Figure 1.

Title: The gunsmith's manual

A complete handbook for the American gunsmith, being a practical guide to all branches of the trade

Author: J. Parish Stelle

Wm. B. Harrison

Release date: October 21, 2023 [eBook #71928]

Language: English

Original publication: New York: Jesse Haney & Co, 1883

Credits: deaurider and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

THE

GUNSMITH’S MANUAL;

A COMPLETE HANDBOOK

FOR THE

AMERICAN GUNSMITH,

BEING A

PRACTICAL GUIDE TO ALL BRANCHES

OF THE TRADE.

By J. P. STELLE and WM. B. HARRISON.

Entered according to Act of Congress, in the year 1883,

By JESSE HANEY & CO.,

In the Office of the Librarian of Congress, at Washington.

| PAGE | |

| CHAPTER I. | |

| History of the Gun | 9 |

| Discovery of Gunpowder | 9 |

| The First Fire Arms | 9 |

| Earliest Hand Guns | 10 |

| Prejudice Against Fire Arms | 10 |

| The First Rifle | 11 |

| The Arquebus | 11 |

| The Match Lock | 12 |

| Musket, Petronel | 13 |

| The Wheel Lock | 13 |

| The Pistol | 14 |

| The Snaphaunce | 14 |

| The Flint Lock | 15 |

| Important Improvements | 15 |

| Advance of the Rifle | 16 |

| The Percussion Lock | 16 |

| The Breech Loader | 18 |

| CHAPTER II. | |

| How Guns are Made | 22 |

| Gunsmith, Gunmaker | 22 |

| Gun Barrels, Best Materials for | 23 |

| On Making Gun Barrels | 24 |

| Finishing and Proving | 25 |

| Action, Stock and Final Finish | 26 |

| On Making the Rifle | 27 |

| Plain Steel Barrel Guns | 27 |

| CHAPTER III. | |

| Guns Now in Use | 29 |

| Gun Defined | 29 |

| The Old Flint Lock Gun | 29 |

| The Percussion Lock Gun | 31 |

| On the Muzzle Loaders | 33 |

| The Breech Loaders | 34 |

| Variety of Breech Loaders | 36[vi] |

| CHAPTER IV. | |

| Pistols Now in Use | 37 |

| Old Style Pistols | 37 |

| The Derringer | 38 |

| The Pepper Box | 38 |

| Old Colt’s Revolver | 38 |

| Sharp’s Four-shooter | 39 |

| The Breech Loading Cartridge Pistols | 39 |

| CHAPTER V. | |

| On General Gunsmithing | 41 |

| The Gunsmith and his Trade | 41 |

| Fitting up a Shop | 41 |

| CHAPTER VI. | |

| Taking Apart, Cleaning and Putting Guns Together | 43 |

| To Take the Gun Apart | 43 |

| To Clean the Gun When Apart | 44 |

| To Put the Gun Together | 45 |

| CHAPTER VII. | |

| Tools Required for Work, Their Cost, etc. | 47 |

| The Alcohol Lamp | 47 |

| The Alcohol Lamp, Self-blowing | 47 |

| Anvil | 48 |

| Barrel Planes | 48 |

| Bevel | 49 |

| Beveling Clamp | 49 |

| Blacksmith’s Tongs | 50 |

| Blow Pipe | 50 |

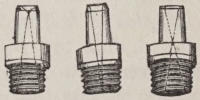

| Breeching Taps | 51 |

| Calipers and Dividers | 51 |

| Chisels | 51 |

| Cutting Pliers | 51 |

| Drill Stock | 51 |

| Tile Cord | 52 |

| Tilting Square | 52 |

| Floats | 52 |

| Forge | 53 |

| Glue Pot | 53 |

| Gouges | 53 |

| Grind Stone | 54 |

| Hack Saw | 54 |

| Hammers | 54[vii] |

| Handles | 55 |

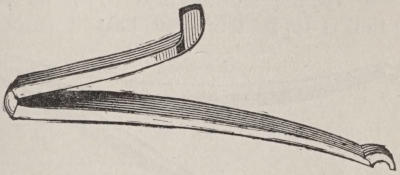

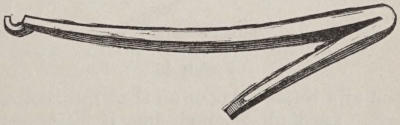

| Hand Shears | 55 |

| Hand Vice | 55 |

| Iron Clamps | 55 |

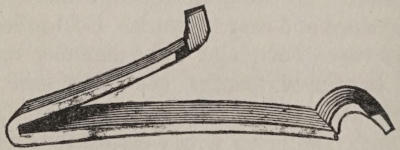

| Mainspring Vise | 56 |

| Marking Gauge | 57 |

| Screw-cutting Tools | 57 |

| Screw Wrench | 57 |

| Soldering Copper | 57 |

| Screw-Drivers | 57 |

| Pliers | 58 |

| Wing Dividers | 58 |

| CHAPTER VIII. | |

| Tools, etc., and How to Make Them | 59 |

| The Alcohol Lamp | 59 |

| A Self-blowing Lamp | 61 |

| Breech Wrenches | 63 |

| The Bit Stock | 64 |

| Bottoming Tools | 65 |

| Chequering Tools | 66 |

| Nipple Wrenches | 67 |

| Portable Forge | 67 |

| Vice Appendages | 69 |

| Shanks of Tools | 72 |

| CHAPTER IX. | |

| The Work Bench | 74 |

| Material for the Work Bench | 74 |

| How to Make the Work Bench | 75 |

| Putting the Vise in Place | 76 |

| Place for Drawer | 76 |

| The Gun Brace | 76 |

| How to Deaden the Noise of Hammering | 77 |

| CHAPTER X. | |

| On Working in Iron | 79 |

| Hand Forging | 79 |

| Welding | 79 |

| Hardening Iron by Hammering | 80 |

| Case-hardening | 81 |

| A Good Way to Case-harden | 82 |

| Material for Case-hardening | 84 |

| Another Way to Case-harden | 85 |

| Another Formula for Case-hardening | 86[viii] |

| Still Another Formula | 87 |

| To Chill Cast Iron | 87 |

| Another Mode | 87 |

| To Soften Wrought Iron | 87 |

| Alloy for Filling Holes in Iron | 87 |

| To Harden Iron for Polishing | 88 |

| CHAPTER XI. | |

| On Working in Steel | 89 |

| Hand Forging Steel | 89 |

| Welding Steel | 89 |

| Tempering | 91 |

| To Restore Burnt Steel | 93 |

| Annealing Steel | 94 |

| To Blue Steel | 94 |

| To Remove Blue Color From Steel | 94 |

| Tempering Knife Blades | 95 |

| The Lead Bath for Tempering | 96 |

| Test for Good Steel | 97 |

| Etching on Steel | 97 |

| CHAPTER XII. | |

| On Working in Silver, Copper and Brass | 99 |

| To Forge Silver | 99 |

| To Polish Silver | 99 |

| Light Plate for Copper or Brass | 99 |

| To Clean Silver | 100 |

| To Work Copper | 100 |

| To Work Brass | 101 |

| To Cast Brass | 101 |

| To Brass Iron | 102 |

| To Clean Brass | 102 |

| To Solder Brass | 102 |

| CHAPTER XIII. | |

| On Working in Wood | 104 |

| The Woods Most in Use | 104 |

| Wood for Gun Stocks | 105 |

| CHAPTER XIV. | |

| On Gun Stocks | 108 |

| Form of Gun Stocks | 108 |

| Dimensions for Single Gun | 111 |

| Dimensions for Double Gun | 111[ix] |

| Laying Out Gun Stocks | 111 |

| How to Stock a Gun | 114 |

| The First Operation in Stocking | 114 |

| Setting in the Barrels | 115 |

| Measure for the Stock | 116 |

| The Butt | 116 |

| Setting in the Locks | 116 |

| Setting in the Trigger Plate | 117 |

| Setting in the Triggers | 117 |

| Secure Fastenings | 118 |

| Fitting Bolt Loops | 118 |

| Hints for Finishing | 119 |

| Fitting the Break-off | 119 |

| To Let in Escutcheons | 120 |

| How to Cast Tips on Fore End of Stock | 120 |

| Chequering | 122 |

| Coloring Gun Stocks | 122 |

| To Stain a Maple Stock | 123 |

| Another Method | 123 |

| To Color a Maple Stock Brown | 123 |

| To Color a Reddish Brown | 123 |

| To Color Black | 124 |

| Rosewood Stain | 124 |

| Black Walnut Stain | 124 |

| Mahogany Stain | 125 |

| Cherry Stain | 125 |

| Oil Finish for Gun Stocks | 125 |

| Varnishing and Finishing | 126 |

| The Varnish for Gun Stocks | 127 |

| The Varnish Can | 128 |

| CHAPTER XV. | |

| On Gun Barrels | 129 |

| Long and Short Barrels | 129 |

| Proof of Barrels | 131 |

| Proof Marks on Barrels | 133 |

| Gauge of Guns | 135 |

| Bursting of Barrels | 138 |

| To Prevent Barrels from Rusting | 138 |

| Protection from Rust | 138 |

| CHAPTER XVI. | |

| On Work on Gun Barrels | 140 |

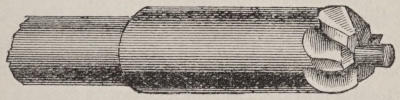

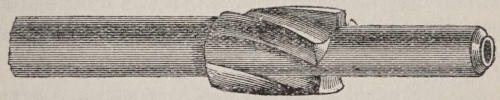

| Boring Gun Barrels | 140 |

| How to Make Cutters for Boring | 141 |

| Quick Boring Gun Barrels | 141[x] |

| Proving the Size During Boring | 142 |

| Draw Boring | 142 |

| Choke Boring | 143 |

| Choke Dressing | 144 |

| Barrels Most Suitable for Choke Boring | 145 |

| Freeing Gun Barrels | 145 |

| Another Method | 146 |

| Finishing Muzzles of Gun Barrels | 147 |

| Old Method of Straightening Barrels | 148 |

| The New Method | 148 |

| Another Method | 153 |

| Fitting Barrels Together | 153 |

| Joining Barrels Together | 156 |

| Soldering Barrels Together | 157 |

| Why Not Brase Barrels | 158 |

| Percussioning | 159 |

| Finishing Nipple Seat | 161 |

| The Vent in Percussion Guns | 162 |

| The Patent Breech | 163 |

| Form of the Chamber or Cup | 164 |

| CHAPTER XVII. | |

| Tools for Breeching Guns | 165 |

| Breeching Reamers | 165 |

| Breeching Taps | 166 |

| Breech Pin Formers | 169 |

| CHAPTER XVIII. | |

| Tools for Chambering Breech Loading Barrels | 170 |

| CHAPTER XIX. | |

| On Gun Ribs | 173 |

