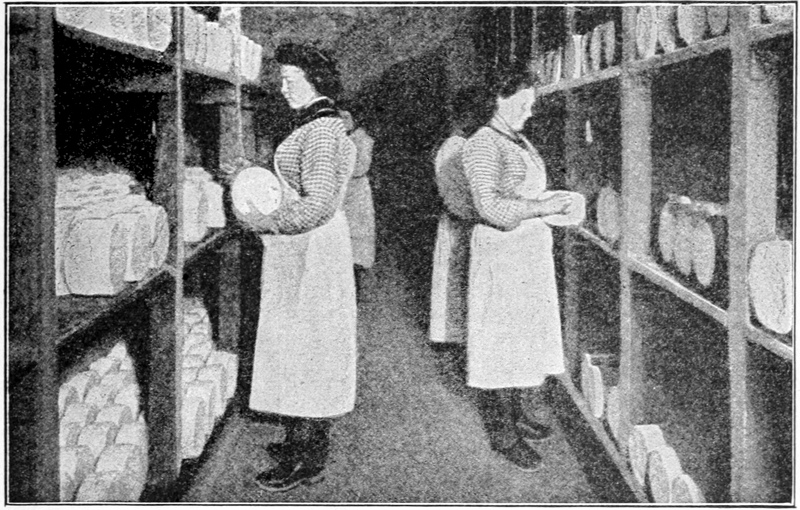

| The Factory System | 99 |

| —Ripening the Milk | 90 |

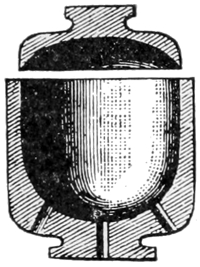

| —Coloring and Setting with Rennet | 92 |

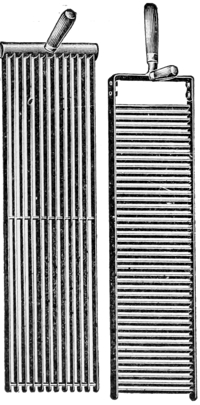

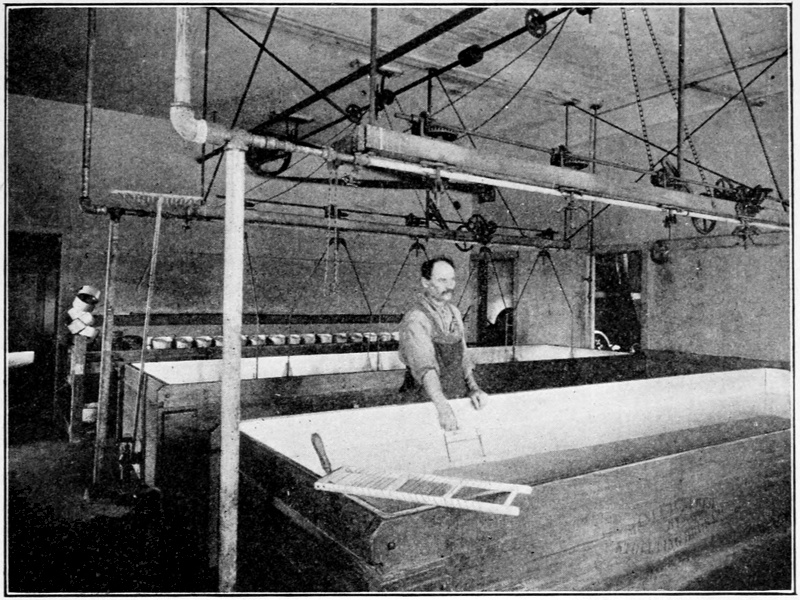

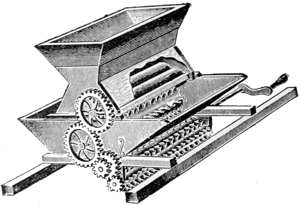

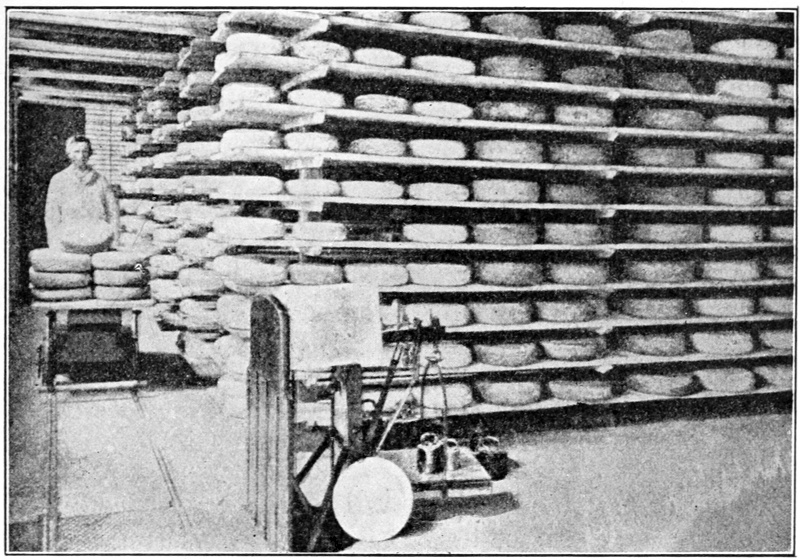

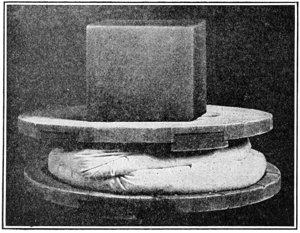

| —Cutting the Curd | 94 |

| VIII—“Cooking” | 94 |

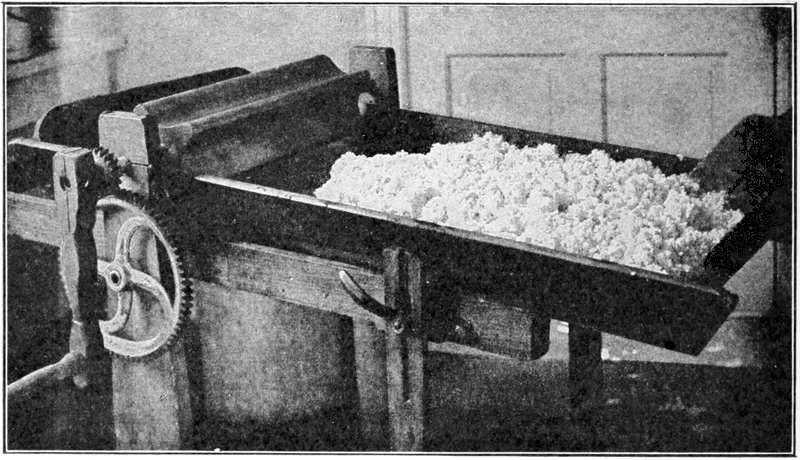

| —Matting | 95 |

| —Salting | 97 |

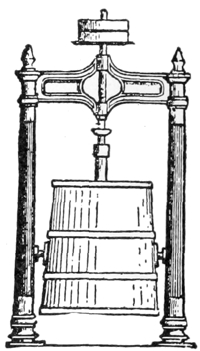

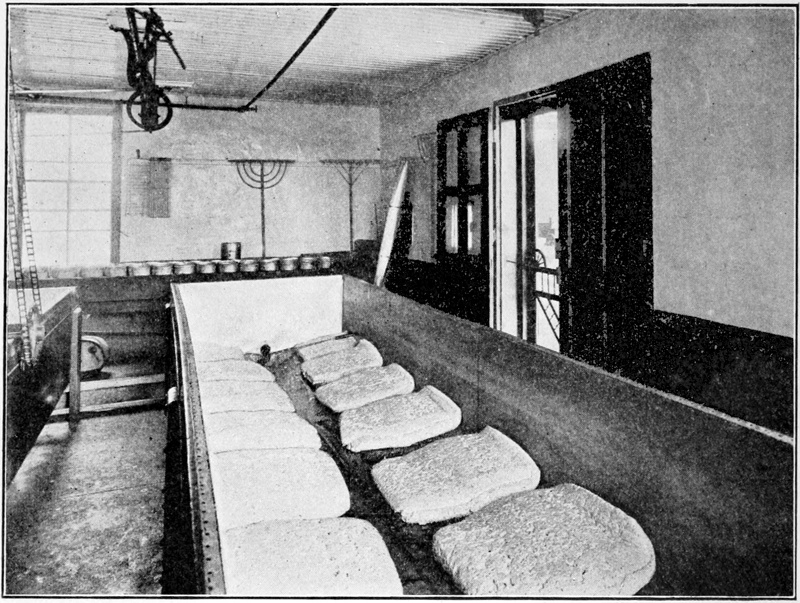

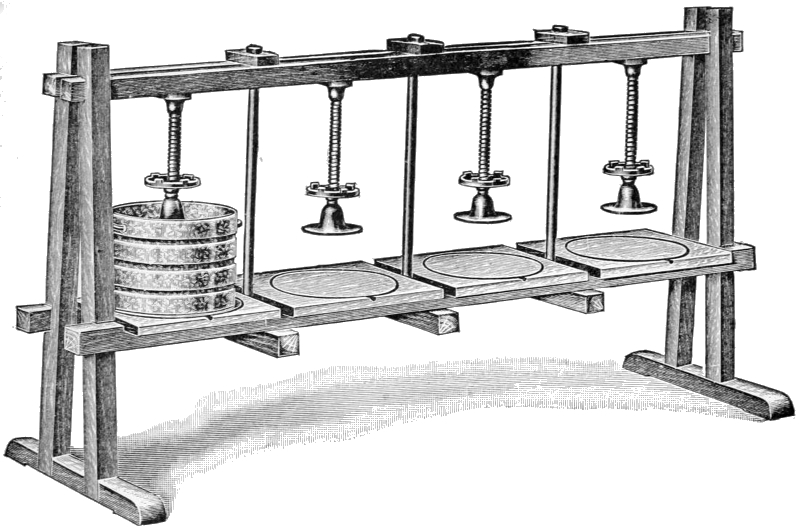

| —Pressing | 97 |

| —Curing | 97 |

| —Form, size and packing | 98 |

| —Cleaning the vats | 101 |

| —Yield | 102 |

| —Composition | 102 |

| —Qualities | 103 |

| Cheese Made from Pasteurized Milk | 103 |

| Making Cheddar Cheese on the Farm | 104 |

| Other Types of Hard Cheese | 111 |

| —Gouda | 112 |

| —Edam | 112 |

| —Swiss | 115 |

| —Roquefort | 120 |

| —Parmesan | 123 |

| —Caccio Cavallo | 124 |

| —Limburger | 125 |

| —Brick | 125 |

| —Munster | 126 |

| Soft Rennet Cheese | 126 |

| —Neufchatel | 126 |

| —Cream Cheese | 127 |

| —Cured Soft Cheese | 128 |

| —French Soft Cheese | 128 |

| Cottage Cheese | 129 |

| —Making Cottage Cheese with Rennet | 132 |

| Snappy Cheese | 134 |

| Club Cheese | 134 |

| Whey Cheese | 134 |

| Milk-Sugar | 135 |

| IXCasein | 135 |

| Milk Powder | 136 |

| —Just-Hatmaker Process | 136 |

| —Eckenberg Process | 136 |

| —Merrell-Soule Process | 136 |

| —Economic Process | 136 |

| —Skim-Milk Powder | 136 |

| —Whole-Milk Powder | 136 |

| Condensed and Evaporated Milk | 137 |

| Whey | 138 |

| Milk as a Food | 139 |

| Nutrients | 139 |

| —Protein | 139 |

| —Fats and Carbohydrates | 139 |

| —Mineral Matters | 140 |

| —Relation | 140 |

| —Nutritive Ratio | 140 |

| —Calories | 141 |

| —Fallacy of Theoretical Valuation | 143 |

| —“Something Unknown” | 143 |

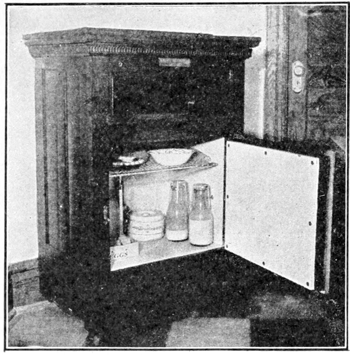

| Care of Milk in the House | 145 |

| —Keep the Milk Cool | 145 |

| —Top-Milk | 146 |

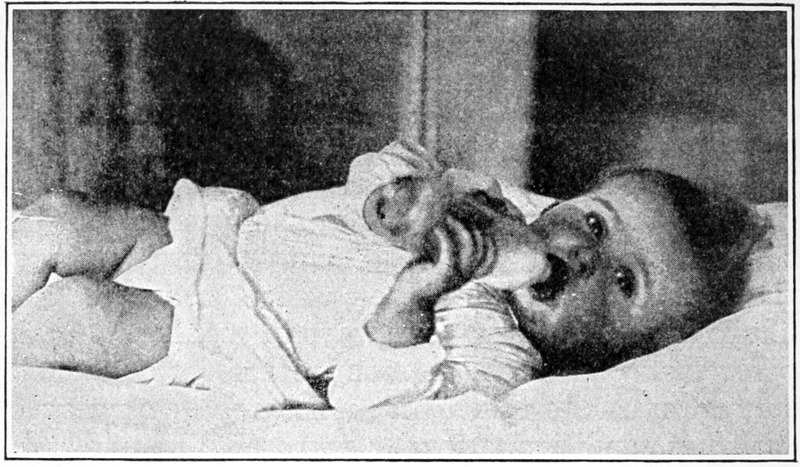

| Milk for Infants | 148 |

| —Modifying Milk | 148 |

| —Recipes for Infant Food | 149 |

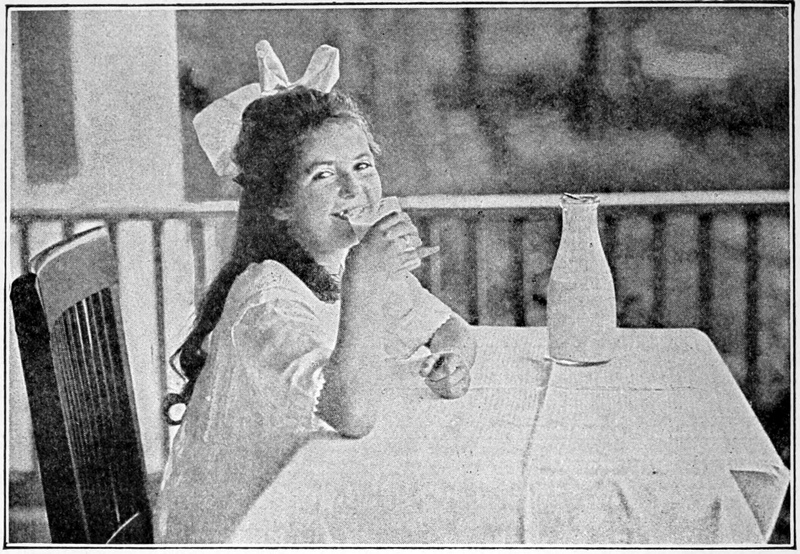

| Milk for Growing Children | 152 |

| Milk Cookery | 154 |

| Soups | 155 |

| X—Cream Soups | 155 |

| —Cereal Cream Soups | 157 |

| —Milk Chowders | 158 |

| —Milk Stews | 158 |

| Milk Cereals | 159 |

| Luncheon and Supper Dishes | 159 |

| —Creamed Dishes | 160 |

| —Souffles | 161 |

| —Cheese Fondu | 161 |

| —Milk Toast | 162 |

| Cheese Dishes as Meat Substitutes | 162 |

| Cheese Salads | 166 |

| Cottage Cheese | 167 |

| Milk Breads and Biscuits | 170 |

| Desserts | 172 |

| Junkets | 179 |

| Milk Beverages | 181 |

| Miscellaneous Suggestions | 184 |

| The Thermometer | 184 |

| Weights and Measures | 185 |

| End Notes | 187 |

| Bibliography | 188 |

The conception of this “Story of Milk” dates many years back. In his life-long study of problems connected with dairy farming and milk industries in two of the world’s greatest dairy countries, Denmark and the United States, the author has felt the need of a concise handbook covering this interesting subject. In his forty years of work in the manufacture and distribution of dairy and milk-food preparations he has been brought constantly into contact with men and women interested in the production of milk and has found a persistent demand for a book that might be consulted by anybody in regard to questions related to these greatest of all foods, which are, or ought to be, a most important part of the daily diet of children and adults alike, at all times, everywhere.

There was a time during the war when, frightened by the soaring of the price which had remained remarkably low for many years, much too low in fact compared with the cost of other food, people began to cut down the consumption of milk to an alarming extent. Even the National Food Administration for a short time recommended saving in the wrong place, forgetting that, at the highest figures reached during the temporary shortage, milk was still one of the cheapest of foods and that it was absolutely indispensable for growing children and exceedingly beneficial for men and women who were called upon to exercise their physical and mental powers as never before. But with XIImen like Dean Russell of the Wisconsin Agricultural College in the Department and Dr. Graham Lusk of Cornell University representing the United States on the Inter-Allied Council of Alimentation, the Food Administration could not long maintain this mistaken attitude but quickly joined the College authorities and the representatives of the dairy industry in advocating a liberal use of milk. And the Department of Agriculture sent out over the country a large force of demonstrators to show the people how to use milk in making cottage cheese and many other ways, and Agricultural Colleges, Farm Bureaus and Home Economics Agents worked hand in hand with Washington in disseminating the knowledge of handling and utilizing milk.

A genuine interest has been aroused in our country in the economy and conservation of food, and in “The Story of Milk” the author hopes to place at the disposal of the student of Domestic Science a comprehensive book of reference which may open the eyes of many to the fact that there is no more interesting subject than “Milk” in connection with the study of the welfare and physical improvement of humanity, and that milk and its products should be used to a much greater extent than heretofore.

It would make a long list of references if the author should mention the sources on which he has drawn for information beyond his own life-long experience in the dairy and related industries. He desires to express his sincere appreciation of the kindness and ready response of institutions and friends to whom he has appealed for photographs and cuts which have enabled him to illustrate the text so liberally. In the back of the book will be found a brief bibliography of standard dairy XIIIliterature in which students may find material for further information.

Many interesting data and several excellent illustrations have been obtained from the bulletins and collections of the Department of Agriculture in Washington and the Dairy Schools at Ithaca, N.Y., Madison, Wis., and Ames, Ia.

The Chapter on Milk Cookery was written and classified by the author’s wife, whose practical experience will make it useful alike to housekeepers and students of Domestic Science.

Little Falls, N.Y.,

April, 1919.

Milk and its products have been known and used from time immemorial. In the Bible milk and milk foods are mentioned in some thirty places. In Gen. 18:8 we read: “... and he (Abraham’s servant) took butter and milk and set it before them ...”; 1 Sam. 17:28: “And Jesse said unto David, his son: ... bring these ten cheeses unto the captain of their thousand and look how thy brethren fare....”; Prov. 30:33: “For the churning of milk bringeth forth butter,” etc.

Though in some of these passages butter is mentioned it is hardly probably that this product was really made or used at the time under the climatic conditions in Palestine. More likely it was various kinds of curd and cheese which the translator called butter. At any rate, the Hebrews of that far-off day coveted milk and its products among their most valued foods. From Egyptian, Greek and Roman history it appears that knowledge of cheese goes back to the most ancient times and that it was made from the milk of sheep, goats, cows, asses, mares, in fact from all domestic animals; in the far North, Lapps and Eskimos still make it from the milk of the reindeer, the Arabs use camel’s milk, Llama cheese is famous in the Cordilleras and Zebu cheese in Ceylon and India.

Even in ancient times the great food value of dairy products was recognized. Plinius tells of Zoroaster that for twenty years he lived exclusively on cheese, and Plutarch calls cheese one of the most nourishing of foods.

As time went by, the cow excelled all other domestic XVIanimals in capacity for the production of milk and by constant use through centuries for the one special purpose,—by care in feeding, breeding and selection,—special breeds of cattle were developed which gave milk in extraordinarily large quantities.

From Maelkeritidende, Copenhagen

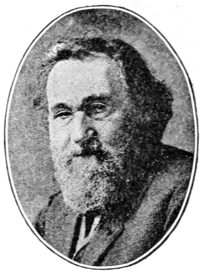

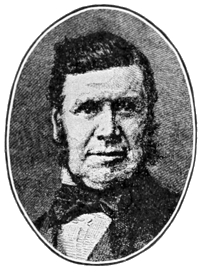

Thomas R. Segelcke, father of scientific dairying in Denmark

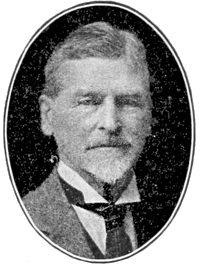

L. B. Arnold, noted dairy expert and writer, of Herkimer County, N.Y.

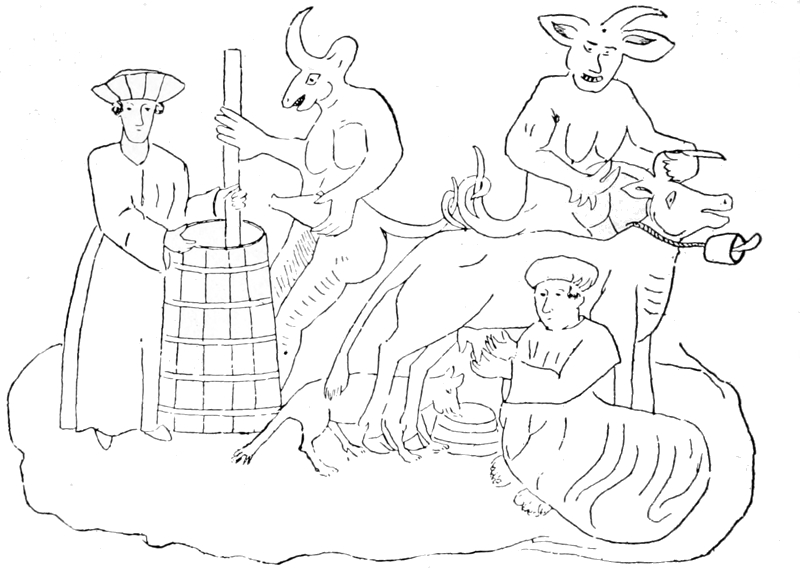

In the cold climate of the northern countries where butter will keep for a long time it has been made for centuries. The illustration above is from a mural painting in an old church in Finland. Evidently at the time when that was built the devil already played havoc with the churn and even up to the days of our grand-fathers his Satanic Majesty was often accused of preventing the butter from “coming.”

XVIINot until the middle of the nineteenth century did dairying take its place among the important industries of the world and science begin to be applied in its development. Between 1860 and 1870 Thomas R. Segelcke, the “Father of Scientific Dairying” in Denmark, introduced the thermometer in churning instead of the rule of thumb and started the keeping of records in the manufacture of butter. N. J. Fjord started a series of experiments in the creameries, continued through the next decades, and which became models for similar work throughout the world, covering pasteurization, ice houses and cold storage, comparison between various systems for raising the cream, separators, feeding rations, etc., and Denmark developed its agriculture and dairy industry to an enviable position. About the same time Dr. Schatzman applied scientific methods in cheese making in Switzerland and Jesse Williams started the first American cheese factory near Rome, N.Y., while L. B. Arnold, X. A. Willard, Harris XVIIILewis, Harry Burrell and many other progressive dairymen made Herkimer County cheese famous.

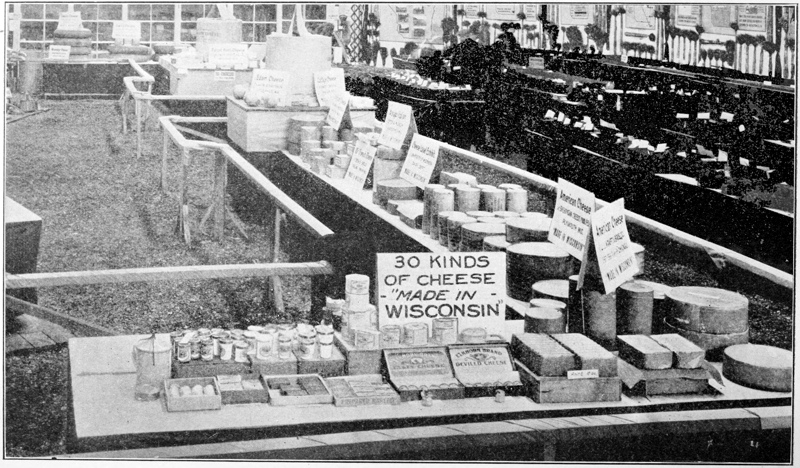

From New York, dairy farming spread rapidly westward through Ohio to Michigan and Northern Illinois, where butter making was developed around Elgin, and to Wisconsin, where Governor Hoard preached the gospel of progress, Babcock invented and gave to the world the famous test that bears his name and Russell made a specialty of dairy bacteriology.

J. H. Monrad, the “Pen and Ink” buttermaker of New York Produce Review

Governor W. D. Hoard, of Wisconsin, promotor of progressive methods of dairying

J. A. Ruddick, Dairy Commissioner of Canada

J. H. Monrad, Assistant Dairy Commissioner of Illinois, student, writer and lecturer on dairy subjects, collected and indexed one of the most complete and valuable libraries of dairy literature found anywhere, which after his death in 1915 was taken over and installed in special rooms by Chr. Hansen’s Laboratorium in Copenhagen, where a librarian is keeping it up to date and it is open to the public.

In Canada, Dairy Commissioners Jas. W. Robertson and J. A. Ruddick, D. M. McPherson, the “Cheese XIXKing,” and others contributed to an enormous development of the manufacture of high-class cheese, and in New Zealand and Australia similar progress was made.

Business and science have vied with each other in increasing the output of dairy products and improving their quality. In the table below, showing estimates for 1917, some interesting figures are given of the amount of milk produced in the United States and the uses to which it is applied.[1]

| Item | Lbs. of Milk | Per Cent |

|---|---|---|

| Product of 22,768,000 cows at 3,716 lbs. per an. | 84,611,350,000 | ── |

| Disposition of milk product: | ───── | |

| 1,650,000,000 lbs. of butter (at 21 lbs. milk) | 34,663,850,000 | 41.0 |

| 420,000,000 lbs. of cheese (at 10 lbs. milk) | 4,200,000,000 | 5.0 |

| 975,000,000 lbs. of condensed milk (at 2½ lbs. milk) | 2,437,500,000 | 2.9 |

| 210,000,000 gals. of ice cream (weighing 6 lbs. to the gallon, 10% fat) | 3,150,000,000 | 3.7 |

| 100,000,000 persons; 45% at 0.7 lb. a day (cities) farms with dairy cows, 30%, 1.5 lbs. per day; other farms and small towns, 25%, 1 lb. a day, approximately | 36,500,000,000 | 43.1 |

| 17,500,000 calves, whole milk (estimated) requirement | 3,660,000,000 | 4.3 |

| ───── | ||

| Total | 84,611,350,000 | 100.0 |

XXAlthough the table accounts for all the milk produced, it does not tell the whole story, since the preparation of a number of products results in the formation of vast quantities of by-products that are not used to the fullest advantage for human food.

New York City alone consumes 1,600,000 quarts of milk a day, but even this enormous quantity means only 0.6 pint per capita. The consuming public has been slow to realize the value of milk and its products, and too much emphasis cannot be laid upon the fact that even at the largely increased cost of all dairy products they are still some of the cheapest and the most healthful of foods, especially for growing children, and should be used in much larger quantities.

Holstein

A number of typical but widely different breeds of dairy cows have been developed in various dairy countries, each owing to the soil and the climatic conditions of its home, as well as to the skill and fancy of the breeders, its characteristic features, form, color, etc.

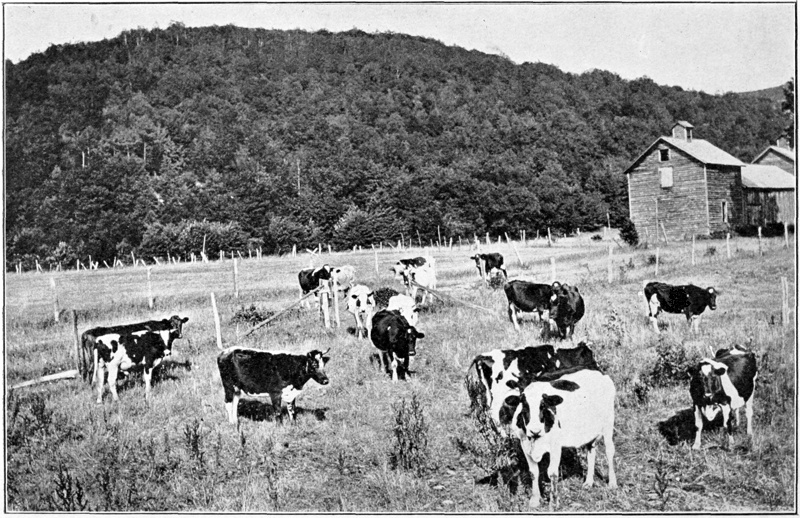

Herd of pure-bred Holstein cows on a farm in central New York

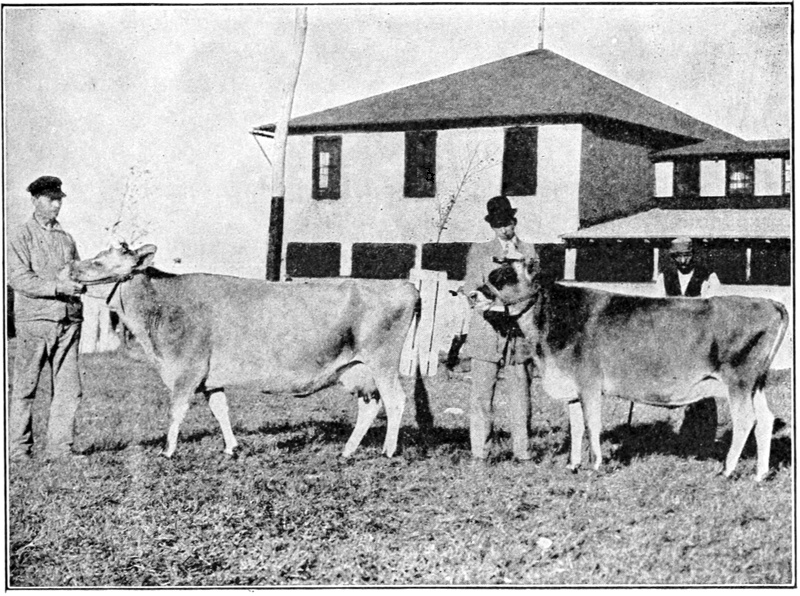

Milk-Breeds.—The black and white Holstein-Friesians (which, by the way, had their home in Holland and not in Holstein) are known for their large production of not very rich milk, while the Guernseys and Jerseys give milk exceedingly rich in butter-fat. A good Holstein cow will give from 7,000 to 10,000 lbs. of milk in a year, containing from 3¼% to 4% butter-fat. Some of them produce as much as 20,000 to 30,000 lbs. in a year—nearly 4,000 gallons—just think of it! Jersey cows will usually not produce as much in quantity as the Holsteins but Jersey milk often contains 5% or 6% or more 3butter-fat, and a few of the best have been known to produce 800 to 900 lbs. of butter in one year, an amount equal to the cow’s own weight. The red Danish cow is an exceedingly good and highly bred milk producer which, however, has not been introduced in the United States, but the Scotch Ayrshires and the Brown Swiss are other well-known dairy breeds which are in favor with many American farmers.

Guernsey

But, alas! too many herds of dairy cattle average less than 5,000 lbs. of milk per cow per year and do not pay for their feed.

Jersey cows

Red Danish

Ayrshire

Shorthorn, beef-strain

Many native cows respond, however, to good care and feed and with a thoroughbred bull a satisfactory herd can readily be built up from carefully selected native stock. Such continued cross-breeding is more apt to succeed than attempts to cross two thoroughbred breeds because the characteristic features in full-blooded animals are so strong as to invariably predominate in the progeny over the less pronounced forms and tendencies inherent in native cows. But where two full-blooded animals are mated and the strong characteristics in each are fighting for predominance the result is apt to be a poor, ill-proportioned offspring as the result of atavism.