| How to Straighten a Rib | 173 |

| How to Fit a Rib | 174 |

| How to Fit a Rib to an Octagon Barrel | 174 |

| How to Solder on a Rib | 174 |

| How to Re-solder Ribs | 176 |

| Height of Ribs | 178 |

| CHAPTER XX. | |

| On Thimbles | 180 |

| How to Make Thimbles | 180 |

| How to Put Thimbles on Barrels | 181[xi] |

| CHAPTER XXI. | |

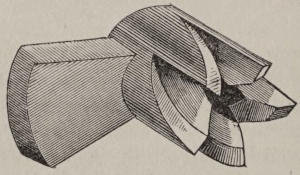

| On Rifling Guns | 183 |

| Importance of Rifling | 183 |

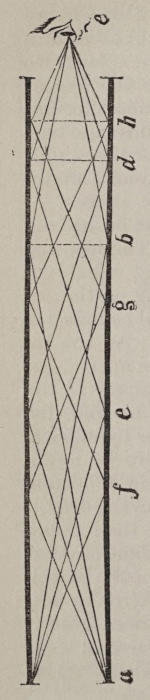

| U. S. Rifling Machines | 184 |

| Old Fashioned Rifling Machines | 186 |

| Gain Twist Rifling Machines | 188 |

| Re-rifling | 188 |

| CHAPTER XXII. | |

| On Gun Locks | 190 |

| Quality of Locks | 190 |

| The Back Action Lock | 191 |

| The Bar Lock | 191 |

| Side Action Lock | 192 |

| The Wesley Bar Lock | 193 |

| The Central Lock | 193 |

| Cleaning Locks, etc. | 194 |

| How to Take Down a Lock | 195 |

| To Clean and Oil the Lock | 196 |

| How to Put up a Lock | 197 |

| CHAPTER XXIII. | |

| On Fitting Gun Hammers | 199 |

| To Fit a Hammer on a Tumbler | 199 |

| The Drift for Squaring the Hole | 200 |

| A Tool for Fitting Hammers | 202 |

| CHAPTER XXIV. | |

| On Nipples or Cones | 205 |

| Forms of Nipples | 205 |

| Nipples for Breech Loading Arms | 206 |

| Nipples with Flat Tops | 206 |

| The American Musket Nipple | 207 |

| Nipples Used in Sporting Guns | 208 |

| Preparing Nipples for Guns | 208 |

| Remedy for Bad Nipples | 209 |

| Pistol Nipples | 209 |

| Plugs for Nipples | 209 |

| CHAPTER XXV. | |

| On Springs | 212 |

| Main Springs | 212 |

| Sear Springs | 212 |

| How to Forge Main Springs | 213 |

| How to Temper Main Springs | 214 |

| Cheap Springs for Revolvers | 215 |

| Coiling Wire for Springs, etc. | 216[xii] |

| CHAPTER XXVI. | |

| On Rods | 220 |

| How to Make Ram Rods | 220 |

| How to Make Wiping Rods | 222 |

| CHAPTER XXVII. | |

| On Bullet Moulds | 224 |

| Joints for Bullet Moulds | 224 |

| How to Make a Ball Cherry | 227 |

| Tempering Ball Cherries | 232 |

| CHAPTER XXVIII. | |

| Screw Making Tools | 233 |

| How to Make Screw Tools | 233 |

| How to Make Small Taps | 235 |

| CHAPTER XXIX. | |

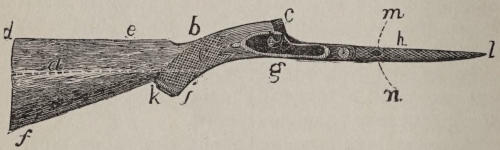

| Nomenclature | 238 |

| Nomenclature of the Gun Stock | 238 |

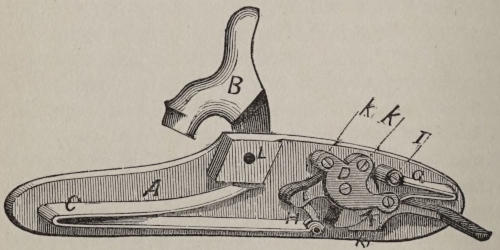

| Nomenclature of the Gun Lock | 239 |

| Nomenclature of the Hammer | 240 |

| Nomenclature of the Lock Plate | 240 |

| Nomenclature of the Tumbler | 241 |

| Nomenclature of the Bridle | 241 |

| Nomenclature of the Main Spring | 241 |

| Nomenclature of the Sear | 241 |

| Nomenclature of the Sear Spring | 241 |

| Nomenclature of the Swivel | 242 |

| Nomenclature of the Breech Pin | 242 |

| Nomenclature of the Screws | 242 |

| CHAPTER XXX. | |

| On Browning | 243 |

| Objects of Browning | 243 |

| Preparatory Process | 243 |

| The Process of Browning | 245 |

| Browning Damascus Barrels | 245 |

| Browning Belgian Damascus Barrels | 245 |

| Browning Inferior Barrels | 246 |

| Plain Welded Barrels Made to Resemble Twist | 247 |

| Smoke Staining | 247[xiii] |

| CHAPTER XXXI. | |

| Recipes for Browning | 249 |

| Thirteen Recipes for Plain Barrels | 249 |

| Four Recipes for Twist Barrels | 252 |

| To Blue Gun Barrels | 252 |

| Brown Tint for Iron or Steel | 253 |

| Transparent Blue for Iron or Steel | 253 |

| Varnish for Browned Barrels, Three Recipes | 253 |

| Finish for Browned Barrels | 254 |

| To Remove Old Browning | 254 |

| CHAPTER XXXII. | |

| Miscellaneous | 255 |

| Shellac and Its Uses | 255 |

| How to Make Shellac Varnish | 255 |

| How to Conceal Bad Places in Wood | 256 |

| Another Method | 256 |

| Emery Cloth and Emery Paper | 256 |

| Uses of the Alcohol Lamp | 257 |

| How to Make Small Springs | 257 |

| How to Make Small Drills | 258 |

| Advantages of the Alcohol Lamp | 258 |

| The Soldering Copper | 258 |

| How to Heat the Copper | 258 |

| How to Tin the Copper | 259 |

| To Prevent Gun Barrels from Glimmering | 259 |

| Repairing Shot Chargers | 260 |

| Broken Plunger Nipples | 261 |

| How to Remove Rusted Screws, Nipples, etc. | 261 |

| Patent Breech, Bursted | 263 |

| Broken Tumblers | 264 |

| Describing Lines on Bright Surfaces | 264 |

| CHAPTER XXXIII. | |

| On Powder and Shot | 267 |

| Comparative Sizes of Shot | 270 |

| Soft Shot Pellets to Ounce | 269 |

| Chilled Shot Pellets to Ounce | 270 |

| Comparative Sizes of Balls | 272 |

| Colt’s Pistol Sizes | 272 |

| Comparative Sizes of Gunpowder | 273 |

| To Select Buck Shot | 267 |

| Weighing Bullets, Powder, etc. | 267[xiv] |

| CHAPTER XXXIV. | |

| Miscellaneous Recipes | 274 |

| Soft Soldering | 274 |

| Good Soft Solder | 274 |

| Soldering Fluid | 275 |

| Brazing | 275 |

| To Brase Lugs on Barrels | 275 |

| Hard Soldering | 275 |

| Hard Solders, Three Formulas | 276 |

| Alloy for Adhering to Iron or Steel | 276 |

| Gun Oil | 276 |

| Gunsmiths’ Glue | 277 |

| CHAPTER XXXV. | |

| On Judging the Quality of Guns | 278 |

| The Muzzle Loading Shot Gun | 279 |

| The Muzzle Loading Rifle | 279 |

| The Breech Loading Shot Gun | 283 |

| The Breech Loading Rifle | 289 |

| CHAPTER XXXVI. | |

| On Using the Rifle | 292 |

| The Old Kentucky Rifle | 292 |

| General Directions | 294 |

| Off-Hand Shooting | 296 |

| Rest Shooting | 299 |

| CHAPTER XXXVII. | |

| On Using the Shot Gun | 302 |

| Born Shooters | 302 |

| How to Shoot | 304 |

| Brewster on the Use of Two Eyes | 306 |

| Dougall’s Reasoning | 307 |

| Gloan on Taking Aim | 310 |

| CHAPTER XXXVIII. | |

| On Using the Pistol | 313 |

| Natural Talent | 313 |

| Taking Aim | 314 |

| Cane Aiming | 315 |

| The Best Pistols to Use | 316 |

| CHAPTER XXXIX. | |

| Vocabulary of Mechanical Terms Used by Gun Makers | 318[xv] |

| CHAPTER XL. | |

| Vocabulary of Chemicals and Substances Used in Varnishes, etc. | 334 |

| CHAPTER XLI. | |

| Calibres of Guns, Rifling, Twist of Rifling, etc. | 342 |

| European Guns | 342 |

| American Guns | 343 |

| Pistols | 344 |

| CHAPTER XLII. | |

| Directions for Taking Apart and Assembling Guns, Rifles and Pistols | 346 |

| Rifles | 346 |

| The Ballard Rifle | 346 |

| The Burgess System | 346 |

| Burnside’s Rifle | 347 |

| The Evans Rifle | 348 |

| Hotchkiss Repeater | 349 |

| Howard’s “Thunderbolt” | 350 |

| The Kennedy Magazine Rifle | 350 |

| Martin Repeating Rifle | 351 |

| The Maynard Rifle | 351 |

| Peabody Martini Rifle | 353 |

| The Phœnix | 354 |

| The Remington System | 355 |

| Remington Magazine Gun (Keene’s Patent) | 357 |

| Remington No. 3 (Hepburn’s Patent) | 358 |

| Sharp’s Rifle | 358 |

| United States Muzzle-Loading Rifle and Musket | 360 |

| Springfield Breech-Loading Rifle | 361 |

| Whitney Breech-Loading Gun | 362 |

| Whitney New System Breech-Loading Gun | 364 |

| Winchester Magazine Gun | 365 |

| Billings’ Breech-Loading Shot Gun | 366 |

| Fox Breech Loading Shot Gun | 367 |

| Lefever Hammerless Gun | 368 |

| Parker Double-Barreled Breech-Loading Shot Gun | 369 |

| Remington Double-Barreled Breech-Loading Shot Gun | 369 |

| Roper Four-Shooting Shot Gun and Rifle | 370 |

Discovery of Gunpowder.—No authentic records have been left to show when or by whom was discovered the wonderful properties of the chemical compound now known as gunpowder; nor have we any information concerning the uses to which it was originally applied. There is little probability that it was at once employed as an agent in fire-arms; indeed, we have pretty strong evidence to show that it was not, for Roger Bacon refers to it in his famous treatise, De Nullitate Magiæ, published A. D., 1216, while fire-arms are mentioned by no writer as having been known earlier than about 1338.

The First Fire-Arms.—The first fire-arms, or guns, as we now call them, are said to have been rude cannon, formed by banding together flat iron bars, something on the plan of our wooden casks or barrels of to-day. These guns were fired with a “slow match,” the gunners retiring to a safe distance while the match was burning to the priming. Their earliest use was as engines of war. The writers[10] of ancient history tell us that they were so employed by the Moors at the noted siege of Algesiras, Spain, in 1341, and at the battle of Calais, in 1346. At the latter battle, Edward III is credited with having had four pieces, which made him victorious.

Earliest Hand-Guns.—It is claimed by Spanish historians that to Spain belongs the honor of having been the first power to furnish her soldiers with fire-arms so small that they could be transported by a single person. They were unwieldy affairs at the beginning, however; really small cannon lashed upon wooden scantlings. The soldier could not fire his piece off-hand, but was forced to carry a “rest” with him wherever he went. Being ready to discharge his arm he balanced it upon the rest, steadied it by holding the scantling under his arm, and then “touched it off” with a live coal of fire, while he sighted along the barrel to take aim at his object. What happened immediately after the coal came in contact with the powder the historian saith not, but a modern writer, who has been examining one of these old guns in a museum, jumps to the conclusion that the soldier, with the scantling under his arm, must have been launched suddenly into an impressive dream of first-class earthquakes, or something else “like unto the combined kicking of about fifty mules.”

Prejudice Against Fire-Arms.—For about two centuries after the invention of hand fire-arms they were so inefficient that the cross-bow, then in general use, was able to quite successfully hold its own[11] against them. It was not until 1596 that Queen Elizabeth, by a proclamation, directed that cross and other bows used in the army should be discarded entirely in favor of muskets. And thereat there arose much murmuring of dissatisfaction throughout the English Empire, according to Michael Montaigne, a most prominent man of his time, who narrates the fact, and adds: “Except the noise in our ears, to which we will be henceforth accustomed, I think the fire-arm is one of very little effect, and I hope that we shall one day give up its use.” Could he return to earth at this age, and see the wonderful fire arms that have developed from the humble beginning of which he was then treating, he would speedily lose his hope to the effect that one day its use would be entirely given up.

The First Rifle.—The first rifle is said to have been made about the close of the fifteenth century, by one Gaspard Zollner, of Vienna. It was a simple barrel with straight grooves; the only object of the grooves being to prevent its becoming so “dirty” from continued use, as did the smooth-bore. Spiral grooving does not seem to have been thought of until many years later.

The Arquebus.—The earliest noted improvement in the hand-gun, making it lighter and giving it a longer barrel, was called the arquebus; but even this was so heavy that a “rest” was necessary while discharging it. This rest was a single staff armed with a steel point which went into the ground like the Jacob-staff of a surveyor, but which fitted it for[12] use as a pike when not employed in connection with the gun. It was called the schweine feder, which rendered into English means the “hog’s bristle.”

The arquebus was a regular “match-gun;” that is, it had a “pan” or receptacle at the side of the breech for the priming powder, which communicated with the interior of the barrel by a small perforation called the “touch-hole.” The priming was lighted by a match, which consisted of a coil of small rope saturated with some kind of chemical, which caused it to burn readily and hold fire for a long time. The soldier using the arquebus carried the match in his hand and kept it burning during an action. The manner of setting off the piece was about the same as with the live coal—he secured his sight and then touched the priming with his lighted match.

The Match Lock.—Later, the serpent-match was invented and looked upon as a startling improvement. It was a simple S-shaped piece of iron or wire hinged to the side of the gun just back of the priming pan. The upper end was provided with a beak which gripped the lighted fuse, while the lower end played the part of a modern trigger. With this contrivance the gunner had only to take sight and then pull with his finger upon the lower end of the S until the lighted fuse was brought down into the priming. After many years of use an improvement was made upon the S, consisting of a small spring which threw it back into an erect position so soon as the pressure upon the lower end was discontinued.

The powder employed with the old arquebus was of two grades as to size of grain; a coarse grade for the charge, and a fine grade for the priming. Its chemical composition does not seem to have differed materially from that of our modern gunpowder.

The serpent match, so called because the upper end holding the fuse was often shaped to represent the head of a serpent, was the first actual step taken towards a gun-lock. It was thought to be perfection itself, especially after the returning spring had been added, and so strong a hold did it take upon all nations that only a few years has elapsed since it was wholly abandoned in some of the most benighted regions, as in China, for instance, where it is known to have been used in the army at a date as late as 1860.

Musket-Petronel.—Next in order to the arquebus came the musket, a Spanish invention. It was heavier than its predecessor, and carried a charge twice as large. Almost simultaneously with this appeared the first cavalry fire-arm, which was called the petronel. It was shorter than the musket and larger in bore; the horseman rested its breech against his breast and communicated the fire by means of the serpent match.

The Wheel-Lock.—In 1517 the Germans astonished the world by inventing and bringing into use the “wheel-lock,” which was a regular gun-lock, entirely doing away with the lighted match. It consisted of a small disk of steel fluted on the edges, set in close contact with the priming pan, and made[14] to revolve with great rapidity by means of a spiral spring arranged somewhat on the plan of the spring of a spring-clock. In contact with its fluted edge, and held there by a spring, was arranged a sharp flint; hence when the steel disk was set in motion a train of sparks was thrown off as it revolved over the edge of flint. These sparks fell into the priming pan and ignited the powder, discharging the piece. The spring was wound up like winding a clock or watch, and a slight pressure upon a trigger under the breech set the wheel in motion. The pressure was continued until the gun was discharged, when it was discontinued, the result of which was an immediate stopping of the wheel. A single winding would usually discharge the gun about half a dozen times.

The Pistol.—The wheel-lock went into quite general use, finally leading to the invention of the pistol, about 1544. The first pistols were single barrel, and very short. The stock was heavy, and the breech or handle, instead of leaving the barrel with a curve, as in later days, dropped at right angles to the iron. It was put into use as a cavalry arm, first by the Germans and afterwards by the people of many other nations. In 1607 the German horse soldiers were all regularly armed with double-barrel wheel-lock pistols.

The Snaphaunce.—After the date just mentioned modifications and improvements in fire-arms were rapid and constant. The wheel-lock was finally followed by the “snaphaunce,” which was a straight[15] piece of furrowed steel brought to bear upon the flint instead of the disk. It was more simple in its construction than the wheel-lock, and hence less liable to get out of order. Of course it worked in obedience to the action of a spring, but the spring was not a spiral—it was more on the plan of the mainspring in modern gun-locks.

The Flint-Lock.—About 1630 Spain again popped to the surface; this time with the regular flint-lock, embracing precisely the same mechanism as the flint-lock used in our Revolutionary war, and familiar to very many of the older people of the present day. Its advantages over the wheel-lock and the snaphaunce were so marked that France at once adopted it for use in her armies, but England held back, contending that the wheel-lock was the better invention, till 1690, when she gave up the contest, and adopted the flint-lock.

Important Improvements.—Rapidly following the invention of the flint-lock came important improvements in the musket. The stock was lightened and put into better shape, and sights were invented and placed upon the barrels. Up to this time the soldier had been forced to carry his ammunition in bulk, but now cartridges were brought into use, carried in convenient and neatly made cartridge-boxes. Steel bayonets to set over the muzzle of the gun also appeared, the first in 1693. Prior to this time a rude kind of bayonet had been more or less in use—it was a sort of dagger set into a wooden handle, the latter to be thrust into the muzzle of the gun in case of a[16] hand-to-hand charge, where loading and firing could not be attended to. Iron ramrods took the place of the inconvenient and unsafe wooden ones formerly in use, which was regarded as a long stride in the efficiency of the musket. With the old wooden ramrods, clumsy and easily broken, the loading of a musket was a slow and laborious task, but the iron rod secured comparative ease and rapidity.

Advance of the Rifle.—With the general improvement of fire-arms the rifle had worked gradually into favor and use. Its main drawback, as an army gun, laid in the difficulty experienced in loading it. But it was admirably adapted to the wants of the people settling the wilds of the American continent, hence they adopted it almost to the entire exclusion of any other kind of fire-arm. In the armies its use was limited to a few corps of sharp-shooters, usually on the frontiers where it was advantageous to harass the enemy by picking off his men at long range. England seems to have been rather prejudiced against the rifle until after our war with her for Independence. In that war she appears to have had so striking a demonstration of its efficiency that she soon after adopted it as a military arm; and other nations, having faith in her superior judgment, finally followed her example, bringing the rifle rapidly upward in rank as an effectual implement of war.

The Percussion Lock.—In 1807 a Scotch clergyman by the name of Alexander Forsyth, invented a new method of igniting the charge in fire-arms,[17] which, after various changes and improvements, settled down to what is now known as the percussion cap. The percussion lock was a simultaneous invention, of course; though it did not differ materially, in point of construction, from the old flint-lock already in use. The main difference consisted in the substitution of a cylinder and tube for the priming pan and frizzen, and a hammer for the cock.

A strong current of prejudice set at once against the percussion lock, though nobody could tell why. All declared it would not do, but none attempted to give a reason for the faith that was in them. As a result the new invention was pretty effectually held in the background until 1834, when its opponents accepted a challenge for a public test of its merits against those of the flint-lock. The test extended to 6,000 rounds. In the course of these the percussion lock (afterwards more commonly known as the cap-lock), gave but six miss-fires, while the flint-lock scored nine hundred and twenty-two misses.

This astounding defeat at once sealed the fate of the flint-lock; still it was a long time before the prejudice existing against the other could be entirely removed. Even as far down as the date of our Mexican war, General Scott flatly objected to its use in his army, and had his men armed with the flint-lock, although there were then in our arsenals percussion-lock muskets enough to have armed all his forces more than twice over.

But facts are such stubborn things that even the strongest prejudice must give way to them sooner or later. So it proved in this instance; one by one the manufacturers of flint-lock fire-arms adopted the improvements resulting from the discoveries of the Scotch clergyman, until finally no more flint-locks were made, and the percussion lock was in undisputed possession of the field.