Shorthorn, milk-strain

Beef-Cattle.—Cattle bred and developed for the purpose of producing beef rather than 5milk are called by contrast beef-cattle. As examples of beef-cows look at the Shorthorns or the Herefords or the Polled Angus at the next State Fair you visit and notice the square, deep, smooth body with muscles and fat strongly developed in contrast to the loosely built, bony milk-cow with its tendency to turn all its food into milk at the expense of the body. There are, however, also among the Shorthorns, strains of good milkers, but as a rule these beef-breeds are not selected for the dairy farm, and “dual purpose” cows are not usually profitable.

Food and Water.—The natural food for the dairy cow in summer is grass, and where rich, succulent grass and clover grow in abundance, as on the fertile meadows of Holland and the Channel Islands, or the Swiss Alps, the highly cultivated Danish farms, the eastern and middle-western states of America, etc., dairying early reached its highest development. As the value of milk and its products for human food became more generally recognized and all-the-year-round production was forced, it was found necessary to feed the cows heavily in winter too, not only hay, but also grain and succulent food such as beets and corn-ensilage (green corn cut, stalks, cobs and all, and packed in a silo), and science was taken into play to formulate Balanced Rations containing the proper amounts and proportions of the various nutrients—Protein, Fat and Carbohydrates. It 7is not the place here to go deeper into this problem which has long been a subject for thorough research and experiments. In fact, more attention has been paid to the feeding of cattle than to the proper nourishment of human beings, and much of what we know about the latter has been deducted from experience and study on the dairy farm, and from laboratory work along that line. In the chapter on “Milk as a Food” we are taking up food values, etc., in relation to the feeding of children and men. Suffice it here to say that the same fundamental principles apply to the feeding of calves and cattle for the production of milk and beef. And we wish to emphasize the fact that, with due consideration to the proper proportion between the various groups of nutrients, it is much more important that the food is succulent, appetizing and easily digestible than that the ration shall be accurately balanced.

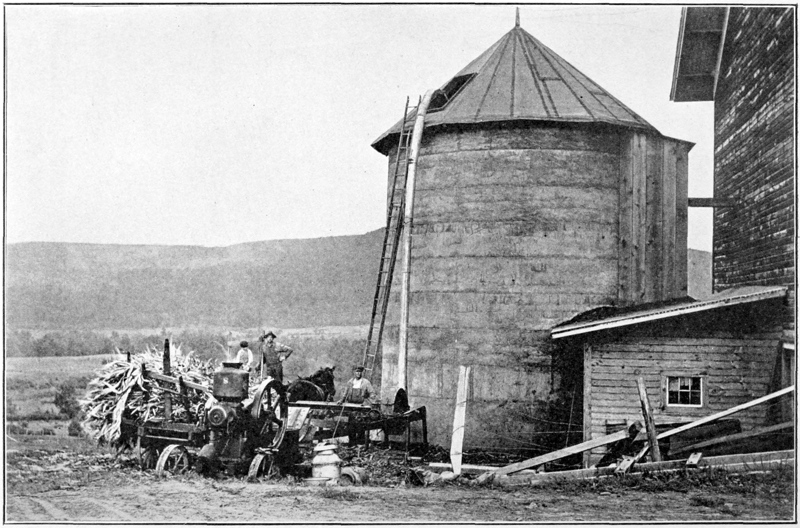

Cutting ensilage and filling the silo

This fact, long well known to practical breeders and dairymen, has recently been confirmed by Dr. E. V. McCullom to whose experiments further reference is made in the chapter on milk as a food for children. He shows that there is a very great difference in the quality of Protein and Fat from various sources and that there is “Something Unknown” in butter-fat, for instance, which is absent in most other fats and which is vital for the growth of the child as well as for the proper nourishment of man. This unknown but essential substance is also found, in small quantities, in the leaves of certain plants, as in alfalfa, while it is absent in the grain of the cereals.

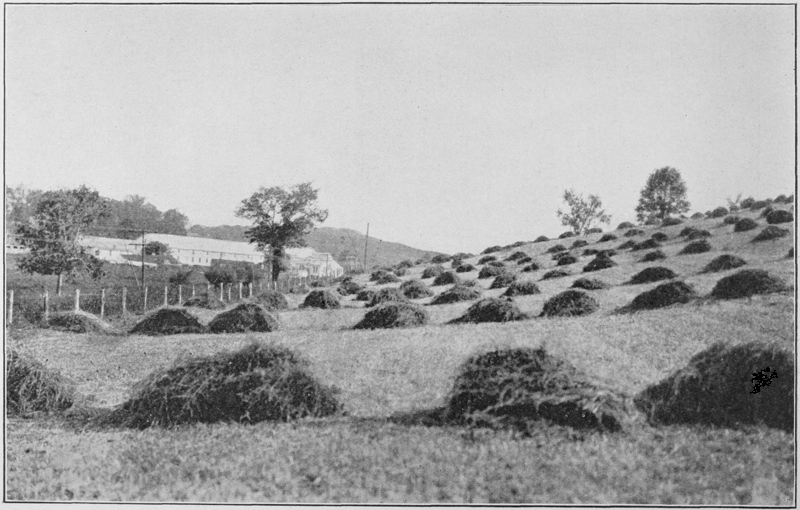

An abundant crop of alfalfa hay; cut three times during the summer. Supplies protein in the ration

In modern dairy farming alfalfa is considered an indispensable source for protein, and corn-ensilage or beets for carbohydrates, while bran, cottonseed meal or oil 9cake, malt-sprouts, gluten, distillers’ grain, etc., may be used to advantage in various combinations.

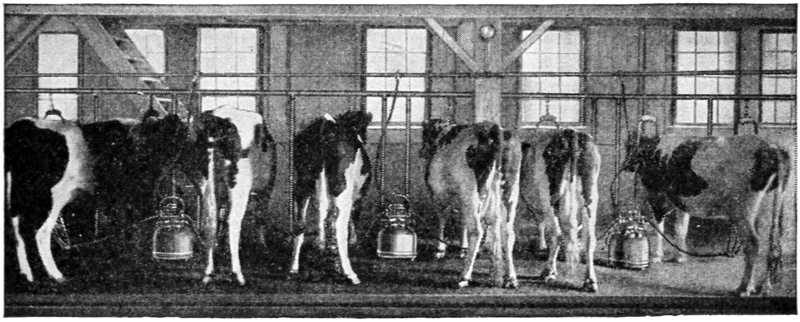

Cows milked with machine

Contrary to a general impression one cannot feed fat into the milk. A large amount of oil cake or other food rich in fat in the daily ration does not increase the percentage of butter-fat in the milk. Rather, it depends largely upon the breed and to some extent upon the period of lactation. Provided the food agrees with her digestion and keeps the cow in a good, healthy condition, the composition of the milk is not changed to any appreciable extent by a change in make-up of the food.

It goes without saying that to produce from 20 to 50 lbs. of milk a day the cow must have an abundance of fresh, pure water to drink and she should not have access to stagnant water.

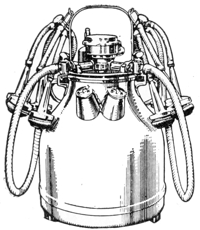

The Barn must be clean, light and well ventilated and the cows should be milked with clean hands into a clean pail which is covered as far as possible so as to prevent dust from falling into the milk, or with one of the excellent milking machines which are now frequently used in large dairies. The milk is strained and cooled immediately after milking.

Milking machine

In the partly covered milk-pail dust does not fall as readily as in the one entirely open

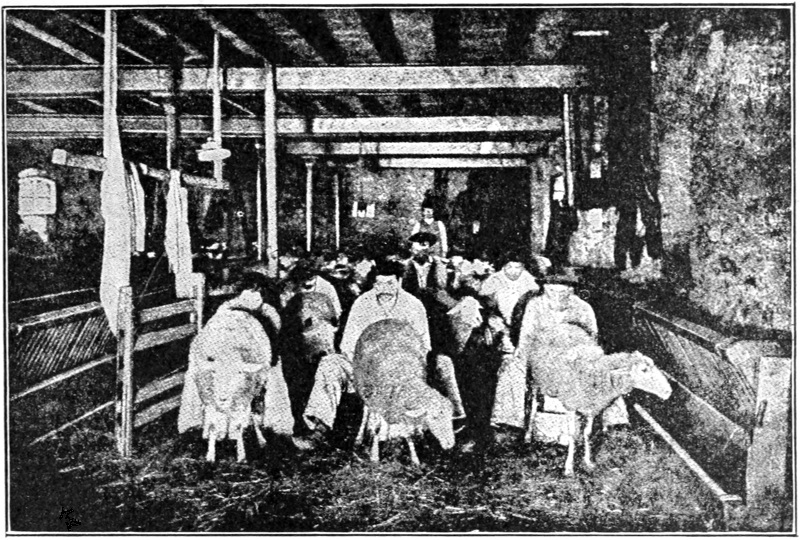

Milking.—The cows are usually milked twice a day; occasionally, when the highest possible yield is desired, as in important tests, three or four times. The first five days after the birth of the calf the milk,—the Colostrum so called,—is not normal and should not be used for human consumption. It may be fed to the calf. The first three to four months the yield of milk generally is higher than later, when it gradually drops until after about ten months it stops altogether and the cow goes “dry” at least for some six weeks before dropping the next calf. The highest annual yield may be obtained by having the cows “come in” in the Fall or early Winter and feeding them well all Winter to keep up an abundant flow of milk. Then, when they come out on pasture in the Spring,—in the latitude of the Great Lakes about May 15th,—the fresh, rich feed will stimulate production and give it a fresh start so that the milk-pail may continue to be filled during the next few months and the shrinkage of the yield will 11not occur until the time when the pastures dry up. The cow will then go dry in the early Fall, when feed is scarce. Usually, however, the cows are allowed to “come in” in the Spring and the yield of milk begins to shrink in the late Summer with little or nothing in the Winter.

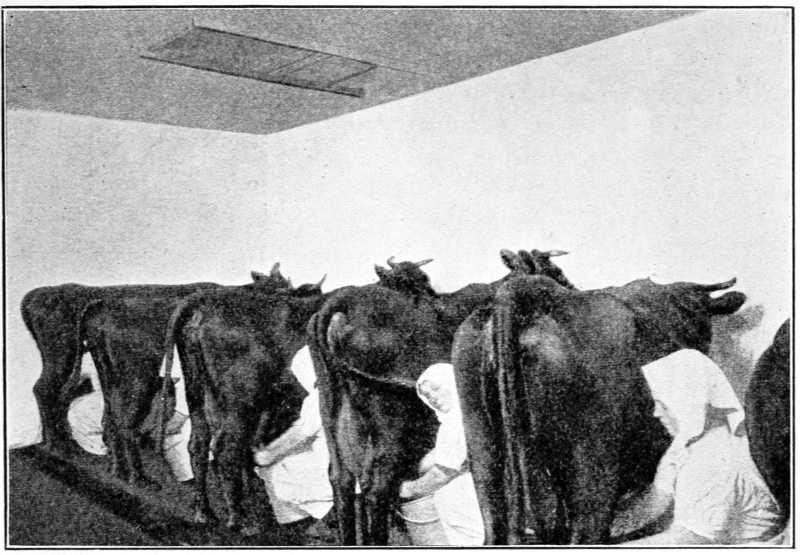

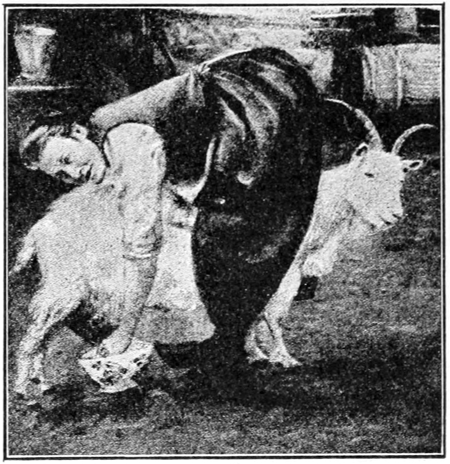

Milking on a Danish farm

Test the Cows.—To ascertain if a cow pays for her feed the amount and the quality of the milk should be tested and computed for the year. If the milk from each cow cannot be weighed every day it may be done regularly once a month or preferably oftener. If it is weighed morning and evening once every ten days it is easy to keep the account by multiplying the number 12of pounds by ten and adding the totals for the year. Occasionally the milk may be subjected to the Babcock Test to ascertain its richness; three or four times during the period of lactation is sufficient.

Where farmers do not have time to do the testing themselves they often combine and hire a young man or woman, trained in an agricultural college, to go around from farm to farm and do the work. These experts not only test the yield and the percentage of fat but also weigh and compute the feed so as to help the farmer make up his rations and calculate whether each cow pays for her feed or not. The members of these associations meet and compare notes and a friendly rivalry is stimulated which may do much toward increasing production. As a matter of fact, where Cow Test Associations have been introduced, both yield and quality of the milk have been largely increased.

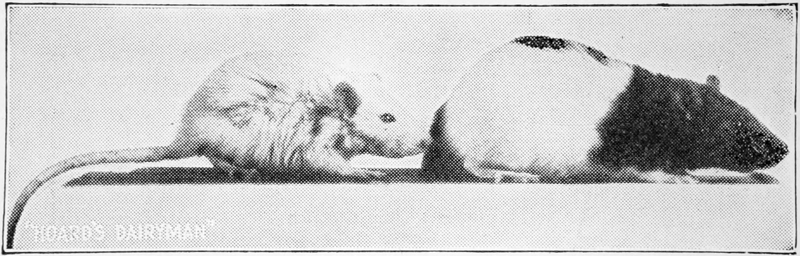

Dr. Bernhard Bang of Copenhagen, Denmark

Healthy Cows alone can be depended upon to produce sanitary milk. In many herds of milk-cows tuberculosis is prevalent, and constant vigilance is necessary to prevent its spread. The Tuberculin Test discovered by Koch is invaluable for the purpose of ascertaining the presence of tuberculosis. It is not necessary, however, to kill every infected animal. Only where the lungs or the udder is affected and a physical examination shows an advanced stage of the disease such radical means are advisable. When the tuberculin test was first introduced many valuable herds were wantonly and foolishly killed off because some of the highly developed dairy cows showed reaction to the test while worthless scrubs were allowed to live and spread the disease. For only the intelligent and public-spirited 13owners of fine herds submitted their cows to the test, a reaction to which, under ill-advised regulations, permitted state officials to condemn the infected herds. In Denmark Dr. Bernhard Bang introduced a system of isolation of the infected animals which together with Compulsory Pasteurization of the milk from such cows has proved efficient for the eradication of tuberculosis, and the Bang Method is now generally recognized as the proper way of handling the matter.

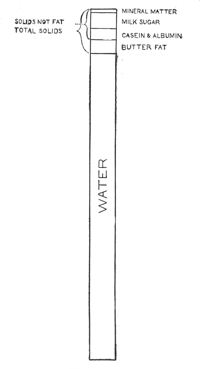

| 87 | lbs. of water |

| 4 | lbs. of butter-fat |

| 3¼ | lbs. of casein and albumin (protein) |

| 5 | lbs. of milk sugar |

| ¾ | lbs. of ash (mineral matter) |

| 100 lbs. total. |

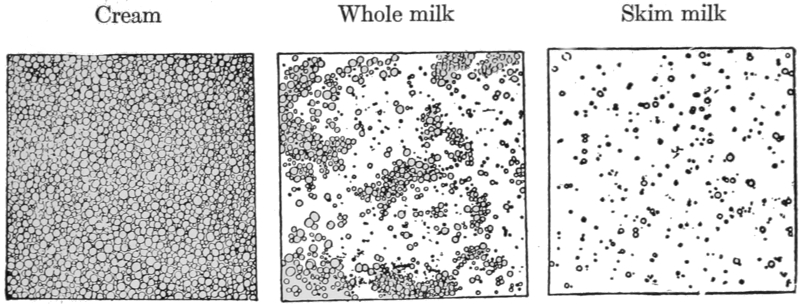

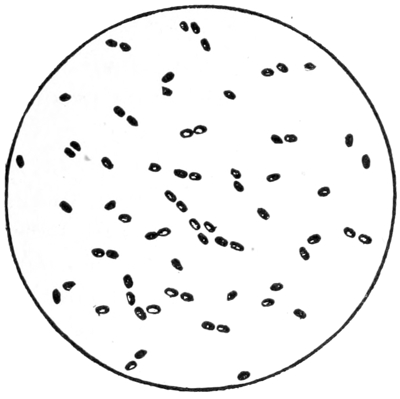

It consists therefore of 87% water and 13% “solids,” 4 of which are fat and 9, “solids—not fat.” Butter-Fat is found in milk in the form of minute globules suspended in the liquid. As fat or oil is lighter than water (has less specific gravity) it naturally floats and the fat globules therefore soon rise to the top when milk stands at rest, forming a layer of cream which may be skimmed off from the milk. In chemical composition butter-fat is very nearly the same as other 14animal and vegetable fats, but the slight variation may make a lot of difference in digestibility and palatability as well as in nutritive value, and it is a mistake to consider Oleomargarine, Butterine, Nut-Butter and other substitutes for butter “just as good” because a chemical analysis shows them to contain “almost” the same elements or compounds. These products may be good and legitimate if sold for what they are, but should never be allowed to be sold or served for what they are not, genuine butter.

Composition of cow’s milk

Casein and Albumin are the proteids or nitrogenous matters of the milk, in chemical composition and in food value much the same as the protein in beans and peas or in meat, or the white of eggs. Casein is present in much larger quantity than albumin and is distinguished from the latter by being precipitated by rennet, which has no effect on albumin. Casein may also be precipitated by acids, while it required boiling as well as acidity to throw the albumin out of solution.

Milk-Sugar is related to the vegetable sugars, glucose, cane sugar, etc., and remains in solution in the whey which separates out from the cheese-curd when milk is curdled with rennet or acids. The whey also contains the mineral matters or ash, which consists largely of phosphate of lime, of use to the young in building up bones. 15When whey is boiled down to a thick syrup and left to stand, the sugar will crystallize out and may be separated from the liquid, still holding in solution the mineral matters.

Fat globules as they appear under the microscope

Mineral Matters.—These may be gathered as ash by boiling off the water from this liquid or from the whole milk and burning the rest, as all the constituents except the ash belong to what in chemistry is called organic matter, which disappears in the air by burning.

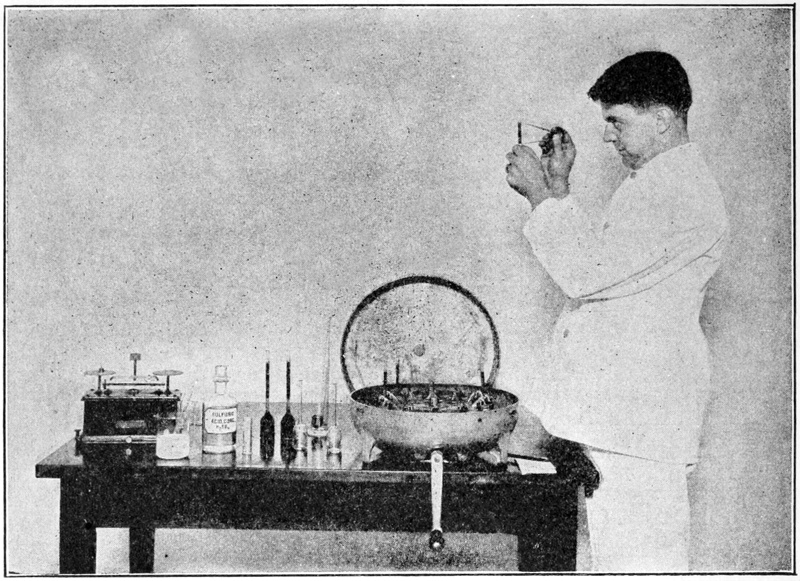

Dr. S. M. Babcock of Madison, Wis.

Milk may be adulterated or decreased in value either by skimming or by watering. In either case the percentage of the most valuable constituent, the butter-fat, is diminished. It is upon this fact that the most practical test, the Babcock, is based.

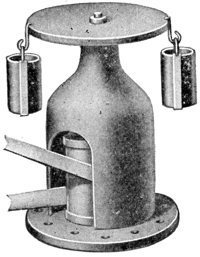

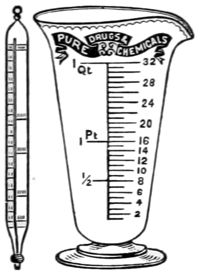

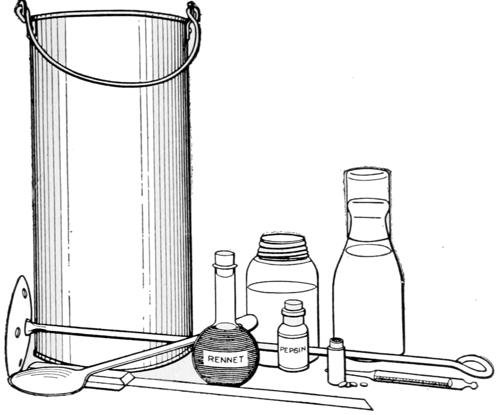

Babcock test outfit

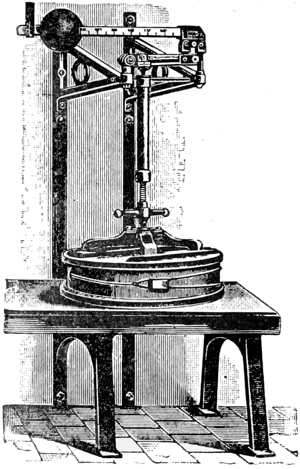

The Babcock Test.[2]—By treating a sample of milk with strong sulphuric acid the butter-fat is liberated as an oil. By subjecting the mixture to centrifugal force the light butter oil is separated from the rest of the 17milk and the percentage can be easily determined. Centrifugal force had already been used in the Fjord Cream Test, but it remained for Dr. Babcock to work out the splendid practical and reliable test which bears his name and in which he has given to the world an invention of incalculable value.

A two-bottle machine

Sampling.—Whether it is new milk or skim milk or buttermilk or cream that is to be tested the first thing to observe is to take a truly representative sample. The liquid must be thoroughly mixed by pouring it several times from one vessel to another, or stirring vigorously.

18It may not always be convenient to make a test immediately when the sample is taken. In the creamery where the milk is paid for according to its fat contents, samples are taken every day from every patron’s milk and it would take too much time for the butter maker to test all of these samples before they would spoil. A preservative, corrosive sublimate,—poisonous but all right for the purpose,—is therefore added and all the samples of one farmer’s milk for several days or a whole week are put together in one glass to be kept and tested at one time. This is called a composite test and has proven entirely satisfactory.

The Lactometer has been used to discover adulterations, depending upon the difference in specific gravity of the various constituents. The specific gravity of whole milk is about 1.032 which means that, if a certain volume of water weighs 1.000 weight units, the same volume of whole milk weighs 1.032, the same volume of butter-fat weighs, say, .900, or of cream about 1.000, and of skim milk 1.036 units. If the Lactometer shows a sample of milk to have a higher specific gravity than 1.032 it may therefore be suspected of having been skimmed. But it will readily be seen that by removing from whole milk some of the cream and adding water, the specific gravity can easily be brought back to normal for whole milk. This test is therefore unreliable and has been discarded with the advent of the Babcock.

The acidemeter

Acidity Test.[3]—The acidity, or sourness, of milk or cream, which depends upon the amount of lactic acid developed in it, may be tested by a liquid normal alkali or by the Farrington Alkaline Tablets, a solution of which added to sour milk neutralizes the acid. A few drops of an indicator, Phenolpthalein, added to the milk, turns it pink when all the acid has been neutralized, and the amount of alkali solution used shows the percentage of acid in the milk. This is quite important in preparing “starters” for ripening the cream in butter making or milk in cheese making, and in the manufacture of “Commercial Buttermilk,” etc.

20There are other tests used in scientific dairying as the Fermentation Test to ascertain the relative purity of milk, the Casein Test, etc., but the above are those mostly used besides the Bacterial Count which is mentioned under the chapter on “Milk Supply,” and the Rennet Test described under “Cheese Making.”

Two classes of ferments are of importance in connection with milk: (1) “unorganized” or chemical ferments, the “enzymes,” and (2) “organized” ferments such as bacteria and yeast.

Rennet.—Among the unorganized ferments, Rennet or Rennin is highly important on account of its power of coagulating or curdling milk by precipitation of the casein. Rennet is extracted from the stomach of the suckling or milk-fed calf, where it serves in digesting the calf’s food. It is in the market in the form of a liquid extract as well as a dry powder compressed into 21tablets (Rennet Tablets and Junket Tablets). The characteristics and use of rennet are described under “Cheese Making” in Chapter III.

Pepsin is another enzyme the office of which in the process of digestion is to dissolve albuminoids. It is not considered identical with rennet though in an acid solution it will curdle milk. It occurs in the stomachs of grown animals fed on solid food and is usually produced from hogs’ stomachs.

Everywhere, in the air, in water, in the soil, and clinging to every object in the world, are minute organisms known under the common names of bacteria or microbes. In contrast to rennet and the other “unorganized” ferments, bacteria belong to the “organized” class. Some are harmful, producing putrefaction, dissolution, poisons or disease; others are beneficial, leading to desirable fermentations and changes; others again are indifferent, neither good nor bad, but harmless.

As the milk comes from the cow it is almost free from bacteria, but milk makes an excellent soil for many of these organisms to grow in, and they soon get in, to multiply with enormous rapidity at any temperature from 60° to 100° F.

Lactic Acid Bacilli are bacteria of special importance to the dairyman, for they convert sugar of milk into lactic acid and produce various more or less agreeable flavors. They are also powerful germicides and scavengers, destroying or neutralizing the products of other bacteria which in the absence of these bacteria and the 22lactic acid produced by them would play havoc with the food and produce putrefaction or disease. Everybody who handles milk knows that pure sour milk or buttermilk in which lactic acid bacteria abound keeps well for a long time, free from other fermentations which have no chance to develop in their presence. It is due to this purifying property that Metchnikoff recommended Bulgarian sour milk as a health food, asserting that it prevents harmful fermentations in the digestive channel.

The principal means at our disposal to prevent or control and regulate bacterial growth are:

Cleanliness, Heat, Cold and Disinfectants.

Cleanliness.—Only the most scrupulous cleanliness will prevent contamination. Hence the necessity of thorough scouring and sterilizing of all utensils, and the need for fresh air and pure water.

Heat.—The prevention of fermentation in milk by heating is called “sterilization” or “pasteurization” according to the intensity of the heat and the length of time the milk is subjected to it. Boiling destroys almost all bacterial life. Some germs require, however, exposure to a much higher temperature, up to 250° F. (boiling under pressure), to be entirely eradicated, but for all practical purposes a thorough boiling is considered sufficient to eliminate all danger of contamination. Such boiling is usually termed Sterilization.

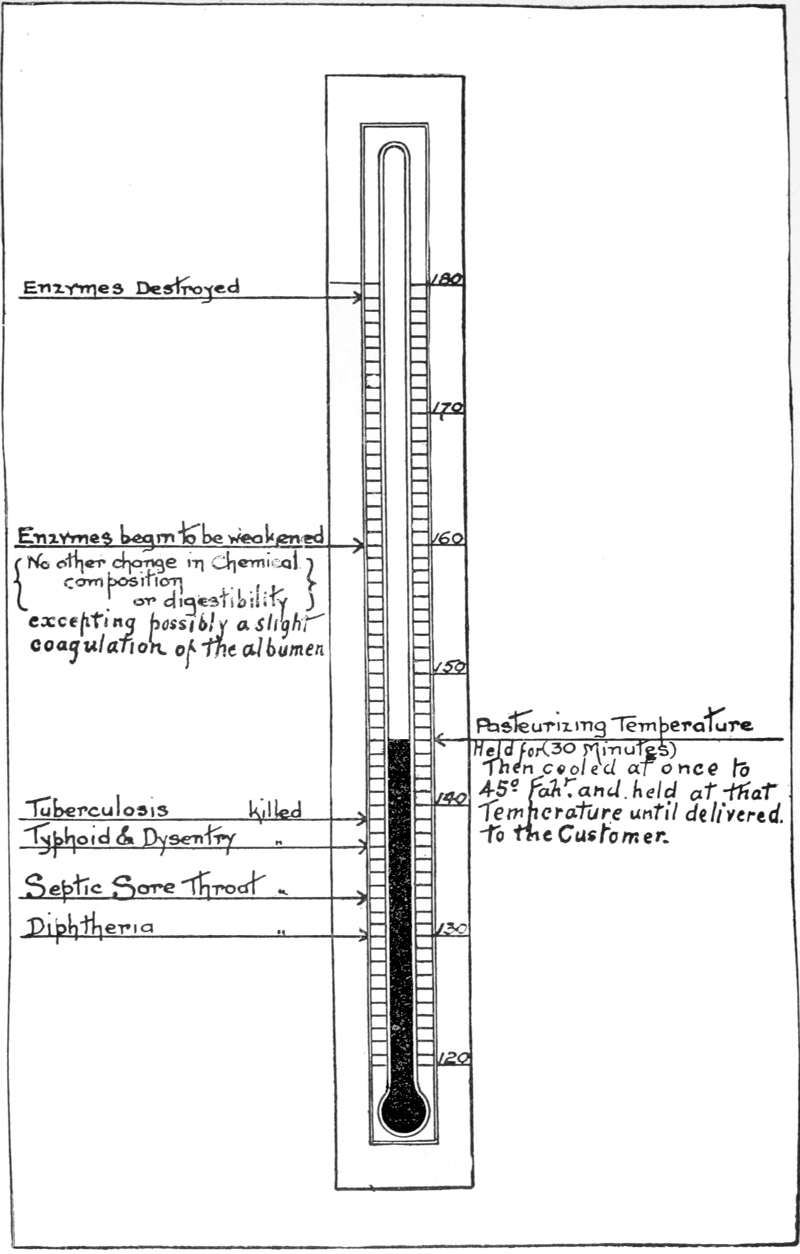

Effect of heating milk to various temperatures.

Published by the Toronto Board of Health

Cooling checks bacterial growth and but few germs thrive at a temperature below 50° F. The following table and diagram[4] show how quickly bacteria multiply 24in milk at ordinary room temperature, 68° to 70°, which emphasizes the importance of keeping milk cool.

Tem. of Milk |

No. of bacteria per c.c. at beginning | At end of 6 hrs. |

At end of 12 hrs. |

At end of 24 hrs. |

At end of 40 hrs. |

|---|---|---|---|---|---|

| °F. | |||||

| 50 | 10 | 12 | 15 | 41 | 62 |

| 68 | 10 | 17 | 242 | 61,280 | 3,574,990 |

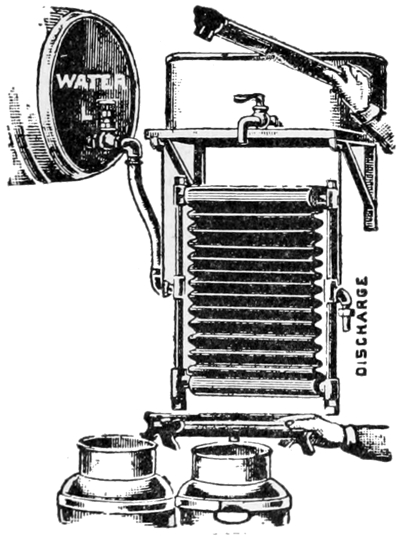

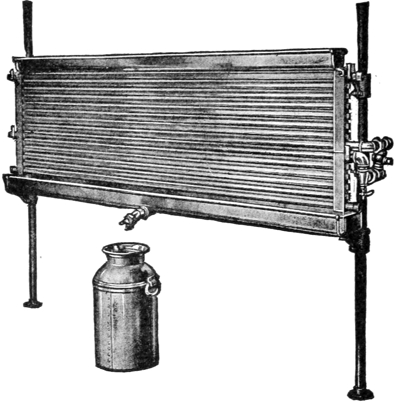

Milk cooler

If the milk had contained 1,000 bacteria per cubic centimeter at the beginning, the part held at 50° F. would have contained 4,100 bacteria at the end of 24 hours, while that held at 68° F. would have contained 256,128,000. The effect of temperature upon the growth of bacteria is shown graphically in the cut.