The Breech-Loader.—When the percussion-lock had been fully adopted by the public, and all the “latest improvements” had been added to it, people thought that the fire-arm had attained to such a degree of perfection as to preclude any further change in the future; but how mistaken! The fate of the percussion-lock is now as much sealed as was that of the flint-lock at the test-trial of 1834. It is going the way of all its predecessors, and its entire extinction is only a matter of time. The breech-loader, with charge and ignition combined in the same cartridge, is rapidly taking its place, and, until some new and wonderful discovery comes to the surface, must, undoubtedly, stand paramount as the gun of the future.

While springing into general favor at one leap, as it were, the breech-loader is no new and sudden appearance. In truth it is of great antiquity. In the Tower of London, the Woolwich Museum, and in the Museum of Paris, may be seen hundreds of breech-loaders that were made centuries ago. Of course they were not made to use the percussion cartridge peculiar to many such guns of modern make, nevertheless[19] they were veritable breech-loaders, and the real suggestors, no doubt, of the modern arm of that character.

In the Museum of Artillery, at Woolwich, there is a breech-loading pierrier, or paterera, of the time of Edward IV. (1471). It consists of a directing barrel, terminating in a square bar or frame of iron, and a separate loading chamber, with handle, which was fastened in its place for firing by an iron wedge. There are also found in the museums many breech-loading pistols, that were evidently in use about cotemporaneous with this gun.

The records kept at St. Etienne, France, show that the French monarch, Henry II, shot with a breech-loading gun in 1540. And the English records show that the Marquis of Worcester took out a patent in that country for a breech action on the “cut-screw” principle in 1661. A portion of the specification reads as follows:

“An invencione to make certain guns or pistols which in the tenth part of one minute of an hour may be re-charged; the fourth part of one turne of the barrell, which remains still fixt, fastening it as foreceably and effectually as a dozen shrids of any screw, which, in the ordinary and usual way require as many turnes.”

There are several specimens of the breech-loader made on this plan, now in the Woolwich Museum. There are also other specimens, on a plan entirely different, made at a date but a little more recent, for it seems that then, as in modern days, one invention[20] was very apt to suggest another. Three years after the Marquis of Worcester had taken out his patent, one Abraham Hill, of London, patented some six different systems of breech-loaders. In his specification concerning one of them he says:

“It is a new way of making a gun or a pistoll, the breech whereof rises on a hindge, by a contrivance of a motion under it, by which it is also let down and bolted fast by one of the same motion.”

This, as will be readily seen, was rubbing pretty close upon the breech-loader of the present day.

Since the dates of the patents just referred to, the breech-loading fire-arm is known to have been in uninterrupted existence; but so strong was the current turned against it by popular prejudice, that it was little known to the people in general. A want of scientific training among the masses was the cause which held it back; they were unable to clearly understand all the whys and wherefores connected with its workings, and, therefore, rejected it on the plea that it was dangerous, without really knowing whether it was or not.

Great improvements in the breech-loader now succeeded each other with astonishing rapidity up to the time when M. Lefaucheux, of France, capped the climax by inventing the cartridge containing within itself the cap, or means of igniting the charge. This made it available as a sporting gun, and hence promptly set it forward into public attention; and finally, after a score or so of improvements, usually at the hands of the English, into public favor. It is,[21] at last, the gun of the period, and the old muzzle-loader, with all its good qualities (and they were certainly many), is rapidly surrendering the field to the more successful candidate, and retiring in the footsteps of its honored predecessors, the wheel-lock and the flint-lock.

Gunsmith—Gunmaker.—The modern gunsmith is not necessarily a gunmaker, but rather a repairer of guns that have happened to get out of order. In earlier days the devotees to his calling may, in their little shops, have made guns entire, but now, if the gunsmith makes them at all, that making consists in merely finishing up the parts and putting them together—generally making the stock entire. All gun parts can now be bought as “gunsmith’s materials,” either finished or in the rough, as may be desired. They are made by a variety of workmen, the business of each man being to make a single part, and nothing more. There is at present too much in a good gun to admit of all being made advantageously by one man; he would need to be a kind of “Jack-of-all-trades,” and, like the traditional Jack, it is but reasonable to suppose that he would be really first-class at none.

In some of the large establishments where guns are made all these different workmen are employed, hence such an establishment is really a collection of workers in many trades. The gunsmith who has his shop for repairing purposes, or for putting together materials under the name of gunmaking, will not be specially concerned with reference to any of[23] these trades; still it is but reasonable to suppose that he would like to know something of how the implements, or parts of implements, that he will be constantly handling, were put up; and, besides, there will exist something akin to a necessity for his possession of such knowledge, owing to the fact that his customers will often call upon him to answer many a question as to how this or that gun was made, etc. With this view of the case, it is really necessary to give a brief outline of gunmaking, following the work from the rough material to the final finish.

Gun-Barrels—Best Materials for.—The barrels of the finest and best guns, either Damascus, or other steel, or iron, are formed, as made in Europe and England, of scraps of iron suited to the purpose, and selected with great skill and the greatest possible care. These scraps, which are usually bought up about the country, are placed in what is called a “shaking tub”—a vessel which is violently shaken and rocked about by machinery or otherwise (depending upon the particular locality) for the purpose of scouring and brightening the scraps. This done, they are carefully picked over by adepts, who cull out the unsuitable pieces. So rigid is the culling that it often happens that out of a ton of scoured scraps not more than one hundred pounds weight of them are chosen as suitable for going into the best barrels.

Among the scraps usually thought to be best are old chains that have been used for many years, the[24] wear and rust of time having left only the best elements of the iron. The Damascus steel, which has attained to so high a reputation, got it by being manufactured out of old coach springs. Of course it is not all made of coach springs now, but it was in years ago; agents then traveled all over the country hunting and buying them up, paying a much higher price for an old broken spring than a new one would cost its owner.

On Making Gun-Barrels.—The selected scraps to be worked into gun-barrel material are cut into small pieces and thrown into a furnace, where they are exposed to intense heat until fused, after which they are brought forth an adhering mass and placed under a hammer, which drives them together and forges them into bars. The bars are next rolled into thin plates, and then cut into strips twelve inches long and six inches wide. The very best guns are made of a combination of iron and steel. Both materials having been rolled and cut into sheets of exactly the same size, these sheets (one-fourth of an inch thick) are piled upon each other alternately to the number of thirty, and subjected to a welding heat; they are then driven together under a five-ton hammer into a consolidated slab. The slabs so formed are next worked down into one-fourth inch square rods. The more the material is hammered and worked the better it is. The rods are next twisted until they present the appearance of a strand of rope, some rods being twisted to the right and others to the left. Two rods, with opposite twist,[25] are heated to the welding degree, placed upon each other, and rolled together; they are now in a narrow slab, presenting that fine curl of “grain” peculiar to the Damascus, or that beautiful wavy figure peculiar to the laminated steel, as the case may be. The next operation is to coil one of these slabs around a mandrel in a spiral form, and weld it securely under the blows of hand-hammers. It is now a gun-barrel in the rough.

Finishing and Proving.—The rough barrel goes from the welder to the borer, where it is put through the process of “rough boring.” From the “rough borer” it goes into the hands of the “fine borer,” who bores it out smoothly and to near the size it is to be when finished. Another operator then takes it in charge and dresses it to smoothness externally, then the “tester” takes it and dips it into strong acid, which soon shows any imperfection in either twist or welding that might exist. If not perfect, it is sent back to be worked over; if all right, it passes to the next department, where it is straightened inside. This part of the work is governed entirely by the eye, and hence demands the services of a workman of great skill, and experience.

Having been “passed on” by the “straightener,” the barrel goes to the “turner,” who turns it in a lathe until the outside is true and correspondingly straight with the interior, and is of exactly the required weight. If the arm is to be a double-barrel shot gun, the barrel next goes into the hands of a workman who joins it to another barrel with the[26] utmost nicety; to attain which, levels and other suitable instruments are brought into requisition. Like the man who straightens the bore, the man who joins the barrels must be a workman of great skill.

The next operation is to braze on the “lumps;” then, next in order, the ribs are put on. Now comes the “proving.” The rear ends having been securely plugged, they go to the proof department, where is placed into each barrel fully four ordinary charges of gunpowder; then, atop of this, a wad of strong brown paper, rammed securely down, then a leaden bullet large enough to exactly fit the bore, and then another wad of brown paper. The charge is fired, and if the barrels stand the ordeal unfazed, they are ready to be fitted to the action; otherwise, they go back to be worked over. In some houses the “proving” is done before the barrels are joined together.

Action, Stock and Final Finish.—The “action man” now takes the perfect barrels in hand and performs his part of the work. In the meantime the stock-maker has not been idle. A stock is already in waiting, and next must come a series of fittings of the most exquisite nicety, until the gun is actually a gun and ready for its final test. This is applied by the “targeteer,” who passes upon it according to its merits. If his report comes in favorable, the gun goes to the proper department for final finish. The stock is dressed up, finished in oil or varnish and chequered, and its mountings put on. Every piece of metal is polished and burnished to[27] the highest possible degree, and all the needed engraving is done. Next comes the case-hardening, coloring, and the browning or bronzing; and this having been well and satisfactorily performed, the gun is ready for market.

On Making the Rifle.—The processes employed in making the modern rifle do not differ materially from those named in the foregoing. Of course there are some processes employed on the shot gun that are not called for in the manufacture of the rifle, and some on the rifle not needed on the shot gun. The general principle is the same, however, and therefore it is not necessary to consume time in further description. The great care mentioned is only done to make a good gun; only the cheap and inferior guns are pitched together in an easier and more irregular way. But the gunsmith would not thank any one for a treatise on cheap and bad guns. They are legion, more’s the pity, and his extensive dealings with them will afford annoyance sufficient to do away with any desire on his part to fight his battles over in a book.

Plain Steel-Barrel Guns.—Of course there are guns with “plain steel barrels,” as they are called, which pass muster as fair; and the barrels of these are made by a process differing materially from that described in the foregoing; all else connected with the making is the same. These plain steel barrels are made of round bars of steel two inches in diameter. The bars are first cut into lengths of nine inches each; a hole or bore three-fourths of an inch[28] in diameter is drilled through the centre. They are now called moulds, and the next step is to pass them through rolls, which reduce them to the required size for barrels and stretch them out to the required length, holding them, at the same time, in the proper shape, externally. Having been thus rolled, they are bored out internally, turned and ground externally, until they have attained to the shape and proportions of correctly-formed barrels. After this comes the fitting up and “proving,” as in the case of the finer guns.