But even frost does not kill the bacteria. If milk which has been kept sweet or at the desired degree of sourness by cooling is allowed to get warm again, the bacteria which have been kept dormant will get a fresh start. For this reason milk and cream for city supply should not only be cooled strongly, but must be kept thoroughly chilled up to the time they are used, which means that they should be delivered cool to the consumer, and kept on ice in the house, never being allowed to warm up until used.

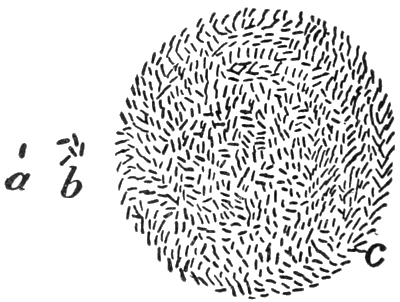

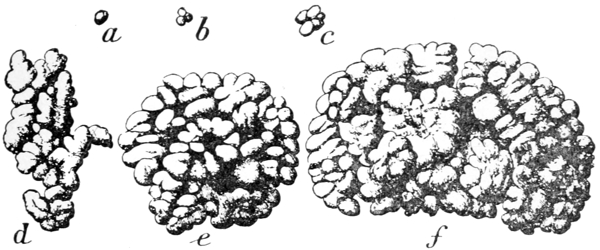

The diagram (after Conn) shows the rapidity with which bacteria multiply in milk not properly cooled. A single bacterium (a) in 24 hours multiplied to 5 (b) in milk kept at 50° F.; (c) represents the number that develop from a single bacterium in milk kept 24 hours at 70° F.

Disinfectants.—Antiseptics, such as benzoate of soda, formalin, boracic acid, etc., are not permissible in milk, but disinfectants such as soda, lime, washing powders, etc., should be freely used in cleaning utensils, bottles, floors and walls where milk is handled, so as to prevent as far as possible any infection.

Louis Pasteur, French scientist and originator of the process of pasteurization.

Pasteurization depends upon the fact that almost all bacteria, and especially the disease-producing species, are checked in their growth and made harmless, if not totally destroyed, by instantaneous exposure to a temperature of 175° F., or a more or less prolonged exposure to lower temperature, for instance for 20 minutes to 157° or 30 minutes to 145°. These lower temperatures are recommended in the case of new milk to be consumed as such, in order not to change its 26digestibility. Pasteurizers with “holding devices” are therefore largely taking the place of the “continuous” sterilizing machines, which allow only momentary exposure to the highest temperature.

Whatever method is used it is essential that after the heating is finished the milk should be cooled as quickly as possible to a temperature sufficiently low to prevent development of the germs that have not been entirely destroyed by the heat and which, if the milk is left for any length of time at a temperature favorable for bacterial life—anywhere between 65° and 110°,—will begin to grow again. Cool the milk to below 60° and if possible to 50° or 40°.

Sometimes a second pasteurization is practiced, the milk being purposely allowed to stand at 70° to 80° for 12 to 24 hours after the first pasteurization for the germs which escaped destruction to develop into full-grown bacteria. They are then killed by the second heating before the milk is finally chilled to stop any further growth.

Pasteurization can be done by placing the milk in any tin or enamelled or glass vessel, set in another vessel containing water (a double boiler). Heat until the milk has reached the desired temperature, hold it at that temperature the necessary time, and then place the vessel in cold running water or in ice water until the milk is thoroughly chilled. It is not advisable to place the hot milk in the ice box as cooling in air is too slow. Not until it is thoroughly cooled in water is it safe to put it in the ice box to keep it cool.

N. J. Fjord, Danish investigator

In the seventies Prof. N. J. Fjord, in Denmark, applied to milk the process which had been developed by Louis Pasteur in France to give keeping quality to wine 27and beer. A Danish dairy expert, J. Moldenhauer, now connected with the New York State Department of Agriculture, first brought the process to this country and used pasteurization in a city creamery in Kentucky. American experiment stations established the temperatures and the time of exposure necessary for best results, and no one has done more for the introduction of pasteurization than the New York philanthropist, Nathan Straus, who has established pasteurizing plants and milk distributing stations in many localities, thereby contributing so largely to the lowering of the death rate among the children of the poor.

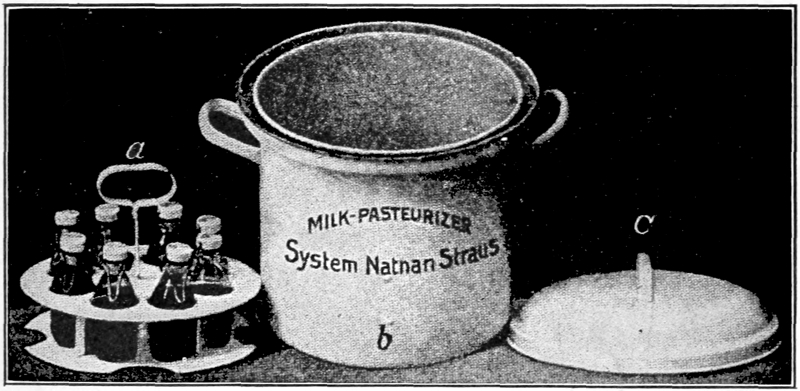

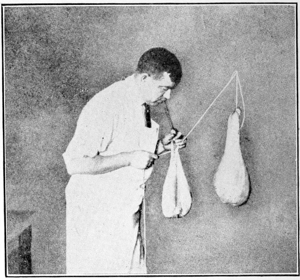

The Straus Pasteurizer

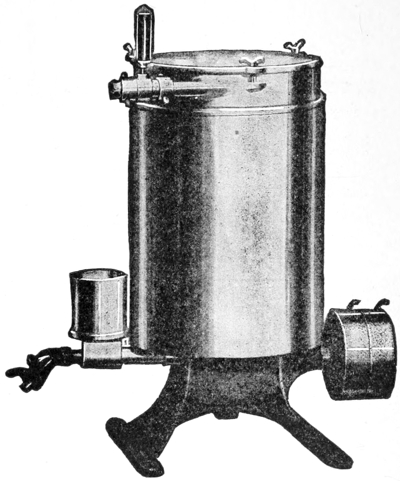

A continuous pasteurizer

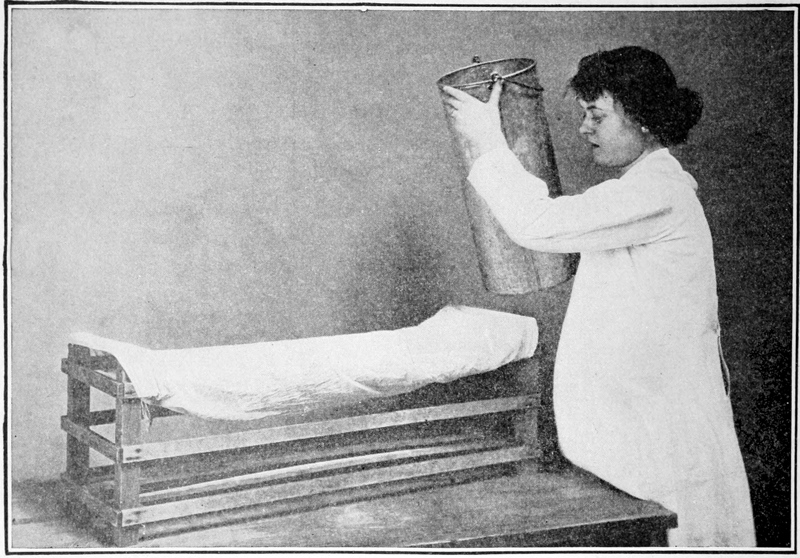

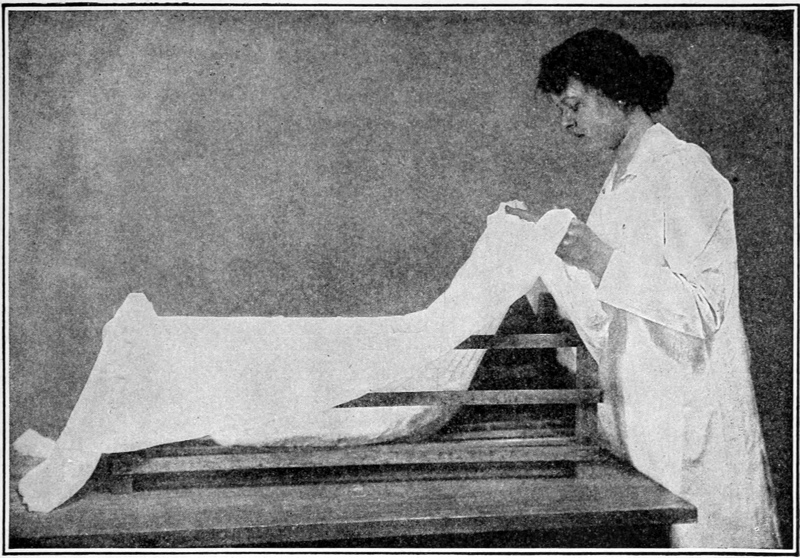

The following directions are given by the Straus 28Pasteurized Milk Laboratories of New York for the pasteurization of milk for babies:

1. Only use fresh, filtered milk, which has been kept cold, and proceed as follows:

2. Set the bottles, after they have been thoroughly cleaned, into the tray (a), fill them to the neck, and put on the corks or patent stoppers.

3. The pot (b) is then placed on a wooden surface (table or floor) and filled to the three supports (in the pot) with boiling water.

4. Place tray (a), with the filled bottles, into the pot (b), so that the bottom of the tray rests on the three supports, and put cover (c) on quickly.

Milk cooler

5. After the bottles have been warmed up by the steam for five minutes, remove the cover quickly, turn the tray so that it drops into the water. The cover is to be put on again immediately. This manipulation is to be made very quickly, so that as little steam as possible can escape. Thus it remains for twenty-five minutes.

6. Now take the tray out of the water and cool the bottles with cold water and ice as quickly as possible, and keep them at this low temperature till used.

7. Before use, warm the milk—in the bottles—to blood heat. Never pour it into another vessel.

8. The milk must not be used for children later than twenty-four hours after pasteurization. Never use remnants.

30In a Continuous Pasteurizer a constant stream of milk is fed into the machine, heated by flowing over a metal surface with steam or hot water on the opposite side, and cooled by running over a cooler furnished with a stream of cold water or ice water.

Professor V. Storch, originator of pure cultures for ripening cream and milk

Before 1890 it was supposed that the flavor of fine butter depended upon certain volatile oils and acids peculiar to butter-fat. In the early nineties Professor V. Storch of the Danish Experiment Station showed, however, that it was due rather to the products of bacteria and he isolated the lactic acid bacilli which would produce such exquisite flavor even when perfectly neutral and tasteless butter-fat was churned with milk acidified or ripened with a pure culture of these bacilli. In this country Dr. H. W. Conn of Wesleyan University, Storrs, Conn., did much to advance the theory and practice of ripening cream with a pure culture starter.

“Pure cultures” are produced in the bacteriological laboratory by picking out under the microscope colonies of the desired species of bacteria, planting them in a sterilized medium and allowing them to grow under the most favorable conditions and with the exclusion of all other germs.

Streptococcus lacticus (Storch, No. 18)

Bacterium lactis acidi (from Storch)

When such a culture has reached its maximum growth it is transplanted into a larger quantity of a sterilized medium containing proper nourishment for the particular 31organism. In the bacteriological laboratory, where alone absolute sterility of utensils and medium, and entire exclusion of foreign infection are possible, the culture may remain pure while this inoculation and propagation are repeated over and over again. But when the propagation is carried on in the house or the dairy, for instance in preparing starters or buttermilk, such absolute cleanliness is impossible and in the long run infections will creep in from the air or from the utensils and after a while it becomes necessary to start with a new “pure culture.” How often such renewal must be resorted to depends largely upon the surroundings and the care of the operator. Usually it must be done after a week’s time, although it is surprising to find milk preparations made by the simplest processes equal in purity to those prepared with the assistance of bacteriological science and technique. This is, for instance, the case in Bulgaria, where the famous Yoghourt sour milk is prepared pure without 32special care and in Denmark where the country is fairly permeated with the lactic acid bacilli used in ripening the cream for the celebrated Danish butter and where careful buttermakers often maintain their starters for months or even for years without “renewal.”

Typical lactic acid bacteria

(L. A. Rogers)

There are many different varieties of bacteria which convert sugar of milk into lactic acid, at the same time developing flavors more or less agreeable and characteristic for the various products. In the bacteriological laboratory certain species are selected which will produce the results desired for the particular purpose in view.

Starters.—Beginning with a commercial dry culture in the form of a powder as generally used in the creamery or the cheese factory as well as for the preparation of commercial buttermilk, or with buttermilk tablets as used in the ordinary household or the hospital, such culture is added to a small quantity of thoroughly pasteurized milk. If fresh, sweet skim milk is available it is preferable to whole milk as the butter-fat in the latter only interferes with the process; but either can be used.

Milk for starters should be strongly pasteurized by being kept at a temperature near the boiling point—at least 180°—for 40 to 60 minutes, then cooled to the degree at which it is to be set, usually between 65° and 3375°, somewhat higher for the first propagation with the pure culture than for the subsequent transplantings when the bacteria, more or less dormant in the dry powder or tablets, have attained full vitality. Some species of bacteria, as the Bacillus Bulgaricus, require higher temperatures—90° to 100° or even 110°—than others. The culture having been thoroughly incorporated in the milk by vigorous and repeated stirring or shaking, the milk is left at rest in an incubator or a waterbath or wrapped in paper or cloth in a warm room where an even temperature can be maintained, until it is curdled, which may take 18 to 24 hours or even longer for the first propagation.

One part of this curdled milk is now added to 5 or 10 parts of fresh pasteurized milk and set to ripen in the same way as described above, possibly at a little lower temperature, and this is repeated every day, thus maintaining the “Mother Starter.” After the second or third propagation the bulk of each batch is used as a starter in the larger lot of material to be ripened, be it cream for butter or milk for cheese or for commercial buttermilk, while a little is taken for maintenance of the mother starter as described above.

The amount of starter to prepare every day depends upon the amount of milk or cream to be ripened and the per cent of starter used in same. For instance, if you have ten gallons of cream to ripen every day in which you wish to use about 10% or 12% starter, or one gallon, take a little less than one pint of the first or second propagation for one gallon of milk; the next day use one pint of this to add to a gallon of fresh starter milk, and the remaining gallon to add to the ten gallons of cream, and so on every day.

34If you have 4,000 lbs. of milk in the cheese vat to ripen with 2% or 80 lbs. starter, prepare 88 lbs. of mother starter. If, on the other hand, you wish to make only a quart of buttermilk every day, take, say, two buttermilk tablets, crush them thoroughly in a spoonful of pasteurized milk and stir this into a tumblerful of the same milk; let stand till it is thickened the next day and use a tablespoonful of this thickened milk in a quart of fresh pasteurized milk which when ripened is your buttermilk, from which you take out a tablespoonful for starter in the next batch, and so on. In this case there is no “mother starter” except that perhaps the first tumblerful prepared with the tablets may be called so, but afterwards the starter is taken right out of the finished product every day.

The process may be modified to suit special purposes and local conditions, but the following precautions should be strictly observed: (1) to interrupt the ripening immediately by quick and intense cooling as soon as it has reached the proper point in case the ripened product is not used at once, and (2) to keep it ice-cold until it is used. If this is done, it may be kept for two or three days without deterioration if it is not convenient to make it fresh every day which, however, should be the rule.

In the first chapter the composition of cow’s milk and the nature of its constituents have been considered, the most important tests for its richness and purity have been described, and the ferments have been mentioned which instigate changes for good or for bad, together with the means at disposal for regulating their activity. To use these means intelligently in handling milk and its products is the key to the dairyman’s success.

We shall now briefly consider the various steps that are of importance in modern dairy industry.

In the first place, the farmer must furnish pure, clean, unadulterated milk, fresh from the cow and cooled immediately after milking. His cows must be healthy.

Bovine Tuberculosis.—Many milk-cows, for the very reason that they have been bred with the one purpose in view of turning all their food into milk and wasting as little as possible in building up the body, are more or less weak-chested and apt to suffer from tuberculosis. Unless this disease is so far advanced as to affect the general health of the cow, or it has spread to the milk organs, the udder and the teats, it is not so dangerous as has heretofore been supposed. It is now held by the great majority of physicians that 36bovine tuberculosis is hardly ever transmitted to grown persons and seldom to children. Neither is it hereditary. Nevertheless, wherever it is possible to have the herd tested with tuberculin, segregating, if not killing, the animals which show by reaction that they are somewhat tuberculous, it should be done. Milk from such cows should always be pasteurized.

Milk as a Disease Carrier.—A greater danger lies in the fact that, warm as it comes from the cow, milk is an ideal medium for human disease germs to grow in, and may thus become a great conveyor of such germs. For this reason it is of the greatest importance that the milkers are healthy and clean, that the udders and teats be free from dirt, and the milk pail covered as far as possible; the barn must be clean, and every source of infection excluded. This fact also points to the advisability of pasteurization. On page 23 a chart is shown, published by the Toronto Board of Health and indicating the temperatures at which various germs of disease are made harmless.

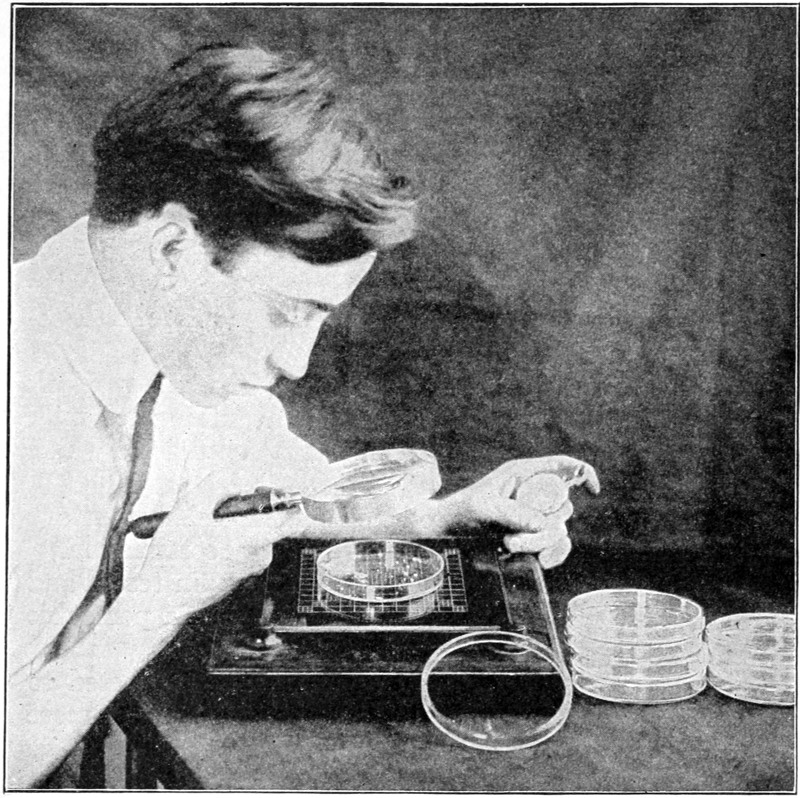

Bacterial Count.—The test for clean milk now mostly used is the “Bacterial Count,” the number of bacteria—or rather colonies of bacteria—found in a cubic centimeter of the milk. It would be better if the nature or quality of the bacteria could be taken into consideration as well as the quantity, but that being as yet impracticable, the next best thing is to depend upon the number. Ordinary good milk often contains hundreds of thousands of bacteria in a cubic centimeter, but where the greatest cleanliness is observed the number may be less than 1,000.

Certified Milk is now sold in many cities which, according to varying city ordinances, is guaranteed to 37have less than 10,000 or 20,000 or 30,000 bacteria, as the case may be.

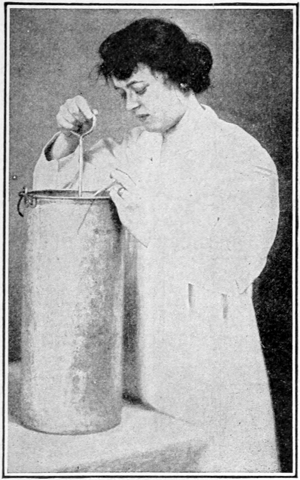

Counting the bacteria in a cubic centimeter of milk

The cost of producing certified milk places it beyond the reach of the great majority of consumers. But such care and cleanliness as can be observed by the farmer and the milkman without extra expense should 38be insisted upon, and milk which nevertheless contains a large number of bacteria can be made safe by pasteurization.

The Sanitary Code.—The regulation of the production and delivery of milk in cities and towns as well as at creameries and cheese factories, the “Sanitary Code” established by state and municipal health authorities, has been very effective in improving the quality of the supply. So enormous have been the improvements in caring for and handling the products by the large establishments engaged in the delivery of milk as to make the increase in cost seem trifling compared with the great benefit to the public health secured by these agencies.

New York State Milk Grading.—The New York State Board of Health prescribes a grading for milk offered for sale, the most important features of which are as follows:

Certified.—Must be produced under specially sanitary conditions approved by a county medical commission.

Grade A Raw.—Cows must be tuberculin tested and milk must not contain over 60,000 bacteria per cubic centimeter.

Grade A Pasteurized.—Cows must be subjected to physical examination and milk must not contain more than 200,000 bacteria before, nor more than 30,000 after pasteurization.

Other grades permitted under the rules, all subject to inspection and approval of the authorities, are:

39Deliveries must be made within a certain time after production or pasteurization, barns and milk stations are inspected, and altogether such safeguards are employed as to make the supply exceedingly safe and reliable.

City Delivery.—In villages and small cities the milk supply is still to a large extent in the hands of farmers who come to town early in the morning peddling their milk, often at considerable waste of time for horse and man. Or a number of peddlers go over the same route so that it takes a dozen wagons to cover a town where three or four could do it.

As long as there was no efficient regulation as to price and quality such waste was perhaps unavoidable, as competition on the part of the producers and distributors was the only means of protection for the consumers. But lately state and municipal control is being exercised to such an extent as to largely eliminate the danger of poor milk and exorbitant prices. Further development of organized delivery systems so much to be desired for sanitary as well as for economical reasons, may be looked for as soon as normal conditions return after the close of the war. The delivery of milk is one of the things that in the interest of public health must be under the strictest official control, and co-operation between farmers and consumers is the logical system for elimination of unnecessary expenses of distribution and for prompt and satisfactory service. Their interests are or should be identical and both classes are hurt by inefficient and wasteful delivery.

In the large cities there has grown up an industry which largely monopolizes the milk supply and which until lately was powerful enough to dictate prices and 40conditions both for producers and consumers. Several attempts have been made from time to time by farmers to combine to regulate prices and dictate the terms to the middlemen. Such attempts have, however, invariably failed as long as they were built on false economic principles and prompted by selfish interests only. No farmers’ association can be strong enough to ignore the law of supply and demand, and it is only quite recently that the Dairymen’s League has succeeded in influencing the market by taking into consideration the actual cost of production of milk as worked out by the agricultural colleges, and fixing the price on a scientific basis. There is one other element entering into the causes on which the price to the consumers depends, namely, Transportation, and while municipal boards of health are looking after the sanitary conditions and prevention of adulteration, State and Federal authorities are stepping in as moderators or arbitrators to reconcile the interests of the Producers, the Railroad Companies, the Distributors and the Consumers. The next step in the development will no doubt be towards full co-operation between producers and consumers and, to a large extent, elimination of the “middlemen.”

It should not be forgotten, however, that while the much abused middlemen in time past have been able to dictate terms and prices and have often abused the privilege; they have at the same time used their influence and power to improve the milk supply. As the supply of oil and gasoline has been perfected and cheapened by the all-powerful Standard Oil Co. as a monopoly crushing all competition, so the “Milk Trust” has improved the distribution of milk and has built up the 41magnificent sanitary plants in which milk is handled, pasteurized, bottled and distributed in a way that might not have been possible without the monopoly. It has served a good purpose, but has at the same time acquired such power that official control has become necessary for the protection of producers and consumers alike, and the time may be near when these two classes will combine and take the matter into their own hands so that the distribution may be done at actual cost.

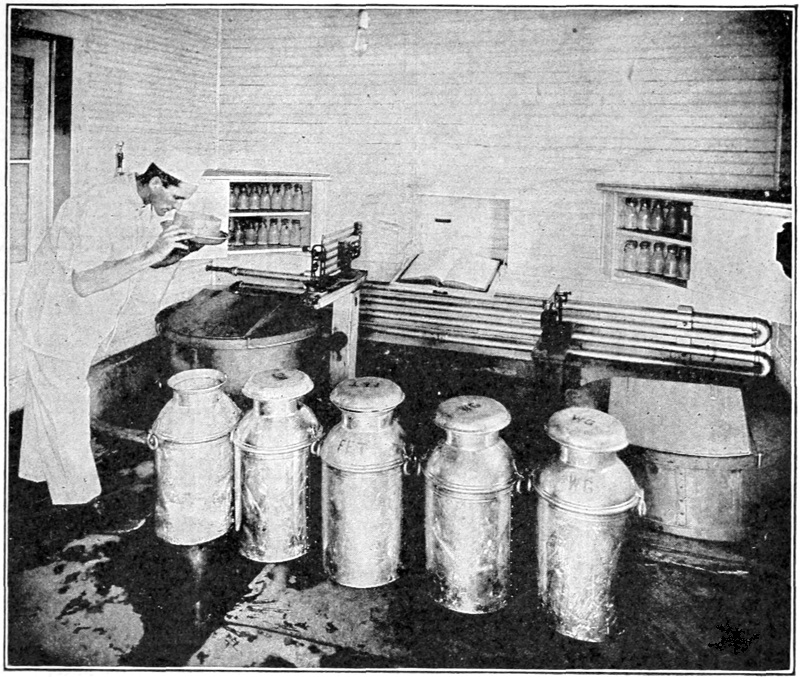

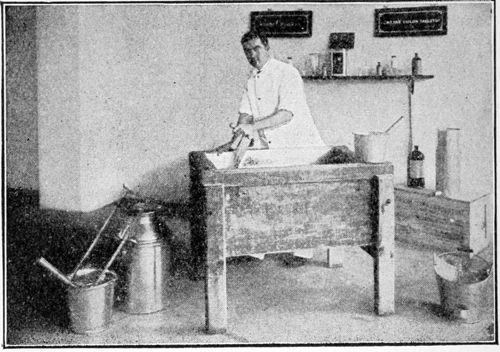

Milk station in the country where milk is received from the farmers to be shipped to the city

Milk Stations are plants erected in dairy sections in the country either by the city milk supply houses or by co-operating farmers, where the milk is delivered and handled so as to make it ready for shipment to the city. As in the creamery and the cheese factory, the milk is carefully examined and, if it is not sweet and pure, it is rejected and sent back to the farm. Any impure flavor remains in the cover for some time and is easily detected by smelling of the cover as soon as it is removed from the can.

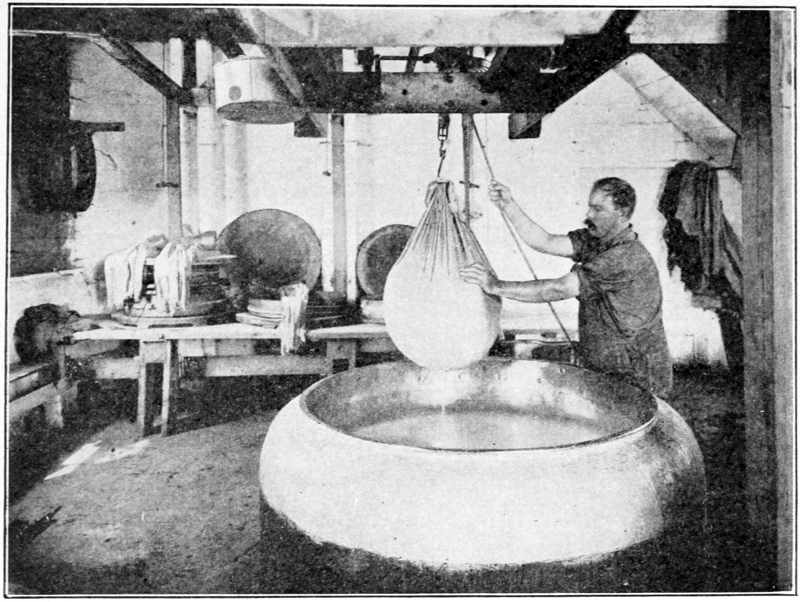

A sample is taken and put aside for the Babcock test and perhaps another for the Fermentation test. Each farmer’s milk is weighed in the Weigh Can and run through a cheese-cloth strainer. The further treatment varies in different plants. The milk may simply be cooled by running it over a cold water or brine cooler and placing it in shipping cans in the refrigerator or in ice water until the milk-train comes along to pick up the cans. Or it may be clarified by running it through a centrifugal machine, the same as a separator, in which, however, cream and milk are not separated, but impurities are thrown out by the centrifugal force and deposited on the wall of the bowl, and the purified 43milk may then be pasteurized and bottled before being shipped to the city.

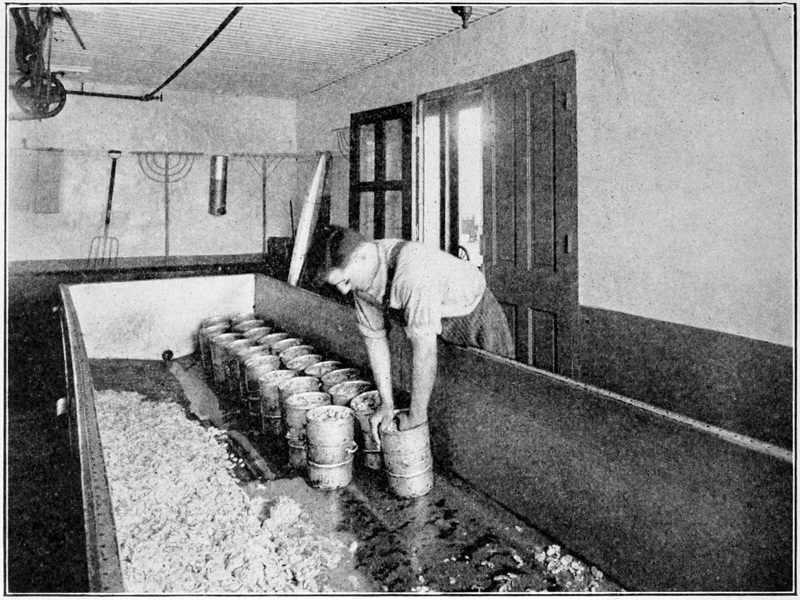

Receiving milk at the milk station

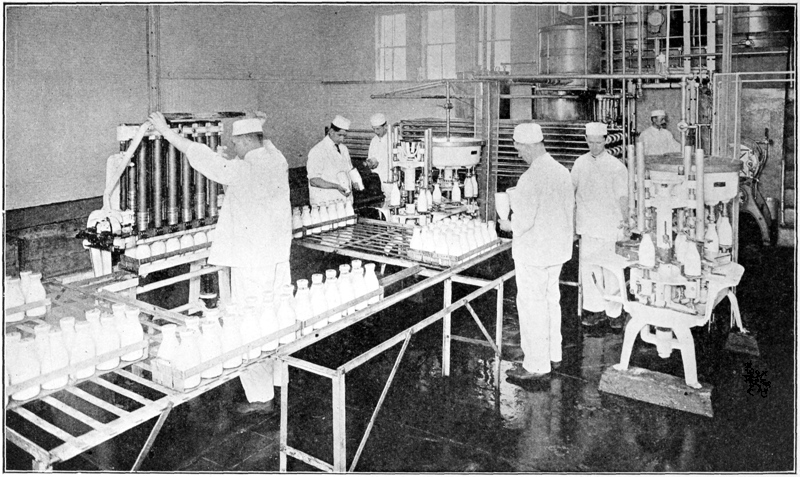

Arriving in the city in iced cars the milk is taken to one of the elaborate plants in which it is pasteurized and bottled, if that has not been done at the country station. The machinery used in these plants is getting more and more perfect and expensive and leaves little to be desired as to sanitary requirements and economy in handling. Pasteurizers, bottling machines, bottle-washing 44machines, conveyors, etc., are wonders of ingenuity, and one needs only to see one of these modern plants to understand that in a large city milk can only be handled to advantage in expensive establishments.