Guns Defined.—Excepting the pistol, and the mortar, perhaps, all fire-arms now in use are classed under the name of guns. The cannon or artillery ordnance in all its sizes and forms, is simply a large gun. It is variously divided off, according to character, into heavy siege-guns, field-pieces, rifled-cannon and smooth-bores. These again are sub-divided into a large number of different kinds, as the Armstrong, the Dahlgren, the Columbiad, the Paixhan, the Parrot, the Whitworth, etc. But with guns of this class the practical gunsmith will have nothing to do, and hence it is but reasonable to suppose that he feels no particular concern about them. It is with the small-arms that his concern will mainly lie, and therefore from this page to the conclusion of this work the gun mentioned will be some instrument classing with the small fire-arms, and liable to be brought to a gunsmith’s shop for repairs.

The small arms, or hand guns, are muskets, rifles, carbines, fowling-pieces and pistols. These may be properly divided into three classes: the flint-lock, the percussion-lock and the cartridge breech-loader.

The Old Flint-Lock Guns.—Of the old flint-locks, only a few are now in existence within the United States. Here and there one has been kept as a kind[30] of heirloom by some family, and occasionally these drop in upon the gunsmith for repairs, but not often. They are more common along the Mexican border in Texas, perhaps, than in any other portion of the country.

A minute description of the old flint-lock-gun need not be given, as, in general characteristics it does not differ materially from all other muzzle-loaders. The barrel is usually longer than that of the more modern gun; and, in the case of the rifle, the stock (all wood) extends nearly to the muzzle. It is what, in later days, when half-stocks had been invented, was called a full-stock. As already intimated the interior mechanism of the lock differs very little from that of the more modern cap or percussion-lock. On the outside, in place of the cap-hammer is a cock arranged with two lips for holding a flint. The lips are brought together firmly upon the flint by means of a screw which passes down immediately back of it. In the top of the lock-plate, directly in front of the cock, is set the priming-pan; a small iron receptacle made to contain, say the fourth of a teaspoonful of gunpowder. When the lock is in position the butt or open end of the pan comes squarely up against the barrel of the gun where a small hole called the “touch-hole” communicates with the interior, and with the charge, when the gun is loaded. Over the priming-pan a cover fits nicely, lying horizontally when the pan is closed, and turning up at right angles on the edge nearest the cock, and standing erect, a small plate of[31] steel, immediately in front of the flint. This cover, with its vertical plate is called the frizzen. It works on a hinge, and is held into whatever position set, by means of a small spring called the heel spring. When the cock is set in motion by drawing upon the trigger and releasing the check to the mainspring, the flint comes in contact with the steel plate of the frizzen, throwing it back upon its hinge and scraping down its face directly towards the priming-pan. As the frizzen flies back the pan is uncovered, of course, enabling the flint to end its journey directly in the priming powder of the pan. In its scrape over the steel plate of the frizzen it causes many brilliant sparks of fire, which descending with it into the priming sets off the charge.

The Percussion-Lock Gun.—As has already been stated, the immediate successor of the old flint-lock was the percussion or cap-lock. While now far beyond its zenith, it is still the prevailing gun in many portions of the country; especially in out-of-the-way districts South and West. In the oldest make of these guns a small plug of iron is screwed into the barrel at the point where the touch-hole of the flint-lock was located. It is called the cylinder. The end passing into the barrel is drilled to communicate with the powder-bed of the gun, and with a cap-tube, which is screwed into the cylinder, to stand erect near the side of the barrel. In more modern guns the cylinder has been discarded, the tube going directly into the barrel and communicating with the powder-bed.

The oldest percussion-lock rifles are set in whole-stock, on the plan of the flint-lock gun; and on account of the fact that all the old-fashioned folks are not yet dead, some factories put up new guns after the same model, calling them Kentucky rifles. The stock reaches the full length of the barrel, which is heavy and about four feet long. It is octagon in shape. But in most of the more modern rifles the barrel is shorter, say from 32 to 36 inches in length, and comparatively light; and the stock extends only half the length of the barrel, joining to a rib affixed to the barrel for the purpose of holding the ramrod-thimbles.

The “patent-breech” may be mentioned as another peculiarity of the percussion-lock gun, since it was not known in the days ere the flint-lock had lost its prestige. In those early days the breech end of the barrel was closed by a plug of iron, screwed in and called the breech-pin. From its upper side there extended backward along the stock a thin plate or strap, through which screws passed at right angles to hold the barrel in place. This method of securing the breech-end of the barrel into the stock has been done away with by the patent breech, which secures it by means of a short hook on the end of the breech-pin; or, rather, on the end of the short plug screwed into the barrel in place of the old breech-pin. It is much more convenient than the old fashioned arrangement, as it enables the barrel to be taken from the stock in a moment, doing away with the labor of drawing the breech-pin screws.

On the Muzzle-Loaders.—The percussion-lock muzzle-loaders all work upon about the same principle. The charge must go in at the muzzle and be put down to the breech. In the case of army guns it is usually contained in a paper cartridge. The soldier bites off the end of the cartridge in which the powder is inclosed, to admit of a communication with the cap, and then forces it down with the ramrod. But in the case of rifles and fowling pieces, or shotguns, as the latter are most commonly called in this country, cartridges are seldom employed. In loading a rifle the powder is first measured in a “charger,” and then poured down the barrel; next comes the patch, which is usually a piece of new and strong cotton cloth, most commonly the kind known as white drilling. This, having been tallowed upon one side, the tallowed side is spread over the muzzle of the gun, and the bullet is pressed upon it into the muzzle, the side from which the “neck,” formed in moulding, has been cut, must be directly downward. Generally with the handle of a knife the bullet is pressed into the bore as far as it can be sent by such means; then the patch is gathered around it and cut smoothly off exactly flush with the muzzle end of the barrel. The next operation is to draw the ramrod, throw the gun under the left arm, with its breech resting upon the ground and its muzzle in front of the breast, and then having set the butt end of the ramrod upon the bullet and grasped it in both hands, the bullet is gradually, and by main strength, forced downward into position.[34] To make sure that it is entirely down the gun is taken from under the arm, by some, and set with the breech resting upon the ground more in front, after which the ramrod is raised up a foot or so and pitched down the bore like throwing a pike. If it does not bound back the bullet is not down solid upon the powder, and the pitching is repeated until it does bound. The upward bound of a few inches is sufficient to settle it that the bullet is down.

In the early times the bullet of the rifle was patched with dressed deer-skin exclusively.

Charging the shot-gun muzzle-loader is an operation somewhat different. First comes the powder poured down the bore from a charger, as in the case of the rifle. Next comes a wad, usually of paper, which must fit tightly, and be rammed down solid upon the powder. Following this comes the shot, measured in the same charger, or in one of the same capacity. The measure of powder and the measure of shot usually made about the same. Over the shot is rammed a loose wad—it needs only to be tight enough to prevent the shot from rolling out when the muzzle of the gun happens to come lower than the breech. Disk-like wads of pasteboard or felt cloth are the latest invention.

The Breech Loaders.—The breech-loading gun is now before the public in considerable variety; and being really the gun of the day, and, consequently, engaging the best thought of inventors, it is constantly appearing in new forms. This being the case, about all that could be expected in this work,[35] is a mere mention of the general principles upon which it works.

Taking a double-barrel shot-gun for illustrating these general principles, it may be stated that the barrels are movable at the breech or rear end, and butt upon the face of the standing breech peculiar to the latest and best muzzle-loaders. The face of these barrels fits smoothly against that of the standing breech. There is nothing in the way of a breech-pin to resist the backward force of the ignited powder, or hold the barrels in place. The hooks mentioned as peculiar to the patent breech muzzle-loader are not there—nothing at all like them. But the barrels, when put into place for shooting are held there by means of a solid piece of iron attached to them underneath, called the “lump.” To effect this, it descends into an iron bed on the stock called the “action,” its projections fitting into suitable recesses in the action and being held there by the agency of keys, wedges, bolts or grips.

There are many devices for gripping, bolting or wedging up the gun, as it is called; and also many for attaching the barrels to the stock. In all cases the barrels play upon a hinge pin, which admits of their dropping down at the muzzle and rising at the breech, the latter to reject the empty cartridge and receive the loaded one. At every discharge the gun is opened and closed by throwing up the barrels for the purpose just named, and then letting them down again into position for shooting. The means by which this opening and closing is effected vary greatly in the guns of different makers.

Variety of Breech-Loaders.—This gives the general idea of about all there is of it. There are a few breech-loaders made in both this country and in Europe whose barrels are fixed, the cartridge being inserted through some other device; and there are still a few others whose barrels slide forward or sideways in the stock to receive the load—do not tilt on a hinge-pin—but neither of these kinds are so common as the kinds just referred to.

Old-Style Pistols.—Pistols, the smallest of fire-arms, were originally plain implements of a single barrel; but, as improvements advanced, a second barrel was added to many of them, presenting what is known as the double-barreled pistol. Some of these old-fashioned single and double-barreled pistols will still occasionally find their way into the shop of the gunsmith, though their numbers, as now in use, are comparatively small, especially the muzzle-loaders. In rare instances a flint-lock “horse pistol” or holster may put in an appearance, though none such are now on sale at any house dealing in fire-arms. Some few houses are still offering the old cap-lock army holster, always a second-hand article that once belonged to the Government, and was bought up by dealers when the Government had discarded it for the adoption of more modern and better arms. A description of this kind of weapon is unnecessary as it is simply a small musket with side-lock, and all on the usual plan, differing only in being short and having a turned-down handle, to be held in one hand, instead of the usual breech. The single or double-barrel muzzle-loaders, outside the line of army holsters, will usually have the central lock, which is next to no lock at all; simply a mainspring[38] working in the handle and throwing the cap-hammer, which is fitted in the middle of the piece immediately behind the breech-end of the barrel. Some very cheap pistols for boys are still made on this plan.

The Derringer.—The old Derringer, though not now much manufactured in this country, is still among the people in considerable numbers. It is a muzzle-loader, with side-lock and full-stock in wood; and, by the way, it is a very good pistol of its kind.

The Pepper Box.—There are quite a number of little breech-loading cartridge-pistols, with single barrels, now in use, but the pistol of the day is a repeater, of which there are kinds in great variety. One of the oldest and now rarest of these is the “pepper-box,” so called. It has a single barrel containing from five to seven bores, which are loaded from the muzzle. A tube for percussion caps communicates with each bore at the breech, and upon these a hammer strikes, having an automatic action, rising up and striking in response to pressure upon a trigger underneath, which pressure also revolves the barrel, bringing the caps into proper position for receiving the blow. It was never a popular pistol, people objecting to a kind of way it had of sometimes letting off its seven charges simultaneously, when the person operating it had intended to fire but one.

Old Colt’s Revolver.—Next among the repeaters, in point of scarcity, is the Colt’s revolver of the earliest patent. It has a stationary single barrel[39] and revolving cylinder, the latter containing from five to seven chambers for receiving the charges. It is not a muzzle-loader, though the charges must be put into the chambers at the breech, somewhat on the muzzle-loading plan. It is fired by means of percussion caps. The cylinder revolves, throwing the chamber to be discharged into proper position at the breech of the barrel when the cap-hammer is drawn back. Though inconvenient, compared to the cartridge pistol of more modern make, the old Colt’s revolver is yet an excellent arm. There are houses still making revolvers on the same plan.

Sharp’s Four Shooter.—Next to the old Colt’s revolver may be placed the Sharp’s four shooter. It is a neat and strong-shooting, little breech-loading pistol, using a No. 22 cartridge. The barrel has four bores but does not revolve; but the hammer has a revolving point, for striking the cartridge, which moves into proper position for a new discharge every time it is drawn back to full cock. The barrel slides forward upon the stock for receiving new cartridges.

The Breech-loading Cartridge Revolvers.—Next comes the regular breech-loading cartridge revolver, which is the pistol now most common and most popular. To attempt a detailed description of every style of this weapon would be to swell our book to unwieldy proportions, and even were the multitudinous styles at present before the public described, it would be impossible to keep pace with the number which would be constantly introduced. But, even[40] were it possible to do so, no good purpose would be subserved. Various as the styles appear, they all embrace devices and combinations which are substantially covered by our several chapters, and the intelligent workman will not require minute descriptions to recognize or understand the individual weapon when well grounded in a knowledge of the class of fire-arms to which it belongs. It is our purpose to give such descriptions, directions and illustrations as shall make everything sufficiently clear and explicit to enable the reader, with careful attention thereto, to handle successfully and satisfactorily any job likely to come to his hands.

The Gunsmith and his Trade.—Few trades present so little regular routine as does that of the gunsmith. In most trades it is the same thing over and over again; but, with the exception of taking the gun to pieces and putting it together; and, perhaps, of tempering, case-hardening and the like, the gunsmith may work regularly for a long time without being called upon to do precisely the same thing twice. As a consequence, the gunsmith must be merely an ingenious mechanic or worker in metals, capable of thinking deeply and searching out causes and requirements—there is little need of his being anything more. The gun, in all its forms, is only a machine, and a simple one at that—so simple as to be easily understood by any one capacitated for making an intelligent study of machinery.

Fitting up a Shop.—The specialties to claim the attention of the gunsmith in fitting up his shop if his means are limited may be few. It will be about like fitting up the shop of any general worker in metals. He will need a forge, an anvil and a vise; in a word he will need a light but complete set of blacksmith’s tools, to begin with. This outfit will be his foundation, so to speak; and he can add to it such smaller tools as judgment and experience[42] may suggest as wanted; such, for instance, as a hand-vise or two, cutting-pliers, bending-pliers, holding-pliers, small files of various shapes, small drills, a screw-plate or two, a few gravers, and so on. He might have many special tools, such as could not be bought at the ordinary hardware store, or at any house dealing in outfits for the general worker in metals, but for ordinary repairing, he will not have much need of them. Among the special tools that he will be compelled to have will be a rifle-guide, a few sets of rifle-saws and a few mould-cherries. These with proper instructions he can make himself if he finds he cannot buy them cheaper than he can make them. There are a few specialties in the way of tools or machines for gunsmiths that are offered to the trade by houses dealing in gunsmith’s materials, and some of them may be found very useful as labor-savers, but the gunsmith can get along without them if he does not wish to buy. Prominent among these is a mainspring-vise or clamp, which has several advantages over the common hand-vise sometimes employed for clamping the mainspring. It would be well to look after these things, and to adopt them in every case where it appeared beyond question that they could be made to pay. There is no occasion to speak against any of the specialties that may be presented to the attention of the trade—of their merits the party most concerned must be his own judge.

To Take the Gun Apart.—With the muzzle-loading guns now in common use this is an operation so simple as to be scarcely worthy a mention. If the gun is an old-fashioned breech-pinned muzzle-loader, the first thing is to push out the small wire pins or bolts which pass through the stock, under the barrel, and through the barrel-loops. The next thing is to draw the breechpin screw; this lets the barrel out of the stock. If it is desirable to unbreech the gun, it is done by clamping the breechpin in a vise, and then turning the barrel by hand until it is screwed off the pin.

The patent-breech muzzle-loader comes apart the same way in every particular, with the exception that there is no breechpin screw to draw; the barrel can be easily lifted from the stock by simply raising the muzzle and unhooking the patent breech, so soon as the pins or bolts before mentioned as holding it down have been removed. The unbreeching is done at the vise much the same as in the other case.

To take apart the ordinary breech-loader, begin by setting the hammer at half-cock. Open the lever, then draw the bolt, starting it with a tap from the[44] handle of the screwdriver. Next detach the fore-piece, and the barrel will come out without further resistance. Instructions to take down and assemble different kinds of breech-loading guns will be found in Chapter XL.

To Clean the Gun when Apart.—In olden times a bucket of water and a wisp of tow and a stout “wiper” had to be brought into requisition, particularly for the interior of the barrel, but now these things are mainly obsolete, so far as relates to the outfit of the gunsmith. The owner of a muzzle-loader, who does not wish to remove the breechpin, may still resort to the old plan of washing out the barrel, though there is now really no necessity for it. A little benzine poured down the muzzle, after stopping the tube, will do the work of cleaning effectually and in a few minutes. Let stand a short time, then remove the plug from the tube and force the benzine out by running down a tow wad on the wiper—all the dirt will go out through the tube with it, leaving you nothing to do but wipe the benzine from the bore with the tow.

In the case of a gun unbreeched, or a breech-loader, all that is necessary is to saturate a bit of cotton flannel with benzine and run it through the barrel a few times. If the gun is a fine one, well finished, this process will leave the interior as shining and bright as a mirror.

With the same arrangement rub thoroughly any of the metal parts that happen not to be clean, and all impurities will promptly leave them. After this,[45] oil and wipe with a chamois skin, and the work is done.

Benzine may be had at any drug store at about the price of kerosene. It is especially valuable as a gun cleaner for two reasons: its peculiar fitness for detaching and carrying away dirt, and its highly volatile properties, which cause it to evaporate and entirely leave the metal in a short time after the application has been made. Its adoption has completely done away with the necessity of ever using a drop of water upon a gun, in any case, which is a matter of decided importance and advantage.

To Put the Gun Together.—With the muzzle-loaders the operation of putting together is simply a work directly in reverse to that of taking apart. In case of the common make of breech-loaders a little more variation may be regarded as necessary. Take the grip of the stock in the left hand, having the lever open. Hook on the barrel and turn the gun over with the hammers underneath, still holding the stock at the grip. The weight of the barrel will keep it in place. With the right hand attach the forepiece and push in the bolt.

Of course there are guns of peculiar make, now and then to be met with, which will require a different routine, both in taking apart and putting together. The details, with full directions for taking down and assembling nearly all the breech-loading guns now made, will be found explained, with cuts of their mechanism and working parts, in Chapter XLII.

A careful study will soon show the gunsmith how they come apart and how they go together. The main thing is to work with extreme care, and to never act until you clearly understand what you are doing.

Given in alphabetical order are some of the tools that will be required by the gunsmith, and in connection a very brief sketch is given of their approximate cost at hardware stores. This list is intended only as a sort of guide in purchasing, and is by no means intended as a complete list of what may be wanted.

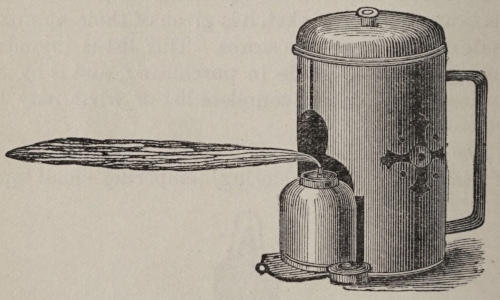

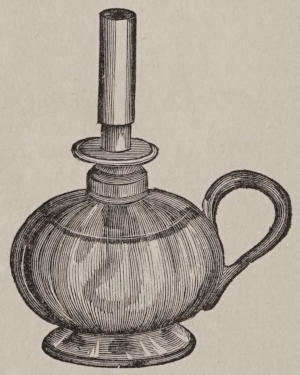

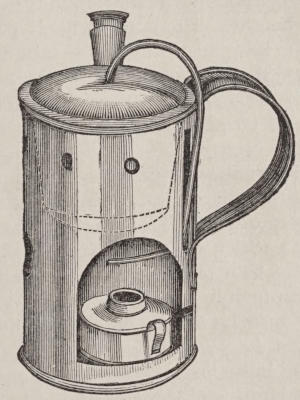

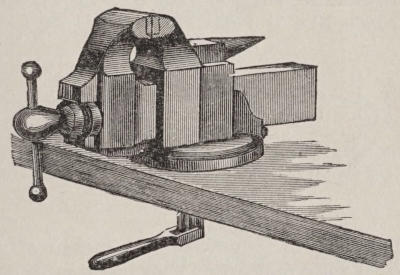

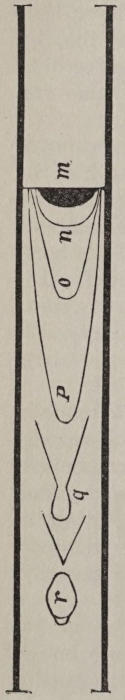

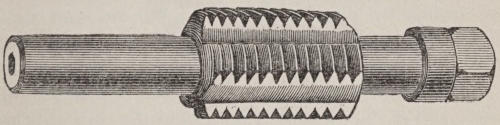

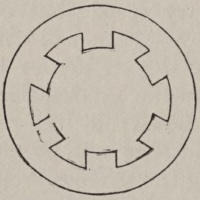

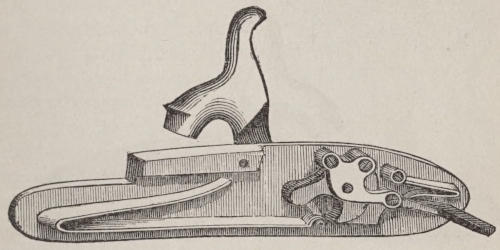

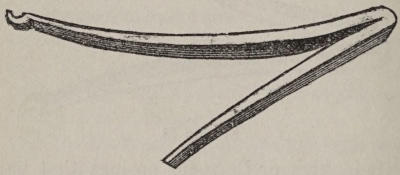

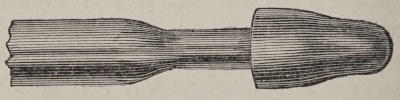

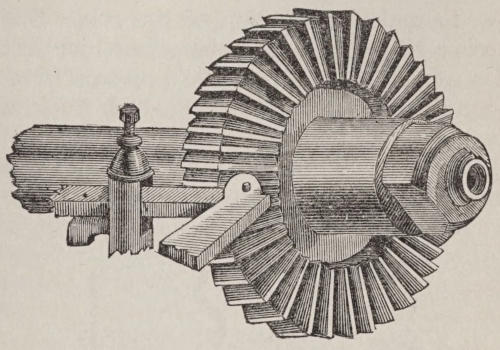

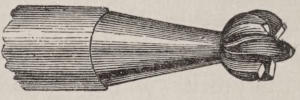

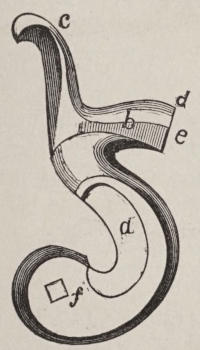

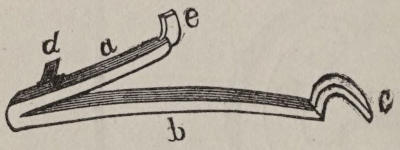

Figure 1.