Skim Milk is one of the cheapest of foods and under proper regulations its sale should not be prohibited. The reason why in times past skim milk has been discredited and excluded from sale was that, as produced by the old methods of raising the cream, before the advent of the separator, it was always more or less old and sour before it was available and certainly before it could be distributed to consumers. Under such conditions it was hardly ever fit for human food. But when produced by the separator and pasteurized and cooled immediately after—within a few hours after milking, which is entirely feasible—it is an excellent and nutritious food for adults and even for children over two years of age. Ripened with a pure culture of lactic acid bacteria, it makes a healthful, refreshing drink, like buttermilk. Only when it is allowed to sour without proper care or control does skim milk, as whole milk does, become unfit for food or drink. On a cold winter morning when men are going to work (or perhaps are looking for work which they cannot find), and children are on their way to school, often underfed, a street-corner wagon or stand where boiling hot, fresh, sweet skim milk might be distributed at a cent or two a glass would be a blessing in any city.

Pasteurizing and bottling milk in a Borden plant

When new milk is left at rest the cream will rise to the top and after 12 to 24 hours a cream-line can be seen in the bottle. This cream-line is sharper 46and more easily seen in raw milk than in pasteurized milk and its absence is not always a sure sign of lack of richness or purity of the milk. By cooling the milk thoroughly so that it will keep, almost all the cream will be at the top in forty-eight hours and can be skimmed off. The cream can be used for coffee or on cereals or fruits or puddings; the skim milk left will still hold ½% or more of butter-fat and can be used to drink or for cooking.

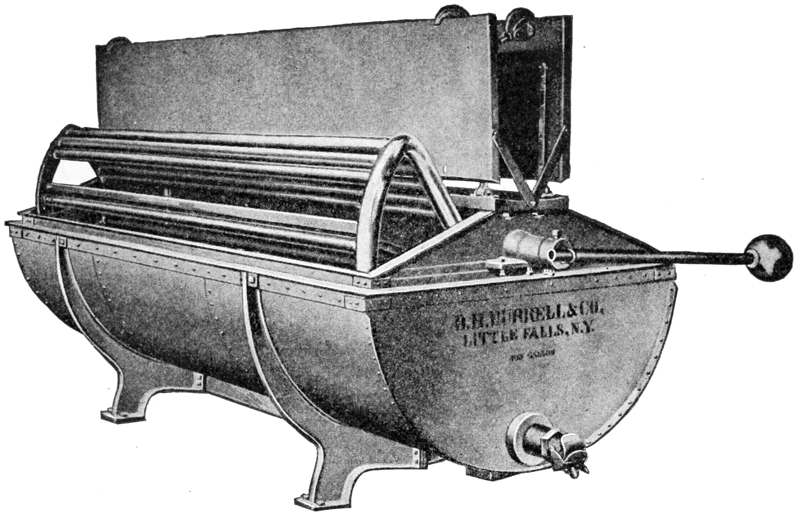

The Separator.—On the farm or in the creamery the cream is no longer raised by gravity, that is, by letting the milk “set” either in shallow pans on the kitchen shelf or in deep cans in ice water, but the fresh, warm milk is run through the separator in a continuous stream.

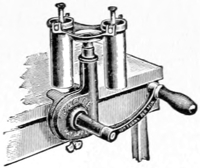

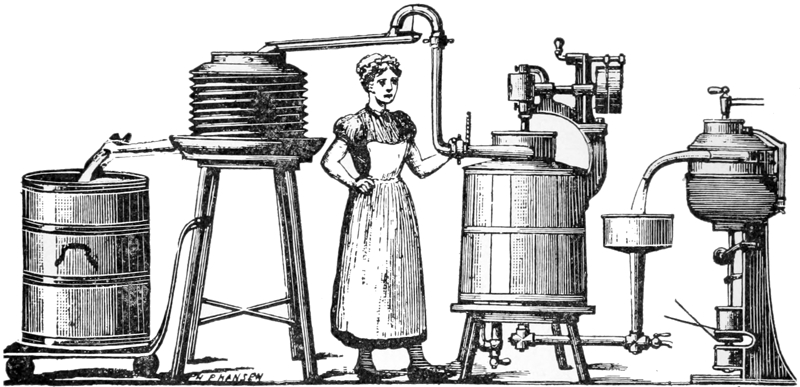

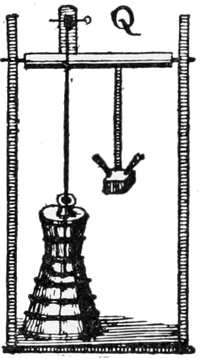

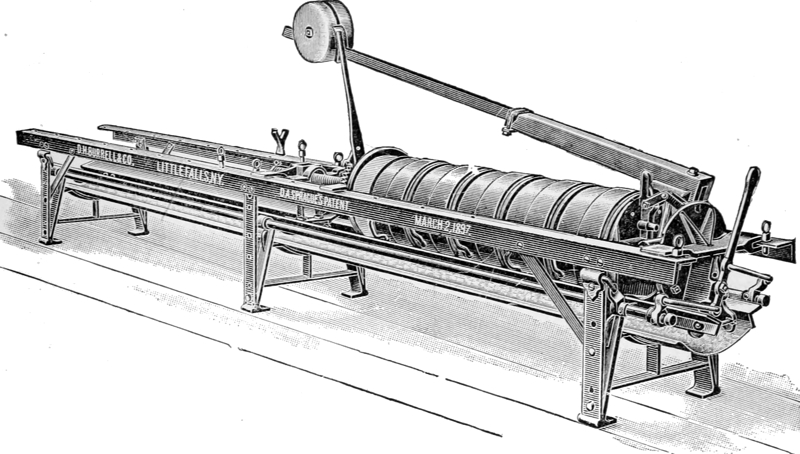

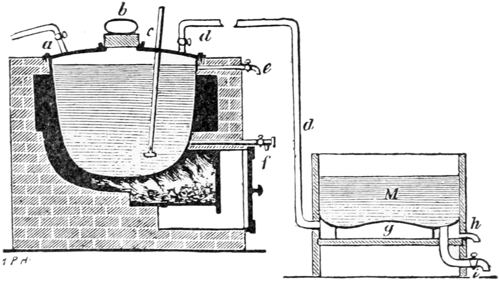

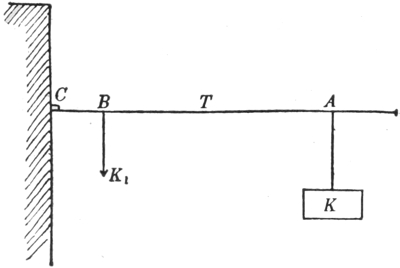

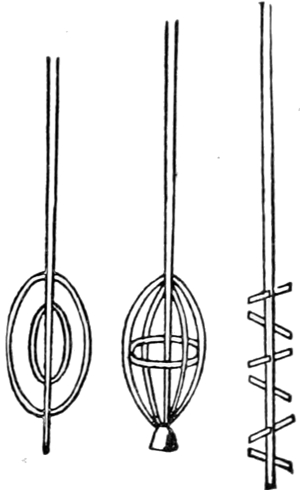

Early conception of the separator

It was noticed that the rising of the cream due to the difference in specific gravity between the butter-fat and the milk-“serum” (the watery solution of the other constituents) might be greatly hastened by subjecting the milk to centrifugal force. This physical phenomenon was taken advantage of in the first conception of the separator where it was shown that if a pail of milk was whirled around like a stone in a sling the heavier milk-serum would be thrown towards the bottom of the separator pail with so much greater force than the lighter cream (butter-fat mixed with a small part of the serum) that the separation which would take 48 hours in the milk at rest, could be accomplished in a 47few minutes when exposed to centrifugal force. From this early crude attempt the continuous bowl-separator was developed and still later a number of divisions in the bowl were designed which increased the capacity and efficiency of the machine wonderfully. The most successful separator was designed by Dr. Gustaf De Laval of Sweden and the machines bearing his name are used all over the world where butter is made. But there are many other excellent separators on the market.

Dr. Gustaf De Laval of Sweden, inventor of the separator bearing his name

In the machine the milk is separated instantaneously by centrifugal force and runs out through two tubes, one for cream and the other for skim milk. A small modern hand machine will take care of from 200 to 1,000 lbs. of milk an hour, and power machines are built to separate 6,000 lbs. or more. By regulating the cream-outlet a heavier or lighter cream can be produced.

Hand separator

Suppose we are separating some milk containing 4% butter-fat. If ⅛ of this milk is separated out as cream and contains all the butter-fat, the cream will be eight times as rich in butter-fat as the original milk; 32% of the cream will be butter-fat. Such cream is called “32% cream.” If we take ¼ as cream, we get a 48cream four times as rich as the milk, a “16% cream.” So out of 100 lbs. of milk we can take 12½ lbs. (⅛) of 32% cream, 25 lbs. (¼) of 16% cream, etc.

Although the skim milk is really valuable as a food, it is worth but little commercially; the cream containing the butter-fat is the expensive part of the milk, and we must be prepared to pay for the cream all that the milk would have cost.

Percentage of Butter-Fat.—The “richness” of cream or milk and their value depend upon the amount of butter-fat in them. So cream or milk is often called “30% cream” or “20% cream” or “4% milk” according as 30% or 20% or 4% of the fluid is butter-fat; 30% cream is quite rich; ordinary market cream varies between 18% and 40%, though it may fall below 18%, or it may be sold as a very expensive article as high as 60%. Rich milk may contain more than 6% of butter-fat and skim milk less than 0.1 of one per cent. The average for good whole milk is between 3% and 4½%.

For a long time scientists and scientific dairymen were the only ones to speak of milk and cream in terms of percentage of butter-fat. Now, however, people are beginning to realize how valuable a part of the milk the butter-fat is and are paying more attention to the actual percentage of butter-fat in the cream or milk they use. So it is no longer unusual to see a dairyman advertise cream of a certain percentage or to hear a housewife ask for it specifically.

Standardizing Cream.—For ice cream or for preparing modified milk for babies, it is often desirable to dilute rich cream to a certain lower standard. The following simple steps can be taken to find out how much milk to add for diluting:

491. From the test—fat-percentage—of the rich cream subtract the test desired.

2. From the test desired subtract the test of the milk used for diluting.

3. Divide the first difference by the second, and the result will be the number of pints (or pounds) of milk to be added for each pint (or pound) of the rich cream.

For instance, you may want to thin some 30% cream to 10% for making ice cream. The milk to be added is skim milk. Then:

1. 30 - 10 = 20.

2. 10 - 0 = 10.

3. 20 divided by 10 = 2. So for each pint of rich cream you may add 2 pints of skim milk.

Or you may wish to thin the 30% cream with whole milk, which has 4% butter-fat. Again:

1. 30 - 10 = 20.

2. 10 - 4 = 6.

3. 20 divided by 6 = 3⅓. So you may add 3⅓ pints of the whole milk to each pint of the 30% cream and still have a 10% cream.

Pasteurized Cream does not look as rich as raw cream, and fresh, sweet cream appears to be thinner than when it is 24 hours old and slightly ripened. So it is well, when buying cream, not to judge by appearances. Demand of the milkman that he furnish you cream of a certain percentage of butter-fat and see to it that you get what you pay for. If you have no Babcock tester the milk inspector will test the cream for you.

Whipped Cream.—For whipping, cream must be fairly rich, from 24% to 32%, and it must be cold. Fresh, sweet cream does not whip as readily as that 50which has been kept for 12 or 24 hours in ice water. There is no other secret connected with the process. Use a rich cream, suitably cooled and aged, and with a good beater there can be no trouble in getting a fine, stiff whipped cream. If the cream is too thin or too warm it may not become stiff. Sometimes, when it is beaten too long, it turns into butter and buttermilk.

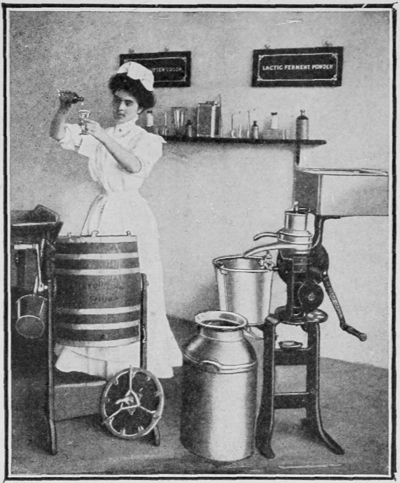

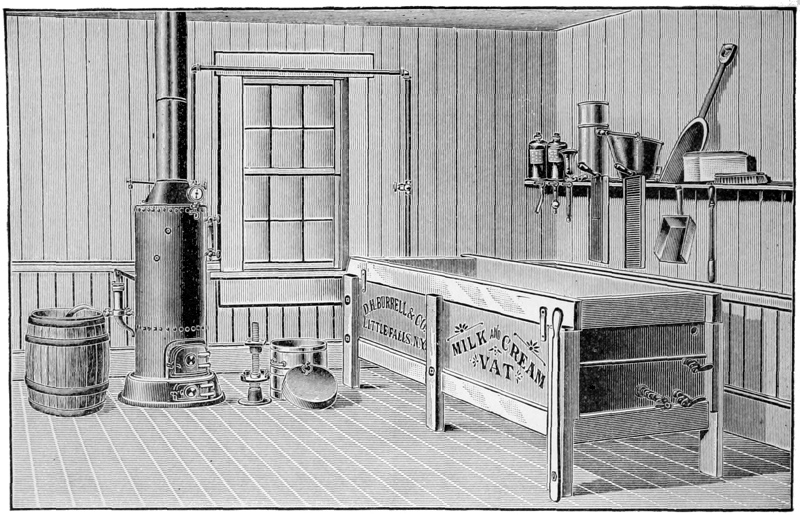

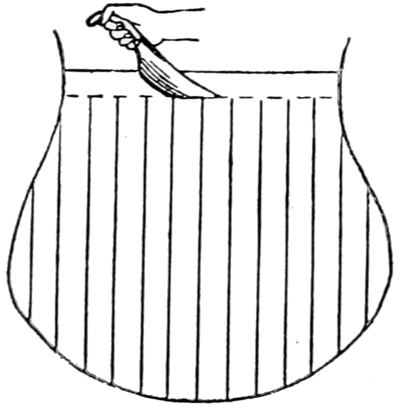

Installation in a Danish creamery.

From the separator at the right the cream runs through the continuous pasteurizer which forces it up over the cooler whence it runs into the cream-vat at the left.

(From Boggild—Maelkeribruget i Danmark)

Emulsified Cream.—One of the recent additions to the already elaborate machinery used in the creamery, the milk supply or the ice cream business, is the Emulsifier. To be sure, emulsifiers were used thirty to forty years ago to mix animal and vegetable fats—oleomargarine oil, lard and cottonseed oil—into skim milk for “Filled Cheese” or for Butterine, but lately they are serving new purposes in the milk industry. By forcing 51melted butter-fat or oil mixed with water or skim milk through exceedingly small apertures under high pressure, or otherwise breaking up the mixture, an emulsion can be formed in which the fat globules are much finer even than those in natural milk or cream, and separation can be prevented. The force used in these emulsifiers may be produced by powerful pumps, or a steam jet, or centrifugal force under high speed; whichever system is used the machines answer the same purpose, to produce a permanent emulsion in which the oil or fat will stay in suspension even after cooling. In some milk supply plants and ice cream factories all the cream is emulsified and the system has especially been applied since the advent of the milk powder. It is now a not infrequent practice to run the new milk through the separator, make sweet, unsalted butter from the cream, and milk powder from the skim milk, and to ship or store these products separately where or until cream is wanted and then bring them together again by running them through the emulsifier with a suitable amount of water. At first thought this process would seem impractical and uneconomical. But it has proven good business because in many cases and places skim milk powder and butter keep better separately or can be shipped at long distance to better advantage than new milk or cream or condensed milk. In ice cream factories business may be dull in cold weather and cream is perhaps not provided and not available, when suddenly a hot spell brings orders for large quantities. With a stock of skim milk powder and butter on hand in the refrigerator, and an emulsifier to mix these products, cream can be produced on short notice and there will be no danger of shortage.