The Alcohol Lamp.—This lamp, shown in Fig. 1, is useful for small soldering, tempering small taps, drills, etc. Glass or brass lamps with caps to prevent evaporation, are sold for about 50 cents each.

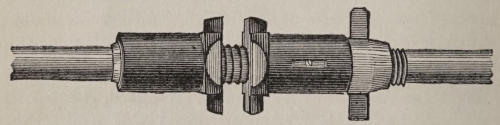

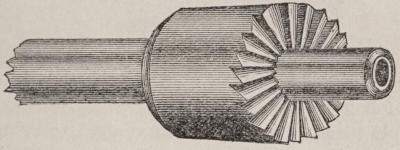

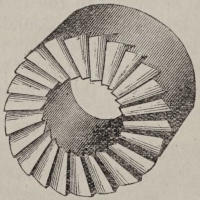

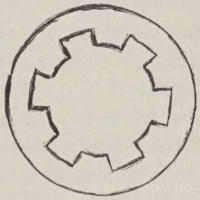

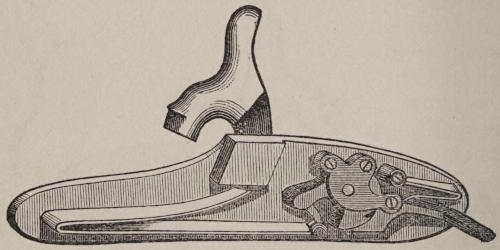

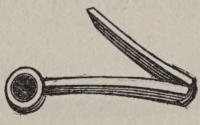

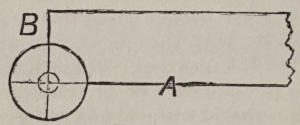

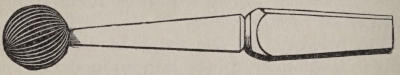

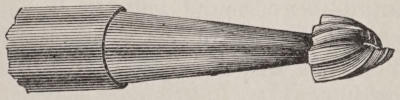

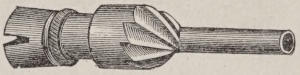

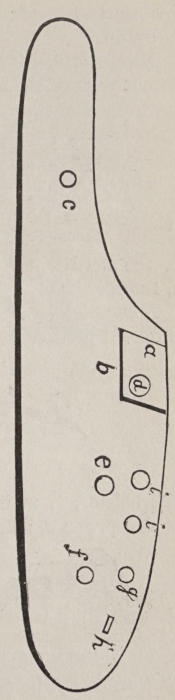

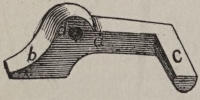

Alcohol Lamp, Self-Blowing.—This lamp, shown in Fig. 2, very convenient when continued blowing is required, or when the “knack” of using the common plow-pipe cannot be readily acquired. It may be used for soldering, brazing small articles, or hardening small tools, Size 2½ inches diameter and 5 inches high, $2; about 3 inches diameter and 6 inches high, $3.

Figure 2.

Anvil.—An anvil weighing about ninety or one hundred pounds is heavy enough. An Eagle anvil of this weight will cost about $9 or $10. The body of this kind of anvil is cast iron with steel face and horn. Price per pound is about ten cents.

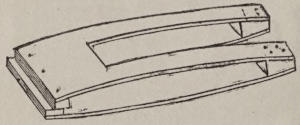

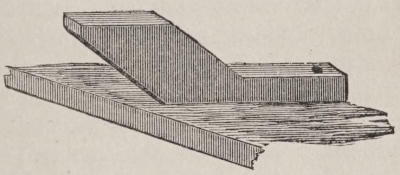

Barrel Planes.—These planes are now but little used, except for stocking guns or rifles which are to be fitted with full-length stocks. As this form of gun is somewhat going out of use, so the stocker’s planes are getting to be cast to one side. They are made similar to a narrow rabbet plane, but have the iron set close to the fore end. Any narrow plane with the fore end cut off to within half an inch of the opening in which the iron is placed will make a substitute for the stocker’s plane. The plane with round face is used to let in round barrels, and one with a face equal in width to the sides of an octagon[49] barrel, for letting in such barrels. A narrow plane is used to let in the ramrod, by cutting a groove centrally in the bottom of the barrel groove. The planes used are about four in number and the cost is about seven or eight dollars for the set as sold by dealers.

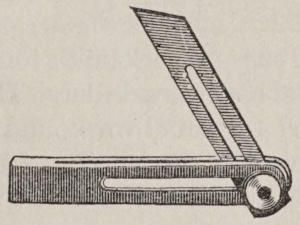

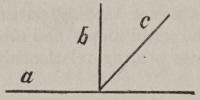

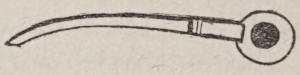

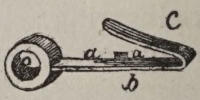

Bevel.—Bevels for ascertaining and forming surfaces, not at a right angle with some certain line, can be had from one dollar upward in price. The four inch is very good size. The blade is held in position by a screw, which forms part of the joint on which the blade turns. Shown in Fig. 3.

Figure 3.

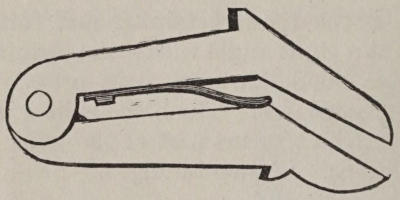

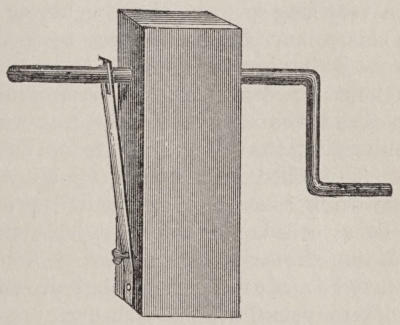

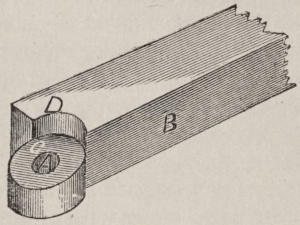

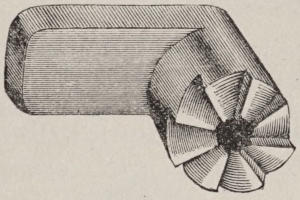

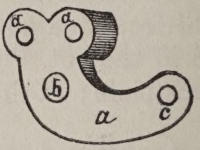

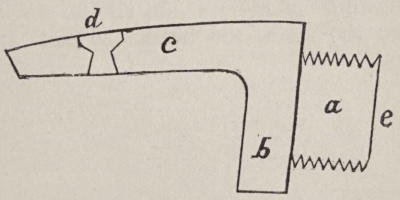

Beveling Clamp.—These tools are generally made of about three sizes, and are used for holding hammers when filing the bevel upon the sides. They are also useful for holding lock-plates while filing the bevel on them. In the vise, work can only be conveniently held at a vertical or horizontal position; this clamp is designed to furnish a means to hold it so as to file an angle of about 45 degrees. The tool is shown in Fig. 4. It is held in the vise, the shoulders resting on the vise jaws. The spring[50] between the jointed portions opens the tool when the vice jaws are opened, the closing of the vise jaws, of course, closing the clamp upon the work that is placed in it. The cost of these tools is from two to three dollars, according to size and quality.

Figure 4.

Blacksmith Tongs.—Blacksmith tongs can now be purchased of the hardware dealer. The twelve-inch length are used for small work, and the fifteen or eighteen for heavier work. The twelve inch cost about 50 cents; the fifteen, 62, and the eighteen, 75 cents each.

Blow-Pipe.—Select a blow-pipe eight or ten inches in length, with bulb or without, as fancy may dictate. If the end where the mouth comes in contact be silver or nickle-plated, it will not taste of brass. If it be difficult to get one plated, tin it with soft solder by wetting with soldering acid, and melting the solder on it by holding it over the lamp. Wipe off all superfluous solder with a rag. The cost of plain eight or ten inch pipe is about 25 cents. Add about one-third or one-half this price for pipes with bulb.

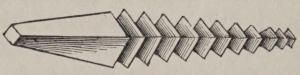

Breeching Taps.—Breeching taps ought to be obtained in pairs, one to enter first and another to follow, cutting a full thread at the bottom. The prices per pair are for the ⅜ inch $2.25; ½ inch, $2.50; ⅝ inch, $2.75. For shot gun taps, ¾ inch, $3.00; ⅞ inch, $3.25. A stock with dies will cost about a like sum, but if the stock be fitted with only two sets of dies, it will be much less. The two threads used for rifle pins are 14 and 16 to the inch.

The 14 and 16 threads are not always adhered to. A house in Philadelphia say they use taps of 18 threads, and a firm in Pittsburg advertise taps of 20 threads per inch.

Calipers and Dividers.—The best length of spring calipers and dividers, for common bench work, is about four inches. The cost is from 50 cents to $1.50, according to quality.

Chisels.—The chisels, as used by stockers, are about half a dozen in number. The narrowest is about one-eighth of an inch wide, and the widest about half inch. The set of six will cost about a dollar or a dollar and a half.

Cutting Pliers.—A pair of cutting pliers, six inches in length, for cutting wire, are indispensable. Select those of good quality. Poor pliers of this description are poor, indeed. The cost will be from 75 cents to $1.50. There are patented pliers of this kind in market that are recommended by many who use them.