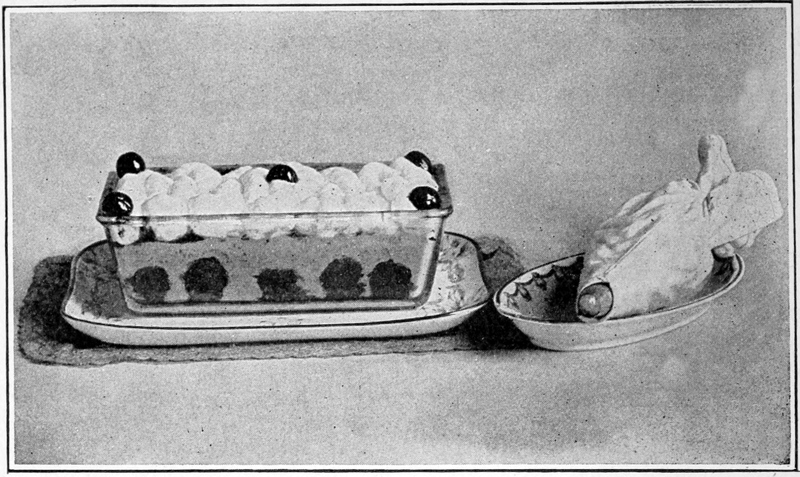

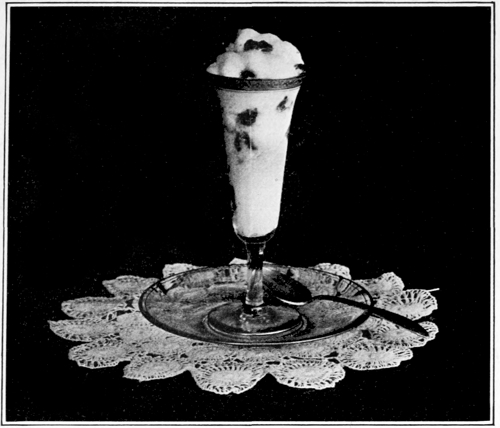

Ice cream has fast become the national dessert served on all festive occasions, winter and summer. Originally it meant a frozen mixture of sweetened and flavored milk and cream, but the name has long been applied to all kinds of frozen delicacies in which cream enters as a constituent. Not even there has the line been drawn, but gums, gelatine, cornstarch, eggs and other “fillers” have been substituted or added to thicken the mixtures and give “body” to “creams,” which have but little relation to the genuine emulsion of butter-fat from cow’s milk. Standardization has been attempted by National and State food authorities with varying success of enforcement. While the application of the name to a great variety of frozen desserts has no doubt become legitimate by long usage it may properly be demanded that as an article of merchandise “ice cream” shall contain at least 8% to 12% butter-fat and that no ingredients dangerous to health enter into its manufacture.

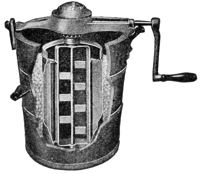

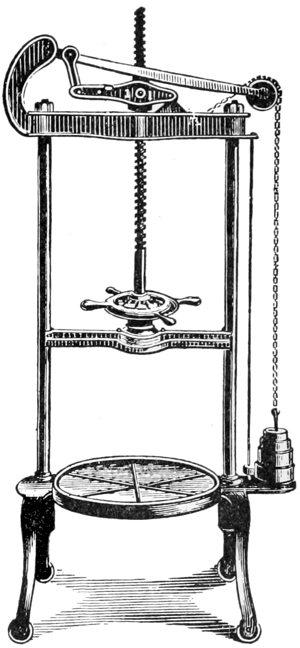

Hand freezer

Freezers.—The freezing is usually done by contact of the material with metal cooled on the other side by a “freezing mixture” of salt and ice which produces temperatures far below the freezing point of water 53while air is whipped into the cream by the rapid motion of the beater. A great variety of excellent freezers of this kind for hand or for power are on the market which answer the purpose for making ice cream at home or at the ice cream parlor.

Coarse-grained salt and crushed ice, mixed in the proportion of 1 part salt to 4 parts of ice, are constantly filled into the space surrounding the ice cream can, and the brine produced by the melting of the mixture is gradually drawn off from the tub. In a good freezer the operation should not take over fifteen minutes. When the cream is frozen to a soft mush, stop the beater and scrape down the hard particles which may have accumulated on the sides of the can, add any ingredients which may be better incorporated at this stage than mixed into the original material, such as crushed fruit or preserves, and finish the freezing without carrying it too far.

Remove the beater, stir the cream which should still be soft enough to handle, and pack in ice with only a little salt. Or the cream may be transferred from the freezer can to the shipping can and packed in it. If bricks are wanted the soft cream is packed in molds of the desired shape and size and buried in the freezing mixture to harden.

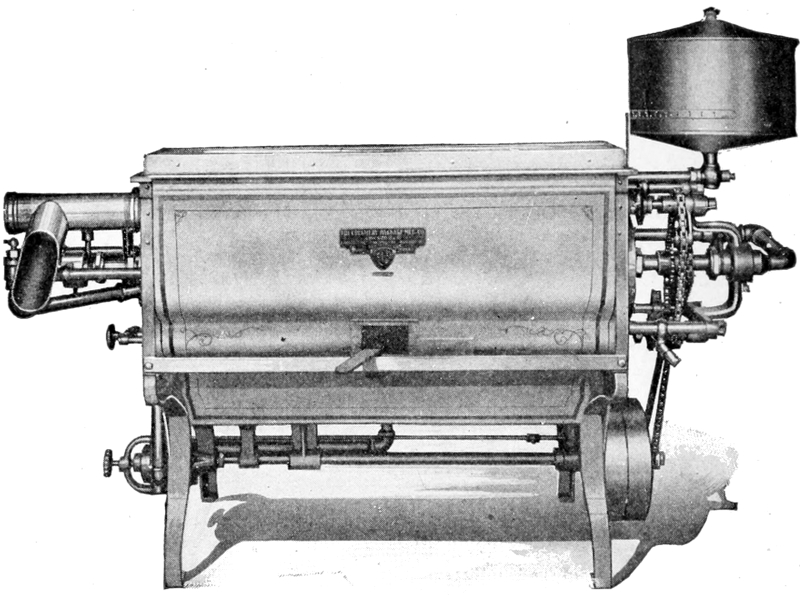

In modern ice cream factories Brine Freezers are generally used. In a Refrigerator Plant intensely low temperatures are produced by the vaporizing of compressed ammonia or carbonic acid in an ice machine, and brine circulating in iron pipes is cooled by such medium and may, in turn, cool the air in the Cold Storage room, or the cream in the freezer, or pure water in metal boxes for the manufacture of Artificial Ice. 54It has been attempted to make the brine freezers continuous, the cream mixture being fed into the machine at one end and discharged frozen at the other. But this system has not so far been successful, and intermittent or batch freezers are most practical yet both for hand and for power.

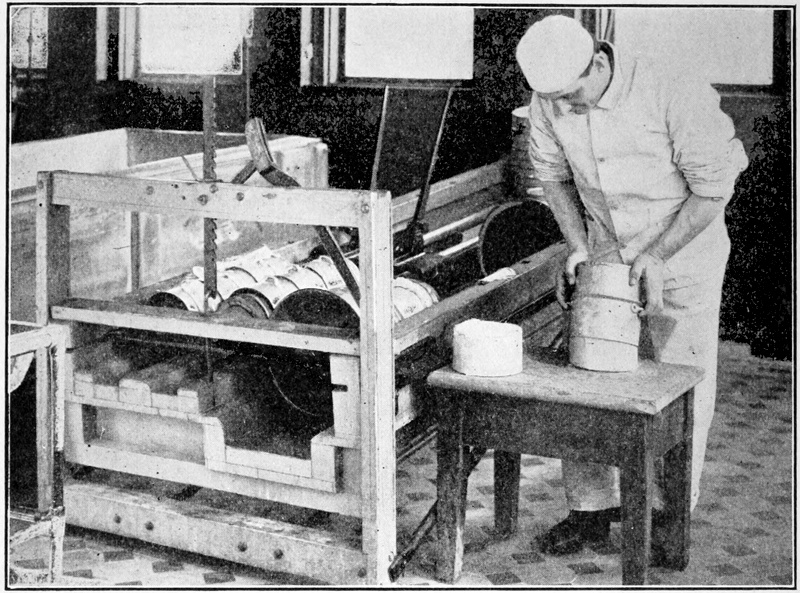

Power brine freezer

Rich material, frozen in a good machine, whether intermittent or continuous, will expand from 50% to 100%, and the original material should not fill the freezer can more than half full.

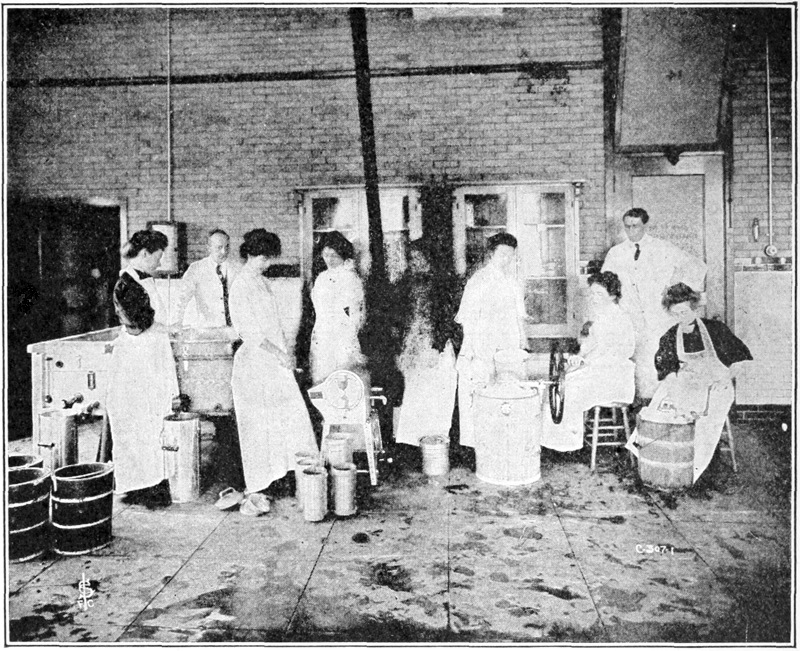

The manufacture of ice cream has been the subject of study and experiments for years in the Dairy Department of the Agricultural College at Ames, Iowa, where Professor M. Mortensen has worked out a comprehensive classification from which any manufacturer 55may readily choose his formulas, modifying them to suit his local conditions and special problems. The outline kindly furnished the author by Professor Mortensen is so interesting and instructive as to be well worth copying substantially in full, leaving out the “Ices” in which no milk or cream is used and which are therefore not of special interest in connection with the purpose of this book—the use of more and better milk.

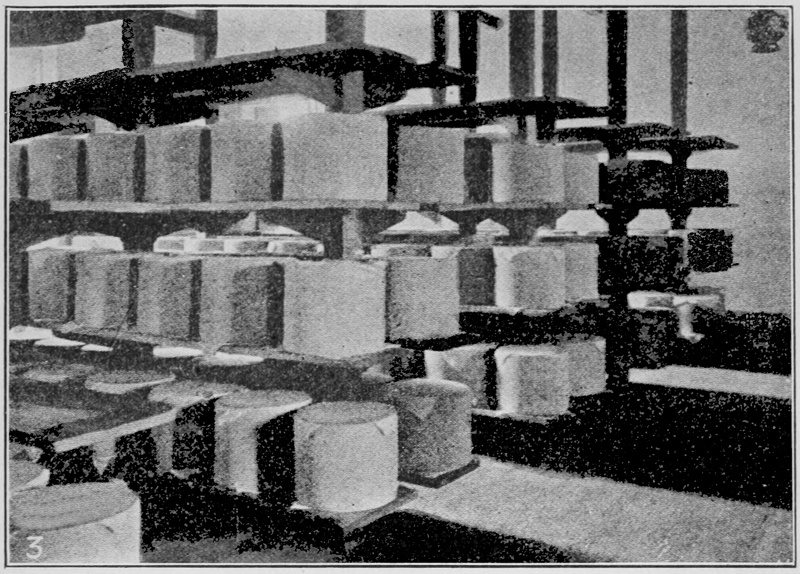

Ice cream factory

Considering the work of former writers as well as names used by business men, the following classification was worked out by the station:

| I. | Plain Ice Creams. |

| II. | Nut Ice Creams. |

| III. | Fruit Ice Creams. |

| IV. | Bisque Ice Creams. |

| V. | Parfaits. |

| VI. | Mousses. |

| VII. | Puddings. |

| VIII. | Aufaits. |

| IX. | Lactos. |

I. Plain Ice Cream is a frozen product made from cream and sugar with or without a natural flavoring.

Formulas are given for making ten gallons of finished ice cream.

Vanilla Ice Cream:

Chocolate Ice Cream:

Maple Ice Cream:

57Caramel Ice Cream:

Coffee Ice Cream:

Mint Ice Cream:

II. Nut Ice Cream is a frozen product made from cream and sugar and sound non-rancid nuts.

Walnut Ice Cream:

According to this general formula the following nut ice creams may be prepared by substituting different kinds of nut meats:

At times pistachio ice cream is made from oil of pistachio instead of from the nuts. If thus prepared, it will come under the head of plain ice cream.

58III. Fruit Ice Cream is a frozen product made from cream, sugar and sound, clean, mature fruits.

Strawberry Ice Cream:

Employing the same formula the following creams may be made by merely substituting other fruits and berries for the strawberries. The amount of sugar may be varied according to the acidity of the fruit.

Preparation of lemon and orange ice creams cannot be included under this general rule. These creams may be prepared as follows:

Lemon Ice Cream:

Orange Ice Cream:

IV. Bisque Ice Cream is a frozen product made from cream, sugar and bread products, marshmallows or 59other confections, with or without other natural flavoring.

Macaroon Ice Cream:

From this formula we can make:

V. Parfait is a frozen product made from cream, sugar and egg yolks with or without nuts or fruits and other natural flavoring.

Walnut Parfait:

From this formula by substituting the nut meats we can make:

By substituting the same proportion of fruits as are used for fruit ice cream, for the vanilla extract and nut meats, fruit parfaits such as strawberry, raspberry and cherry parfaits and others may be prepared.

60Coffee Parfait:

Maple Parfait:

Tutti-Frutti:

VI. Mousse is a frozen whipped cream to which sugar and natural flavoring have been added.

Cranberry Mousse:

From the same formula combinations may be made with various other fruit juices and natural flavors, such as coffee, vanilla, maple, caramel, pistachio, etc.

Sultana roll, as indicated by the name, is made in a round mold. The center of the mold is filled with tutti-frutti, and the outside with pistachio mousse.

VII. Pudding is a product made from cream or milk, with sugar, eggs, nuts and fruits, highly flavored.

61Nesselrode Pudding:

Manhattan Pudding:

Plum Pudding:

VIII. Aufait is a brick cream consisting of layers of one or more kinds of cream with solid layers of frozen fruits.

Fig aufait may be made from three layers of cream of various flavors with two layers of whole or sliced figs. It is most satisfactory to slice the figs lengthwise in halves.

Other aufaits may be made from a variety of preserved 62fruits and berries and combined with different creams.

IX. Lacto is a product manufactured from skimmed or whole sour milk, eggs and sugar, with or without natural flavoring.

Formulas for lactos may be found in Bulletin No. 140 published by the Ames Station.

As an example, the following mixture will make 5 gallons of

Cherry Lacto:

“Lacto Milk” is the same as described under “Commercial Buttermilk” and “Thick Milk,” pages 81 and 82.

The sugar is first dissolved in the lacto milk. The eggs are then prepared. The whites and yolks are kept in separate containers and each lot is beaten with an egg beater. Both the yolks and whites are then added to the milk. The mixture is thoroughly stirred and strained through a fine wire gauze. The fruit juices are added last. The freezer is now run until it turns with difficulty when the paddle is removed. The brine is removed and the freezer repacked with ice and salt and left for an hour before the contents are served.

Orange, Mint, Pineapple, Maraschino, Raspberry or Grape Lacto may be prepared by substituting any of these flavors for the Cherry.

X. Ices are frozen products made from water or sweet skimmed or whole milk, and sugar, with or without eggs, fruit juices or other natural flavoring.