Drill Stock.—Many kinds are in market, from eight inches in length upward. Some are termed[52] hand drills, and the larger ones, used against the breast, are called breast drills. The hand drills can be obtained as low as 50 cents and upward; the price of breast drills from two to three dollars. Select a drill stock, if one be required, of a size and strength to suit the work to which it will be used.

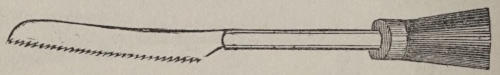

File Card.—This is for cleaning filings, dirt, etc., that may collect in files. It consists of a strip of common cotton card tacked to a piece of wood conveniently shaped to handle. It is also useful to clean the dirt and debris that will collect in screw taps. The cost is about 25 cents. Shown in Fig. 5.

Figure 5.

Fitting Square.—A fitting square with a four, five or six-inch blade is required for many purposes, not only for laying out iron stocks and marking off “square work,” but other work that will come into a gun shop. The gun squares used by carpenters and cabinet makers are very good. If the stock be of iron, or an iron frame filled with wood, they are better than those with wooden stocks. The cost of the six-inch may be about 75 cents. The other somewhat less.

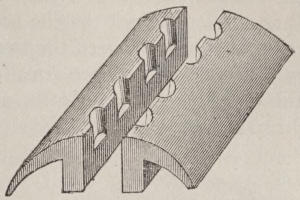

Floats.—For half-stocking, the gouge and floats are used for letting in barrels. The floats are made with a handle bent at an angle so that the hand will not hit the work. The round float in form resembles[53] a gouge with teeth like a coarse file cut on the rounded or bottom surface. Floats have been made by drawing the temper of a thick gouge and cutting teeth in it, or taking a half-round file and drawing the temper, and then cutting teeth on the round side. Floats for octagon barrels are flat, like a chisel with teeth cut on one of the flat sides. A thin float for letting in cross bolts is made in the same manner. A float for fitting ramrods may be made of a steel rod with teeth cut on one end, and a handle fixed to the other. The bolt float will cost about 50 cents. The rod float about $1.00 each for two sizes. Rifle, two sizes, about $1.25 each. Shot gun, two sizes, about $1.50 each.

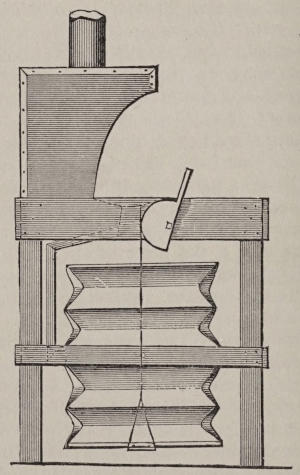

Forge.—Little advice can be given respecting a forge. Some prefer the bellows forge, while others select the fan blower. The great requirement of the gunsmith is portability and occupying little space. It should also be so enclosed as to prevent escape of dust, and be free from accident of fire escaping if left with the fire lighted. The cost of either form of portable forge will be from $20, upward.

Glue Pot.—Glue pots can be purchased with kettle fitting inside the pot and tinned on inside, quart size about 75 cents. A glue pot may be extemporized by selecting a common round fruit can, cutting out the cover so as to allow a smaller can to fit and be held in place. Where economy is desired or a pot cannot be purchased, the can glue pot will answer every purpose.

Gouges.—About six gouges are needed. The sizes[54] are about one-eighth for the smallest, and increasing to three-quarters for the largest. The cost of the set will be about one dollar and a quarter.

Grind Stone.—An Ohio stone, about 20 inches diameter and 2½ inches thick, mounted plain, can be got up for about three or four dollars. The iron fixtures will cost about a dollar, and the stone a cent and a half or more per pound, according to locality.

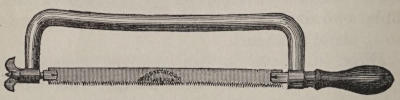

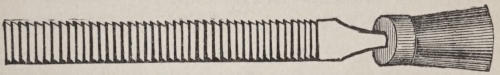

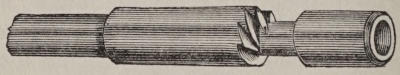

Hack Saw.—A hack saw shown in Fig. 6, with iron frame, to hold a blade of eight or ten inches in length is required for cutting off barrels, slotting screws, cutting off rods of iron, brass, etc., besides many other uses. The eight inch with blade will cost about $1.25, the ten inch about $1.50. If at any time a blade be broken they can be replaced at from 25 to 50 cents.

Figure 6.

Hammers.—In choosing hammers select the plain riveting hammer with cross pein. The sizes generally most used are a four ounce, a twelve ounce and a heavier one for use at the forge. The four ounce costing about 30 cents, the twelve ounce about 50 cents, and the larger one according to weight. In selecting hammers try the pein with a fine file to[55] learn the temper. In many cases the pein is left too soft for riveting steel.

Handles.—Handles for files or screwdrivers are best when made of maple or apple wood. Maple is generally preferred. Some mechanics like soft wood, as bass-wood or white birch, for file handles, but they are not so neat as those made of maple. Get those with ferrules made from sheet brass, raised to form. Soft wood handles are worth about 25 cents per dozen, and the hard wood about 50 cents.

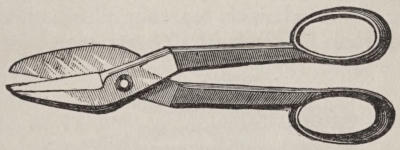

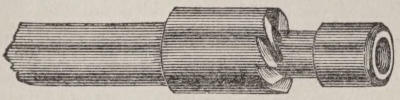

Hand Shears.—For cutting sheet tin, brass, thin sheet steel, small springs, etc., select a pair of hand shears about nine or ten inches in length, costing about $1.50. With these, common watch-springs can be cut lengthwise, for making small springs for pistols. The temper need not be drawn to cut them. (Shown in Fig. 7.)

Figure 7.

Hand-vise.—A hand-vise for holding wire, screws, etc., is needed. About four or four and a half inches in length is most convenient. For holding small wire, cut a groove with a three-square file across the jaws toward the jointed end. The cost will be from 50 cents to $1.00, according to quality.

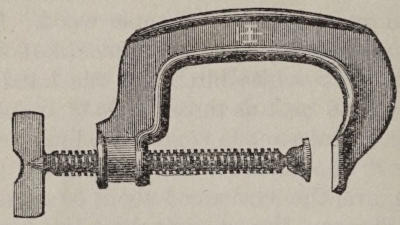

Figure 8.

Iron Clamps.—A pair of malleable iron clamps (shown in Fig. 8), opening about four inches, are useful for holding barrels into the stock during stocking, holding a lock plate or strap in place for marking, holding barrels together, pieces of wood to be glued, etc. Cost, about 50 cents each.

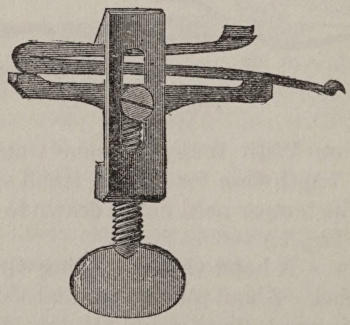

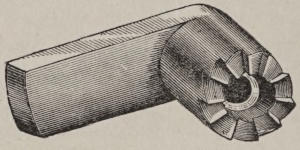

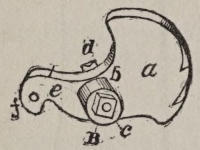

Figure 9.

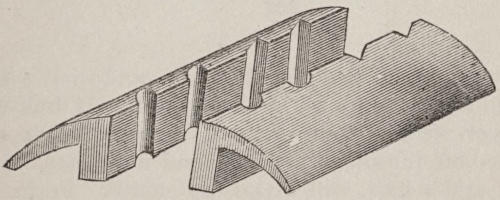

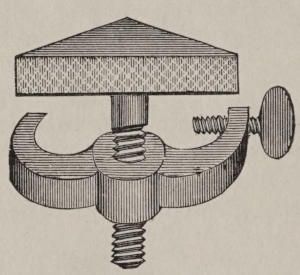

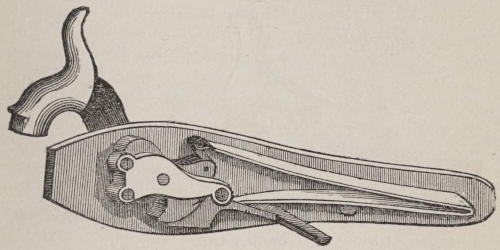

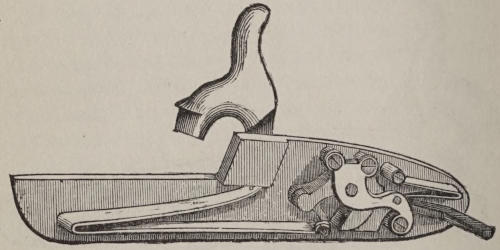

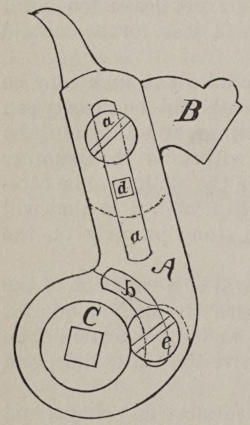

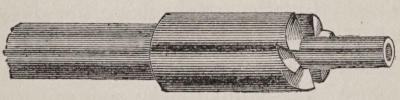

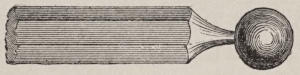

Mainspring Vise.—This tool (shown in Fig. 9, as clamping a spring) is used to clamp the mainspring,[57] preparatory to removing it from the lock. The hammer is set at full cock, and the vise applied, the screw tightened until the spring can be lifted from place. In taking down double guns, a vise for each lock spring is very convenient, as the springs can then rest in the vise, being cramped in place, until ready to be put back into their respective places. The cost of these vises is from 25 cents to $2 each, according to quality and make. For a left-side lock, reverse the sliding piece, so that the short end will bear on the bend of the mainspring.

Marking Gauge.—A wood marking gauge is used for laying out lines parallel to a surface already formed. If made of beech wood, and plain, it is generally sold for about 25 cents each.

Screw-cutting Tools.—A small die stock and dies, with taps for lock work, will cost about $2.50. A plate and ten taps, suitable for all sizes of nipples, English and German, can be had for about $8.00.

Screw Wrench.—One of Coe’s patent wrenches, about twelve-inch size, costing about a dollar, is the best make and the most durable size for all purposes. This wrench is generally known as a “monkey wrench.”

Soldering Copper.—A copper for soldering, similar to the kind used by tinners, is the kind to get. A good size—No. 3—will weigh about a pound and a half, costing about 75 cents.